Closed loop with linear encoders but still backlash?

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

25 Dec 2019 16:43 - 25 Dec 2019 17:23 #153199

by PCW

Replied by PCW on topic Closed loop with linear encoders but still backlash?

Theoretically, I term is not needed, The reason for this is that the stepgen has a very wide

velocity dynamic range (the 7I95 stepgens minimum settable frequency is ~.025 Hz)

With the OPs 1200 steps/mm settings and P term of 90, the minimum

correctable error is ~.2 nanometers, way below the scale resolution

I term may be useful for analog or low resolution velocity mode systems

I would check that

1. Your DRO is reading actual rather than commanded position

2. You don't have lost motion between where you are measuring and the scale

Because if you are reading actual position and it has no error, the scale is in the correct position but

the rest of your mechanics are not. This might be the result of loose gibs on a dovetail way system.

velocity dynamic range (the 7I95 stepgens minimum settable frequency is ~.025 Hz)

With the OPs 1200 steps/mm settings and P term of 90, the minimum

correctable error is ~.2 nanometers, way below the scale resolution

I term may be useful for analog or low resolution velocity mode systems

I would check that

1. Your DRO is reading actual rather than commanded position

2. You don't have lost motion between where you are measuring and the scale

Because if you are reading actual position and it has no error, the scale is in the correct position but

the rest of your mechanics are not. This might be the result of loose gibs on a dovetail way system.

Last edit: 25 Dec 2019 17:23 by PCW. Reason: use "actual" instead of "feedback" since thats what the display options are called

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

25 Dec 2019 18:24 #153200

by Hakan

Replied by Hakan on topic Closed loop with linear encoders but still backlash?

What I see myself is that there is after all some time needed to catch up on the backlash, or the following error.

When the slides go really slow there is virtually no following error, as the speed increases there is more and more.

It is not realistic to expect no following error at full speed. But at low speed one should expect really low error.

Set Backlash=0 in the ini file, let the feedback handle that instead.

When the slides go really slow there is virtually no following error, as the speed increases there is more and more.

It is not realistic to expect no following error at full speed. But at low speed one should expect really low error.

Set Backlash=0 in the ini file, let the feedback handle that instead.

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

23 Jan 2020 19:52 #155568

by Gnevko

Replied by Gnevko on topic Closed loop with linear encoders but still backlash?

