Closed loop with linear encoders but still backlash?

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

05 Nov 2020 18:54 #188421

by andypugh

There is what might be considered another layer of HAL inside the 7i80 firmware. Depending on the firmware loaded each of the IO pins can have (almost) any function.

In the particular case of an encoder the firmware determines which physical pins on the board are A, B, Z. LInuxCNC never needs to see those pins, instead the LinuxCNC driver creates HAL pins for encoder position and counts.

It's like the normal LinuxCNC encoder module has been moved on to the Mesa board, so you see the outputs, but not the inputs.

The 7i80HD is mainly intended for interfacing with the Mesa daughter cards with 50-pin HD headers. See for example the 7i33 etc here: store.mesanet.com/index.php?route=product/category&path=83_86 (mainly those beginning 7i3* and 7i4*)

The 7i98 is aimed at the "DB25" daughter cards here: store.mesanet.com/index.php?route=product/category&path=83_87

But it can also be used with generic parallel port breakout boards because it uses the same connector and the pinout can be set (by the firmware) to match a parallel port. (the difference is that the p-port has pins that are hard-wired in or out, whereas any Mesa boardpion can be in or out)

It looks like you want to control stepper motors and have a spindle encoder. What type of spindle drive do you expect to use?

You might want to look at the 7i96

as that does not require any additional interface cards and includes an encoder interface. (However it does not have a digital potentiometer like the 7i76 etc have. If you are using a VFD then they can often be controlled by a USB-to-Modbus link. And the neatest one of those that I have found is www.amazon.co.uk/gp/product/B082KKG55T/ with the croc-clips cut off)

Replied by andypugh on topic Closed loop with linear encoders but still backlash?

Then I found out, I can not assign the Spindle-Encoder A,B & Z Signals to any of the pins inside the pncconf tool... then I started to look at the documentation of the 7i80HD, and found out, that the ports&Pins inside PNCconfig, do not correspond with the Hardware manual of the 7i80HD

There is what might be considered another layer of HAL inside the 7i80 firmware. Depending on the firmware loaded each of the IO pins can have (almost) any function.

In the particular case of an encoder the firmware determines which physical pins on the board are A, B, Z. LInuxCNC never needs to see those pins, instead the LinuxCNC driver creates HAL pins for encoder position and counts.

It's like the normal LinuxCNC encoder module has been moved on to the Mesa board, so you see the outputs, but not the inputs.

2-If a Manual Assignment of MESA-Card-Pins, to my CNC-Machine-IO's needs to be done after all, what would then hinder me in using the 7i98 Card, that is only half of the price of a 7i80HD ?

The 7i80HD is mainly intended for interfacing with the Mesa daughter cards with 50-pin HD headers. See for example the 7i33 etc here: store.mesanet.com/index.php?route=product/category&path=83_86 (mainly those beginning 7i3* and 7i4*)

The 7i98 is aimed at the "DB25" daughter cards here: store.mesanet.com/index.php?route=product/category&path=83_87

But it can also be used with generic parallel port breakout boards because it uses the same connector and the pinout can be set (by the firmware) to match a parallel port. (the difference is that the p-port has pins that are hard-wired in or out, whereas any Mesa boardpion can be in or out)

It looks like you want to control stepper motors and have a spindle encoder. What type of spindle drive do you expect to use?

You might want to look at the 7i96

as that does not require any additional interface cards and includes an encoder interface. (However it does not have a digital potentiometer like the 7i76 etc have. If you are using a VFD then they can often be controlled by a USB-to-Modbus link. And the neatest one of those that I have found is www.amazon.co.uk/gp/product/B082KKG55T/ with the croc-clips cut off)

The following user(s) said Thank You: Ronald J

Please Log in or Create an account to join the conversation.

- Ronald J

-

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 0

05 Nov 2020 19:46 #188431

by Ronald J

Replied by Ronald J on topic Closed loop with linear encoders but still backlash?

wow  , that all makes sense... So thats the trick, Thanks Andy.

, that all makes sense... So thats the trick, Thanks Andy.

That means, using the 7i98 as an example, would cost me at least $237 ( 7i98 (Controller Only) - $99 / 7i78 (Step&dir) - $69 / 7i85 (Encoders & RS422) - $69 / =$237), having the basic required IO in place.

