Mesa 7i76e - Joint 0/2 following error

- JackBerkhout

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 2

16 Jul 2017 11:23 - 16 Jul 2017 12:31 #95839

by JackBerkhout

Mesa 7i76e - Joint 0/2 following error was created by JackBerkhout

Hi,

I'm new to LinuxCNC. I try to use it for an Emco Compact 5 (CNC) Latthe, where the existing electronics were destroyed.

For this, I got a Mesa 7i76e board.

In PncConf, I selected Latthe and the board and kept everything else on default, as I have no clue yet what I should look for in the wizard.

So now I have my ini and hal file.

I connected one (open-loop) stepper driver and stepper motor, just to see if it would turn while running the gcode "EMC2 AXIS", and it does! (I think it is a bit strange example gcode for the lathe configuration, but it lets me nicely try this.)

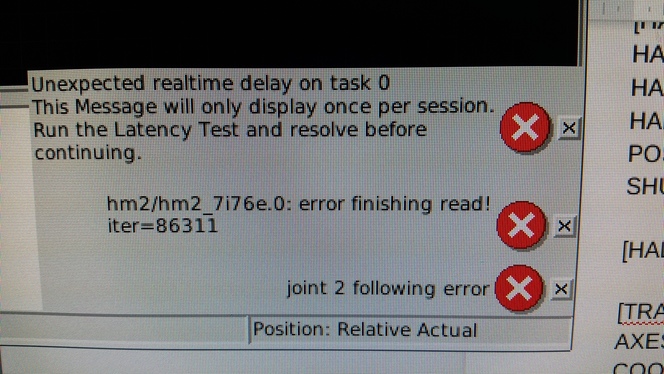

However I randomly get these errors (all four at once):

1.

Unexpected realtime delay on task 0

This message will only display once per session.

Run the latency Test and resolve before continuing.

I run it, but running that doesn't resolve it. Maybe I have to do something with the vales, but it doesn't tell what to do with each reading.

For me it not really a helpful message.

2.

hm2/hm2_7i76e.0: error finishing read!

iter=312321

Honestly, I have no clue what this tells me.

3.

Joint 0 following error

4.

Joint 2 following error

I couldn't find a solution for the joint following error. Somebody solved the same error, but didn't tell how he did it.

After this nothing works anymore, except quiting LinuxCNC.

The PC is not particular fast (A Zotac ZBOX Nano 320, AMD 1GHz)

What could be the problem of all these problems?

First checking here would be the best approach to solve the problem.

Otherwise I would maybe better of with EdingCNC?

If it helps, my hal file looks like this (Note, the IP address have been changed, so I can experiment with LinuxCNC on my existing network, and that's why I can post the hal file here):

# Generated by PNCconf at Sat Jul 8 01:50:45 2017

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.2.130" config="firmware=hm2/7i76/7i76e.BIT num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=00xxxx"

setp hm2_7i76e.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

addf hm2_7i76e.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_7i76e.0.write servo-thread

setp hm2_7i76e.0.dpll.01.timer-us -50

setp hm2_7i76e.0.stepgen.timer-number 1

# external output signals

# external input signals

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.00.dirsetup [AXIS_0]DIRSETUP

setp hm2_7i76e.0.stepgen.00.dirhold [AXIS_0]DIRHOLD

setp hm2_7i76e.0.stepgen.00.steplen [AXIS_0]STEPLEN

setp hm2_7i76e.0.stepgen.00.stepspace [AXIS_0]STEPSPACE

setp hm2_7i76e.0.stepgen.00.position-scale [AXIS_0]STEP_SCALE

setp hm2_7i76e.0.stepgen.00.step_type 0

setp hm2_7i76e.0.stepgen.00.control-type 1

setp hm2_7i76e.0.stepgen.00.maxaccel [AXIS_0]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.00.maxvel [AXIS_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_7i76e.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.01.dirsetup [AXIS_2]DIRSETUP

setp hm2_7i76e.0.stepgen.01.dirhold [AXIS_2]DIRHOLD

setp hm2_7i76e.0.stepgen.01.steplen [AXIS_2]STEPLEN

setp hm2_7i76e.0.stepgen.01.stepspace [AXIS_2]STEPSPACE

setp hm2_7i76e.0.stepgen.01.position-scale [AXIS_2]STEP_SCALE

setp hm2_7i76e.0.stepgen.01.step_type 0

setp hm2_7i76e.0.stepgen.01.control-type 1

setp hm2_7i76e.0.stepgen.01.maxaccel [AXIS_2]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.01.maxvel [AXIS_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= axis.2.motor-pos-cmd

