Current turning capabilities status

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 424

- Thank you received: 95

Currently I am way to back, and now concerned about the control panel and servo drives as I want to use the current motors (one is 4Kw continuous, that limits my choice range).

Please Log in or Create an account to join the conversation.

- jtc

-

- Offline

- Premium Member

-

- Posts: 147

- Thank you received: 12

I have some questions how to use a mesa 7i73 board, please see my topic:

www.linuxcnc.org/index.php/english/forum...mesa-5i20--5i44-7i73

tnks,

João

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 424

- Thank you received: 95

We are working on the A axis (tool changer) and we would like to know if it is possible to configure this axis to act like "rollover". For example:

Issuing:

"G0 A1" the toolholder should rotate 1 degree in one direction

"G0 A359" the toolholder should rotate 2 degrees in the reverse direction

Currently, the axis is configurated as angular and the path that it comes is always like it was linear. We also tested with the flag WRAPPED_ROTARY = 1.

This is for getting the shortest path in each toolchange (we are planning to issue internal commands, for example G0 A0; G0 A30; G0 A60 for each toolposition - or maybe there is a better way to do it?)

Thank you

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

This is for getting the shortest path in each toolchange (we are planning to issue internal commands, for example G0 A0; G0 A30; G0 A60 for each toolposition - or maybe there is a better way to do it?)

The "Orient" component knows how to find the shortest route.

If you set the encoder scale correctly you can quite possibly just wire the tool-number HAL pin to the PID controller, and not consider the toolchanger as an axis at all.

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 424

- Thank you received: 95

The "Orient" component knows how to find the shortest route.

If you set the encoder scale correctly you can quite possibly just wire the tool-number HAL pin to the PID controller, and not consider the toolchanger as an axis at all.

The only ORIENT that I found was related with the spindle www.linuxcnc.org/docs/devel/html/config/emc2hal.html, that I suppose is not the one that should be applied here. (or is it?)