And using the 7i96m would cost me $188 ( 7i96 (Controller + 4Stepper IO + 11 GPIO.in + 6 GPIO.out) - $119 / 7i85 (Encoders & RS422) - $69 / =$188)

I however do not see support in pncconf for the 7i85... but maybe this is not needed, because of.... some reason ??

And for your question about the Spindle-Drive. Currently only "on/off/CW/CCW" are planned using GPIO. But the next uprade will involve a PWM or Potentiometer controlled Spindle-motor-driver.

That leads me to this:

Is any of you thinking of writing a book about LinuxCNC+Mesa Cards, and practical application for CNC-Conversions ? I would buy 2 !. But serious, is there a good information-base, where one can first read & absorb all the basics about LinuxCNC, Mesa-cards for practical application ?

!. But serious, is there a good information-base, where one can first read & absorb all the basics about LinuxCNC, Mesa-cards for practical application ?

I have seen so many Youtube movies, read so many Forum-threads... but not once, have I seen, a complete example

(Like: 1. This is my Lathe / 2. This is LinuxCNC & my MESA-Card I am going to use -> And now I am going to show you step-by-step, how to do this conversion & Tuning).

Is there any Source you would recommend me to fully absorb first, before I take your precious time again and ask not-so.educated questions ?

I really appreciate the help, because your answers really helped me. I hope I can once return a favor.

BR,

R.

That means, using the 7i98 as an example, would cost me at least $237 ( 7i98 (Controller Only) - $99 / 7i78 (Step&dir) - $69 / 7i85 (Encoders & RS422) - $69 / =$237), having the basic required IO in place.

And using the 7i96m would cost me $188 ( 7i96 (Controller + 4Stepper IO + 11 GPIO.in + 6 GPIO.out) - $119 / 7i85 (Encoders & RS422) - $69 / =$188)

I however do not see support in pncconf for the 7i85... but maybe this is not needed, because of.... some reason ??

And for your question about the Spindle-Drive. Currently only "on/off/CW/CCW" are planned using GPIO. But the next uprade will involve a PWM or Potentiometer controlled Spindle-motor-driver.

That leads me to this:

Is any of you thinking of writing a book about LinuxCNC+Mesa Cards, and practical application for CNC-Conversions ? I would buy 2

I have seen so many Youtube movies, read so many Forum-threads... but not once, have I seen, a complete example

(Like: 1. This is my Lathe / 2. This is LinuxCNC & my MESA-Card I am going to use -> And now I am going to show you step-by-step, how to do this conversion & Tuning).

Is there any Source you would recommend me to fully absorb first, before I take your precious time again and ask not-so.educated questions ?

I really appreciate the help, because your answers really helped me. I hope I can once return a favor.

BR,

R.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

05 Nov 2020 20:23 #188439

by andypugh

What do you actually need by way of IO, stepgens and encoders?

Replied by andypugh on topic Closed loop with linear encoders but still backlash?

That means, using the 7i98 as an example, would cost me at least $237 ( 7i98 (Controller Only) - $99 / 7i78 (Step&dir) - $69 / 7i85 (Encoders & RS422) - $69 / =$237), having the basic required IO in place.

And using the 7i96m would cost me $188 ( 7i96 (Controller + 4Stepper IO + 11 GPIO.in + 6 GPIO.out) - $119 / 7i85 (Encoders & RS422) - $69 / =$188)

What do you actually need by way of IO, stepgens and encoders?

Please Log in or Create an account to join the conversation.

- Ronald J

-

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 0

05 Nov 2020 22:04 #188450

by Ronald J

Replied by Ronald J on topic Closed loop with linear encoders but still backlash?

Dear Andy,

All the machine IO‘s are shown in the pdf I attached to my initial post from today.

You should be able to see all the used steppers & encoders.

But basically, it is the basic full-Feedback Lathe cnc conversion using steppers, core components:

2x stepper motors

2x linear encoders for x & z (Incr. AB Z)

1x spindle encoder (incr. Quadrature, ABZ)

1x spindle Motor

2x Limit Sensors

The rest is shown in the pdf.

R.

All the machine IO‘s are shown in the pdf I attached to my initial post from today.

You should be able to see all the used steppers & encoders.

But basically, it is the basic full-Feedback Lathe cnc conversion using steppers, core components:

2x stepper motors

2x linear encoders for x & z (Incr. AB Z)

1x spindle encoder (incr. Quadrature, ABZ)

1x spindle Motor

2x Limit Sensors

The rest is shown in the pdf.