net z-vel-cmd <= axis.2.joint-vel-cmd

net z-output <= hm2_7i76e.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i76e.0.stepgen.01.position-fb

net z-pos-fb => axis.2.motor-pos-fb

net z-enable <= axis.2.amp-enable-out

net z-enable => hm2_7i76e.0.stepgen.01.enable

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i76e.0.encoder.00.counter-mode 0

setp hm2_7i76e.0.encoder.00.filter 1

setp hm2_7i76e.0.encoder.00.index-invert 0

setp hm2_7i76e.0.encoder.00.index-mask 0

setp hm2_7i76e.0.encoder.00.index-mask-invert 0

setp hm2_7i76e.0.encoder.00.scale [SPINDLE_9]ENCODER_SCALE

net spindle-revs <= hm2_7i76e.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i76e.0.encoder.00.velocity

net spindle-index-enable <=> hm2_7i76e.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Kind regards,

Jack.

I'm new to LinuxCNC. I try to use it for an Emco Compact 5 (CNC) Latthe, where the existing electronics were destroyed.

For this, I got a Mesa 7i76e board.

In PncConf, I selected Latthe and the board and kept everything else on default, as I have no clue yet what I should look for in the wizard.

So now I have my ini and hal file.

I connected one (open-loop) stepper driver and stepper motor, just to see if it would turn while running the gcode "EMC2 AXIS", and it does! (I think it is a bit strange example gcode for the lathe configuration, but it lets me nicely try this.)

However I randomly get these errors (all four at once):

1.

Unexpected realtime delay on task 0

This message will only display once per session.

Run the latency Test and resolve before continuing.

I run it, but running that doesn't resolve it. Maybe I have to do something with the vales, but it doesn't tell what to do with each reading.

For me it not really a helpful message.

2.

hm2/hm2_7i76e.0: error finishing read!

iter=312321

Honestly, I have no clue what this tells me.

3.

Joint 0 following error

4.

Joint 2 following error

I couldn't find a solution for the joint following error. Somebody solved the same error, but didn't tell how he did it.

After this nothing works anymore, except quiting LinuxCNC.

The PC is not particular fast (A Zotac ZBOX Nano 320, AMD 1GHz)

What could be the problem of all these problems?

First checking here would be the best approach to solve the problem.

Otherwise I would maybe better of with EdingCNC?

If it helps, my hal file looks like this (Note, the IP address have been changed, so I can experiment with LinuxCNC on my existing network, and that's why I can post the hal file here):

# Generated by PNCconf at Sat Jul 8 01:50:45 2017

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt trivkins

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hostmot2

loadrt hm2_eth board_ip="192.168.2.130" config="firmware=hm2/7i76/7i76e.BIT num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=00xxxx"

setp hm2_7i76e.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.z,pid.s

addf hm2_7i76e.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_7i76e.0.write servo-thread

setp hm2_7i76e.0.dpll.01.timer-us -50

setp hm2_7i76e.0.stepgen.timer-number 1

# external output signals

# external input signals

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [AXIS_0]P

setp pid.x.Igain [AXIS_0]I

setp pid.x.Dgain [AXIS_0]D

setp pid.x.bias [AXIS_0]BIAS

setp pid.x.FF0 [AXIS_0]FF0

setp pid.x.FF1 [AXIS_0]FF1

setp pid.x.FF2 [AXIS_0]FF2

setp pid.x.deadband [AXIS_0]DEADBAND

setp pid.x.maxoutput [AXIS_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.00.dirsetup [AXIS_0]DIRSETUP

setp hm2_7i76e.0.stepgen.00.dirhold [AXIS_0]DIRHOLD

setp hm2_7i76e.0.stepgen.00.steplen [AXIS_0]STEPLEN

setp hm2_7i76e.0.stepgen.00.stepspace [AXIS_0]STEPSPACE

setp hm2_7i76e.0.stepgen.00.position-scale [AXIS_0]STEP_SCALE

setp hm2_7i76e.0.stepgen.00.step_type 0

setp hm2_7i76e.0.stepgen.00.control-type 1

setp hm2_7i76e.0.stepgen.00.maxaccel [AXIS_0]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.00.maxvel [AXIS_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= axis.0.motor-pos-cmd

