Can anyone give an explanation?

- SummerLotus

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 1

16 Jul 2024 09:11 #305331

by SummerLotus

Can anyone give an explanation? was created by SummerLotus

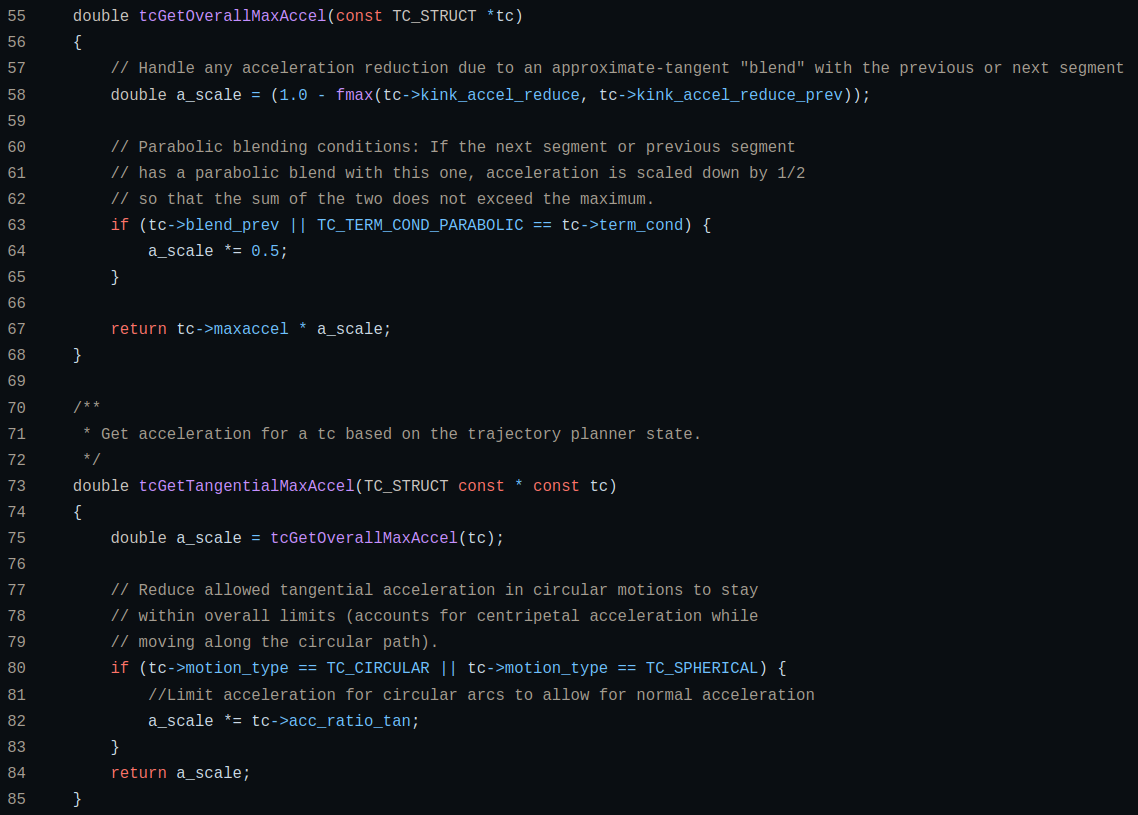

I don't understand the content of this part, why use half of the acceleration? Is there any article that can explain this problem in detail?

Important User Concepts (linuxcnc.org) 1.4. Planning MovesMake sure moves are long enough to suit your machine/material. Principally because of the rule that the machine will never move at such a speed that it cannot come to a complete stop at the end of the current movement, there is a minimum movement length that will allow the machine to keep up a requested feed rate with a given acceleration setting.The acceleration and deceleration phase each use half the INI file MAX_ACCELERATION. In a blend that is an exact reversal, this causes the total axis acceleration to equal the INI file MAX_ACCELERATION. In other cases, the actual machine acceleration is somewhat less than the INI file acceleration.To keep up the feed rate, the move must be longer than the distance it takes to accelerate from 0 to the desired feed rate and then stop again. Using A as 1/2 the INI file MAX_ACCELERATION and F as the feed rate in units per second, the acceleration time is ta = F/A and the acceleration distance is da = F*ta/2. The deceleration time and distance are the same, making the critical distance d = da + dd = 2 * da = F2/A.For example, for a feed rate of 1 inch per second and an acceleration of 10 inches/sec2, the critical distance is 12/10 = 1/10 = 0.1 inches.For a feed rate of 0.5 inch per second, the critical distance is 52/100 = 25/100 = 0.025 inches.

Important User Concepts (linuxcnc.org) 1.4. Planning MovesMake sure moves are long enough to suit your machine/material. Principally because of the rule that the machine will never move at such a speed that it cannot come to a complete stop at the end of the current movement, there is a minimum movement length that will allow the machine to keep up a requested feed rate with a given acceleration setting.The acceleration and deceleration phase each use half the INI file MAX_ACCELERATION. In a blend that is an exact reversal, this causes the total axis acceleration to equal the INI file MAX_ACCELERATION. In other cases, the actual machine acceleration is somewhat less than the INI file acceleration.To keep up the feed rate, the move must be longer than the distance it takes to accelerate from 0 to the desired feed rate and then stop again. Using A as 1/2 the INI file MAX_ACCELERATION and F as the feed rate in units per second, the acceleration time is ta = F/A and the acceleration distance is da = F*ta/2. The deceleration time and distance are the same, making the critical distance d = da + dd = 2 * da = F2/A.For example, for a feed rate of 1 inch per second and an acceleration of 10 inches/sec2, the critical distance is 12/10 = 1/10 = 0.1 inches.For a feed rate of 0.5 inch per second, the critical distance is 52/100 = 25/100 = 0.025 inches.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

16 Jul 2024 09:30 - 16 Jul 2024 09:36 #305332

by Aciera

Replied by Aciera on topic Can anyone give an explanation?

Yes this sentence in particular:

This behavior has been discussed several times but I don't think anybody had an explanation for it:

forum.linuxcnc.org/38-general-linuxcnc-q...long?start=10#210458

forum.linuxcnc.org/49-basic-configuratio...n-config-file#279913

This one is particularly interesting:

forum.linuxcnc.org/49-basic-configuratio...eration-value#128957

Seems to allude to coordinated motion of more than one axis but why is that 'an exact reversal'?In a blend that is an exact reversal, this causes the total axis acceleration to equal the INI file MAX_ACCELERATION.

This behavior has been discussed several times but I don't think anybody had an explanation for it:

forum.linuxcnc.org/38-general-linuxcnc-q...long?start=10#210458

forum.linuxcnc.org/49-basic-configuratio...n-config-file#279913

This one is particularly interesting:

forum.linuxcnc.org/49-basic-configuratio...eration-value#128957

Last edit: 16 Jul 2024 09:36 by Aciera.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

16 Jul 2024 09:47 - 16 Jul 2024 09:52 #305333

by Aciera

Replied by Aciera on topic Can anyone give an explanation?

Attachments:

Last edit: 16 Jul 2024 09:52 by Aciera.

The following user(s) said Thank You: tommylight, SummerLotus

Please Log in or Create an account to join the conversation.

Time to create page: 0.361 seconds