Early Omniturn gang lathe to Linuxcnc?

- gearheaded

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

This is my first post to the forum, but I'm not a complete stranger to Linuxcnc. In the early 2000's I converted a Sherline mill with EMC2 and had enough problems with unstable computers to get a fairly good education by the time it was working well. Since then I have built up a fairly nice manufacturing center at my home including a Hardinge DSM-A automatic turret lathe with bar feeder, two Omniturn Hardinge gang tool lathe attachments, a 1992 Kira mill/tap w/Fanuc O-mate control (same footprint as Haas Super Mini Mill), Dyna Myte 2400, Manual support equipment...etc.

I've managed to do pretty good biding my time and buying old machines for cheap that have significant life left with a little know how.

That being said, one issue has been driving me nuts for about 6 years. My first Omniturn, which has given me flawless money making service for 15 years is quirky and old, but simple and easy to use, I've upgraded it with an LCD screen and an SSD, and I'm satisfied with its performance at this time( except it could use a poly V belt conversion). My second Omniturn was purchased because my product lines were keeping the other machine to busy to use for prototyping new products. After a new ball screw and a few electronic upgrades, I fired the machine up and promptly found out something I had previously unknown about Omniturn lathes...

They had an early version of there control, produced for only a year and a half from 1991-93 or so, that is frustratingly different and annoying to use. The setup procedure for the tools is esoteric to say the least, and you must call a G92 after each tool call. There are also quite a few minor differences in the controls that make it difficult to determine if you have set your tools correctly. Anyway, I hate using it, and only set it up if absolutely needed. I thought I had bought a replica to my other machine, but it just looks the same, even the control screens, the little differences make you realize why they changed it. Even Omniturn said I would hate it...however, they want more than I paid for the machine to upgrade the control.

Finally serious about fixing the problem, and since I'm considering other upgrades in the future such as C-axis and live tooling, I figured doing it myself would be the best option. Linuxcnc lathe support is much stronger now than when I first looked into this years ago, and I'm not fond of Centroid or other companies offerings.

Parts have arrived and more on the way, this is the new hardware:

AS Rock J3355B-ITX MB

4GB 1333mhz memory

3GB Industrial SATA Dom SSD

Mesa 6I25/7I77 combo

Old parts to be reused:

All four motors on both machines are the same and I can't find any detailed info on them...company long gone and no datasheets.

However, I was able to piece together information from various sources and took them apart to figure out the encoders.

The two motors in the machine to be converted are:

Quality Motion Control QMC 33DCMTE 2514-1

These are DC brushed servo motors with analog tach and TTL encoder output. Powered at 34V DC in this machine.

Encoder is a Renco 77822-033 which is also obsolete and I can't find data sheet. However, I did find a pinout. And it is a 5V TTL quadrature encoder with 1000 PPR

Interesting thing about the wiring for the encoders. they cut back and disabled 3 of the signals. A-, B+, Index- ...

Doesn't this mean the usual 4000 counts are 2000 for this application? I guess it doesn't matter since I can attach the extra wires to the 7I77, but it would be interesting to hear any thoughts on why this was done.

The servo amps in this machine are Z-axis:

Glentek SMA 7110-1. I can't find a full datasheet, but I did find a PDF product flyer here: Servo Amp Data

The amp appears to be wired for velocity control using an analog tach feedback, but is capable of torque control.

I called Glentek, and they confirmed the amp series, but said it was an OEM part number and he could not release the option settings, however tracing the wires and a voltmeter should tell me whether active high or low on the pins that matter.

X-axis:

Advanced Motion Control 25A8D-NC1 25 amp 80V

Can't find much of anything, but is wired the same as the Z, might be a later replacement. But I am going to assume they are meant as equivalent because my other machine has two identical Copley amps on the X and Z.

I'm not to worried about the electro mechanical retrofit, I've been doing this kind of stuff for 30 years in both home and commercial industrial environments...but as anyone who has tried this kind of stuff before, the devil is in the details.