net x-vel-cmd <= axis.0.joint-vel-cmd

net x-output <= hm2_7i76e.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i76e.0.stepgen.00.position-fb

net x-pos-fb => axis.0.motor-pos-fb

net x-enable <= axis.0.amp-enable-out

net x-enable => hm2_7i76e.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => axis.0.home-sw-in

net x-neg-limit => axis.0.neg-lim-sw-in

net x-pos-limit => axis.0.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [AXIS_2]P

setp pid.z.Igain [AXIS_2]I

setp pid.z.Dgain [AXIS_2]D

setp pid.z.bias [AXIS_2]BIAS

setp pid.z.FF0 [AXIS_2]FF0

setp pid.z.FF1 [AXIS_2]FF1

setp pid.z.FF2 [AXIS_2]FF2

setp pid.z.deadband [AXIS_2]DEADBAND

setp pid.z.maxoutput [AXIS_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror .0005

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.01.dirsetup [AXIS_2]DIRSETUP

setp hm2_7i76e.0.stepgen.01.dirhold [AXIS_2]DIRHOLD

setp hm2_7i76e.0.stepgen.01.steplen [AXIS_2]STEPLEN

setp hm2_7i76e.0.stepgen.01.stepspace [AXIS_2]STEPSPACE

setp hm2_7i76e.0.stepgen.01.position-scale [AXIS_2]STEP_SCALE

setp hm2_7i76e.0.stepgen.01.step_type 0

setp hm2_7i76e.0.stepgen.01.control-type 1

setp hm2_7i76e.0.stepgen.01.maxaccel [AXIS_2]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.01.maxvel [AXIS_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= axis.2.motor-pos-cmd

net z-vel-cmd <= axis.2.joint-vel-cmd

net z-output <= hm2_7i76e.0.stepgen.01.velocity-cmd

net z-pos-fb <= hm2_7i76e.0.stepgen.01.position-fb

net z-pos-fb => axis.2.motor-pos-fb

net z-enable <= axis.2.amp-enable-out

net z-enable => hm2_7i76e.0.stepgen.01.enable

# ---setup home / limit switch signals---

net z-home-sw => axis.2.home-sw-in

net z-neg-limit => axis.2.neg-lim-sw-in

net z-pos-limit => axis.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_9]P

setp pid.s.Igain [SPINDLE_9]I

setp pid.s.Dgain [SPINDLE_9]D

setp pid.s.bias [SPINDLE_9]BIAS

setp pid.s.FF0 [SPINDLE_9]FF0

setp pid.s.FF1 [SPINDLE_9]FF1

setp pid.s.FF2 [SPINDLE_9]FF2

setp pid.s.deadband [SPINDLE_9]DEADBAND

setp pid.s.maxoutput [SPINDLE_9]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---Encoder feedback signals/setup---

setp hm2_7i76e.0.encoder.00.counter-mode 0

setp hm2_7i76e.0.encoder.00.filter 1

setp hm2_7i76e.0.encoder.00.index-invert 0

setp hm2_7i76e.0.encoder.00.index-mask 0

setp hm2_7i76e.0.encoder.00.index-mask-invert 0

setp hm2_7i76e.0.encoder.00.scale [SPINDLE_9]ENCODER_SCALE

net spindle-revs <= hm2_7i76e.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i76e.0.encoder.00.velocity

net spindle-index-enable <=> hm2_7i76e.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= motion.spindle-speed-out-rps

net spindle-vel-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-vel-cmd-rpm <= motion.spindle-speed-out

net spindle-vel-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-enable <= motion.spindle-on

net spindle-cw <= motion.spindle-forward

net spindle-ccw <= motion.spindle-reverse

net spindle-brake <= motion.spindle-brake

net spindle-revs => motion.spindle-revs

net spindle-at-speed => motion.spindle-at-speed

net spindle-vel-fb-rps => motion.spindle-speed-in

net spindle-index-enable <=> motion.spindle-index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

net jog-x-pos halui.jog.0.plus

net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.jog.0.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

net jog-z-pos halui.jog.2.plus

net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.jog.2.analog

net jog-selected-pos halui.jog.selected.plus

net jog-selected-neg halui.jog.selected.minus

net spindle-manual-cw halui.spindle.forward

net spindle-manual-ccw halui.spindle.reverse

net spindle-manual-stop halui.spindle.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

Kind regards,

Jack.