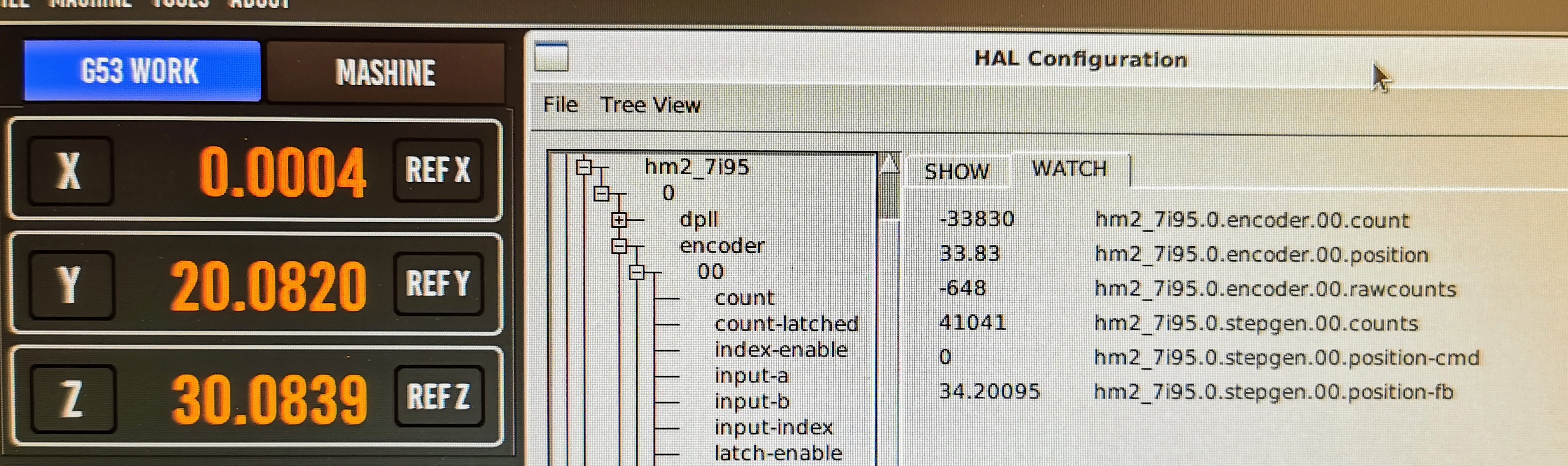

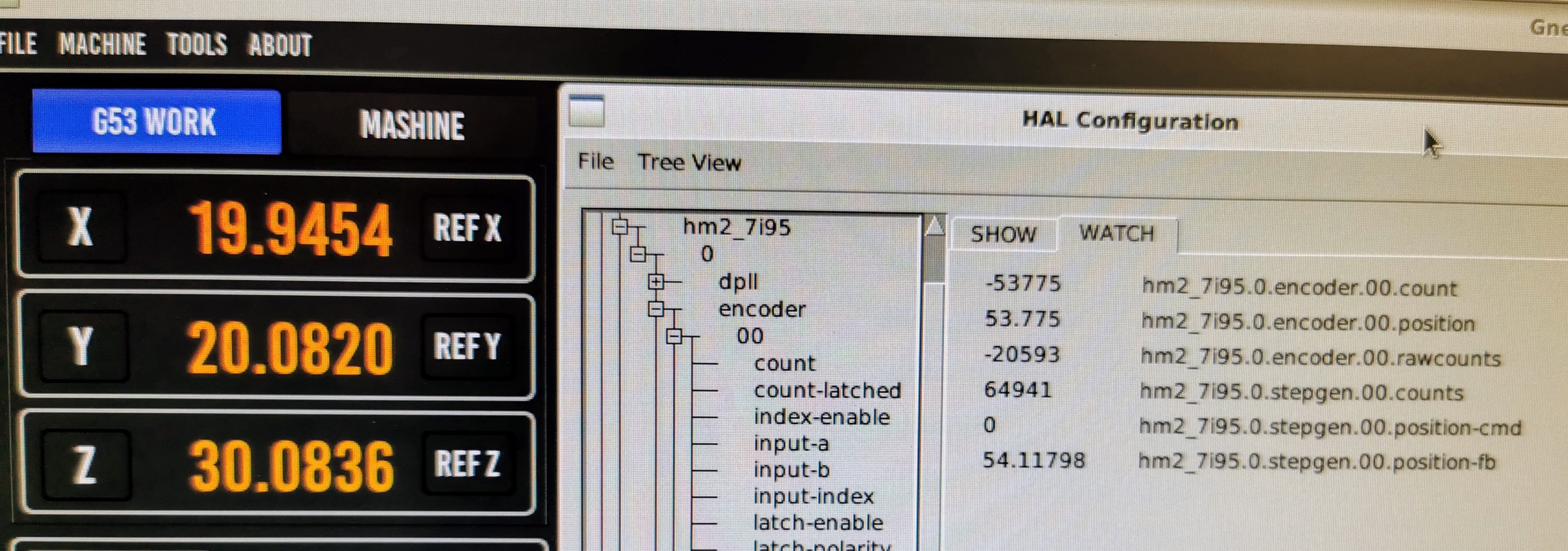

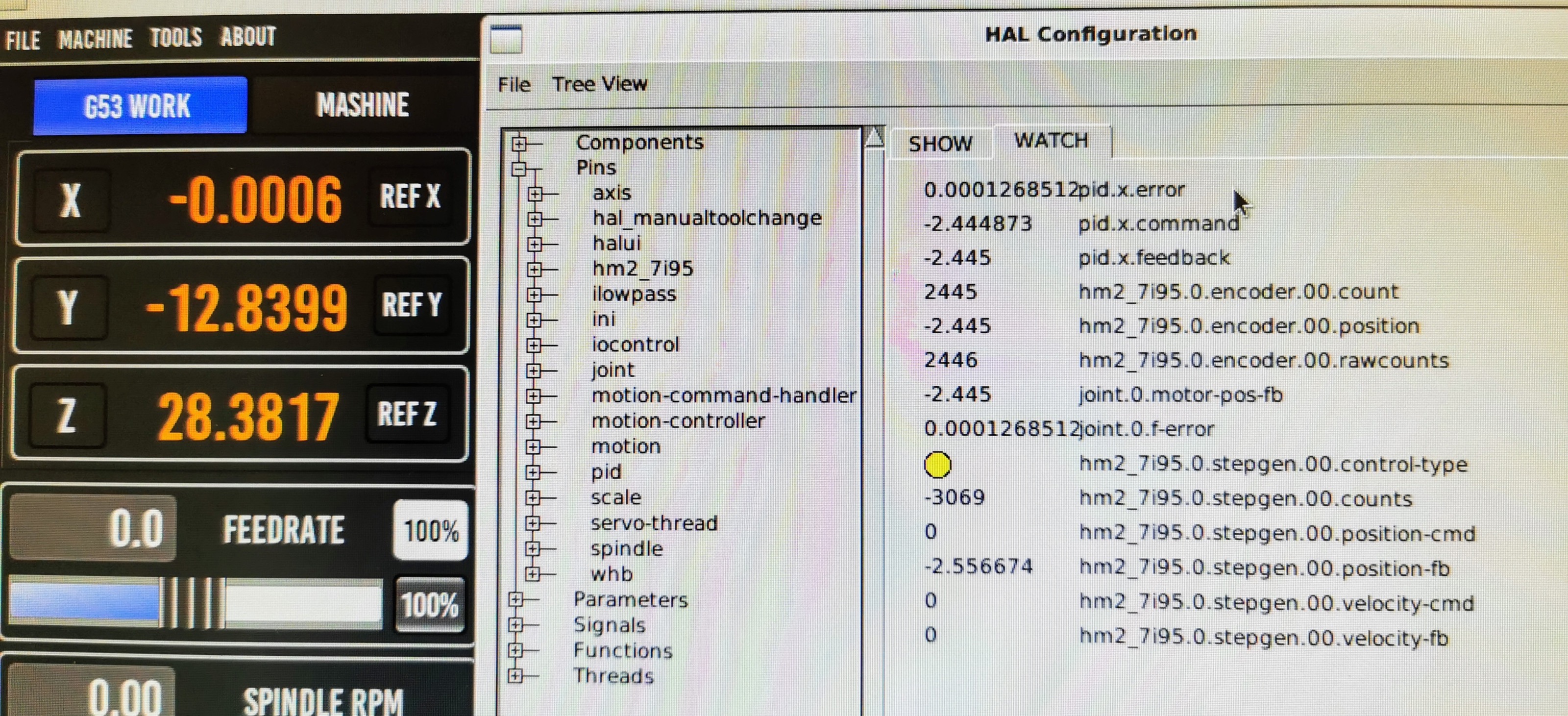

Today I had time to make some more additional tests on my machine. And of course as usual I am a little bit confused. The test is very simple:

1) to take a parallel with exactly 20.00 mm wide and set X axis to zero on the left side:

2) after that navigate to the right side of the parallel and read the value from DRO.

I expected to see something about 20.00mm (+- 0.01) but as you can see it is only 19.945mm

With is also very strange - the encoder position is not the same as stepgen.position-fb.

