- GCode and Part Programs

- G&M Codes

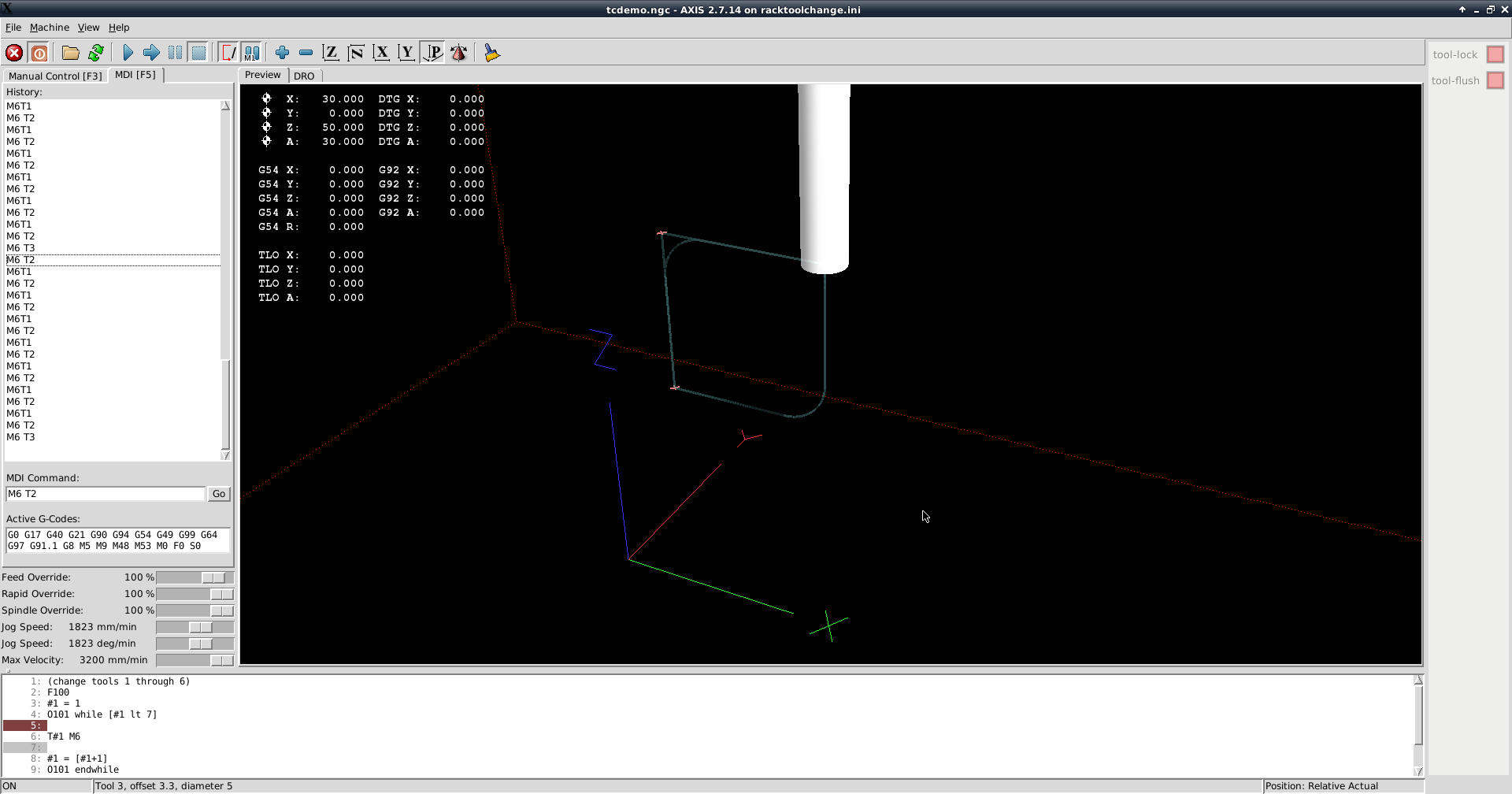

- Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

24 Apr 2019 16:27 #131775

by andypugh

Use a G-code digital output

I didn't say that. I said that it could.

If you load the selected tool and do a g43 then the parameters #5401 to #5409 will take the values from the tool table.

You aren't using UVW so you could use those tool table entries to hold the pocket locations for each tool and move there with a G53 absolute move.

Replied by andypugh on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

1) Can you explain how to activate Pneumatic cylinder using parallel port configuration to declamp tool how to setup output pin delay and all ? I m not able to find any details of output.

Use a G-code digital output

net tool-clamp motion.digital-out-00 => parport.0.pin-00-out2) Also in last lines you said that tool table decides tool pocket Location,

I didn't say that. I said that it could.

If you load the selected tool and do a g43 then the parameters #5401 to #5409 will take the values from the tool table.

You aren't using UVW so you could use those tool table entries to hold the pocket locations for each tool and move there with a G53 absolute move.

G53 G0 X#5407 Y#5408

The following user(s) said Thank You: marq_torque

Please Log in or Create an account to join the conversation.

- marq_torque

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 2

24 Apr 2019 16:40 #131777

by marq_torque

Replied by marq_torque on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Great,

I m trying it just in a while.

Thanks,

Ankit

I m trying it just in a while.

Thanks,

Ankit

Please Log in or Create an account to join the conversation.