Last edit: 16 Jul 2017 12:31 by JackBerkhout.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

16 Jul 2017 11:58 #95842

by rodw

Replied by rodw on topic Mesa 7i76e - Joint 0/2 following error

Jack, I had a bit of this happening when I set up my 7i76e.

These settings in my .ini file were the what was causing it for me..

Increasing these I mean

These settings in my .ini file were the what was causing it for me..

MAX_VELOCITY = 300

MAX_ACCELERATION = 1500

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 700

STEPGEN_MAXACCEL = 2000Increasing these I mean

STEPGEN_MAXVEL = 700

STEPGEN_MAXACCEL = 2000Please Log in or Create an account to join the conversation.

- JackBerkhout

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 2

16 Jul 2017 12:12 - 16 Jul 2017 12:27 #95843

by JackBerkhout

Replied by JackBerkhout on topic Mesa 7i76e - Joint 0/2 following error

Hi Rodw,

thank you very much for your quick response:

I had these values in my ini file for Axis X and Axis Z, by default:

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

I changed those to

MAX_VELOCITY = 300

MAX_ACCELERATION = 1500

STEPGEN_MAXVEL = 700

STEPGEN_MAXACCEL = 2000

After testing, I quickly got the same messages, except joint 0 following error was not there, only jont 2 following error.

And of course the other two errors. They all pop-up at the same time.

Could my barebone PC be too slow?

Kind regards,

Jack.

thank you very much for your quick response:

I had these values in my ini file for Axis X and Axis Z, by default:

MAX_VELOCITY = 25.0

MAX_ACCELERATION = 750.0

STEPGEN_MAXVEL = 31.25

STEPGEN_MAXACCEL = 937.50

I changed those to

MAX_VELOCITY = 300

MAX_ACCELERATION = 1500

STEPGEN_MAXVEL = 700

STEPGEN_MAXACCEL = 2000

After testing, I quickly got the same messages, except joint 0 following error was not there, only jont 2 following error.

And of course the other two errors. They all pop-up at the same time.

Could my barebone PC be too slow?

Kind regards,

Jack.

Last edit: 16 Jul 2017 12:27 by JackBerkhout.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

16 Jul 2017 12:44 #95844

by rodw

Replied by rodw on topic Mesa 7i76e - Joint 0/2 following error

Jack, I'm not sure about the "error finishing read". Perhaps someone like PCW can be clearer in his response.

Perhaps attach your .ini file and report your stepper motor driver model and it specifications in relation to step timings so others can review. Also report your latency results.

I'm using a USFF pc with a Celeron N3160 in it and I've had no troubles. Yours might be a bit slower.

If you are using the internal wifi card, remove it as they are massive latency hogs. Use a USB wifi dongle instead. PCW has spoken about this a few times. I tried mine and he was right!

I wondered if you have a motor on joint 2 on a lathe. Are you sure you are not using joint 0 & 1? How did you wire them in on the 7i76e? (eg. which stepgens did you use?)

Perhaps attach your .ini file and report your stepper motor driver model and it specifications in relation to step timings so others can review. Also report your latency results.

I'm using a USFF pc with a Celeron N3160 in it and I've had no troubles. Yours might be a bit slower.

If you are using the internal wifi card, remove it as they are massive latency hogs. Use a USB wifi dongle instead. PCW has spoken about this a few times. I tried mine and he was right!

I wondered if you have a motor on joint 2 on a lathe. Are you sure you are not using joint 0 & 1? How did you wire them in on the 7i76e? (eg. which stepgens did you use?)

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

16 Jul 2017 13:55 - 16 Jul 2017 13:56 #95846

by PCW

Replied by PCW on topic Mesa 7i76e - Joint 0/2 following error

It appears that your main issue is that your host PC has poor latency

All subsequent errors are caused by the real time delay, the "error finishing read" means that LinuxCNC sent out a request to the 7I76e to read data but nothing was returned before linuxCNC timed out the request and gave up. The

following error happens because of lack of up-to-date position feedback

Have you run a latency test or better latency-histogram on your PC?