HAL Configuration for X:

MPG Configuration (because I made the navigation with it):

1) to take a parallel with exactly 20.00 mm wide and set X axis to zero on the left side:

2) after that navigate to the right side of the parallel and read the value from DRO.

I expected to see something about 20.00mm (+- 0.01) but as you can see it is only 19.945mm

With is also very strange - the encoder position is not the same as stepgen.position-fb.

HAL Configuration for X:

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .000

# Step Gen signals/setup

setp hm2_7i95.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i95.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i95.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i95.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i95.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i95.0.stepgen.00.step_type 0

setp hm2_7i95.0.stepgen.00.control-type 1

setp hm2_7i95.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i95.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---Encoder feedback signals/setup---

setp hm2_7i95.0.encoder.00.counter-mode 0

setp hm2_7i95.0.encoder.00.filter 1

setp hm2_7i95.0.encoder.00.index-invert 0

setp hm2_7i95.0.encoder.00.index-mask 0

setp hm2_7i95.0.encoder.00.index-mask-invert 0

setp hm2_7i95.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i95.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i95.0.encoder.00.position

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i95.0.stepgen.00.enable

#net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# ---setup home / limit switch signals---

net min-home-x hm2_7i95.0.inmux.00.input-00 joint.0.home-sw-in joint.0.neg-lim-sw-inMPG Configuration (because I made the navigation with it):

# Connect axis position related signals

net pdnt.halui.axis.0.pos-feedback halui.axis.x.pos-feedback whb.halui.axis.0.pos-feedback

net pdnt.halui.axis.1.pos-feedback halui.axis.y.pos-feedback whb.halui.axis.1.pos-feedback

net pdnt.halui.axis.2.pos-feedback halui.axis.z.pos-feedback whb.halui.axis.2.pos-feedback

net pdnt.halui.axis.0.pos-relative halui.axis.x.pos-relative whb.halui.axis.0.pos-relative

net pdnt.halui.axis.1.pos-relative halui.axis.y.pos-relative whb.halui.axis.1.pos-relative

net pdnt.halui.axis.2.pos-relative halui.axis.z.pos-relative whb.halui.axis.2.pos-relativeAttachments:

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

23 Jan 2020 20:09 #155570

by Todd Zuercher

Replied by Todd Zuercher on topic Closed loop with linear encoders but still backlash?

What was your following error on the X axis at both those points? The PID may need more tuning.

2nd how much do you trust your edge finder gauge? It might be informative to find one side of an edge, then turn the spindle 180 degrees and check the gauge again.

2nd how much do you trust your edge finder gauge? It might be informative to find one side of an edge, then turn the spindle 180 degrees and check the gauge again.