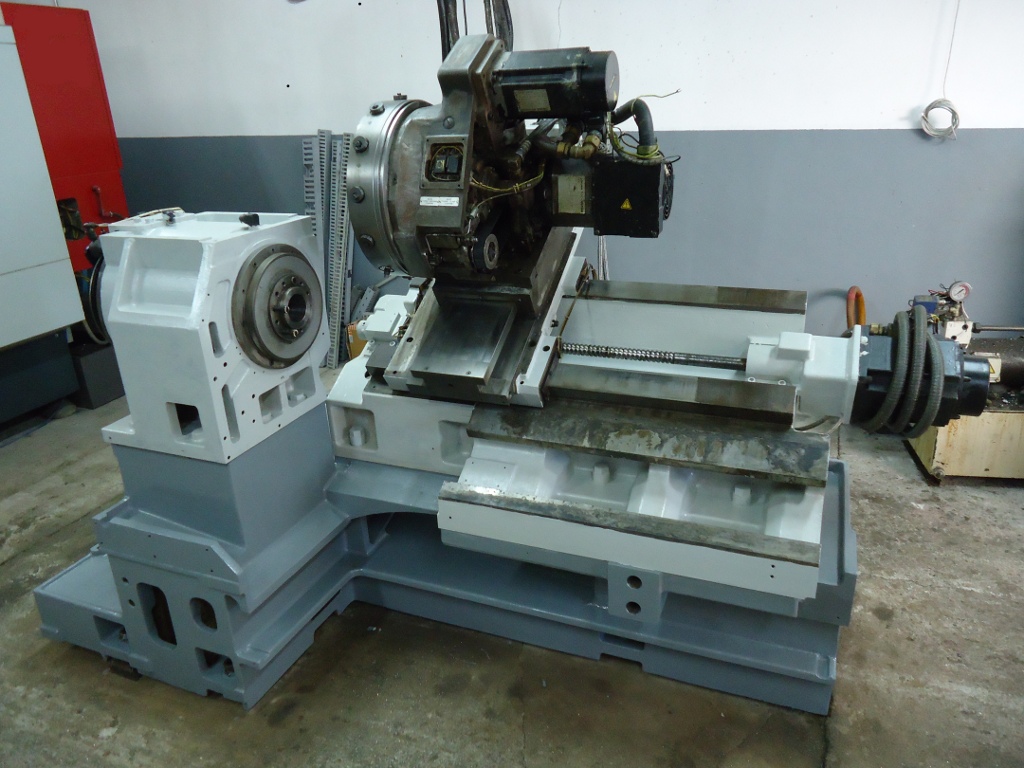

Regarding the toolchange, I think I got the overall idea, if there are no "middle positions". This is not true in some of my machines - the turret very different from the one in the picture were mechanically you can only go in increments of 30º.

I have machines here there is no clamping on the turret and you can define the angle of the turret using GCode. This allow that the tool to be placed in a very differently way providing freedom for the user and the hability of machining different shapes as the tool will also be "different" in respect to the spindle.

In this latter case I need to use G0 A30, or G0 A31.23 (same tool, with different approach angle)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

That is the one I was thinking of. Look at what it does, not what it is for.The only ORIENT that I found was related with the spindle www.linuxcnc.org/docs/devel/html/config/emc2hal.html, that I suppose is not the one that should be applied here. (or is it?)

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 240

Issuing:

"G0 A1" the toolholder should rotate 1 degree in one direction

"G0 A359" the toolholder should rotate 2 degrees in the reverse direction

This precisely why on the last toolchanger I wrote and on others prior to it, I did not even consider using a rotary axis and defined it as LINEAR

Then you just need to work out how many units equal the ATC move you want and you can issue positive or negative move commands directly

to the stepgen.NN.position-cmd

Regards the orient component, speak to Thomas (tkamster)

He is trying to use it on his set up and may be able to assist

regards

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 424

- Thank you received: 95

This is a bit confusing to me about the direction that I should take as there are some options (maybe ladder or a component - that I do not have a clear ideia about it). Both options are on the dark side for us.

My current idea:

Using ANGULAR axis. I think that we can implement all that we want, if in some part off the tool change process we gained access to the current position (or current slot) and the desired slot position.

For example:

Machine currently is in slot 3 (lets say 90.40 degrees)

A tool change is requested to slot 5 (lets consider 152.00), lets say, in the command line using T0505

Now, if I can catch the current position that is 90.40 degrees and the desired position (that is 152 degrees), if I can program something that is trigered due to the tools change, I think I can manage to output the needed amount of travel and direction.

My current dough is to know if such thing exist; this is, if I can execute something that is triggered due to the tool change, and if I can have access to the linuxemc internals (position, status ....) during that execution, and if I can issue move commands also in that execution.

If this is covered in the documentation, we were not able to find it.

Thank you

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 240

iocontrol outputs several signals for a tool change, all of which are documented here

linuxcnc.org/docs/2.5/html/man/man1/iocontrol.1.html

A component can connect to a stepgen (assuming a stepper ATC) and directly command movement via stepgen.NN.position-cmd

In a 'typical' toolchange component

The component connects to iocontrol and receives the tool-prepare tool-change signals

It processes the number required against its current position and calculates the movement required to that tool number

It outputs the required move (can be directly to the stepgen)

When move is completed, the locks in place etc. it returns the tool-changed signal to iocontrol and motion continues

It is only the details based upon the relays, rams, switches etc that varies, the principle is fairly general

There are 3 toolchangers in the contributed components section of the wiki

wiki.linuxcnc.org/cgi-bin/wiki.pl?ContributedComponents

I am about to add a 4th, which is a variation which has a carousel of tools

They might give you some ideas.

To help get your thoughts clear, it can help to write a flow chart.

The signals you will get from iocontrol , the physical and electrical steps in the actual tool change for your machine and what you are going to do to interface them and command the required tool change.

The more you can break it down into steps, the clearer it becomes and the easier to implement.

regards

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 424

- Thank you received: 95

I will try to understand it based on the examples. I will post if I have problems.

Please Log in or Create an account to join the conversation.