Gildemeister NEF 480 Retrofit

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

11 Jul 2021 20:02 - 12 Jul 2021 08:50 #214315

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Thanks spindle and gears are working now

Now it’s time to tune everything and take the first cut.

Now it’s time to tune everything and take the first cut.

Last edit: 12 Jul 2021 08:50 by anfänger.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

14 Jul 2021 08:18 - 14 Jul 2021 08:21 #214688

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Added some new features for the gearchange yesterday, but the rain kept me from testing it.

Now I have buttons for each gear / spindle speed range.

When presse a custom MCode is executed, which stops the spindle and brings up a dialogue with the leaver positions.

Then sets the right clutch und spindle speed.

I think this will come in useful.

But what should be a quick session took me a lot longer than planned as always with me when I try to code I don‘t do it regularly and forget quite quick.

What is still missing is too write spindle speed and gear to a persistent parameter and reload it when powered on again.

Is there a best practice which parameters to use?

Next is to find a way to implement this in the post processor

OK and testing I hope I find the time for testing this evening

Thanks for reading

Patrick

Now I have buttons for each gear / spindle speed range.

When presse a custom MCode is executed, which stops the spindle and brings up a dialogue with the leaver positions.

Then sets the right clutch und spindle speed.

I think this will come in useful.

But what should be a quick session took me a lot longer than planned as always with me when I try to code I don‘t do it regularly and forget quite quick.

What is still missing is too write spindle speed and gear to a persistent parameter and reload it when powered on again.

Is there a best practice which parameters to use?

Next is to find a way to implement this in the post processor

OK and testing I hope I find the time for testing this evening

Thanks for reading

Patrick

Last edit: 14 Jul 2021 08:21 by anfänger.

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

14 Jul 2021 20:25 #214774

by anfänger

made sone progress on the gearbox change today.

Three problem I've got.

First the the spindle sounds like it needs new bearings,

second the parameter #<_spindle_on> os 0 even when the spindle is running, so the spindle doesn't restart after gear change

third the MCode to load the stored gear (M245) doesn't work when I put it in the startup codes. then linuxcnc errors our with M144 unknown.

M144 is a bash script and nit mapped in the INI.

When I run it in MDI later it works fine M144 is the script which brings the popup window wit the gear settings.

Thaks Patrick

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

made sone progress on the gearbox change today.

Three problem I've got.

First the the spindle sounds like it needs new bearings,

second the parameter #<_spindle_on> os 0 even when the spindle is running, so the spindle doesn't restart after gear change

third the MCode to load the stored gear (M245) doesn't work when I put it in the startup codes. then linuxcnc errors our with M144 unknown.

M144 is a bash script and nit mapped in the INI.

When I run it in MDI later it works fine M144 is the script which brings the popup window wit the gear settings.

Thaks Patrick

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

16 Jul 2021 06:31 #214992

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

Fixed the spindle start by reading the hal pins. Now it works, But I didn’t make a video.

What I did film was the successful homing:

Then I removed Chuck and the mechanical clamping device.

I will clean the spindle and then start to prepare for mounting a normal chuck.

The Schunk Cuck and the clamping thing will get a a cleaning and the n will be stored till I have a need for it.

What I did film was the successful homing:

Then I removed Chuck and the mechanical clamping device.

I will clean the spindle and then start to prepare for mounting a normal chuck.

The Schunk Cuck and the clamping thing will get a a cleaning and the n will be stored till I have a need for it.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7285

16 Jul 2021 12:00 #215026

by tommylight

Replied by tommylight on topic Gildemeister NEF 480 Retrofit

I wonder if that chuck would fit my Mazak Micro Slant 15 ???

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

16 Jul 2021 12:08 - 16 Jul 2021 12:24 #215028

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

What kind of Spindle Node do you have? And where her you from?

But I am not sure If I will sell it.

Now that I know how to mount it and if I make some tools mounting and dismounting won’t take that long.