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

23 Jan 2020 20:49 #155572

by Gnevko

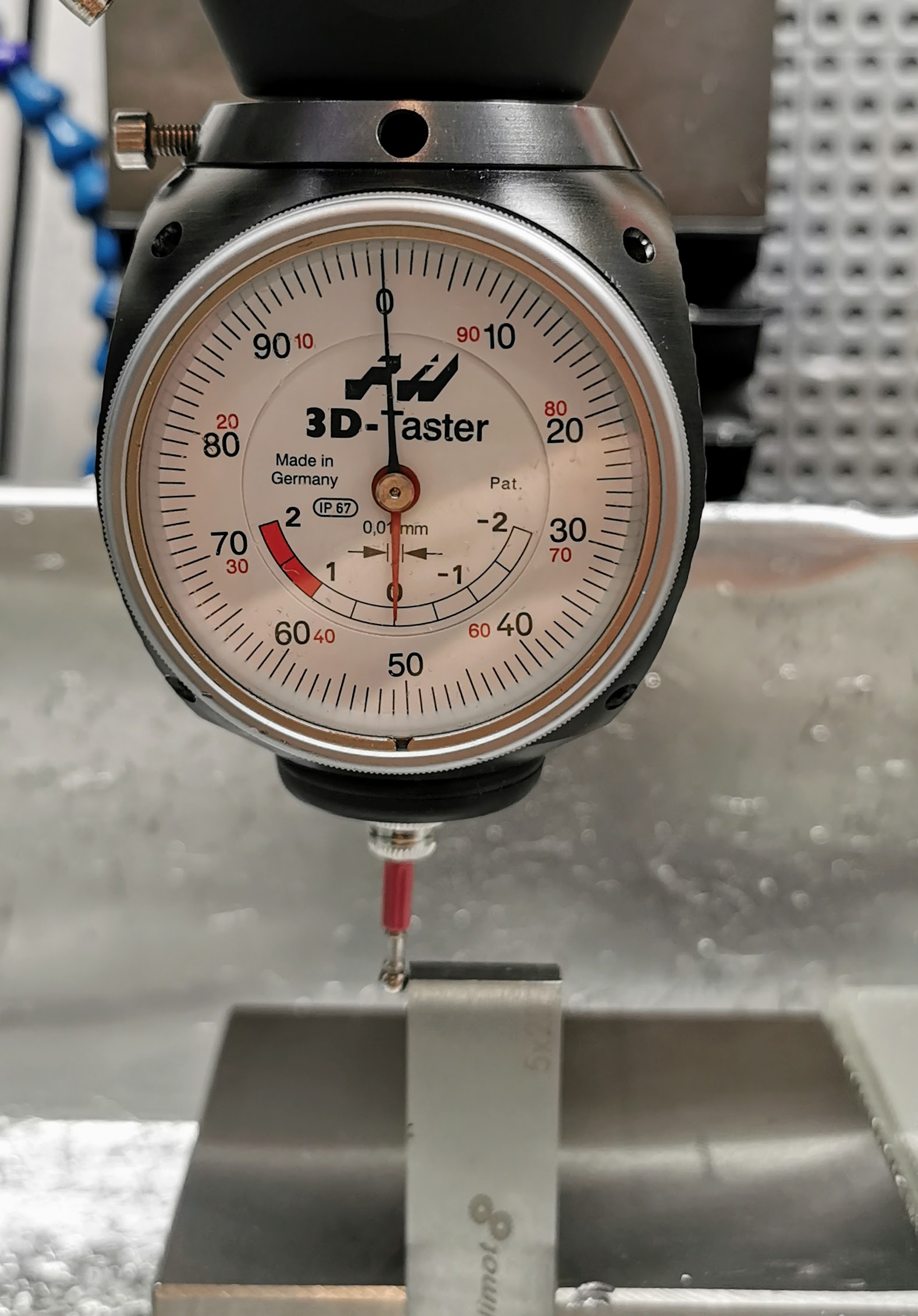

Position 1

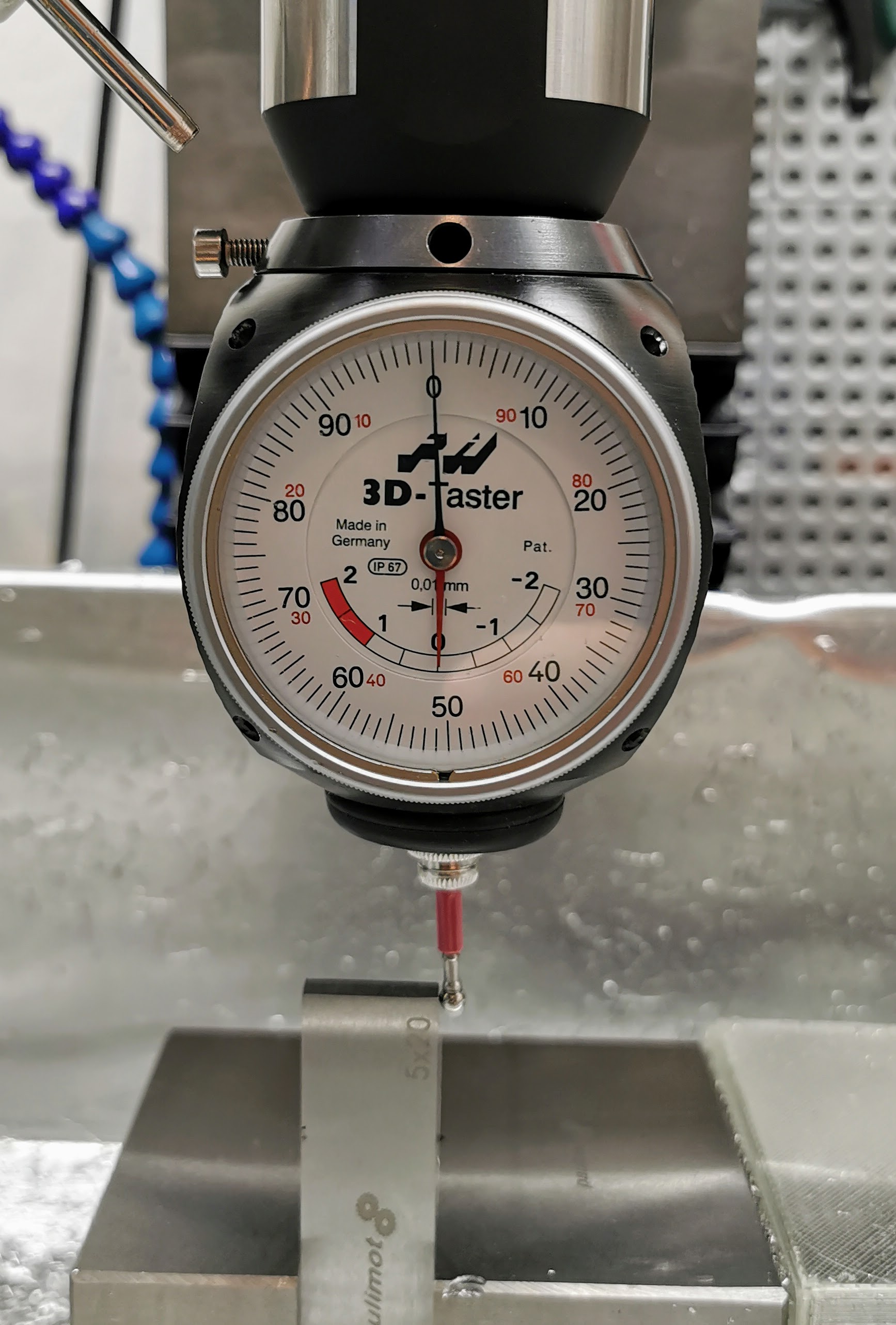

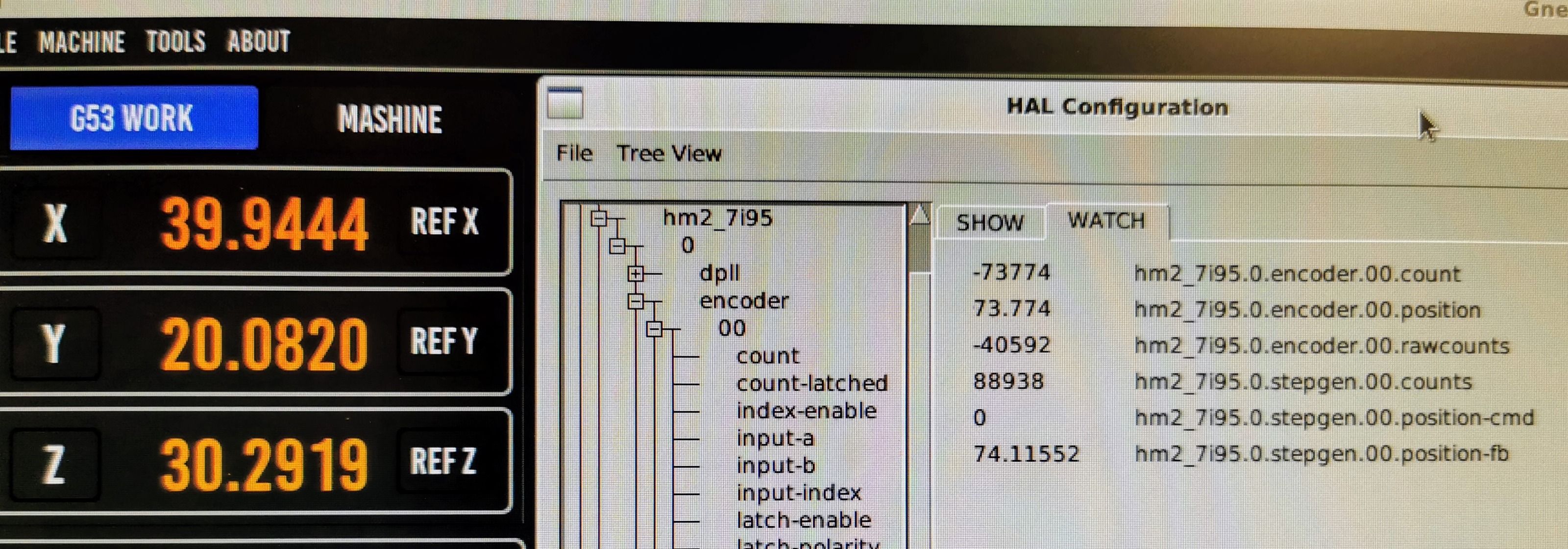

Position 2

I made this test already more times Deviation is something under 0.01mm and not only for 180 degrees, but also for 90 and 270 degrees.

Deviation is something under 0.01mm and not only for 180 degrees, but also for 90 and 270 degrees.

Replied by Gnevko on topic Closed loop with linear encoders but still backlash?

What was your following error on the X axis at both those points? The PID may need more tuning.

Position 1

Position 2

2nd how much do you trust your edge finder gauge? It might be informative to find one side of an edge, then turn the spindle 180 degrees and check the gauge again.

I made this test already more times

Attachments:

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

23 Jan 2020 21:28 #155576

by Todd Zuercher

