Installing LinuxCNC On HP T610 Thin Client

- ALittleOffTheRails

-

- Visitor

-

01 Jan 2022 01:14 #230426

by ALittleOffTheRails

Replied by ALittleOffTheRails on topic Installing LinuxCNC On HP T610 Thin Client

Nice work Tommy

Some interesting info regarding memory on the T610

www.parkytowers.me.uk/thin/hp/t610/firmware.shtml

For shits & giggles I've ordered one to play with.

Some interesting info regarding memory on the T610

www.parkytowers.me.uk/thin/hp/t610/firmware.shtml

For shits & giggles I've ordered one to play with.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7279

01 Jan 2022 01:56 #230429

by tommylight

Replied by tommylight on topic Installing LinuxCNC On HP T610 Thin Client

Yeah, seen that on a lot of laptops and PC's with integrated graphics, i usually set that manually to 256 or 512MB.

Leaving it in auto messes up latency badly whenever it decides it needs more ram for video as it has to interrupt all calls to ram until the resize is over.

Leaving it in auto messes up latency badly whenever it decides it needs more ram for video as it has to interrupt all calls to ram until the resize is over.

Please Log in or Create an account to join the conversation.

- ALittleOffTheRails

-

- Visitor

-

01 Jan 2022 02:00 #230430

by ALittleOffTheRails

Replied by ALittleOffTheRails on topic Installing LinuxCNC On HP T610 Thin Client

There's also a PCIe x4 port hiding in there as well.

Please Log in or Create an account to join the conversation.

- davidimurray

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 5

01 Jan 2022 20:23 - 01 Jan 2022 20:27 #230476

by davidimurray

Replied by davidimurray on topic Installing LinuxCNC On HP T610 Thin Client

Hi All

Sorry for the late reply, removed the wifi card from the PC and it then refused to boot so I had to do a fresh install.

Bit confused why the report was only showing 2GB of ram in it. The BIOS is showing 4GB and so does linux. I;ve re-run the script now and latency is no better - see report below.

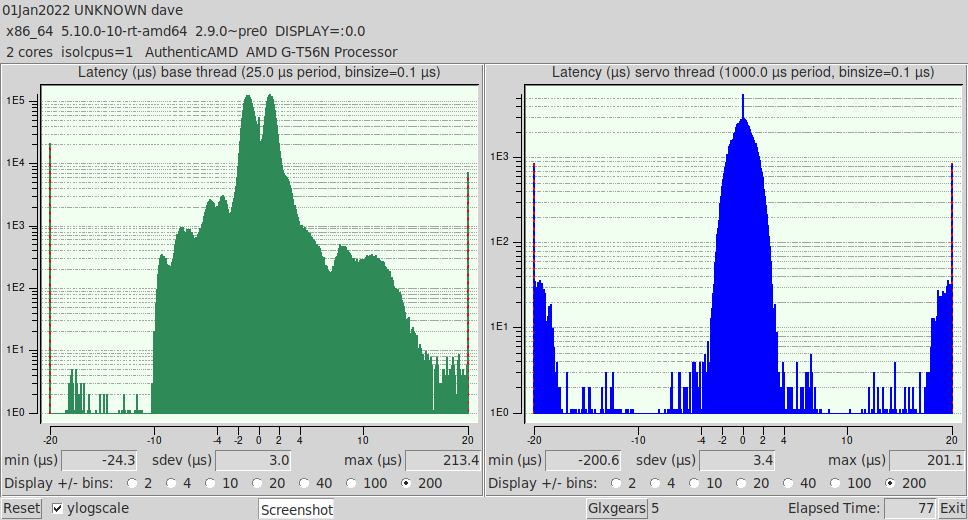

I also ran the latency test and latency-histogram (results attached) with similar results.

Is there something I am missing?

Sorry for the late reply, removed the wifi card from the PC and it then refused to boot so I had to do a fresh install.

Bit confused why the report was only showing 2GB of ram in it. The BIOS is showing 4GB and so does linux. I;ve re-run the script now and latency is no better - see report below.

I also ran the latency test and latency-histogram (results attached) with similar results.

Is there something I am missing?

