Retrofitting a 1986 Maho 400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1507

- Thank you received: 558

20 Sep 2018 10:25 #117779

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Hi John, how is your MAHO coming along?

Yes we made the twitching constant, and independant of what is happening during the gear change. The flow chart of what we did is here (it is in open office format, so It will open in most linux distros:

github.com/jin-eld/mh400e-linuxcnc/blob/...e%20flow%20chart.odg

I have a friend in Germany with an MH500E, and he made two videos of his machine doing gear changes, which really helped to get a feel for that behavior. It looked to me that MAHO and Phillips also implemented a constant about 1 sec per direction.

There is a fair bit of inertia in the system, so the spindle is still turning in one direction when the relay for the other direction energises. Since this is only pushing 90VAC though the 400V motor, I figured it should be no issue. You could probably increase that 200ms off out to 500ms, but it seems to work fine like this.

Mark

Yes we made the twitching constant, and independant of what is happening during the gear change. The flow chart of what we did is here (it is in open office format, so It will open in most linux distros:

github.com/jin-eld/mh400e-linuxcnc/blob/...e%20flow%20chart.odg

I have a friend in Germany with an MH500E, and he made two videos of his machine doing gear changes, which really helped to get a feel for that behavior. It looked to me that MAHO and Phillips also implemented a constant about 1 sec per direction.

There is a fair bit of inertia in the system, so the spindle is still turning in one direction when the relay for the other direction energises. Since this is only pushing 90VAC though the 400V motor, I figured it should be no issue. You could probably increase that 200ms off out to 500ms, but it seems to work fine like this.

Mark

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

20 Sep 2018 15:33 #117797

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

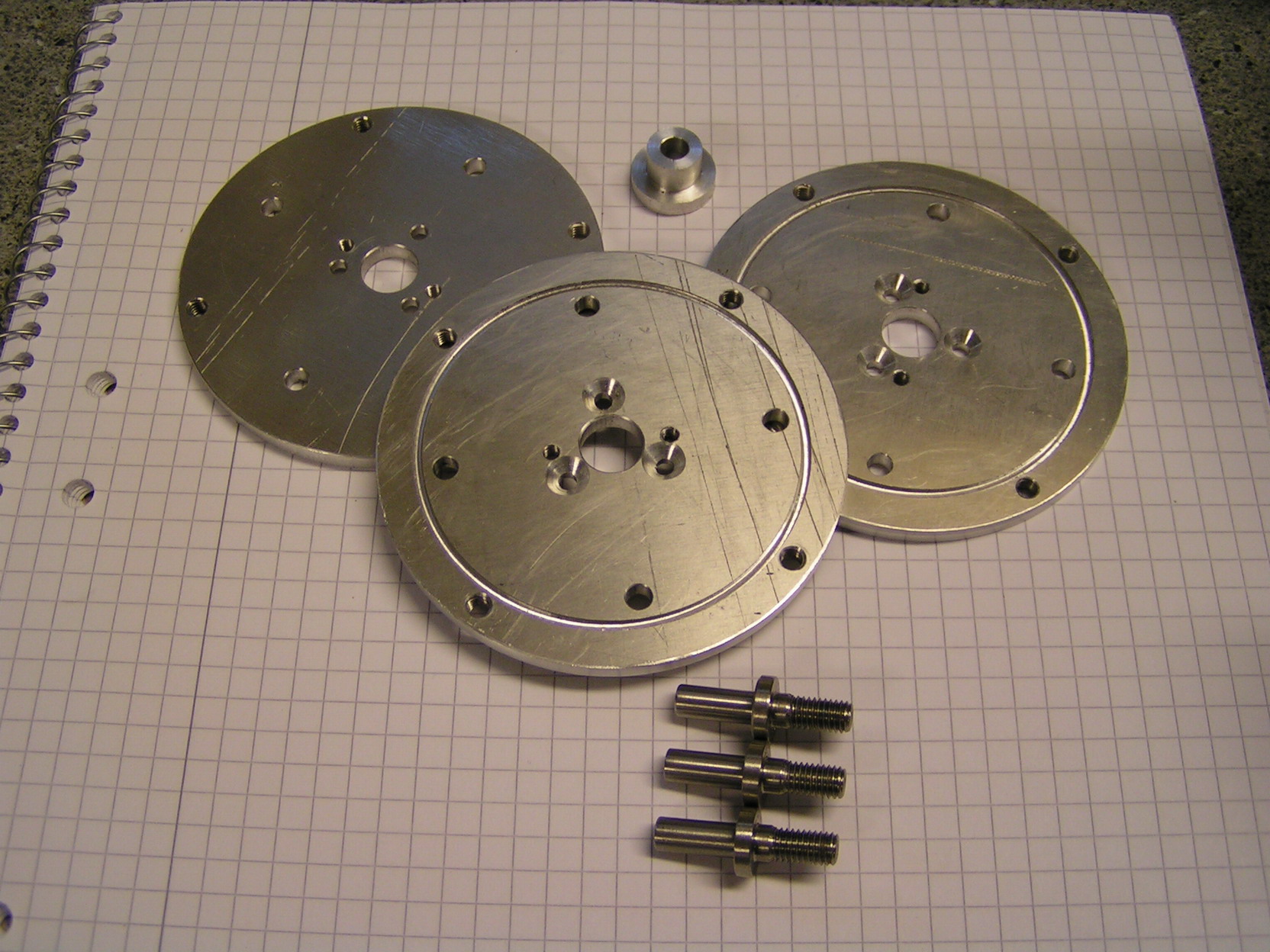

I am having troubles with the servo adaptors. They screw at the end of the tachometer and they have considerable rounout.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