Replied by Todd Zuercher on topic Closed loop with linear encoders but still backlash?

Make sure you don't have backlash compensation enabled.

Double check your encoder scale is correct.

It looks like your stepgen position feedback is closer to correct than your linear scale.

Can you measure some other sizes to see if the error is static or linear or something else? (Does the error get twice as large for double the length or is it the same?)

Double check your encoder scale is correct.

It looks like your stepgen position feedback is closer to correct than your linear scale.

Can you measure some other sizes to see if the error is static or linear or something else? (Does the error get twice as large for double the length or is it the same?)

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

24 Jan 2020 06:34 - 24 Jan 2020 06:37 #155633

by Gnevko

I have BACKLASH = 0 in the config ini file for the X and Y joints.

The encoders have 0.001 resolution, 1000 counts per 1 mm and it seams to be correct.

It looks like your stepgen position feedback is closer to correct than your linear scale.

and as you can see, the error is the same, not double.

Some additional observation: I know that the machine has physically ca 0.06 mm backlash. I move an axis with MPG (0,01 mm steps) in one direction and can see that the value on edge finder gauge also change. Then I reverse the direction of moving and ... encoder.counter value reacts immediately on it but the value on edge finder gauge - not (ca first three steps). But how it could be? If I move the encoder per hand it reacts also linuxcnc really reads the correct value from it.

Replied by Gnevko on topic Closed loop with linear encoders but still backlash?

Make sure you don't have backlash compensation enabled.

I have BACKLASH = 0 in the config ini file for the X and Y joints.

Double check your encoder scale is correct.

The encoders have 0.001 resolution, 1000 counts per 1 mm and it seams to be correct.