LinuxCNC pc tests, version 20200930, started 01.01.2022 19:13:41

********************************************************************************

General info:

Hewlett-Packard, HP t610 WW Thin Client

Bios version K30 v01.20, dated 03/10/2015

Chipset: Harddisk is non-rotational, ie. SSD

The amount of swap currently used is 0

================================================================================

CPU related data:

model name : AMD G-T56N Processor

cpu cores : 2

stepping : 0

cache size : 512 KB

================================================================================

RAM related data:

Maximum Capacity: 8 GB

Size: 2 GB

Size: 2 GB

================================================================================

GPU related data:

product: Wrestler [Radeon HD 6320]

configuration: driver=radeon latency=0

================================================================================

Parallel port related data:

number of parallel ports is 1

parport0: PC-style at 0x378 (0x778), irq 7 [PCSPP,TRISTATE,EPP]

================================================================================

Os and desktop related data:

PRETTY_NAME="Debian GNU/Linux 11 (bullseye)"

Should the info below not match with your machine,

kindly post the output of pstree here, including a brief

desciption of your desktop environment, window manager and

display manager. Tia

https://forum.linuxcnc.org/18-computer/39370-script-for-automated-testing-of-computer-latency

Desktop environment : gnome

Windowmanager : Metacity (Marco)

Displaymanager : lightdm

================================================================================

Kernel related data:

Kernel 5.10.0-10-rt-amd64

GRUB_CMDLINE_LINUX_DEFAULT="quiet isolcpus=1"

Cpu idle driver: acpi_idle

================================================================================

Kernel modules data:

Check if pcspkr is loaded: [0;31mYes, may cause bigger latency.[0m

can be eliminated using:

sudo echo "install pcspkr /bin/true" >/etc/modprobe.d/pcspkr.conf

Check if snd modules are loaded: [0;31mYes, may cause bigger latency.[0m

can probably be disabled in bios, alternatively, you can run

"./block-snd-modules"

which has just now been created for your convenience.

================================================================================

Keyboard & Mouse related data:

Number of mice: 1

Mouse 0 : Telink Wireless Receiver Mouse

Mice attached to USB:

Keyboards attached to USB:

Dell Computer Corp. Keyboard SK-8115

================================================================================

LinuxCNC related data:

LinuxCNC version is: 2.9.0~pre0

================================================================================

Preparing for latency test:

Started glxgears No. 1, 2, 3, 4, 5

..........

Started firefox with 'https://vimeo.com/150574260', WID

================================================================================

Command for latency test is:

su dave -c "latency-histogram --nobase --sbinsize 1000 --nox 2>&1 | tee -a 1641064327.lat &"

Latency testing loop started Sat 1 Jan 19:14:14 GMT 2022,

should end after Sat 1 Jan 19:27:34 GMT 2022

Manual termination requested at 01.01.2022 19:16:26

================================================================================

Swap useage: prerun: 0, running: 0

================================================================================

CPU core temperatures:

Note: Using POSIX realtime

4 s servo min:-124.100 us max: 122.200 us sdev: 1.800 us

5 s servo min:-124.100 us max: 122.200 us sdev: 2.200 us

7 s servo min:-124.100 us max: 122.200 us sdev: 1.900 us

8 s servo min:-124.100 us max: 124.300 us sdev: 1.600 us

9 s servo min:-124.100 us max: 124.300 us sdev: 1.100 us

11 s servo min:-173.900 us max: 174.200 us sdev: 1.400 us

12 s servo min:-173.900 us max: 174.200 us sdev: 1.700 us

13 s servo min:-173.900 us max: 174.200 us sdev: 1.800 us

14 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

15 s servo min:-173.900 us max: 174.200 us sdev: 1.800 us

16 s servo min:-173.900 us max: 174.200 us sdev: 1.800 us

18 s servo min:-173.900 us max: 174.200 us sdev: 1.800 us

19 s servo min:-173.900 us max: 174.200 us sdev: 1.800 us

20 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

21 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

22 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

23 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

24 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

25 s servo min:-173.900 us max: 174.200 us sdev: 2.200 us

26 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

27 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

28 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

29 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

30 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

32 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

33 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

34 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

35 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

36 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

36 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

38 s servo min:-173.900 us max: 174.200 us sdev: 2.100 us

39 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

40 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

41 s servo min:-173.900 us max: 174.200 us sdev: 2.000 us

42 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

43 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

44 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

45 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

46 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

47 s servo min:-173.900 us max: 174.200 us sdev: 1.900 us

48 s servo min:-176.900 us max: 178.000 us sdev: 1.900 us

49 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

50 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

51 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

52 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

54 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

55 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

56 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

57 s servo min:-180.100 us max: 180.800 us sdev: 1.900 us

58 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

59 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

60 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

62 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

63 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

64 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

65 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

67 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

68 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

69 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

71 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

72 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

73 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

74 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

75 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

77 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

78 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

79 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

80 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

82 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

83 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

84 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

86 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

87 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

88 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

89 s servo min:-180.100 us max: 180.800 us sdev: 1.600 us

90 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

91 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

92 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

93 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

94 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

95 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

96 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

97 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

98 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

99 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

100 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

101 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

102 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

103 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

104 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

105 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

106 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

107 s servo min:-180.100 us max: 180.800 us sdev: 1.800 us

108 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

109 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

110 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

111 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

112 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

113 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

114 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

115 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

116 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

117 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

118 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

119 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

121 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

122 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

123 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

124 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

125 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

126 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

127 s servo min:-180.100 us max: 180.800 us sdev: 1.700 us

128 s servo min:-181.200 us max: 180.800 us sdev: 1.700 us

129 s servo min:-181.200 us max: 180.800 us sdev: 1.700 us

131 s servo min:-181.200 us max: 180.800 us sdev: 1.700 us

132 s servo min:-181.200 us max: 180.800 us sdev: 1.700 us

133 s servo min:-181.200 us max: 180.800 us sdev: 1.700 usAttachments:

Last edit: 01 Jan 2022 20:27 by davidimurray. Reason: attachment missing

Please Log in or Create an account to join the conversation.

- ALittleOffTheRails

-

- Visitor

-

01 Jan 2022 20:53 #230483

by ALittleOffTheRails

Replied by ALittleOffTheRails on topic Installing LinuxCNC On HP T610 Thin Client

First off no need for a base thread if you are going to use Ethernet.

Second a couple of posts up I gave a link that explains “the missing ram” mystery. Also what to do to mitigate it.

Second a couple of posts up I gave a link that explains “the missing ram” mystery. Also what to do to mitigate it.

Please Log in or Create an account to join the conversation.

- davidimurray

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 5

01 Jan 2022 21:06 #230484

by davidimurray

Replied by davidimurray on topic Installing LinuxCNC On HP T610 Thin Client

Hi

I am not selecting the base thread when running the test. Currently seeing over 200 which i understand is likely to cause issues with an ethernet setup.

I've followed Joco's BIOS settings and the graphics card is forced to 64m - this has made no improvement to it being in auto.

Seems strange my results are so poor compared to Joco's

I am not selecting the base thread when running the test. Currently seeing over 200 which i understand is likely to cause issues with an ethernet setup.

I've followed Joco's BIOS settings and the graphics card is forced to 64m - this has made no improvement to it being in auto.

Seems strange my results are so poor compared to Joco's

Please Log in or Create an account to join the conversation.

- ALittleOffTheRails

-

- Visitor

-

01 Jan 2022 23:04 #230494

by ALittleOffTheRails

Replied by ALittleOffTheRails on topic Installing LinuxCNC On HP T610 Thin Client

There are quite a few differences in setups.

For instance the kernels are different, OS are different, WIndow managers & Desktop environments are different, even the kernel command lines are different.

Actually the differences are so much so that it is no wonder there are differences in latency figures. You are not really comparing apples with apples. There is nothing really strange about it.

The latency histogram clearly shows you are running a base thread.

For instance the kernels are different, OS are different, WIndow managers & Desktop environments are different, even the kernel command lines are different.

Actually the differences are so much so that it is no wonder there are differences in latency figures. You are not really comparing apples with apples. There is nothing really strange about it.

The latency histogram clearly shows you are running a base thread.

Please Log in or Create an account to join the conversation.

- seuchato

- Offline

- Platinum Member

-

Less

More

- Posts: 381

- Thank you received: 125

02 Jan 2022 00:55 #230507

by seuchato

Replied by seuchato on topic Installing LinuxCNC On HP T610 Thin Client

Hi

If, then please play with amount of ram yourself and post results in a seperate thread. You WILL see a considerable difference, once there is ENOUGH Ram. I use old PCs for my CNC. If I have to add Ram, I have the bad habit max it out and forget about that issue. Costs little, brings a lot => My opinion.

