Lathe conversion from stock to CNC

- jbraun

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 15

04 Nov 2012 23:21 #26254

by jbraun

So scaling the index is a no-no.

An encoder running at some ratio is okay but a seperate 1ppr signal must be read directly 1:1 .

There is no reason to connect the encoder's built-in index to linuxcnc in a case like this.

Am I understanding all of this correctly ?

Apologies to soundreflections for the interruption.

Replied by jbraun on topic Re:Lathe conversion from stock to CNC

Can LinuxCNC use a scaled index pulse, or should I keep that on the main spindle?

It needs to be exactly once per rev, but a simple flag on the spindle shaft will do.

The geared-down encoder is fine. Even if it turns out to have a non-integer number of pulses per rev (though that is vanishingly unlikely considering the function of the gear you are using)

So scaling the index is a no-no.

An encoder running at some ratio is okay but a seperate 1ppr signal must be read directly 1:1 .

There is no reason to connect the encoder's built-in index to linuxcnc in a case like this.

Am I understanding all of this correctly ?

Apologies to soundreflections for the interruption.

Please Log in or Create an account to join the conversation.

- Soundreflections

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

05 Nov 2012 01:28 #26257

by Soundreflections

Replied by Soundreflections on topic Re:Lathe conversion from stock to CNC

Hi Jbraun,

No problem, I am also learning how these things work. Basically, AFAIK we need 3 signals for the best performance, namely the spindle index, one PPR, which I think is just used in tapping, as I see no effect on the RPM, or any other signal when I send an input there, a bit of a dissapointment, as it is the only pin so far connected between lathe and PC. Then there are two pulses, phase A^B, B being optional, increasing resolution and giving direction sensing. They are used by the RPM counter, I have yet to figure out where to calibrate them, but will first mount them, then worry about them.

I now have my index. 1:1, LinuxCNC gives me true / false, so it must be working, I just cannot see anytrhing in the main program itself.

No problem, I am also learning how these things work. Basically, AFAIK we need 3 signals for the best performance, namely the spindle index, one PPR, which I think is just used in tapping, as I see no effect on the RPM, or any other signal when I send an input there, a bit of a dissapointment, as it is the only pin so far connected between lathe and PC. Then there are two pulses, phase A^B, B being optional, increasing resolution and giving direction sensing. They are used by the RPM counter, I have yet to figure out where to calibrate them, but will first mount them, then worry about them.

I now have my index. 1:1, LinuxCNC gives me true / false, so it must be working, I just cannot see anytrhing in the main program itself.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

05 Nov 2012 01:37 #26258

by BigJohnT

Replied by BigJohnT on topic Re:Lathe conversion from stock to CNC

Have you read the spindle control chapter with spindle feedback?

linuxcnc.org/docs/html/examples/spindle.html

John

linuxcnc.org/docs/html/examples/spindle.html

John

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23503

- Thank you received: 4997

05 Nov 2012 04:21 #26261

by andypugh

You would need to set the encoder module to "counter mode" and connect your single ppr to the A channel.

You can then connect the encoder position-interpolated pin to motion.spindle-position and the encoder velocity pin to motion.spindle-speed-in and that should give you CSS and feed-per-rev modes.

Replied by andypugh on topic Re:Lathe conversion from stock to CNC

You can probably do something with that, if you want to experiment.spindle index, one PPR, which I think is just used in tapping, as I see no effect on the RPM, or any other signal when I send an input there, a bit of a dissapointment, as it is the only pin so far connected between lathe and PC.

You would need to set the encoder module to "counter mode" and connect your single ppr to the A channel.

You can then connect the encoder position-interpolated pin to motion.spindle-position and the encoder velocity pin to motion.spindle-speed-in and that should give you CSS and feed-per-rev modes.

Please Log in or Create an account to join the conversation.

- Soundreflections

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

20 Nov 2012 14:08 #26820

by Soundreflections

Replied by Soundreflections on topic Re:Lathe conversion from stock to CNC

I have now received my driver kits, though on Saturday I fly to Rotterdam for a 2 week training course so won’t be able to do anything about building until I get back. Maybe take the kits, a motor and a heat sink with.

Please Log in or Create an account to join the conversation.

- JamesNewton

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

21 Nov 2012 01:03 #26831

by JamesNewton

Replied by JamesNewton on topic Re:Lathe conversion from stock to CNC

Check the parts in the kit before you leave. I had another customer tell me that one of the current tuning resistors fell out of it's package and got lost. We are now taping them inside the bag to make sure that doesn't happen again, but they are tiny and easy to loose. I just want to make sure you have everything so you can start building once you get back. Let me know if there are any issues.

Please Log in or Create an account to join the conversation.

- Soundreflections

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

12 Feb 2013 21:44 #29948

by Soundreflections

Replied by Soundreflections on topic Re:Lathe conversion from stock to CNC

I will do a more detailed write-up, with pictures, on the building of the stepper drivers, but I have them built and running.

I have bought some timing belt pulleys and have mounted my X axis motor. I have a 10 tooth on the motor and a 12 on thr spindle, but I had to go to 10:15 to get the scaling accurate. (I will re-check my lead-screw pitch, something gives me doubt now that I have no direct access to the machine, sitting at work).

I need to bore the Z axis gear to 15mm, I only have a 12mm mill and I am not sure how to make a 15mm bore from a 10mm HSS blank - unless I round the bottom part it won't work. (annoyance of being relatively new to metal turning).

My X axis worked very well, except that after several minutes of 50mm "axis test" The driver obviously overheated and went very strange. Power off to cool and all went well again. I have got some small fans today that I will be mounting on the drivers when next I get a chance.