My questions and reason for writing all this, is I'm trying to decide about the overall setup configuration.

So given what I have said here, would it be better to stay with velocity with tach feedback, or try to implement torque control? I don't really understand the ramifications of the differences for my application.

Is a touch screen worth the investment, or is a keyboard and MPG better, or both?

Is there anything I haven't thought of I should be?

Anyway, thanks to anyone taking the time to read this and respond if any insight is to be had. And I'm more than happy to provide more info if I forgot anything important.

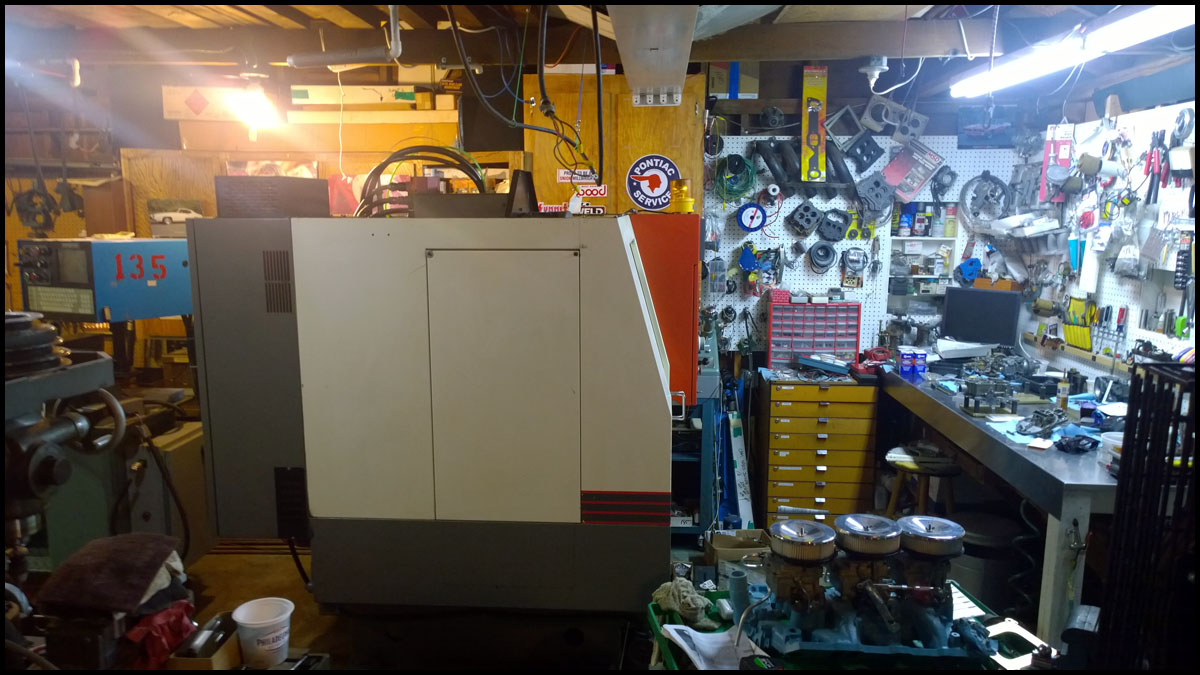

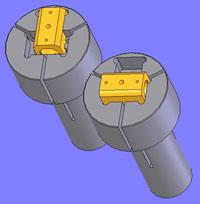

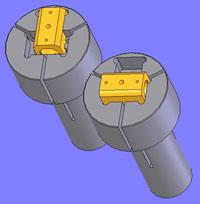

Here is a pic or two of my crazy crowded but usable shop. Lathe #135 is the one up for LInuxcnc.

Thanks

Karl

Portland,OR

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

so as yoiu got alot of expiriance

and with the Help here you will be running soon

the cutback is as the old electronics from fanuc does only suport a positiv A/B and a negativ Index

they dident change this until the 2010 production change in control

is the mashine equipt with the 12ATC as the Haas is

Please Log in or Create an account to join the conversation.

