Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

21 Sep 2018 08:14 - 21 Sep 2018 08:26 #117841

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Last edit: 21 Sep 2018 08:26 by RotarySMP.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

21 Sep 2018 14:32 #117850

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Sep 2018 11:59 #117865

by drimaropoylos

John

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I think the dekel gearbox motor rotates only in one direction end cycles from all 3 gears so the is no need for 4rt camAlso it looks the the gear stage motors are controlled LH/OFF/RH with a single, relay per stage, whereas the MAHO uses separate on/off and polarity reverse relays. Although maybe I understand the logic here wrong..

Mark

John

Please Log in or Create an account to join the conversation.

- gernoff

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 2

22 Sep 2018 16:49 #117871

by gernoff

Replied by gernoff on topic Retrofitting a 1986 Maho MH400E

Although most of the work has probably already been done here,I will be starting a new thread for converting a Deckel FP5NC machine. Give me a few days to gather an post what prints I can get my hands on.

I have determnind that the FP5 machine is a 6 speed gearbox. It used a 10hp BBC Thyristor drived 10HP spindle motor (now dead). I am replacing it with a Yaskawa 5hp VFD driven setup. Once the spindle is back up and running I can begin reverse engineering the shift logic and circuits.

BTW, it is a small world. I too am an Avionics Technician: I have worked on F16, F15 and now C130 avionics.

I have determnind that the FP5 machine is a 6 speed gearbox. It used a 10hp BBC Thyristor drived 10HP spindle motor (now dead). I am replacing it with a Yaskawa 5hp VFD driven setup. Once the spindle is back up and running I can begin reverse engineering the shift logic and circuits.

BTW, it is a small world. I too am an Avionics Technician: I have worked on F16, F15 and now C130 avionics.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

23 Sep 2018 05:48 #117892

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Indeed in the deckels the gearbox motors rotate in only one direction. So they don't need 4rt cam. The lader or .comp development for this gearbox will be much easier.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