It is a nice three jaw chuck and I have a lot of jaws for it.

But I font think I will ever need the automatic clamping it was fun to get it running and it nice for a Job shop but for me it is more or less useless, cause I don’t think I will make more thank three same parts in a row.

But I would would be really tempted trade it for a 250mm there jaw chuck with two piece jaws cable of 2250 rpm

But I am not sure If I will sell it.

Now that I know how to mount it and if I make some tools mounting and dismounting won’t take that long.

It is a nice three jaw chuck and I have a lot of jaws for it.

But I font think I will ever need the automatic clamping it was fun to get it running and it nice for a Job shop but for me it is more or less useless, cause I don’t think I will make more thank three same parts in a row.

But I would would be really tempted trade it for a 250mm there jaw chuck with two piece jaws cable of 2250 rpm

Last edit: 16 Jul 2021 12:24 by anfänger.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7285

16 Jul 2021 12:23 #215034

by tommylight

Replied by tommylight on topic Gildemeister NEF 480 Retrofit

No idea on the spindle node.

I am in Kosovo.

No worries, i will keep searching for it, in the mean time i might also use a normal chuck, when i get to retrofit it, the Mesa boards i have for it age getting a bit moldy waiting ...

I am in Kosovo.

No worries, i will keep searching for it, in the mean time i might also use a normal chuck, when i get to retrofit it, the Mesa boards i have for it age getting a bit moldy waiting ...

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

16 Jul 2021 12:28 #215037

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

It’s not really near by, good look on the search.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- anfänger