Greez

chris

2 GB has been too low in many cases. I am No windows Guru. Last Windows install on a PC owned by myself dates back to about 2010.Have you got any testing to back that up ?

I’ve seen extremely great results with an dual core Athalon with 4Gig ram running the latest Buster ISO. Yep this is a 2008 or there about setup. The test was also with a base and servo thread.

I feel this is getting into “Windows Guru” territory by just proclaiming “add more ram” to improve latency.

It would be interesting to see your test results with various ram quantities on the same setup.

If, then please play with amount of ram yourself and post results in a seperate thread. You WILL see a considerable difference, once there is ENOUGH Ram. I use old PCs for my CNC. If I have to add Ram, I have the bad habit max it out and forget about that issue. Costs little, brings a lot => My opinion.

Greez

chris

Please Log in or Create an account to join the conversation.

- ALittleOffTheRails

-

- Visitor

-

02 Jan 2022 01:28 #230509

by ALittleOffTheRails

Replied by ALittleOffTheRails on topic Installing LinuxCNC On HP T610 Thin Client

That's not how things work. It's up to those who make the claim to prove the point.

So no I'll think I'll pass trying to prove your point.

But what I have done is bought one of these little buggers to play with and see what I can get out of one.

As for the Windows Guru thing.

The usual answer to anything in windows is "apply all s\w updates, install latest drivers" not matter what the issue. I dare say that would be the answer if your windows pc burst into flames whilst powered off sitting in the middle of a grassy meadow.

So no I'll think I'll pass trying to prove your point.

But what I have done is bought one of these little buggers to play with and see what I can get out of one.

As for the Windows Guru thing.

The usual answer to anything in windows is "apply all s\w updates, install latest drivers" not matter what the issue. I dare say that would be the answer if your windows pc burst into flames whilst powered off sitting in the middle of a grassy meadow.

Please Log in or Create an account to join the conversation.

- Joco

-

- Offline

- Platinum Member

-

Less

More

- Posts: 531

- Thank you received: 327

03 Jan 2022 06:44 #230630

by Joco

Replied by Joco on topic Installing LinuxCNC On HP T610 Thin Client

A couple of suggestions to look into.

[1] Consider adding idle=poll to the kernel command line. I decided not to use this as it makes things run very hot and keeps it that way even when no load in place. However if you have good cooling it might not be a concern.

[]2 I used a "hog" script to drive the cpu hertz on the cpu 1 (not cpu 0) to max Hz. A quirk of the AMD arch is that this will also drive CPU0 to max Hz as well when CPU1 is driven to max. The effect of this is that you will likely see improved latency,

See forum.linuxcnc.org/18-computer/39533-ins...ient?start=20#206996 for these.

I used path #2 as it means that when you shut off linuxcnc it will drop the cpu load and give things a chance to cool. Depending on your usage pattern this may or may not be useful.

But with the setup i had (4GB ram, Miny 19.3 and the RT kernel noted in the posts) this hog script approach was FUNDAMENTAL to getting acceptable latency.

Cheers - James.

[1] Consider adding idle=poll to the kernel command line. I decided not to use this as it makes things run very hot and keeps it that way even when no load in place. However if you have good cooling it might not be a concern.

[]2 I used a "hog" script to drive the cpu hertz on the cpu 1 (not cpu 0) to max Hz. A quirk of the AMD arch is that this will also drive CPU0 to max Hz as well when CPU1 is driven to max. The effect of this is that you will likely see improved latency,

See forum.linuxcnc.org/18-computer/39533-ins...ient?start=20#206996 for these.

I used path #2 as it means that when you shut off linuxcnc it will drop the cpu load and give things a chance to cool. Depending on your usage pattern this may or may not be useful.

But with the setup i had (4GB ram, Miny 19.3 and the RT kernel noted in the posts) this hog script approach was FUNDAMENTAL to getting acceptable latency.

Cheers - James.

The following user(s) said Thank You: seuchato

Please Log in or Create an account to join the conversation.

Time to create page: 0.175 seconds