30 Sep 2018 08:39 #118226

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

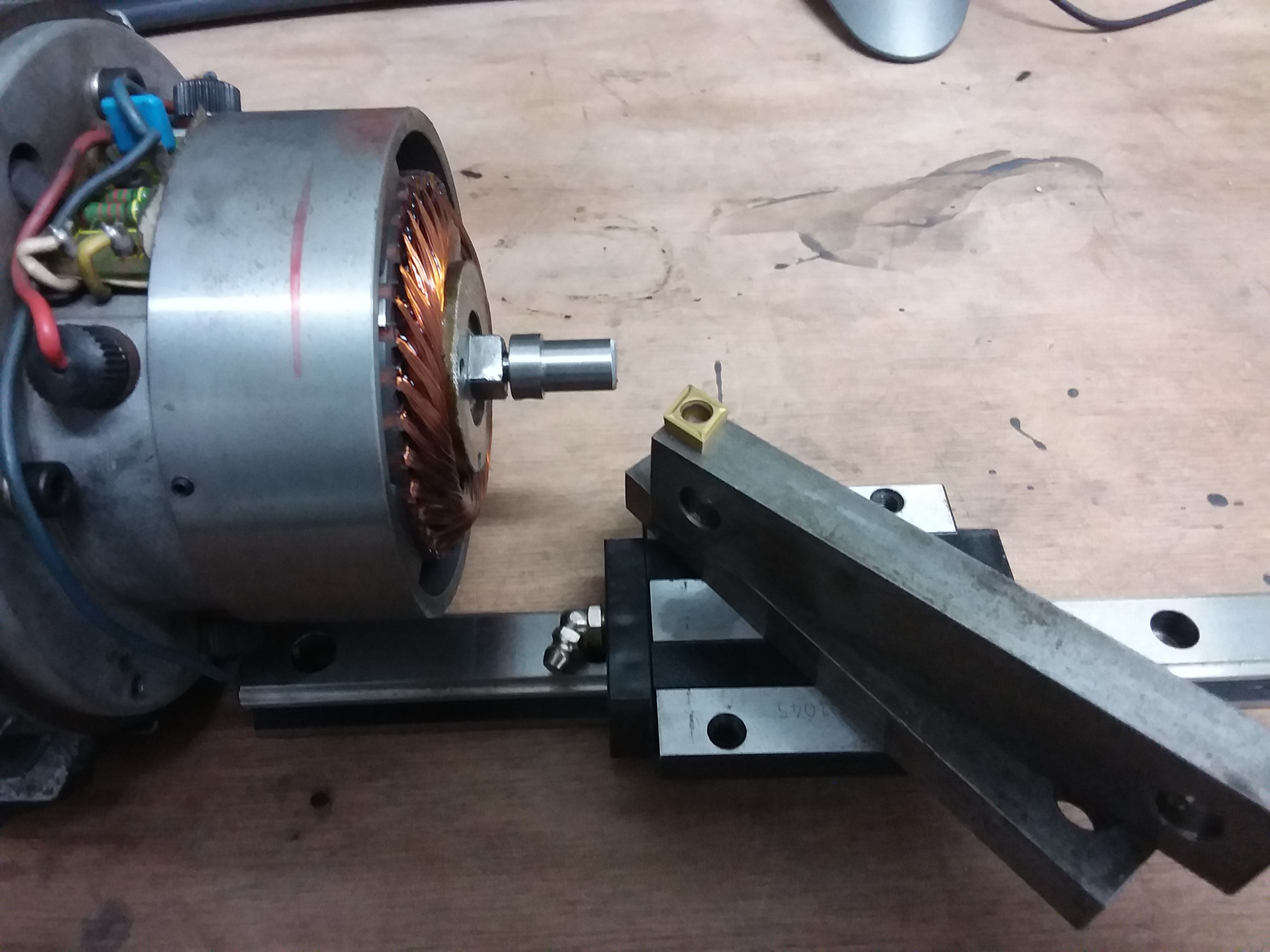

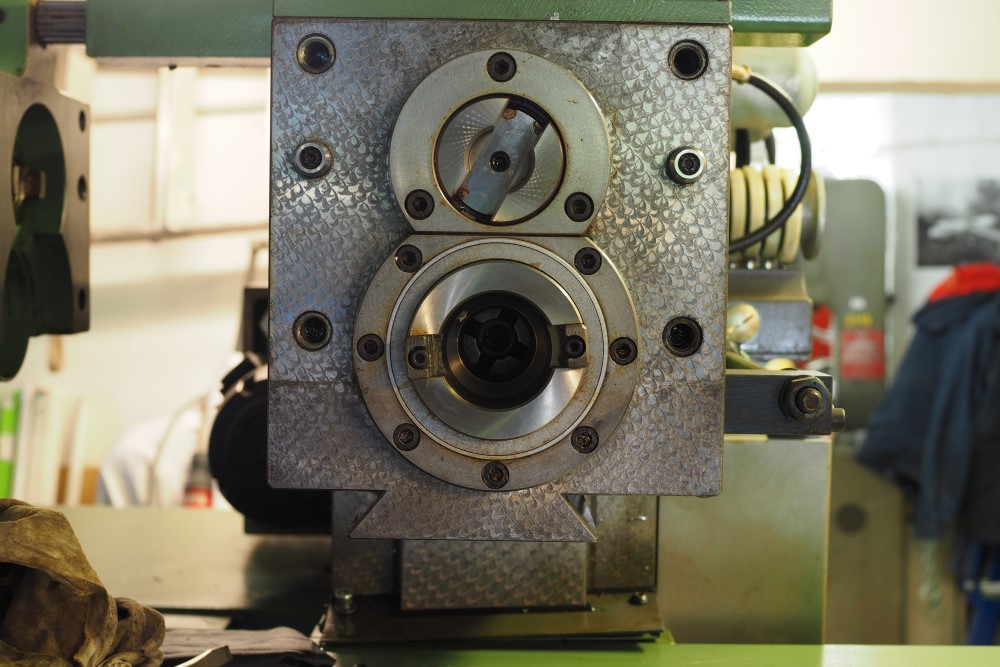

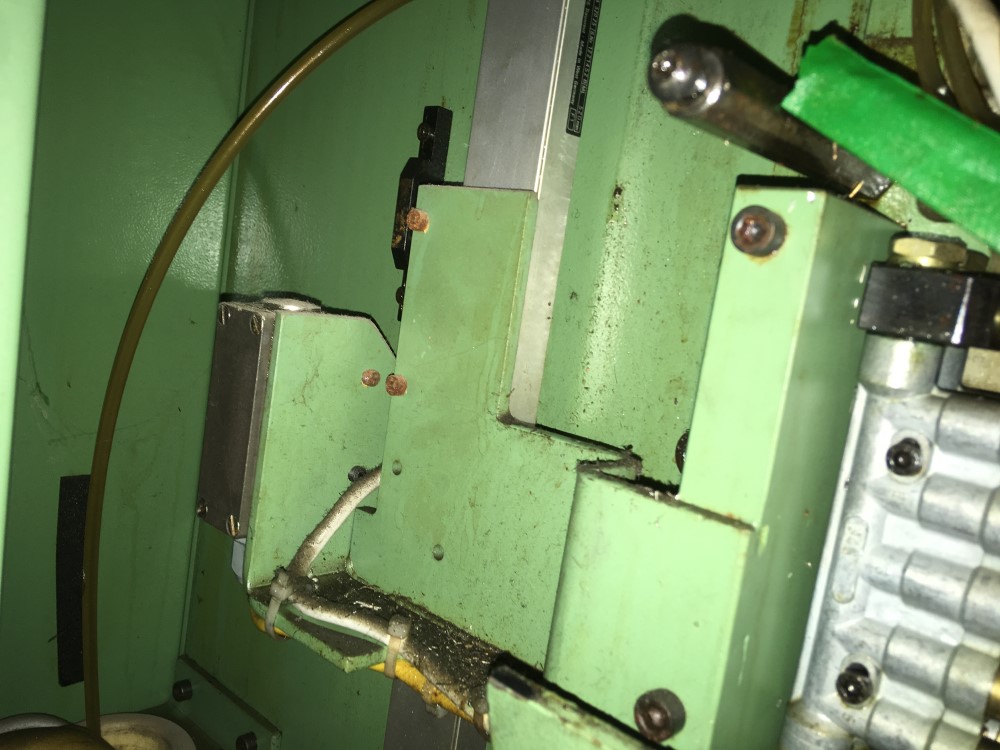

Not much done this week. Since the Z has crept up, I was able to finally remove the LH side rear splash shield, and the transformer cover, so I could get to the Z linear encoder. With that splash shield off, the vertical head could be swung out of the way. It looks like the horizontal spindle has never ever had a tool in it. Pristine.

Next the Z linear encoder will need trouble shooting.

The Y encoder worked again yesterday, so there must be an intermittent fault in that system, which will need tracking down.

Mark

Next the Z linear encoder will need trouble shooting.

The Y encoder worked again yesterday, so there must be an intermittent fault in that system, which will need tracking down.

Mark

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

01 Oct 2018 01:25 #118263

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Mark Always good to read of your progress with the MAHO. Hope you get into the details on how to find the problem and then fixing the scales.

Question - Your last photo ( Y axis scale ? ) shows a flex-conduit going past the scale body. My question is Who makes that flex conduit., or who (other than DMG ) sells that type and style of flex conduit ?

Hoping you get stuff sorted out and still have time to stuff the MAHO thru the way too small shop door before winter. Might think about some easy clean floor oil drip catcher. My machines mark their spot as much as a Harley or Triumph motorcycle does/did.