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 627

- Thank you received: 256

17 Jul 2021 20:41 #215170

by anfänger

Replied by anfänger on topic Gildemeister NEF 480 Retrofit

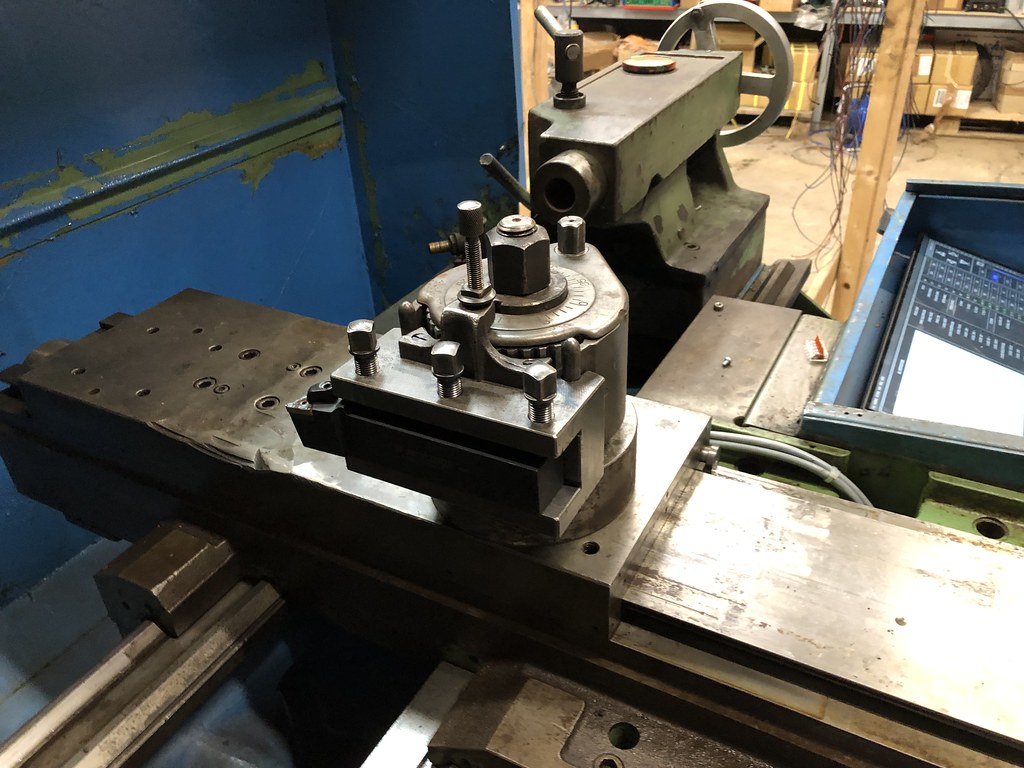

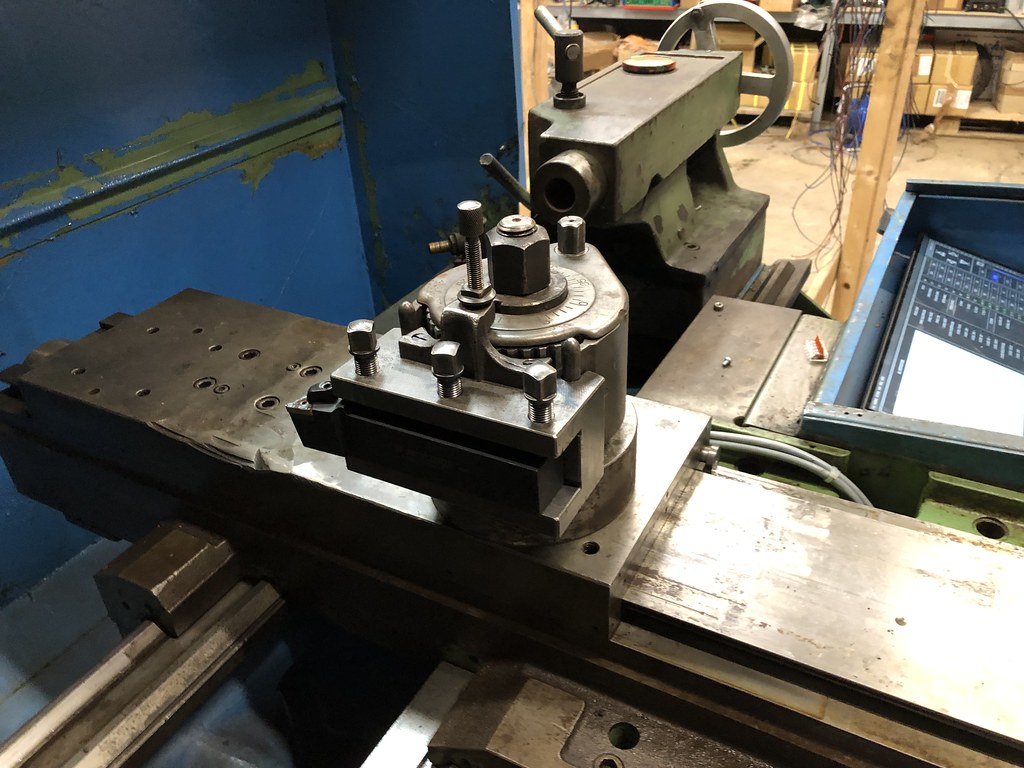

put the tool mount back on the lathe:

then I took the first cut on the machine:

used the hand wheels to tale the first gut of the face plate

After adjusting the spindle speed the surface finish got better. And I should close the cable ways and make me son wipers.

so here it is ready for drilling the faceplate for the new chuck

looks a lit lost, bu should be enough for most of what's coming next time

then I took the first cut on the machine:

used the hand wheels to tale the first gut of the face plate

After adjusting the spindle speed the surface finish got better. And I should close the cable ways and make me son wipers.

so here it is ready for drilling the faceplate for the new chuck

looks a lit lost, bu should be enough for most of what's coming next time

The following user(s) said Thank You: RotarySMP, tommylight

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1570

- Thank you received: 576

18 Jul 2021 07:18 #215208

by RotarySMP

Replied by RotarySMP on topic Gildemeister NEF 480 Retrofit

It is a cool feeling to make a part on the machine for the first time. You are way ahead of me

Mark.

Mark.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.122 seconds