Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

03 Sep 2018 07:23 - 03 Sep 2018 07:28 #117005

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

MAHO added that fourth cam "[Stage]_LEFT_CENTER". (german Links-mitte)

It tells you that you need to rotate CCW to get back to the mid position. However this seems redundant to me, as you can acheive this with only the three main target switches, as below...

This logic should work without the fourth cam:

If the "[stage]_LEFT" pin is high, then your only option is to move CW -->(Reverse pin stays deenergised).

If the "[stage]_RIGHT" pin is high, then your only option is to move CCW - > (need "Reverse" energised)

If the "[stage]_CENTER" pin is high, then you can move either direction...

If the target bitmask for that stage is "[stage]_LEFT", then move CCW - > (need "Reverse" energised)

else

move CW -->(Reverse pin stays deenergised).

SInce MAHO didn't seem to do anything redundant, I must be missing something about this. Can someone please explain the error of my logic?

Mark

It tells you that you need to rotate CCW to get back to the mid position. However this seems redundant to me, as you can acheive this with only the three main target switches, as below...

This logic should work without the fourth cam:

If the "[stage]_LEFT" pin is high, then your only option is to move CW -->(Reverse pin stays deenergised).

If the "[stage]_RIGHT" pin is high, then your only option is to move CCW - > (need "Reverse" energised)

If the "[stage]_CENTER" pin is high, then you can move either direction...

If the target bitmask for that stage is "[stage]_LEFT", then move CCW - > (need "Reverse" energised)

else

move CW -->(Reverse pin stays deenergised).

SInce MAHO didn't seem to do anything redundant, I must be missing something about this. Can someone please explain the error of my logic?

Mark

Last edit: 03 Sep 2018 07:28 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

03 Sep 2018 14:19 - 03 Sep 2018 14:26 #117011

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

You are right they have done this for a reason. With your approach if for any reason the gears are not meshed then the controller have no way to know the position of that gear.

John

John

Last edit: 03 Sep 2018 14:26 by drimaropoylos.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

03 Sep 2018 17:05 #117017

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks John,

Is this logic correct then...

If the gearbox is not in mesh, and no switch is closed then current position between LH and MID, -->turn CCW to the LH and CW to mid position.

else if

gearbox not in mesh, and LEFT_CENTER switch closed, then current position between MID and RH and RH, --> turn CCW to mid and CW to RH

Mark

Is this logic correct then...

If the gearbox is not in mesh, and no switch is closed then current position between LH and MID, -->turn CCW to the LH and CW to mid position.

else if

gearbox not in mesh, and LEFT_CENTER switch closed, then current position between MID and RH and RH, --> turn CCW to mid and CW to RH