It looks like your stepgen position feedback is closer to correct than your linear scale.

Of course I checked it too: just added second 20.00mm parallel:Can you measure some other sizes to see if the error is static or linear or something else? (Does the error get twice as large for double the length or is it the same?)

and as you can see, the error is the same, not double.

Some additional observation: I know that the machine has physically ca 0.06 mm backlash. I move an axis with MPG (0,01 mm steps) in one direction and can see that the value on edge finder gauge also change. Then I reverse the direction of moving and ... encoder.counter value reacts immediately on it but the value on edge finder gauge - not (ca first three steps). But how it could be? If I move the encoder per hand it reacts also linuxcnc really reads the correct value from it.

Attachments:

Last edit: 24 Jan 2020 06:37 by Gnevko.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

24 Jan 2020 15:14 #155652

by PCW

Replied by PCW on topic Closed loop with linear encoders but still backlash?

Can you measure the motion near the encoder?

it sounds like lost motion in the linear mechanics

(loose gibs etc)

it sounds like lost motion in the linear mechanics

(loose gibs etc)

The following user(s) said Thank You: Gnevko

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

24 Jan 2020 15:16 #155653

by Todd Zuercher

Replied by Todd Zuercher on topic Closed loop with linear encoders but still backlash?

Well that seems to point at a problem with the ways, like Peter mentioned. Somehow the table is moving (twisting, tilting) in such a way that your movement at the piece is not the same as the movement at your linear scale.

The following user(s) said Thank You: Gnevko

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

26 Jan 2020 11:08 #155785

by Gnevko

Replied by Gnevko on topic Closed loop with linear encoders but still backlash?

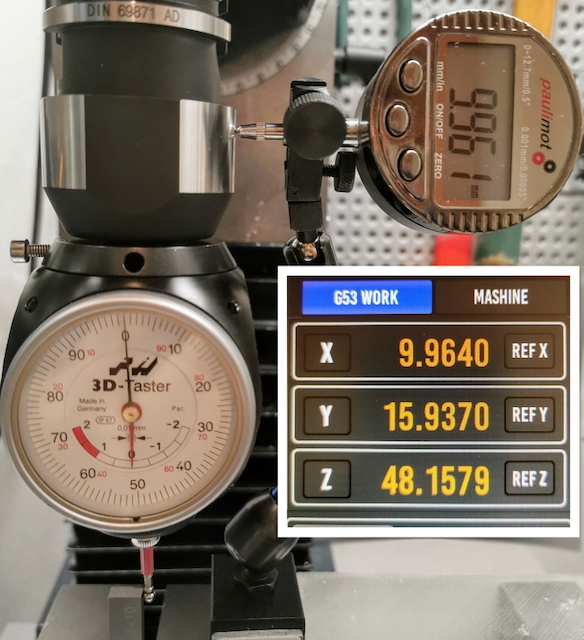

At first - thank you, guys, for the trying to help! Yesterday I spend a lot of time and check all possible mechanical parts, but without susses, It seams that mechanics work correctly. But ok, if mechanics are ok, than I need to search the problem by the edge finder gauge. One more tests with the following results:

As you can see I used 10.01mm parallel, because my digital gauge can only 12,5 mm. At first I found Zero Point on the left side, set the machine and digital gauge also to Zero, and as usual tried to measure the parallel from right side. And ... the result on the digital gauge is the same (deviation is only 0.003 what it pretty cool) as the linuxcnc displays and it has the same error as by other tests with 20mm parallels.

As you can see I used 10.01mm parallel, because my digital gauge can only 12,5 mm. At first I found Zero Point on the left side, set the machine and digital gauge also to Zero, and as usual tried to measure the parallel from right side. And ... the result on the digital gauge is the same (deviation is only 0.003 what it pretty cool) as the linuxcnc displays and it has the same error as by other tests with 20mm parallels.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.225 seconds