To do this, type

latency-histogram --nobase

And run it for at least an hour or so while doing other normal computer things

Are _all_ power management options disabled in the BIOS?

This means all "cool and quiet", C-state, turbo speed options etc

All subsequent errors are caused by the real time delay, the "error finishing read" means that LinuxCNC sent out a request to the 7I76e to read data but nothing was returned before linuxCNC timed out the request and gave up. The

following error happens because of lack of up-to-date position feedback

Have you run a latency test or better latency-histogram on your PC?

To do this, type

latency-histogram --nobase

And run it for at least an hour or so while doing other normal computer things

Are _all_ power management options disabled in the BIOS?

This means all "cool and quiet", C-state, turbo speed options etc

Last edit: 16 Jul 2017 13:56 by PCW.

Please Log in or Create an account to join the conversation.

- JackBerkhout

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 2

16 Jul 2017 14:28 #95848

by JackBerkhout

Replied by JackBerkhout on topic Mesa 7i76e - Joint 0/2 following error

Basically, I run PncConf with default, but for "lathe" and Mesa 7i76e board.

Then for test, I connected one stepperdriver and NEMA17 motor, just for test.

The lathe which is going to be converted is in another city, I would like to get the configuration right on the "test-bench", before heading there.

I run thee gcode that is loaded at startup and measured with a scope where the step and dir signals resided.

Those happen on TB2.

My board doesn't have pin numbers near those connectors, but in the manual I only see a black dot at the bottom, when holding the Ethernet connector to the left-top side (board in landscape).

For now I assume numbering starts from the bottom.

So I connected just one cheap Chinese (open-loop) stepperdriver to TB2

www.aliexpress.com/item/TB6600-4A-9-42V-...xes/32702091551.html

Step on pins 8 and 9

Dir on pins 10 and 11

The signals also appear on pins 2, 3, 4,, and 5. For the there are two axis: X and Z, right?

Though, I didn't find where those pins are configured in the hal or ini file, that's why I used a oscilloscope, to find out.

You see I'm totally new on LinuxCNC, and having a bit hard time to advance.

I have to study it much more, before giving up on it.

Maybe we can get things right,

There are no step timings stated for this stepper driver. But since I do not use any movement feedback, that probably doesn't matter, as long as the motor turns reliable, which it seems to me.

The board would if I connected a stepper driver to one of its outputs I guess.

In the hal file I can make up we have joint 0 and joint 2, and only those seem to give errors.

I don't know what joints are, yet.

The I7i76e does not seem to have a WiFi on-board, as far as I can see, and the manual doesn't talk about WiFi.

Because I didn't configure WiFi, it shouldn't be the problem, right?

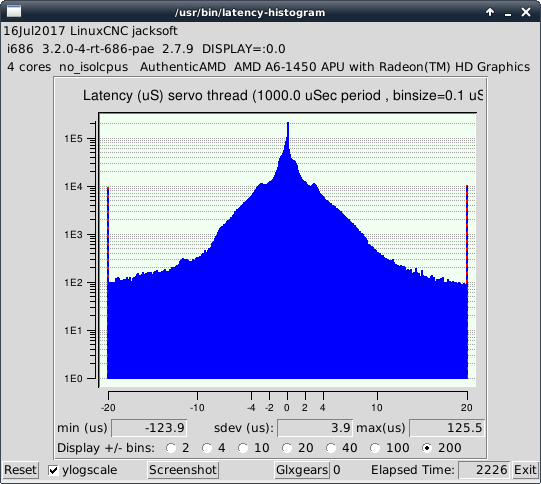

After 5 minutes of running the latency test, the bold values are:

Servo thread (1ms) 78998607

Base thread (25us): 123410

Attached the ini and hal file.

Then for test, I connected one stepperdriver and NEMA17 motor, just for test.

The lathe which is going to be converted is in another city, I would like to get the configuration right on the "test-bench", before heading there.

I run thee gcode that is loaded at startup and measured with a scope where the step and dir signals resided.

Those happen on TB2.

My board doesn't have pin numbers near those connectors, but in the manual I only see a black dot at the bottom, when holding the Ethernet connector to the left-top side (board in landscape).

For now I assume numbering starts from the bottom.

So I connected just one cheap Chinese (open-loop) stepperdriver to TB2

www.aliexpress.com/item/TB6600-4A-9-42V-...xes/32702091551.html

Step on pins 8 and 9

Dir on pins 10 and 11

The signals also appear on pins 2, 3, 4,, and 5. For the there are two axis: X and Z, right?

