Remora - ethernet NVEM / EC300 / EC500 cnc board

- fintech

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

10 Feb 2023 00:37 #264191

by fintech

Replied by fintech on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

I'm a new to linuxCNC. How do get outputs to work with M7 M8 M9. trying t test some outputs. Anything else I need to configure. Anything in the ini file?

net coolant-flood => remora.output.3

net coolant-mist => remora.output.4

net coolant-flood => remora.output.3

net coolant-mist => remora.output.4

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

10 Feb 2023 01:21 - 10 Feb 2023 01:32 #264193

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

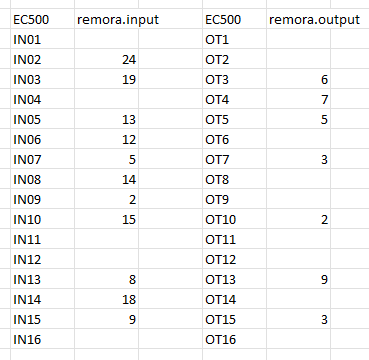

Attachments:

Last edit: 10 Feb 2023 01:32 by scotta.

The following user(s) said Thank You: heiterkiter

Please Log in or Create an account to join the conversation.

- fintech

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

10 Feb 2023 03:46 #264197

by fintech

Replied by fintech on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Thanks Scott, I got it to work with:

net coolant-flood iocontrol.0.coolant-flood remora.output.6

net coolant-mist iocontrol.0.coolant-mist remora.output.7

Now I need to figure out inputs and spindle.

net coolant-flood iocontrol.0.coolant-flood remora.output.6

net coolant-mist iocontrol.0.coolant-mist remora.output.7

Now I need to figure out inputs and spindle.

The following user(s) said Thank You: scotta

Please Log in or Create an account to join the conversation.

- dec0077

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 1

10 Feb 2023 06:31 #264206

by dec0077

Replied by dec0077 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Mine is STM32 based.

I would have to un-wire the board to be able to remove the lid, but I could take a picture if you think it could help

I would have to un-wire the board to be able to remove the lid, but I could take a picture if you think it could help

Please Log in or Create an account to join the conversation.

- Domi

- Offline

- Senior Member

-

Less

More

- Posts: 64

- Thank you received: 0

10 Feb 2023 09:06 #264211

by Domi

Replied by Domi on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hello. How do I invert the 0-10V output for the spindle? when stopped I have 10V and at maximum revolutions it is 0V. or will someone provide a hall for the spindle? I use linuxcnc 2.8.2 and NVEM V2. Well thank you

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

10 Feb 2023 20:45 #264247

by scotta

There is an example hal using lincurve to invert the output. You will need to adapt the scale and lincurve parameters appropriately.

remora-docs.readthedocs.io/en/latest/sof...incurve-compensation

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

There seems to be a few versions of the STM32 based NVEM v2, especially when it comes to the output circuit for the analogue 0-10v.Hello. How do I invert the 0-10V output for the spindle? when stopped I have 10V and at maximum revolutions it is 0V. or will someone provide a hall for the spindle? I use linuxcnc 2.8.2 and NVEM V2. Well thank you

There is an example hal using lincurve to invert the output. You will need to adapt the scale and lincurve parameters appropriately.

remora-docs.readthedocs.io/en/latest/sof...incurve-compensation

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

10 Feb 2023 20:56 #264249

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

When you say that the output is always 10v, is this the case when LinuxCNC is not talking with the board? I'm suspicious that your board might have a different circuit and IO pin than the board I used for development. A photo might help but a real pain with the NVEM not having plug headers.Mine is STM32 based.

I would have to un-wire the board to be able to remove the lid, but I could take a picture if you think it could help

Please Log in or Create an account to join the conversation.

- fintech

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 5

10 Feb 2023 21:13 #264251

by fintech

Replied by fintech on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

So far this is my working HAL on EC500 V5.

# Basic HAL config file for NVEM controller board running Remora firmware

# Configured for 3 joints (A, Y, Z axes) with home and limit switches

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

# load the Remora real-time component

loadrt remora-nv

# estop and SPI comms enable and feedback

net user-enable-out <= iocontrol.0.user-enable-out => remora.enable

net user-request-enable <= iocontrol.0.user-request-enable => remora.reset

net remora-status <= remora.status => iocontrol.0.emc-enable-in

# add the remora and motion functions to threads

addf remora.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf remora.update-freq servo-thread

addf remora.write servo-thread

# joint 0 setup (X axis)

setp remora.joint.0.scale [JOINT_0]SCALE

setp remora.joint.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

net j0pos-cmd joint.0.motor-pos-cmd => remora.joint.0.pos-cmd

net j0pos-fb remora.joint.0.pos-fb => joint.0.motor-pos-fb

net j0enable joint.0.amp-enable-out => remora.joint.0.enable

# joint 1 setup (Y axis)

setp remora.joint.1.scale [JOINT_1]SCALE

setp remora.joint.1.maxaccel [JOINT_1]STEPGEN_MAXACCEL

net j1pos-cmd joint.1.motor-pos-cmd => remora.joint.1.pos-cmd

net j1pos-fb remora.joint.1.pos-fb => joint.1.motor-pos-fb

net j1enable joint.1.amp-enable-out => remora.joint.1.enable

# joint 2 setup (Z axis)

setp remora.joint.2.scale [JOINT_2]SCALE

setp remora.joint.2.maxaccel [JOINT_2]STEPGEN_MAXACCEL

net j2pos-cmd joint.2.motor-pos-cmd => remora.joint.2.pos-cmd

net j2pos-fb remora.joint.2.pos-fb => joint.2.motor-pos-fb

net j2enable joint.2.amp-enable-out => remora.joint.2.enable

#Spindle Control 0V-10V Analog (working with 24K Spindle) At 12K getting 4.96V at 24K getting 9.77V

