- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Help please !!! Servo configuration with stepconf.

Help please !!! Servo configuration with stepconf.

- cmorley

- Offline

- Moderator

-

- Posts: 7283

- Thank you received: 2125

steps per revolution is meaning the motor - most are 200 steps per rev.

you put 10000 steps per rev which would seem to mean 200 motor steps/rev and 50 microsteps (200x50=10000)

But as you have found out either way will still give you the right scaling. (just wanted you to understand why)

to me your max velocity and max acceleration seem odd - but I never read the rest of the thread.

your max velocity is 1mm/s (60mm per minute) which is pretty damn slow.

but your acceleration is 12.5 mm per sec (x something else) which seems really fast.

and it looks like you calculated the acceleration....I must be missing something

Please Log in or Create an account to join the conversation.

- ishman

- Offline

- Premium Member

-

- Posts: 83

- Thank you received: 0

The reason for my conclusion was when I increased the ratio on screen it changes the speed accordingly. I didn't even touched the drive's gear during test.drive microstepping is just that - the DRIVE'S microstepping factor (nothing to do with linuxcnc internals)

you caught a good point. my velocity is 1mm and acceleration is 12.5mm.............lol.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I found an indirect solution is to divide screw pitch according to drives gearing ratio. But I think there should be any direct solution.

Well, there is only one number to set the scaling, and that is a combination of all the other factors. So, it doesn't matter how you do it as long as the single scale factor for that axis in the HAL is correct.

Please Log in or Create an account to join the conversation.

- ishman

- Offline

- Premium Member

-

- Posts: 83

- Thank you received: 0

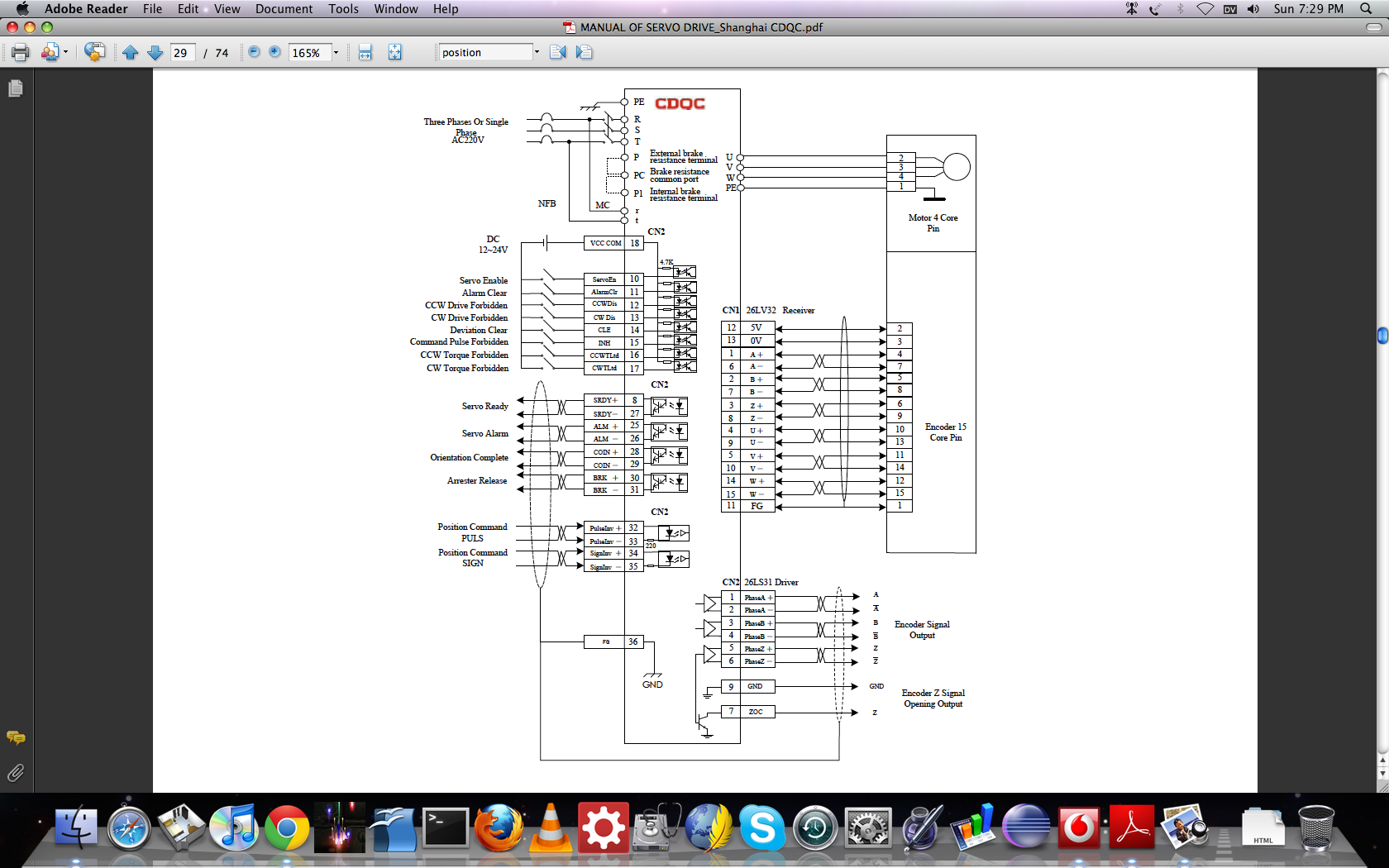

here is the schematic image.

Many thanks in advance.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

John

Please Log in or Create an account to join the conversation.

- ishman

- Offline

- Premium Member

-

- Posts: 83

- Thank you received: 0

Thanks for confirmation John! I tried it once. But no luck. I will try again tomorrow.FG36 is the shield drain ground... it should be grounded only on one end!

John

Please Log in or Create an account to join the conversation.

- wlater2

- Offline

- New Member

-

- Posts: 1

- Thank you received: 0

I am wondering whetehr you could share Bonmet ServoFly sorftware as it is not available on Bonmet web site any more and Bonmet support is not answering more that 10 days.

Please Log in or Create an account to join the conversation.

- jepler

-

- Offline

- Administrator

-

- Posts: 70

- Thank you received: 33

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Help please !!! Servo configuration with stepconf.