Though, I didn't find where those pins are configured in the hal or ini file, that's why I used a oscilloscope, to find out.

You see I'm totally new on LinuxCNC, and having a bit hard time to advance.

I have to study it much more, before giving up on it.

Maybe we can get things right,

There are no step timings stated for this stepper driver. But since I do not use any movement feedback, that probably doesn't matter, as long as the motor turns reliable, which it seems to me.

The board would if I connected a stepper driver to one of its outputs I guess.

In the hal file I can make up we have joint 0 and joint 2, and only those seem to give errors.

I don't know what joints are, yet.

The I7i76e does not seem to have a WiFi on-board, as far as I can see, and the manual doesn't talk about WiFi.

Because I didn't configure WiFi, it shouldn't be the problem, right?

After 5 minutes of running the latency test, the bold values are:

Servo thread (1ms) 78998607

Base thread (25us): 123410

Attached the ini and hal file.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

16 Jul 2017 14:37 #95849

by PCW

Replied by PCW on topic Mesa 7i76e - Joint 0/2 following error

This is _not_ a hal/ini file issue, this is a latency issue our your PC which can likely

be resolved by BIOS setup

Try running the latency-test or latency-histogram with the base thread disabled

as the stock base thread period will cause issues on your relatively slow PC

preventing accurate latency measurement

For the latency histogram you do this with:

latency-histogram --nobase

for the latency test:

latency-test 1ms 1ms

be resolved by BIOS setup

Try running the latency-test or latency-histogram with the base thread disabled

as the stock base thread period will cause issues on your relatively slow PC

preventing accurate latency measurement

For the latency histogram you do this with:

latency-histogram --nobase

for the latency test:

latency-test 1ms 1ms

Please Log in or Create an account to join the conversation.

- JackBerkhout

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 2

16 Jul 2017 14:40 - 16 Jul 2017 15:10 #95850

by JackBerkhout

Replied by JackBerkhout on topic Mesa 7i76e - Joint 0/2 following error

Last edit: 16 Jul 2017 15:10 by JackBerkhout.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

16 Jul 2017 15:49 - 16 Jul 2017 15:51 #95851

by PCW

Replied by PCW on topic Mesa 7i76e - Joint 0/2 following error

That looks OK though not great

Have you disabled all power management options in the BIOS?

Have you tried running normal PC applications, moving windows around, playing videos etc while the latency test is running?

Also what Ethernet hardware is used on your PC? (may need the results of dmesg to check)

Also as rodw mentioned ,disable any internal WIFI cards as some of those are notoriously bad for latency

(Broadcom anything is a disaster)

Have you disabled all power management options in the BIOS?

Have you tried running normal PC applications, moving windows around, playing videos etc while the latency test is running?

Also what Ethernet hardware is used on your PC? (may need the results of dmesg to check)

Also as rodw mentioned ,disable any internal WIFI cards as some of those are notoriously bad for latency

(Broadcom anything is a disaster)

Last edit: 16 Jul 2017 15:51 by PCW.

Please Log in or Create an account to join the conversation.

- JackBerkhout

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 2

16 Jul 2017 16:38 - 16 Jul 2017 16:59 #95852

by JackBerkhout

Replied by JackBerkhout on topic Mesa 7i76e - Joint 0/2 following error

Thank you very much PCW!!!

Maybe I found something.

The Ethernet interface in the barebone didn't work after LinuxCNC installation, so I used a USB-to-Ethernet adapter.

I removed it and tried the Ethernet port again and it now works, probably because of updates.

Such an adapter is far from ideal, I guess.

I disabled the power options in the BIOS, but could not find the WiFi disable option.

Testing sofar, that seems to make the difference!

Kind regards,

Jack.

Maybe I found something.

The Ethernet interface in the barebone didn't work after LinuxCNC installation, so I used a USB-to-Ethernet adapter.

I removed it and tried the Ethernet port again and it now works, probably because of updates.

Such an adapter is far from ideal, I guess.

I disabled the power options in the BIOS, but could not find the WiFi disable option.

Testing sofar, that seems to make the difference!

Kind regards,

Jack.

Last edit: 16 Jul 2017 16:59 by JackBerkhout.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.180 seconds