Just a thanks for more of the saga.

Bob

Question - Your last photo ( Y axis scale ? ) shows a flex-conduit going past the scale body. My question is Who makes that flex conduit., or who (other than DMG ) sells that type and style of flex conduit ?

Hoping you get stuff sorted out and still have time to stuff the MAHO thru the way too small shop door before winter. Might think about some easy clean floor oil drip catcher. My machines mark their spot as much as a Harley or Triumph motorcycle does/did.

Just a thanks for more of the saga.

Bob

Please Log in or Create an account to join the conversation.

- Loddestuen

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

01 Oct 2018 05:41 #118270

by Loddestuen

Replied by Loddestuen on topic Retrofitting a 1986 Maho MH400E

Hi RotarySMP and others,

I'm new to this forum, I hope you don't mind me asking the following questions in your thread.

I have the opportunity to buy a Maho MH 700 C for cheap - don't know how cheap yet..

My question is:

Is all the knowledge you have created by doing your retrofit applicable to the MH 700 C?

Can I retrofit the MH 700 C to Linux CNC?

About the machine:

Its an 1983 MH 700 C with an Phillips CNC 432/9

The machine parameters are lost. New battery is with the machine, don't know why they unplugged it before changing it..?

There is a ton of books and several print outs of different updated machine parameters. Last on from 2001. Also electrical diagrams for this particular machine.

No wise - no tool holders.

The screen worked before the machine was unplugged and moved.

Don't know the history..

Hour meter - don't know yet..