- gearheaded

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

The Fanuc control has little memory, no drip feed, and an esoteric tool setting procedure. That being said, it is a great little hunk of quality Japanese iron, and has 700 ipm rapids, rigid tapping, chip auger, and a BT30 10 tool mechanical ATC, which I really like because there is far less expensive things to go wrong in the spindle. It does mean using a special bar to load and unload tools, but it works just like any other ATC after they are loaded, just no hydraulics or air systems to deal with...

I was fortunate, the machine came with over 80 tool holders, and I was able to purchase it under power for only $5500. After removing some spindle cabling, it made it in the garage on a pallet jack with .5" clearance to the garage door.

Anyways, it's lathe #135 that I want to convert, my Mesa boards should be here tomorrow.

I forgot to ask a question in the original post...from other lathe users, what is the best distribution and GUI for gang lathe conversion such as this?

Thanks

Karl

Edited to correct spelling error...

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 617

- Thank you received: 75

So given what I have said here, would it be better to stay with velocity with tach feedback, or try to implement torque control? I don't really understand the ramifications of the differences for my application.

I would use the drives as configured if they are currently working on your machine. They are tuned to match your setup.

Just simply read in the encoders either single ended or differential to the 7i77, hook up the analog control 10v signal, add a drive enable and estop circuit and you should be good to go.

For best performance you'll have to do final tuning to match linuxcnc to the machine. Which will be easier if you didn't tamper with the drive settings.

Please Log in or Create an account to join the conversation.

- gearheaded

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

I received the Mesa cards today, downloaded and burned an ISO, cleaned up my work bench, hooked up the MB and PWR supply, and...nothing. Power and fan come on for a split second,red led on 6I25 card on for the same split second, then it all shuts down.

I am not used to hooking up systems outside of an enclosure, so maybe I'm doing something wrong.

Unfortunately, since I've never had a new bad power supply, I made the mistake of cutting the wiring harness back and soldering in a 5v lead for the SATA Dom SSD. So at this point I hope it's the mother board so I can return it. No other ATX power supply on hand. Oh well,

back to the drawing board.

Karl

Please Log in or Create an account to join the conversation.

- gearheaded

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

It responds the same way, firing for a split second, then powering down.

Shouldn't the fan stay running, until I ground the MB pwr switch pins and boot the MB?

Thanks

Karl

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21368

- Thank you received: 7288

No they should not, they should turn on after you turn on the motherboard.

Shouldn't the fan stay running, until I ground the MB pwr switch pins and boot the MB?

Please Log in or Create an account to join the conversation.

- gearheaded

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 29

- Thank you received: 1

Now the problem is I can't get it to boot up.

Trying to install (linuxcnc-stretch-uspace-i386.iso)

I've now tried Rufus, LiveLinux USB creator, WinDisk manager, and Unetbootin-Windows to create a bootable usb drive. So far none will boot. The Bios recognizes it as a bootable drive, but when initiated, just goes to a blank screen for a moment, then back to the boot choices screen. I've tried NTSF and Fat 32 file systems, basically, I've tried every option available for each program, plus tried each usb port separately for each attempt,. I did checksum the download and it passed.

Searched the forum for any solutions and came up with only that many others seem to get frustrated as well.

AndyPugh has given up and uses a usb dvd drive...so after four hours of getting nowhere, I went and bought a usb dvd drive and burned an image onto the rw+ drive in my windows machine. The BIOS recognizes a bootable dvd, but I get the same result.

Tried burning one from my Ubuntu laptop using K3B on a rw- disk...same problem.

Anyone have any ideas?

I am not new to this stuff, been programming computers since batches of punch cards, and building Windows and Linux systems for seemingly forever, but I've run out of ideas for what I might try differently.

Maybe its the wrong distribution to be using?

Thanks

Karl

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 617

- Thank you received: 75

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21368

- Thank you received: 7288

Please Log in or Create an account to join the conversation.