I have now tapped the threads for limit switches to go in. After my next "working" session I should have X axis ready for action.

I thought I had better do a quick update on this project!

I have bought some timing belt pulleys and have mounted my X axis motor. I have a 10 tooth on the motor and a 12 on thr spindle, but I had to go to 10:15 to get the scaling accurate. (I will re-check my lead-screw pitch, something gives me doubt now that I have no direct access to the machine, sitting at work).

I need to bore the Z axis gear to 15mm, I only have a 12mm mill and I am not sure how to make a 15mm bore from a 10mm HSS blank - unless I round the bottom part it won't work. (annoyance of being relatively new to metal turning).

My X axis worked very well, except that after several minutes of 50mm "axis test" The driver obviously overheated and went very strange. Power off to cool and all went well again. I have got some small fans today that I will be mounting on the drivers when next I get a chance.

I have now tapped the threads for limit switches to go in. After my next "working" session I should have X axis ready for action.

I thought I had better do a quick update on this project!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23503

- Thank you received: 4997

12 Feb 2013 22:17 #29950

by andypugh

I have a whole bunch of these (and the correct holder) for making small bores.

www.ebay.co.uk/itm/PH-Horn-Type-105-supe...&hash=item3a7e2b3f91

But you should be able to copy that shape in your HSS blank.

shows the process nicely.

Boring bars tend to flex. This means that your finish cut will tend to take more than you expect, leading to an oversize bore. I like to make an extra pass with zero extra cut before measuring and taking the final finish cut. That can make the bore undersize after that cut, but that is better than the alternative. A second finish pass with no extra cut should then be spot-on.

Replied by andypugh on topic Re:Lathe conversion from stock to CNC

The best way to make a bore to the required size is single-point boring. Drills and milling cutters will not make an exact size. (Well, they will make an exact size, but not necessarily the one you wanted, or the one stamped on their side).I need to bore the Z axis gear to 15mm, I only have a 12mm mill and I am not sure how to make a 15mm bore from a 10mm HSS blank!

I have a whole bunch of these (and the correct holder) for making small bores.

www.ebay.co.uk/itm/PH-Horn-Type-105-supe...&hash=item3a7e2b3f91

But you should be able to copy that shape in your HSS blank.

shows the process nicely.

Boring bars tend to flex. This means that your finish cut will tend to take more than you expect, leading to an oversize bore. I like to make an extra pass with zero extra cut before measuring and taking the final finish cut. That can make the bore undersize after that cut, but that is better than the alternative. A second finish pass with no extra cut should then be spot-on.

Please Log in or Create an account to join the conversation.

- JamesNewton

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

13 Feb 2013 10:20 #29998

by JamesNewton

Replied by JamesNewton on topic Re:Lathe conversion from stock to CNC

CPU fan heatsinks are the best. And yes, those driver do get hot and do need a fan. Let us know how it goes!

Please Log in or Create an account to join the conversation.

- Soundreflections

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

04 May 2013 22:34 #33603

by Soundreflections

Replied by Soundreflections on topic Re:Lathe conversion from stock to CNC

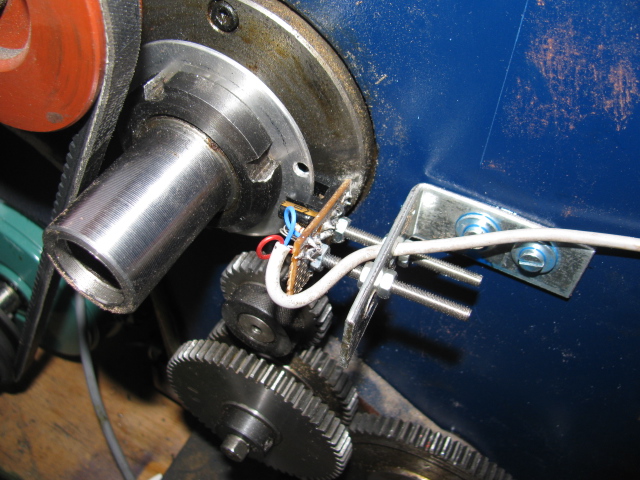

A quick update on non-logged progress:

I have now got X and Z axis's running, though Z needs to be very slow or the motor skips, I may try further micro stepping, or running to max rated current. I am yet to get my spindle encoder going, as well as the spindle control, so XZ only right now.

I now desperately need to get the game controller I bought running, even more desperately need to figure out how to operate LinuxCNC and how to create diagrams and convert to G code. I have tried several CAD programs, but when they cannot draw thread I quit them and try the next one.

I have committed to helping my cousin with a project to make a scale solar system, for which I now need to turn quite a few pulleys, hence my sudden return to the project and furthering completion.

I hope to soon write a number of outstanding posts, starting with stepper driver construction and hopefully having less colourful language than I used mounting my Z motor and making the face plate for my 4 jaw chuck.

I have now got X and Z axis's running, though Z needs to be very slow or the motor skips, I may try further micro stepping, or running to max rated current. I am yet to get my spindle encoder going, as well as the spindle control, so XZ only right now.

I now desperately need to get the game controller I bought running, even more desperately need to figure out how to operate LinuxCNC and how to create diagrams and convert to G code. I have tried several CAD programs, but when they cannot draw thread I quit them and try the next one.

I have committed to helping my cousin with a project to make a scale solar system, for which I now need to turn quite a few pulleys, hence my sudden return to the project and furthering completion.

I hope to soon write a number of outstanding posts, starting with stepper driver construction and hopefully having less colourful language than I used mounting my Z motor and making the face plate for my 4 jaw chuck.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.138 seconds