20 Sep 2018 15:37 #117799

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- gernoff

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 2

20 Sep 2018 17:03 #117805

by gernoff

Replied by gernoff on topic Retrofitting a 1986 Maho MH400E

Will the gearbox.comp allow shifting with infinitely variable spindle speed. I have a Deckell FP5NC with variable speed spindle motor, VFD controlled. It has what looks to be the same 18 speed gearbox.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

20 Sep 2018 17:52 - 20 Sep 2018 17:53 #117809

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Yes, but you have to ad to the hall file something to properly scale the output for the vfd with the selected speed

Last edit: 20 Sep 2018 17:53 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

20 Sep 2018 18:53 #117814

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

You also have to change the file .comp and hall to match the structure of your gearbox, cams, and relays.

John

John

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 39

20 Sep 2018 19:01 #117816

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

They deckels gearbox seem very similar to the mahos.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

21 Sep 2018 03:58 #117835

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Mark A big congratulations to you on getting the gear shifting working. Also, a big Thank-You to all of the helpers on the gear shifting . It is the first time I have seen real documentation and written discussion about the how and why along with ----and here is the code to do it.

.Thank You very much

Bob

.Thank You very much

Bob

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1507

- Thank you received: 558

21 Sep 2018 06:56 - 21 Sep 2018 07:47 #117838

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I have to thank Sergey for this. He did the heavy lifting. Also John and Dominik for the classic ladder and comp solutions which they generously posted. I only redid this because I'm too dumb to get my head around classic ladder, and too thick to understand Dominiks comp.

I did a lot of internet searching for info on the MAHO gearbox control. There are various fragments of information, but most of the persons who had actually done functioning control, like Müllernick, were highly experienced in this sort of thing, and hadn't seen much need to clearly lay out the steps which were for them obvious.

Having a willing and enthusiastic programmer pushed me to finally get stuck into understanding how this all works together, as he wanted a clear, usuable specification. It was also Sergey that pushed me to document the facts as they surfaced in github wiki, as that is where he worked his magic, and he documents his programming work clearly as a matter of course.

Yesterday, I started working on getting the comp and sim to play nicely with gmoccapy. Because I set up my test laptop with Fedora 28, to more closely match Sergey's test environment, I still have a bit of work to do to get the right packages installed.

That video of the open deckel gearbox is excellent. I added a link to it in the guthub gearbox.comp wiki. With respect to the Deckel gearbox, while mechanically similar, from the wiring diagrams in the video John posted, it looks like the deckel feedback is done with three switches per stage, rather than four by the MAHO. If so different logic will be needed to determine which direction to turn the motor from an unknown position (assuming the Left-mid feedback is the missing one).

Also it looks the the gear stage motors are controlled LH/OFF/RH with a single, relay per stage, whereas the MAHO uses separate on/off and polarity reverse relays. Although maybe I understand the logic here wrong.

Expanding this gearbox.comp to include VFD control in addition to the gear changesis an attractive further development. Although my machine has no VFD, adding one would give the ablity to implement spindle speed override, which would not be a good idea with the current comp, as stopping the spindle to change gear while engaged in the work, would ruin the work.

Mark

I did a lot of internet searching for info on the MAHO gearbox control. There are various fragments of information, but most of the persons who had actually done functioning control, like Müllernick, were highly experienced in this sort of thing, and hadn't seen much need to clearly lay out the steps which were for them obvious.

Having a willing and enthusiastic programmer pushed me to finally get stuck into understanding how this all works together, as he wanted a clear, usuable specification. It was also Sergey that pushed me to document the facts as they surfaced in github wiki, as that is where he worked his magic, and he documents his programming work clearly as a matter of course.

Yesterday, I started working on getting the comp and sim to play nicely with gmoccapy. Because I set up my test laptop with Fedora 28, to more closely match Sergey's test environment, I still have a bit of work to do to get the right packages installed.

That video of the open deckel gearbox is excellent. I added a link to it in the guthub gearbox.comp wiki. With respect to the Deckel gearbox, while mechanically similar, from the wiring diagrams in the video John posted, it looks like the deckel feedback is done with three switches per stage, rather than four by the MAHO. If so different logic will be needed to determine which direction to turn the motor from an unknown position (assuming the Left-mid feedback is the missing one).

Also it looks the the gear stage motors are controlled LH/OFF/RH with a single, relay per stage, whereas the MAHO uses separate on/off and polarity reverse relays. Although maybe I understand the logic here wrong.

Expanding this gearbox.comp to include VFD control in addition to the gear changesis an attractive further development. Although my machine has no VFD, adding one would give the ablity to implement spindle speed override, which would not be a good idea with the current comp, as stopping the spindle to change gear while engaged in the work, would ruin the work.

Mark

Last edit: 21 Sep 2018 07:47 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1507

- Thank you received: 558

21 Sep 2018 07:05 #117840

by RotarySMP

Have you considered making new shaft exensions with oversize encoder extensions, installing them on the servos, strap the servos to the bed of the lathe, power the servo, and turn the encoder shaft extensions to final diameter so that they run true to the servo?

Mark

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I am having troubles with the servo adaptors. They screw at the end of the tachometer and they have considerable rounout.

Have you considered making new shaft exensions with oversize encoder extensions, installing them on the servos, strap the servos to the bed of the lathe, power the servo, and turn the encoder shaft extensions to final diameter so that they run true to the servo?

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.466 seconds