Gildemeister NEF 480 Retrofit

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

28 Jun 2021 11:02 #213118

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

My belt pulled are ready to be shipped. So There might be more progress in the next weeks.

I allow started to tool up, so I can make chips with this beast.

Still an open question is the the chuck. I wonder if I should change it.

On one hand the Chuck is nice for repetitive work, but I think a normal chuck should be more versatile. I was thinking about simply holding a normal 160mm chuck in this 250mm beast, but everyone tole me it’s not safe. I am nit sure If I can fit a 160mm chuck to my din 55022/27 size 6 spindle nose. The mach plates for 160mm chucks are only available in size 5. Is a 160mm chuck on as size 6 just uncommon or impossible to fit

I allow started to tool up, so I can make chips with this beast.

Still an open question is the the chuck. I wonder if I should change it.

On one hand the Chuck is nice for repetitive work, but I think a normal chuck should be more versatile. I was thinking about simply holding a normal 160mm chuck in this 250mm beast, but everyone tole me it’s not safe. I am nit sure If I can fit a 160mm chuck to my din 55022/27 size 6 spindle nose. The mach plates for 160mm chucks are only available in size 5. Is a 160mm chuck on as size 6 just uncommon or impossible to fit

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

04 Jul 2021 07:28 #213649

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

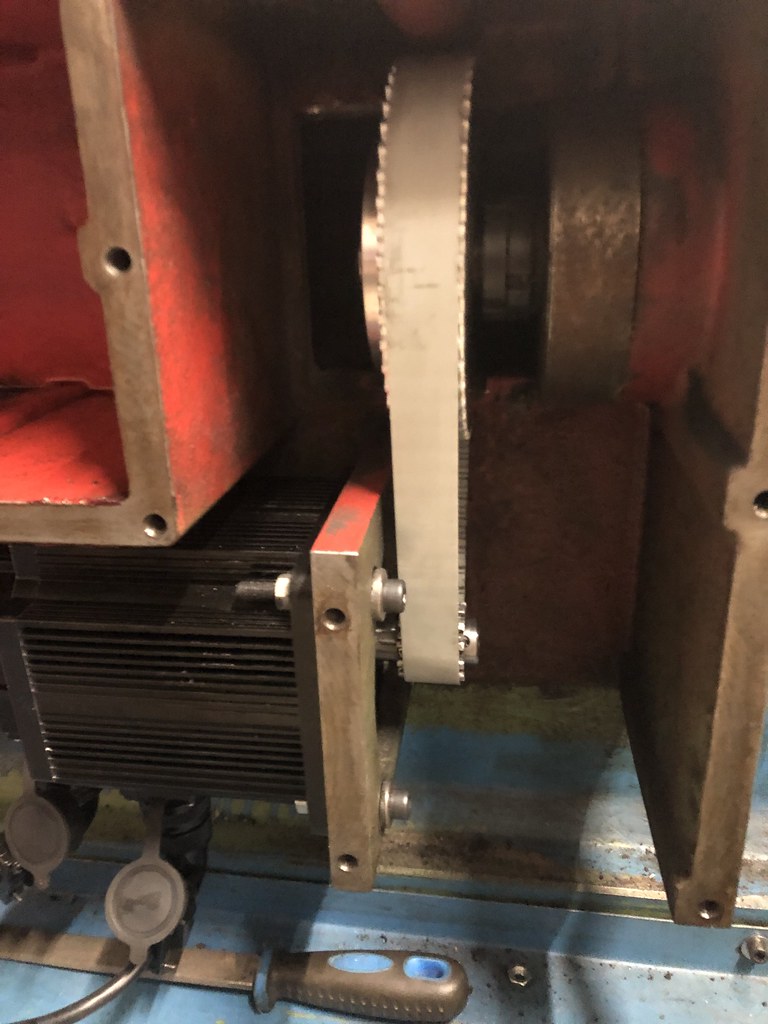

after some trouble the tight pulleys arrived:

low I just need to make the locking devices to clamp the pulleys to the shaft. And make some light modifications to the housing to fit the new bigger pulley.

But this will get me from 0.0012 mm/p to 0.001 mm/p what are actually 0.00025mm/p with the servo drives. only issue at the moment it I don't get the index from the servos for homing but I can home without indes for now.

Looking forward to also get the Z-Axis moving

low I just need to make the locking devices to clamp the pulleys to the shaft. And make some light modifications to the housing to fit the new bigger pulley.

But this will get me from 0.0012 mm/p to 0.001 mm/p what are actually 0.00025mm/p with the servo drives. only issue at the moment it I don't get the index from the servos for homing but I can home without indes for now.