net spindle-cw remora.output.5

loadrt pwmgen output_type=1

loadrt scale count=1

loadrt lowpass count=1

loadrt abs count=1

addf scale.0 servo-thread

addf lowpass.0 servo-thread

addf abs.0 servo-thread

setp scale.0.gain 0.00416666667

net spindle-cmd-rpm spindle.0.speed-out => scale.0.in

net spindle-cmd-rpm-abs scale.0.out => abs.0.in

net spindle-speed-DAC abs.0.out => remora.SP.0

net spindle-cw <= spindle.0.forward

#Output Coolant Control M7 M8 M9

net coolant-flood iocontrol.0.coolant-flood remora.output.6

net coolant-mist iocontrol.0.coolant-mist remora.output.7

#Inputs

net estop-ext <= remora.input.24

net home-x <= remora.input.19

net home-y <= remora.input.13

net home-z <= remora.input.12

net spindle-index <= remora.input.5

# Basic HAL config file for NVEM controller board running Remora firmware

# Configured for 3 joints (A, Y, Z axes) with home and limit switches

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

# load the Remora real-time component

loadrt remora-nv

# estop and SPI comms enable and feedback

net user-enable-out <= iocontrol.0.user-enable-out => remora.enable

net user-request-enable <= iocontrol.0.user-request-enable => remora.reset

net remora-status <= remora.status => iocontrol.0.emc-enable-in

# add the remora and motion functions to threads

addf remora.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf remora.update-freq servo-thread

addf remora.write servo-thread

# joint 0 setup (X axis)

setp remora.joint.0.scale [JOINT_0]SCALE

setp remora.joint.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

net j0pos-cmd joint.0.motor-pos-cmd => remora.joint.0.pos-cmd

net j0pos-fb remora.joint.0.pos-fb => joint.0.motor-pos-fb

net j0enable joint.0.amp-enable-out => remora.joint.0.enable

# joint 1 setup (Y axis)

setp remora.joint.1.scale [JOINT_1]SCALE

setp remora.joint.1.maxaccel [JOINT_1]STEPGEN_MAXACCEL

net j1pos-cmd joint.1.motor-pos-cmd => remora.joint.1.pos-cmd

net j1pos-fb remora.joint.1.pos-fb => joint.1.motor-pos-fb

net j1enable joint.1.amp-enable-out => remora.joint.1.enable

# joint 2 setup (Z axis)

setp remora.joint.2.scale [JOINT_2]SCALE

setp remora.joint.2.maxaccel [JOINT_2]STEPGEN_MAXACCEL

net j2pos-cmd joint.2.motor-pos-cmd => remora.joint.2.pos-cmd

net j2pos-fb remora.joint.2.pos-fb => joint.2.motor-pos-fb

net j2enable joint.2.amp-enable-out => remora.joint.2.enable

#Spindle Control 0V-10V Analog (working with 24K Spindle) At 12K getting 4.96V at 24K getting 9.77V

net spindle-cw remora.output.5

loadrt pwmgen output_type=1

loadrt scale count=1

loadrt lowpass count=1

loadrt abs count=1

addf scale.0 servo-thread

addf lowpass.0 servo-thread

addf abs.0 servo-thread

setp scale.0.gain 0.00416666667

net spindle-cmd-rpm spindle.0.speed-out => scale.0.in

net spindle-cmd-rpm-abs scale.0.out => abs.0.in

net spindle-speed-DAC abs.0.out => remora.SP.0

net spindle-cw <= spindle.0.forward

#Output Coolant Control M7 M8 M9

net coolant-flood iocontrol.0.coolant-flood remora.output.6

net coolant-mist iocontrol.0.coolant-mist remora.output.7

#Inputs

net estop-ext <= remora.input.24

net home-x <= remora.input.19

net home-y <= remora.input.13

net home-z <= remora.input.12

net spindle-index <= remora.input.5

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 956

- Thank you received: 486

10 Feb 2023 21:27 #264252

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Thanks for sharing, it will definitely help others. You've picked up LinuxCNC quickly.

Please Log in or Create an account to join the conversation.

- dec0077

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 1

10 Feb 2023 21:32 #264253

by dec0077

Replied by dec0077 on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

I didn't check the voltage on VSO when Linuxcnc is not running, I didn't think it would be useful, but I can do that, it'll be just a minute to do so.

My main issue is of course the output voltage when the system is up&running, as I have everything else working fine with my board (movement, limits, inputs, outputs to enable forward and reverse rotation of the spindle, etc.) but the analog 0-10V.

I'll try to get a picture, but this time I'll leave the lid off, in case I need to access it again. I'm also guessing if, to solve the issue, I'll have to flash a new version of the firmware, I'll have to free the board again... Maybe, without the lid on, I can leave the serial headers soldered on.

I'm getting an oscilloscope, will be here in a few days, so then I should be able to understand what is going on with the VSO output (it's a shame there are no other float pins on the board, just digital ones).

Thank you

My main issue is of course the output voltage when the system is up&running, as I have everything else working fine with my board (movement, limits, inputs, outputs to enable forward and reverse rotation of the spindle, etc.) but the analog 0-10V.

I'll try to get a picture, but this time I'll leave the lid off, in case I need to access it again. I'm also guessing if, to solve the issue, I'll have to flash a new version of the firmware, I'll have to free the board again... Maybe, without the lid on, I can leave the serial headers soldered on.

I'm getting an oscilloscope, will be here in a few days, so then I should be able to understand what is going on with the VSO output (it's a shame there are no other float pins on the board, just digital ones).

Thank you

Please Log in or Create an account to join the conversation.

Time to create page: 0.582 seconds