Spindle location on the opposite side

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

22 Jan 2025 17:43 - 22 Jan 2025 17:58 #319650

by Murphy

Replied by Murphy on topic Spindle location on the opposite side

Jog button is the virtual button on axis.

Looking down on the lathe from the top view in fusion. Tip is facing up. Tool can face and turn. Tool path is facing.

Iv just noticed something also what could be causing all of this my linuxcnc version is 2.10. That's not fully released yet.

my linuxcnc version is 2.10. That's not fully released yet.

Edit,

I read that link you posted ,that's very handy. But looks like I had everything setup right so it's not not either lol

Looking down on the lathe from the top view in fusion. Tip is facing up. Tool can face and turn. Tool path is facing.

Iv just noticed something also what could be causing all of this

Edit,

I read that link you posted ,that's very handy. But looks like I had everything setup right so it's not not either lol

Last edit: 22 Jan 2025 17:58 by Murphy.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1959

- Thank you received: 796

22 Jan 2025 18:47 #319655

by spumco

Replied by spumco on topic Spindle location on the opposite side

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1959

- Thank you received: 796

22 Jan 2025 19:15 #319660

by spumco

Replied by spumco on topic Spindle location on the opposite side

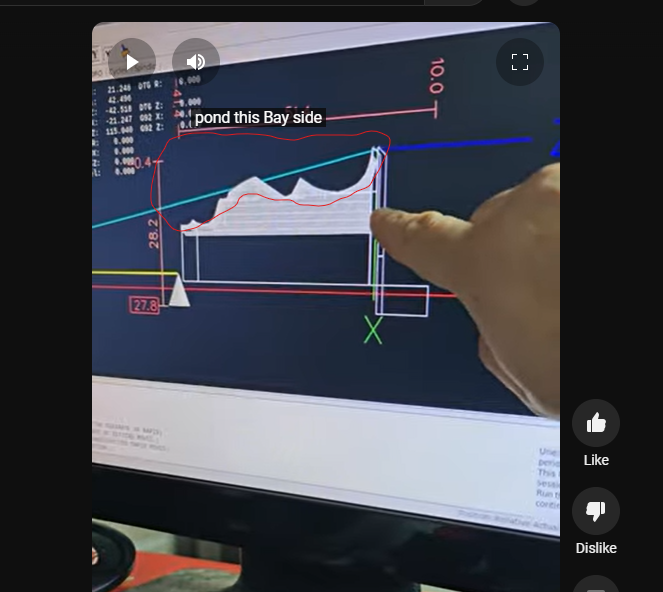

O.M.G.

I just watched your video. @Aciera was right, as usual.

What you are pointing at is the tool path, not the pawn. I've circled the 'pawn' in red. What you are pointing at and claiming is the 'base' is, in fact the pawn's head after the cuts are made.

White = tool path (are tool will cut)

Black = pawn after material is removed

This still doesn't explain why positive SEARCH_VEL moves left during homing but we can circle back to that.

I just watched your video. @Aciera was right, as usual.

What you are pointing at is the tool path, not the pawn. I've circled the 'pawn' in red. What you are pointing at and claiming is the 'base' is, in fact the pawn's head after the cuts are made.

White = tool path (are tool will cut)

Black = pawn after material is removed

This still doesn't explain why positive SEARCH_VEL moves left during homing but we can circle back to that.

Attachments:

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

22 Jan 2025 19:21 #319661

by Murphy

Replied by Murphy on topic Spindle location on the opposite side

LOL i think i need one trying to figure this out.

hal , test file and pawn attached

When i touch off g54 on X it drops the model down in the preview. Its thinking Im cutting from the top down and also the Z is inverted on the model. no matter what I do in fusion changing flipping axis or flipping the chuck placing its still the same.

hal , test file and pawn attached

When i touch off g54 on X it drops the model down in the preview. Its thinking Im cutting from the top down and also the Z is inverted on the model. no matter what I do in fusion changing flipping axis or flipping the chuck placing its still the same.

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

22 Jan 2025 19:42 #319664

by Murphy

Replied by Murphy on topic Spindle location on the opposite side

No way lol, it's amazing what you see when there's a finger pointing right at it. That was stupid on me it's so obvious.

What was throwing me off was when ever I touched off the x and z . The program wouldnt run because it was exceeding the limits. Even though there's plenty of space there. So there has to be an issue with my limits etc ?

What was throwing me off was when ever I touched off the x and z . The program wouldnt run because it was exceeding the limits. Even though there's plenty of space there. So there has to be an issue with my limits etc ?

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1959

- Thank you received: 796

22 Jan 2025 20:13 #319668

by spumco

Replied by spumco on topic Spindle location on the opposite side

And we're back to your X limit values in INI file being wacky.