Looking forward to also get the Z-Axis moving

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

04 Jul 2021 15:26 #213698

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

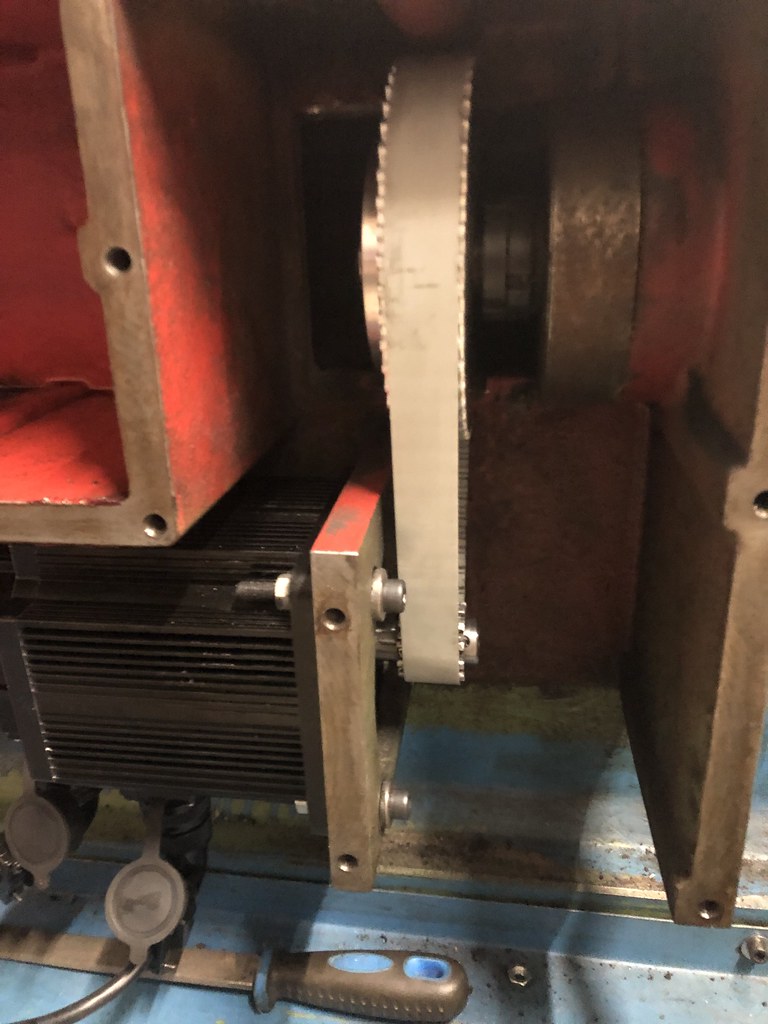

after some grinding the new pulley fits

this session then ended when I tried to machine the the bore for the clamping thingies. the pulley is to big for ma old lathe and I can't clamp on the recess cause I can't flip it 180° cause the it won't fit.

So the new plan is too machine it in the mill, but this is not a Sunday project.

this session then ended when I tried to machine the the bore for the clamping thingies. the pulley is to big for ma old lathe and I can't clamp on the recess cause I can't flip it 180° cause the it won't fit.

So the new plan is too machine it in the mill, but this is not a Sunday project.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

05 Jul 2021 22:07 #213794

by andypugh

Replied by andypugh on topic Gildemeister NEF 480 Retrofit

The small pulley flanges look to have gone missing?

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

06 Jul 2021 04:56 - 06 Jul 2021 04:57 #213822

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

I used the old x axis pulley for testing. Without the flange it is easier to set up. It took me three tries before I had ground away enough for the belt to run without touching anything.

For final assembly the flanged pulley will be used.

For final assembly the flanged pulley will be used.

Last edit: 06 Jul 2021 04:57 by anfänger.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

10 Jul 2021 15:40 #214185

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

got some shop time today and machined the threes and pocket for the clamping set in the pulley:

a little later it was done, setting up took longer than machining.

then all was a bit blurry

but after tightening everything up all axis were moving:

So it was time to close the oil tank

so far it doesn't leak, the clutch is working again and the gears get oil. So now it's "just" tuning, some more work on config and the vcp. Before I can take the first cut. The new tools also arrived and they look way bigger than the old ones:

a little later it was done, setting up took longer than machining.

then all was a bit blurry

but after tightening everything up all axis were moving:

So it was time to close the oil tank

so far it doesn't leak, the clutch is working again and the gears get oil. So now it's "just" tuning, some more work on config and the vcp. Before I can take the first cut. The new tools also arrived and they look way bigger than the old ones:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Jul 2021 16:14 #214280

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

my pwmgen seems to be inverted at max rpm its 0 and at low rom it gives me 10v any ideas where to look?

I think I need to organize more. here my ini and Hal files

Thanks Patrick

I think I need to organize more. here my ini and Hal files

Thanks Patrick

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17628

- Thank you received: 5157

11 Jul 2021 16:26 #214283

by PCW

Replied by PCW on topic Gildemeister NEF 480 Retrofit

There were some changes to the 7I97 firmware so I would suggest

upgrading firmware. These changes:

1. Invert PWM

2. Force output to 0V when disabled

NOTE: this will invert all PWM channels so you may need to change the sign

of PWM scale to avoid runways

If you dont want to change the firmware you can just invert the PWM pin polarity on hal

upgrading firmware. These changes:

1. Invert PWM

2. Force output to 0V when disabled

NOTE: this will invert all PWM channels so you may need to change the sign

of PWM scale to avoid runways

If you dont want to change the firmware you can just invert the PWM pin polarity on hal

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Jul 2021 16:38 #214284

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Thanks for your quick reply, I would prefer to keep my firmware. How can I change polarity in Hal?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17628

- Thank you received: 5157

11 Jul 2021 16:45 #214285

by PCW

Replied by PCW on topic Gildemeister NEF 480 Retrofit

setp hm2_7i97.0.pwmgen.0N.out0.invert_output true

The following user(s) said Thank You: anfänger

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.103 seconds