R.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

06 Nov 2020 00:02 #188467

by andypugh

Replied by andypugh on topic Closed loop with linear encoders but still backlash?

The simplest all-in-one solution is probably the 7i95, but that is somewhat overkill for a lathe.

Looking at your docs, you generally don't need to add encoder channels to your GPIO tally, on Mesa boards the encoders are dedicated differential inputs.

Some other options:

Ethernet + 50-pin cards, eg 7i93 + 7i52S for $158 (but doesn't offer any 24V IO, for that you would be adding a 7i33TA (for example)

If you have a PCIe slot, then the 6i24 offers a lot of IO (and is what I have in my lathe. But I needed to hook up a 7i49, smart-serial drives and a lot of MPGs)

It looks like 7i96 + 7i85 is probably the best fit other than the 7i95 though the lowest cost option is probably a 7i92M + 7i85S ($158) with a generic parallel port BoB on the second connector. But the extra $30 for terminal blocks etc of the 7i96 to get proper high(ish) voltage isolated IO is probably money well spent.

Looking at your docs, you generally don't need to add encoder channels to your GPIO tally, on Mesa boards the encoders are dedicated differential inputs.

Some other options:

Ethernet + 50-pin cards, eg 7i93 + 7i52S for $158 (but doesn't offer any 24V IO, for that you would be adding a 7i33TA (for example)

If you have a PCIe slot, then the 6i24 offers a lot of IO (and is what I have in my lathe. But I needed to hook up a 7i49, smart-serial drives and a lot of MPGs)

It looks like 7i96 + 7i85 is probably the best fit other than the 7i95 though the lowest cost option is probably a 7i92M + 7i85S ($158) with a generic parallel port BoB on the second connector. But the extra $30 for terminal blocks etc of the 7i96 to get proper high(ish) voltage isolated IO is probably money well spent.

Please Log in or Create an account to join the conversation.

- Ronald J

-

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 0

06 Nov 2020 07:48 #188479

by Ronald J

Replied by Ronald J on topic Closed loop with linear encoders but still backlash?

Thanks again Andy, great to hear that the 7i96 + 7i85 seems to be a good fit for a Full Feedback (or Closed-Loop) CNC-Retrofit for a Lathe.

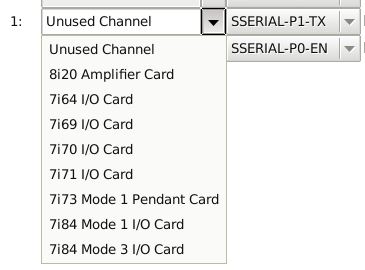

I see the SW-package for the 7i96 supplies a BIT-File for the 7i96 + 7i85 Combination (7i96_7i85d.bit), which is great. However, if you try to do the configuration using Pncconf, you find that you cannot select the 7i85 from the drop-down list (Picture from Message #188431)... so how can one now assign the needed LinuxCNC-Signals to the 7i85 Card ?

I see the SW-package for the 7i96 supplies a BIT-File for the 7i96 + 7i85 Combination (7i96_7i85d.bit), which is great. However, if you try to do the configuration using Pncconf, you find that you cannot select the 7i85 from the drop-down list (Picture from Message #188431)... so how can one now assign the needed LinuxCNC-Signals to the 7i85 Card ?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

06 Nov 2020 13:09 #188499

by andypugh

Replied by andypugh on topic Closed loop with linear encoders but still backlash?

You need to look at the 7i85 manual (google for 7i85man) and then allocate the 7i96 pins to match the 7i85's expectations.

(Probably)

The 7i85 is just a passive break-out board really.

(Probably)

The 7i85 is just a passive break-out board really.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

06 Nov 2020 15:39 #188509

by PCW

Replied by PCW on topic Closed loop with linear encoders but still backlash?

To change a plain step/dir 7I96 configuration to one using encoder feedback

is fairly simple with minor hal file edits, just change the position feedback

source from the stepgen to the encoder (one statement per axis).

Of course the PID tuning will be very different.

is fairly simple with minor hal file edits, just change the position feedback

source from the stepgen to the encoder (one statement per axis).

Of course the PID tuning will be very different.

Please Log in or Create an account to join the conversation.

Time to create page: 0.118 seconds