- marq_torque

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 2

24 Apr 2019 21:44 #131798

by marq_torque

Replied by marq_torque on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Hello Andy, Hello pl7i92,

I am almost done with this setup, thanks tonns, actually G 38.2 i didnt tried on machine, will try tomorrow with dummy switch.

Apart from that I found one bug, whenever i close EMC with tool in spindle, its not saving existing tool, it shows no tool in next startup. any ideas to avoid this ?

Thanks & Regards,

Ankit

I am almost done with this setup, thanks tonns, actually G 38.2 i didnt tried on machine, will try tomorrow with dummy switch.

Apart from that I found one bug, whenever i close EMC with tool in spindle, its not saving existing tool, it shows no tool in next startup. any ideas to avoid this ?

Thanks & Regards,

Ankit

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

24 Apr 2019 22:04 #131799

by andypugh

That's normal, but is also something that is being looked in to.

(It's not a bug, LinuxCNC has always done that)

Replied by andypugh on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Apart from that I found one bug, whenever i close EMC with tool in spindle, its not saving existing tool, it shows no tool in next startup. any ideas to avoid this ?

That's normal, but is also something that is being looked in to.

(It's not a bug, LinuxCNC has always done that)

The following user(s) said Thank You: marq_torque

Please Log in or Create an account to join the conversation.

- marq_torque

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 2

24 Apr 2019 22:14 #131800

by marq_torque

Replied by marq_torque on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Yes my bad, its not bug its normal... Okay, so all the time when machine starts up we need to remove tool manually and place it in its pocket and then after i can get GCode running.?

Are there any parameters for this ? To overcome this situation ?

Thanks,

Ankit

Are there any parameters for this ? To overcome this situation ?

Thanks,

Ankit

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

24 Apr 2019 22:47 #131802

by andypugh

Replied by andypugh on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Not at the moment.

Supposedly it is good practice to unload tools at the end of the day (not that I bother)

M6 T0 before shutting down?

Supposedly it is good practice to unload tools at the end of the day (not that I bother)

M6 T0 before shutting down?

The following user(s) said Thank You: marq_torque

Please Log in or Create an account to join the conversation.

- marq_torque

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 2

28 Apr 2019 02:14 #132144

by marq_torque

Replied by marq_torque on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Yes AndyPugh, i tried unloading with M6T0

But problem with my spindle is, its Alfred Jaeger HF spindle 10000-600000RPM, it cant be left unloaded without tool for longer time, or cant be forced to run without tool loaded into it. Doing so can damage spindle collet mechanism and internals Warned by Manufacturer

So have to think over how to keep tool into it and still manage to change with respective number.

But problem with my spindle is, its Alfred Jaeger HF spindle 10000-600000RPM, it cant be left unloaded without tool for longer time, or cant be forced to run without tool loaded into it. Doing so can damage spindle collet mechanism and internals Warned by Manufacturer

So have to think over how to keep tool into it and still manage to change with respective number.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

28 Apr 2019 09:47 #132165

by andypugh

Replied by andypugh on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Have you read this series of posts? There is a solution here that will tide you over until something gets built-in to LinuxCNC.

forum.linuxcnc.org/38-general-linuxcnc-q...mory?start=10#130062

forum.linuxcnc.org/38-general-linuxcnc-q...mory?start=10#130062

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

28 Apr 2019 12:45 - 28 Apr 2019 12:48 #132171

by bevins

Replied by bevins on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

There will always be a free pocket unless you place the tool in the spindle in the rack. Either way you can check to see if there is a free pocket, assuming you have switches that detect a tool in pocket, and if, tool in spindle, then you have the tool thats in the spindle. I do this on every tool change so I know the status of tool-rack and whats in the spindle.

I can do this because I have sensors that detect if there is a tool in the spindle and sensors that detect if there is a tool in each pocket.

I also set selected tool and pocket before updating parameters after I set toolchange flag to true. I dont know if Linuxcnc really needs this because on every tool change, I run the functions to test what I asked for and where the tool is.

Keep in mind doing this you need the tool# to be the same as the tool_pocket always. So you have to govern yourself accordingly when setting up tools and doing your cam stuff.

I can do this because I have sensors that detect if there is a tool in the spindle and sensors that detect if there is a tool in each pocket.

I also set selected tool and pocket before updating parameters after I set toolchange flag to true. I dont know if Linuxcnc really needs this because on every tool change, I run the functions to test what I asked for and where the tool is.

Keep in mind doing this you need the tool# to be the same as the tool_pocket always. So you have to govern yourself accordingly when setting up tools and doing your cam stuff.

Last edit: 28 Apr 2019 12:48 by bevins.

Please Log in or Create an account to join the conversation.

- aluplastvz

- Offline

- Senior Member

-

Less

More

- Posts: 52

- Thank you received: 9

03 May 2020 07:39 #166479

by aluplastvz

Replied by aluplastvz on topic Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Regards to all

I was somewhat able to run this example ATC and it works fine, but I have two questions if you can help me,

1. how to do new tool = current tool ignore tool replacement.

2. my machine requires tool orientation

Thanks a lot

I was somewhat able to run this example ATC and it works fine, but I have two questions if you can help me,

1. how to do new tool = current tool ignore tool replacement.

2. my machine requires tool orientation

Thanks a lot

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- G&M Codes

- Anyone with succesful Rack Type Tool Changer with Auto Tool length probe ?

Time to create page: 0.154 seconds