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

03 Sep 2018 18:12 #117021

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

03 Sep 2018 18:49 #117023

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

www.flickr.com/photos/mahomh600p/

www.flickr.com/photos/mahomh600p/8293681086

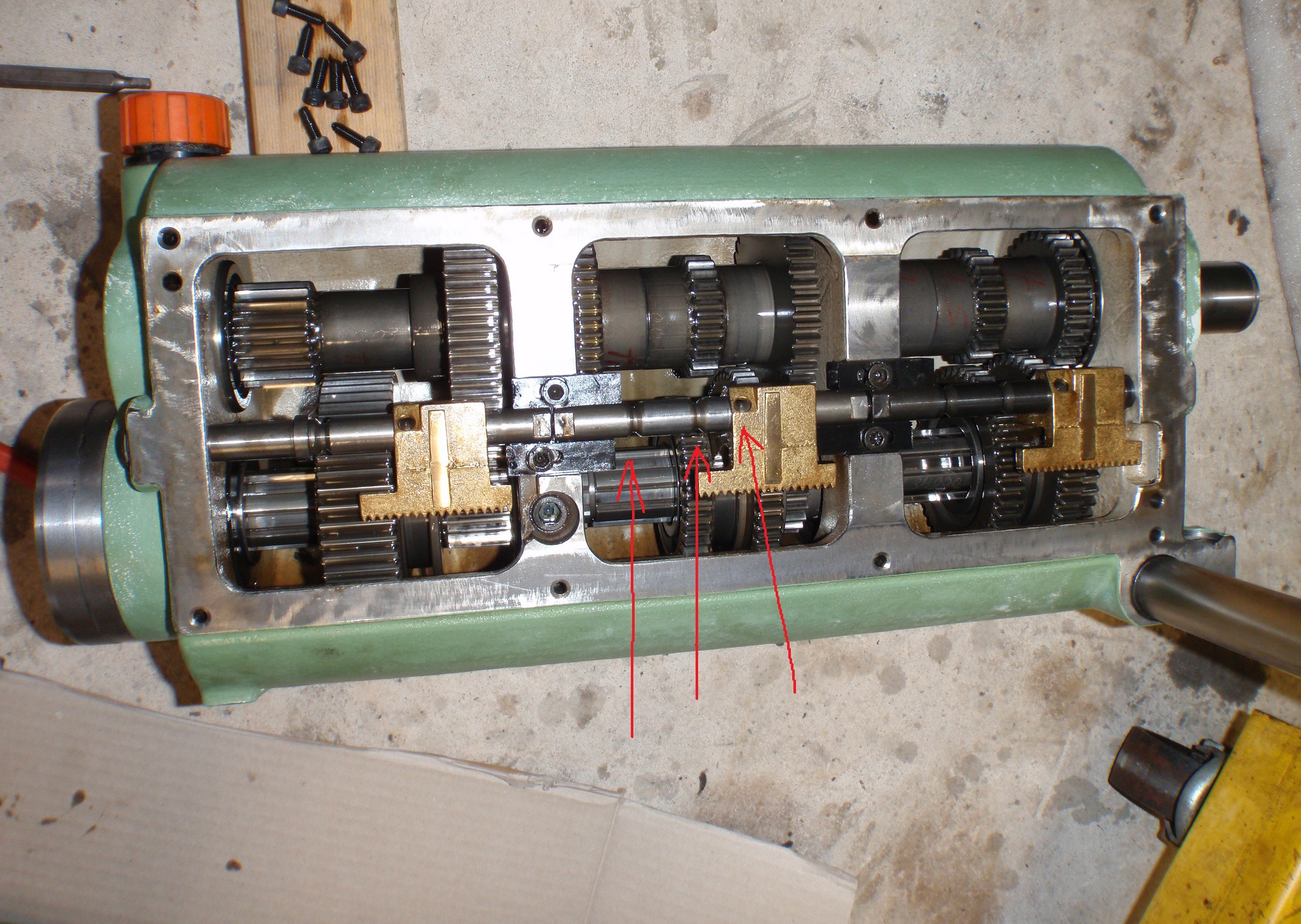

Even if the motors overshoot just a little the gearbox has some ball locking mechanism.

www.flickr.com/photos/mahomh600p/8293681086

Even if the motors overshoot just a little the gearbox has some ball locking mechanism.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

03 Sep 2018 20:46 #117025

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks again John, that is much clearer now.

I just took a look through those photos. What a great reference.

Mark

I just took a look through those photos. What a great reference.

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

09 Sep 2018 18:55 - 09 Sep 2018 20:09 #117249

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

My friend has made great progress on the gearbox.comp and a gearbox simulator to test it...

Github Wiki

It is looking really good.