About me:

I'm from 1977

I'm an machinist and mechanical engineer. I have done a bit of CNC in the past - and i have general understanding in what its all about.

I'm a fix-it-all-myself kind of guy.

I have a lot of vintage HP vintage measuring equipment (also other brands)

I have a full shop with lathe and mill - just no CNC yet..

I fix up old electronics and HiFi equipment. Especially cassette recorders and reel to reel machines. I like them because they are both mechanical, electromechanical and electronic devises..

I can read electrical diagrams - also electronic diagrams.

I fix and build my computers myself.

I'm not afraid of extensive wiring looms.

But:

I do not know Linux CNC

I'm not use Linux

I have only very little computer programming knowledge <- This is why I'm a bit afraid to buy this old machine an commence to this project..

I would like your 10 cents on this one.

If i choose to proceed, I will document my progress here on the forum in a MAHO MH 700 C retrofit thread - I promise

Kind Regards

Jesper Holm, Denmark.

I'm new to this forum, I hope you don't mind me asking the following questions in your thread.

I have the opportunity to buy a Maho MH 700 C for cheap - don't know how cheap yet..

My question is:

Is all the knowledge you have created by doing your retrofit applicable to the MH 700 C?

Can I retrofit the MH 700 C to Linux CNC?

About the machine:

Its an 1983 MH 700 C with an Phillips CNC 432/9

The machine parameters are lost. New battery is with the machine, don't know why they unplugged it before changing it..?

There is a ton of books and several print outs of different updated machine parameters. Last on from 2001. Also electrical diagrams for this particular machine.

No wise - no tool holders.

The screen worked before the machine was unplugged and moved.

Don't know the history..

Hour meter - don't know yet..

About me:

I'm from 1977

I'm an machinist and mechanical engineer. I have done a bit of CNC in the past - and i have general understanding in what its all about.

I'm a fix-it-all-myself kind of guy.

I have a lot of vintage HP vintage measuring equipment (also other brands)

I have a full shop with lathe and mill - just no CNC yet..

I fix up old electronics and HiFi equipment. Especially cassette recorders and reel to reel machines. I like them because they are both mechanical, electromechanical and electronic devises..

I can read electrical diagrams - also electronic diagrams.

I fix and build my computers myself.

I'm not afraid of extensive wiring looms.

But:

I do not know Linux CNC

I'm not use Linux

I have only very little computer programming knowledge <- This is why I'm a bit afraid to buy this old machine an commence to this project..

I would like your 10 cents on this one.

If i choose to proceed, I will document my progress here on the forum in a MAHO MH 700 C retrofit thread - I promise

Kind Regards

Jesper Holm, Denmark.

Please Log in or Create an account to join the conversation.

- cgroth

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 9

01 Oct 2018 11:58 #118281

by cgroth

Replied by cgroth on topic Retrofitting a 1986 Maho MH400E

Mark, to get it right, your machine was already equipped with Heidenhain scales instead of Philips ones? What series is mounted? How is the cable mounted? My Kunzmann has LS903 as far as I remember that have a remote socked with about 20cm cable. I already dismantled one to clean the sealing. Cable to the CNC is connected using the 9-pin Heidenhain round socket. The scales have 11uA sinusoidal signals, so any dirt between pins or bad insulation may have severe impact. What EXE converters do you use? I bought 3 brand new EXE 602 last week for 40€ each, so in case your not sure about yours it may be worth to buy one new and test.

Please Log in or Create an account to join the conversation.

- cgroth

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 9

01 Oct 2018 12:04 #118283

by cgroth

Replied by cgroth on topic Retrofitting a 1986 Maho MH400E

Hi Jesper,

I am just a listener as I can't spend time on my project at the moment. With your skills I suggest to start with setting up the machine running the Philips CNC. If that was working before moving the machine, restoring the parameters by hand is easy. And you can play around with the machine for a while discovering all its features before starting a conversion. A lot of information may be useful to your machine thought there might be difference for instance if your machine has a variable speed DC spindle drive.

Christian

Christian

I am just a listener as I can't spend time on my project at the moment. With your skills I suggest to start with setting up the machine running the Philips CNC. If that was working before moving the machine, restoring the parameters by hand is easy. And you can play around with the machine for a while discovering all its features before starting a conversion. A lot of information may be useful to your machine thought there might be difference for instance if your machine has a variable speed DC spindle drive.

Christian

Christian

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.946 seconds