See the error about "Line 17" in your screencap?

Line 17 in the pawn file is the first move with an X axis value. Specifically:N20 G0 X55.56 Z10.And if you look at your INI file:MIN_LIMIT = -48.0

MAX_LIMIT = 3.00

Something isn't going to work out when you tell LCNC to move to an X position greater than the MAX_LIMIT unless you have a tool offset active that drives the commanded position back inside the MAX/MIN limits.

Problem #1 is that your MAX should be something like 51, and MIN should be something like 0. Or maybe closer to 40 and -14 if you want the turret centerline tools to be at machine "0" after homing. I've no idea what the actual stroke length is for X.

Problem #2 is that you probably have F360 programmed with a HUGE clearance diameter/radius. F360 has no idea about your machine's travel limits (unless you define them in the Machines Definitions), so it doesn't alert you when you tell it you want a gigantic clearance. Try setting your clearance to 1 or 2mm from the stock OD and re-post. Line #17 will probably look more like:

N20 G0 X35.56 Z10.

So circle back to my earlier post about adjusting your X MAX/MIN values, and once you've got them where you want, re-do all three F360 operations to have a minimum clearance value and re-post. You can then look at the g-code and immediately see whether F360 is trying to drive your X-axis beyond the max limit.

See the error about "Line 17" in your screencap?

Line 17 in the pawn file is the first move with an X axis value. Specifically:N20 G0 X55.56 Z10.And if you look at your INI file:MIN_LIMIT = -48.0

MAX_LIMIT = 3.00

Something isn't going to work out when you tell LCNC to move to an X position greater than the MAX_LIMIT unless you have a tool offset active that drives the commanded position back inside the MAX/MIN limits.

Problem #1 is that your MAX should be something like 51, and MIN should be something like 0. Or maybe closer to 40 and -14 if you want the turret centerline tools to be at machine "0" after homing. I've no idea what the actual stroke length is for X.

Problem #2 is that you probably have F360 programmed with a HUGE clearance diameter/radius. F360 has no idea about your machine's travel limits (unless you define them in the Machines Definitions), so it doesn't alert you when you tell it you want a gigantic clearance. Try setting your clearance to 1 or 2mm from the stock OD and re-post. Line #17 will probably look more like:

N20 G0 X35.56 Z10.

So circle back to my earlier post about adjusting your X MAX/MIN values, and once you've got them where you want, re-do all three F360 operations to have a minimum clearance value and re-post. You can then look at the g-code and immediately see whether F360 is trying to drive your X-axis beyond the max limit.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1959

- Thank you received: 796

22 Jan 2025 20:57 #319674

by spumco

Replied by spumco on topic Spindle location on the opposite side

And another thing...

I saw in your last screencap that the DRO is displaying "G54 X: -17.xxx", but TLO X: 0.

I think this means that when you 'touched the tool off', you actually set the G54 work offset for X, and not the tool length offset.

On a lathe, the work offset for Z always changes depending on the stock/chuck length. But X offset should never change - it should always remain zero - otherwise LCNC thinks the spindle centerline is offset from reality.

You need to zero out the G54 X-offset value, and then redo the tool touch-off under the Machine menu. Here's the manual section:

linuxcnc.org/docs/devel/html/gui/axis.html#_manual_control

I saw in your last screencap that the DRO is displaying "G54 X: -17.xxx", but TLO X: 0.

I think this means that when you 'touched the tool off', you actually set the G54 work offset for X, and not the tool length offset.

On a lathe, the work offset for Z always changes depending on the stock/chuck length. But X offset should never change - it should always remain zero - otherwise LCNC thinks the spindle centerline is offset from reality.

You need to zero out the G54 X-offset value, and then redo the tool touch-off under the Machine menu. Here's the manual section:

linuxcnc.org/docs/devel/html/gui/axis.html#_manual_control

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

22 Jan 2025 21:31 #319677

by Murphy

Replied by Murphy on topic Spindle location on the opposite side

Great I'll try this , thanks for all the help. It's much appreciated. Travel on X is 48mm In the specs.

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

26 Jan 2025 09:15 - 26 Jan 2025 13:49 #319874

by Murphy

Replied by Murphy on topic Spindle location on the opposite side

Last edit: 26 Jan 2025 13:49 by Murphy.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1959

- Thank you received: 796

26 Jan 2025 14:25 #319887

by spumco

Replied by spumco on topic Spindle location on the opposite side

Congrats!

So... for future reference what settings/changes did you wind up making?

So... for future reference what settings/changes did you wind up making?

Please Log in or Create an account to join the conversation.

Time to create page: 0.090 seconds