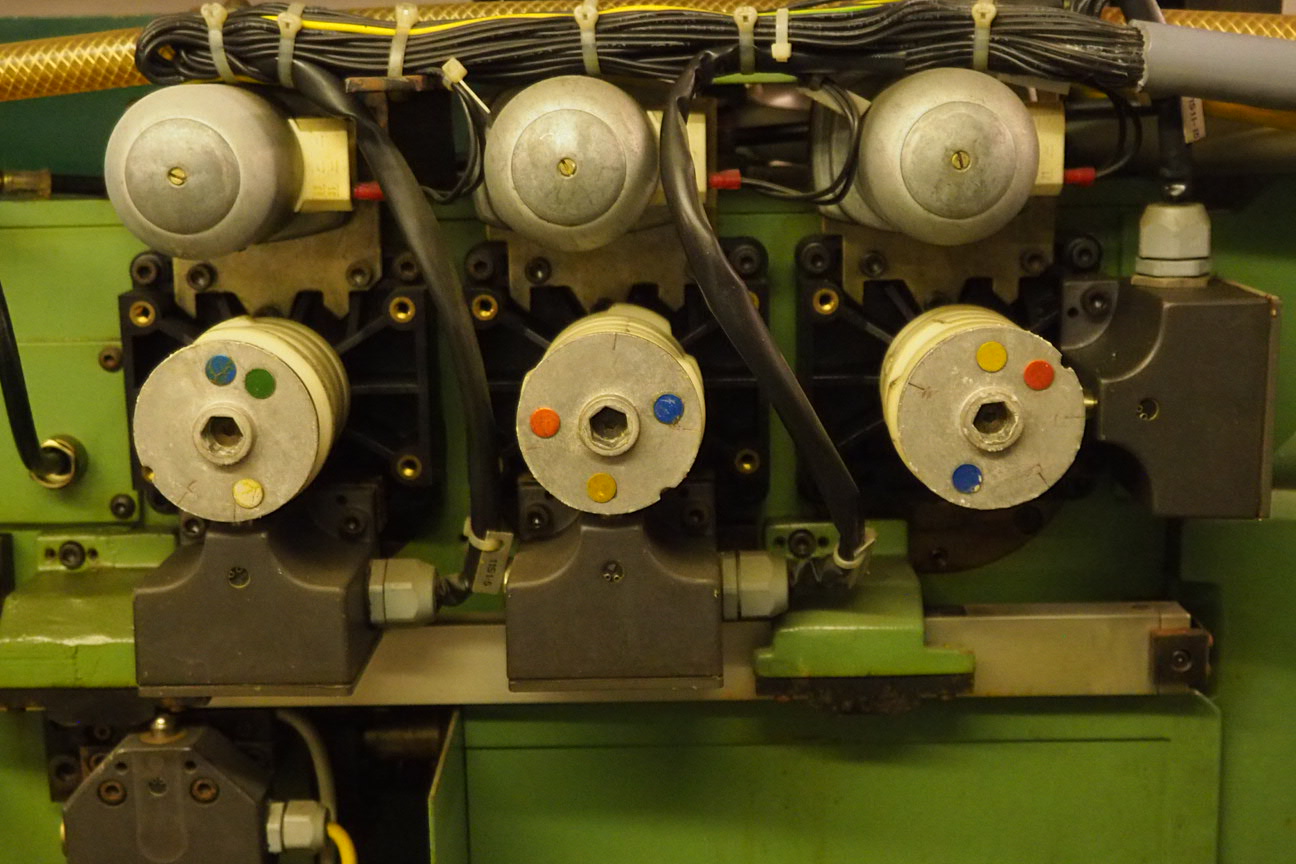

I have a question about the mechanical's of the gear change motors.

They are rated:

U=24v

I=0.8A

n=28 rpm

P2=6W.

I am "Assuming" that these motors are so wimpy that if I run them into a hard stop due to the having a direction sense reversed in the software, they should stall without an tooth decay on the plastic gears. Am I being unrealistically optimistic here?

I also have a question with regards to the matrix-KB pin:

matrix_kb.MAHO_Panel.col-1-in

does the column and row numbering start at 0 or 1?

Mark

Github Wiki

It is looking really good.

I have a question about the mechanical's of the gear change motors.

They are rated:

U=24v

I=0.8A

n=28 rpm

P2=6W.

I am "Assuming" that these motors are so wimpy that if I run them into a hard stop due to the having a direction sense reversed in the software, they should stall without an tooth decay on the plastic gears. Am I being unrealistically optimistic here?

I also have a question with regards to the matrix-KB pin:

matrix_kb.MAHO_Panel.col-1-in

does the column and row numbering start at 0 or 1?

Mark

Last edit: 09 Sep 2018 20:09 by RotarySMP.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

09 Sep 2018 21:58 #117262

by tommylight

I own a gear motor that is rated a bit higher at 24V/2A that would beg to differ, the very first time it hit a hard stop it chewed the plastic gears, and it was powered by a cordless drill battery at 14.4V, but it had enough current to render it unusable. If they are driven by relays, i would not risk it. Using current limiters is advisable, or a power supply with 1A max with automatic current limiting. Laptop adapters are very nice for such things but they tend to be in the 3.62A or 4.5A or 6.7A variety, so to much for your needs.

Or get some buck voltage regulars with current limiting for 1 to 3$ a piece on fleebay and set the voltage to 20V on their outputs a limit current to 1A. Used plenty of those to limit the current to motor drives that had no current limiting.

Replied by tommylight on topic Retrofitting a 1986 Maho MH400E

I am "Assuming" that these motors are so wimpy that if I run them into a hard stop due to the having a direction sense reversed in the software, they should stall without an tooth decay on the plastic gears. Am I being unrealistically optimistic here?

I own a gear motor that is rated a bit higher at 24V/2A that would beg to differ, the very first time it hit a hard stop it chewed the plastic gears, and it was powered by a cordless drill battery at 14.4V, but it had enough current to render it unusable. If they are driven by relays, i would not risk it. Using current limiters is advisable, or a power supply with 1A max with automatic current limiting. Laptop adapters are very nice for such things but they tend to be in the 3.62A or 4.5A or 6.7A variety, so to much for your needs.

Or get some buck voltage regulars with current limiting for 1 to 3$ a piece on fleebay and set the voltage to 20V on their outputs a limit current to 1A. Used plenty of those to limit the current to motor drives that had no current limiting.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1538

- Thank you received: 571

10 Sep 2018 12:33 #117287

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks for the sanity check Tommy.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21143

- Thank you received: 7221

10 Sep 2018 20:52 #117311

by tommylight

Replied by tommylight on topic Retrofitting a 1986 Maho MH400E

You are welcomed . Always.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.218 seconds