Retrofit of Precix 5x10 CNC

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

13 Mar 2021 18:19 #202123

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

I remember reading something about these PRECIX controllers need a change of capacitors in the power supply. Since my machine is 20yrs old, figured it was time. I had thought about changing them out and/or getting a new power supply at one point. I haven't since it was working fine. Today I got a following error, so I am looking at my servo tuning. Happened while I was resurfacing my spoilboard, and about 25% through I got a following error. Just shuttered and errored out. Didn't hit anything... just taking 0.05" off spoilboard with very little load on spindle.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

13 Mar 2021 23:54 - 13 Mar 2021 23:55 #202167

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Since I have brand new encoder cables I am thinking it's the motor or tuning. Odd since this machine was behaving up until today. This motor is pretty ancient. It could be the power supply failing I suppose.

Anyone have any input on why I'd be getting joint 0 following errors all of a sudden?

Debating on getting 3 new NEMA 34 servos/driver/power supplies, one for each axis. Looks like you can get a set for around $800. Wefixprecix had motor/encoder assembly for $550.00 a year ago, not sure if he still has any available.

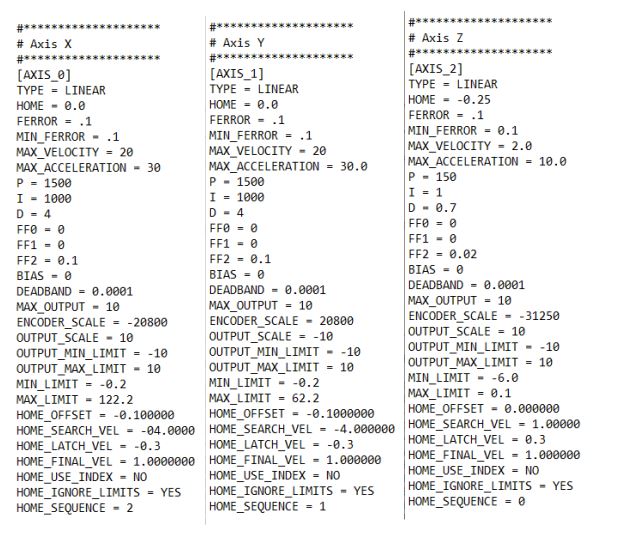

I notice my PID numbers look way off compared to most posts where I read about PID tuning for SERVO motors.

Think I need to start from scratch. Odd I haven't touched my setting in months. Although the last thing I did to was lower the ferror, I was told it was too high.

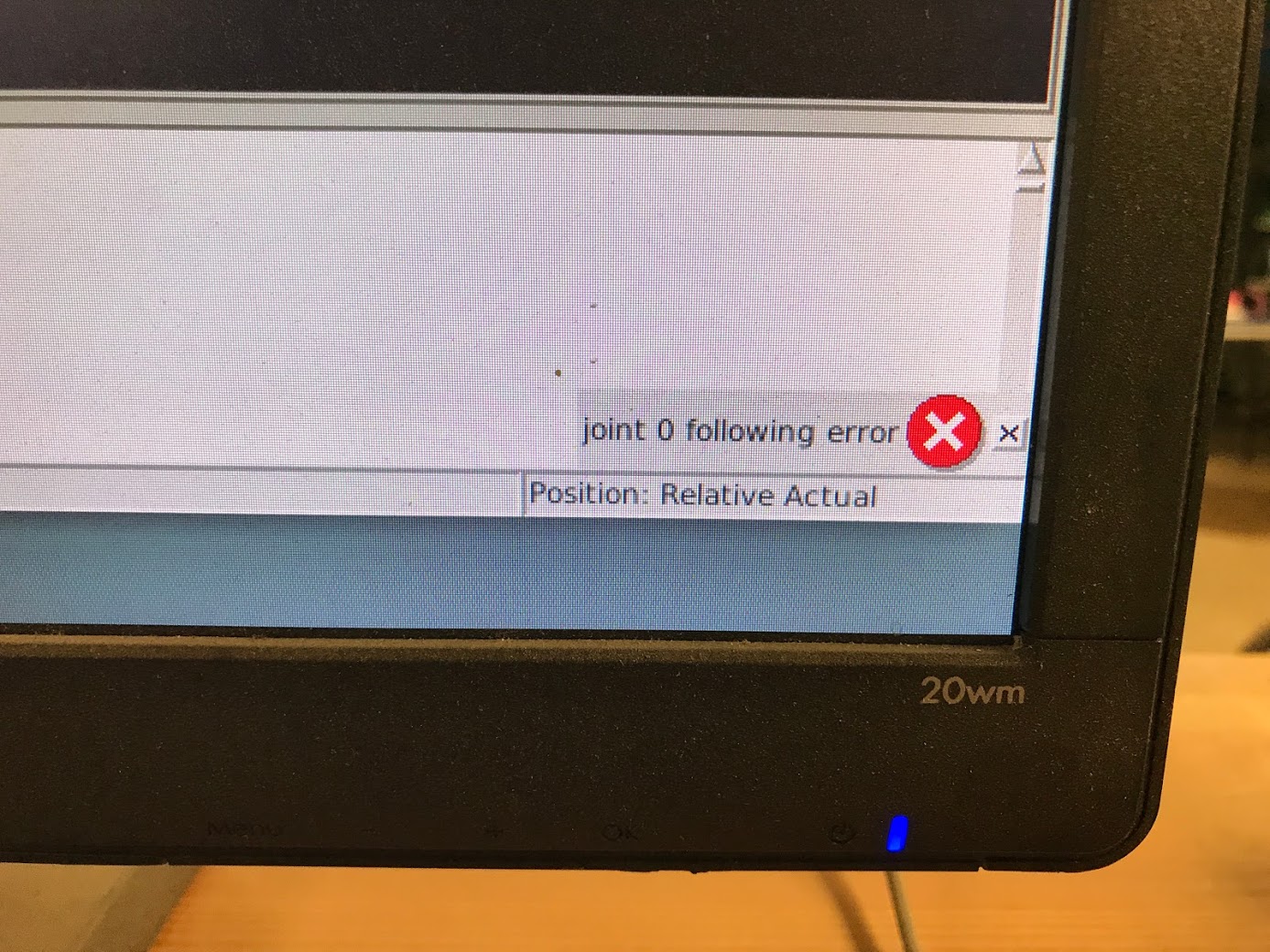

error, which I am sure everyone has seen

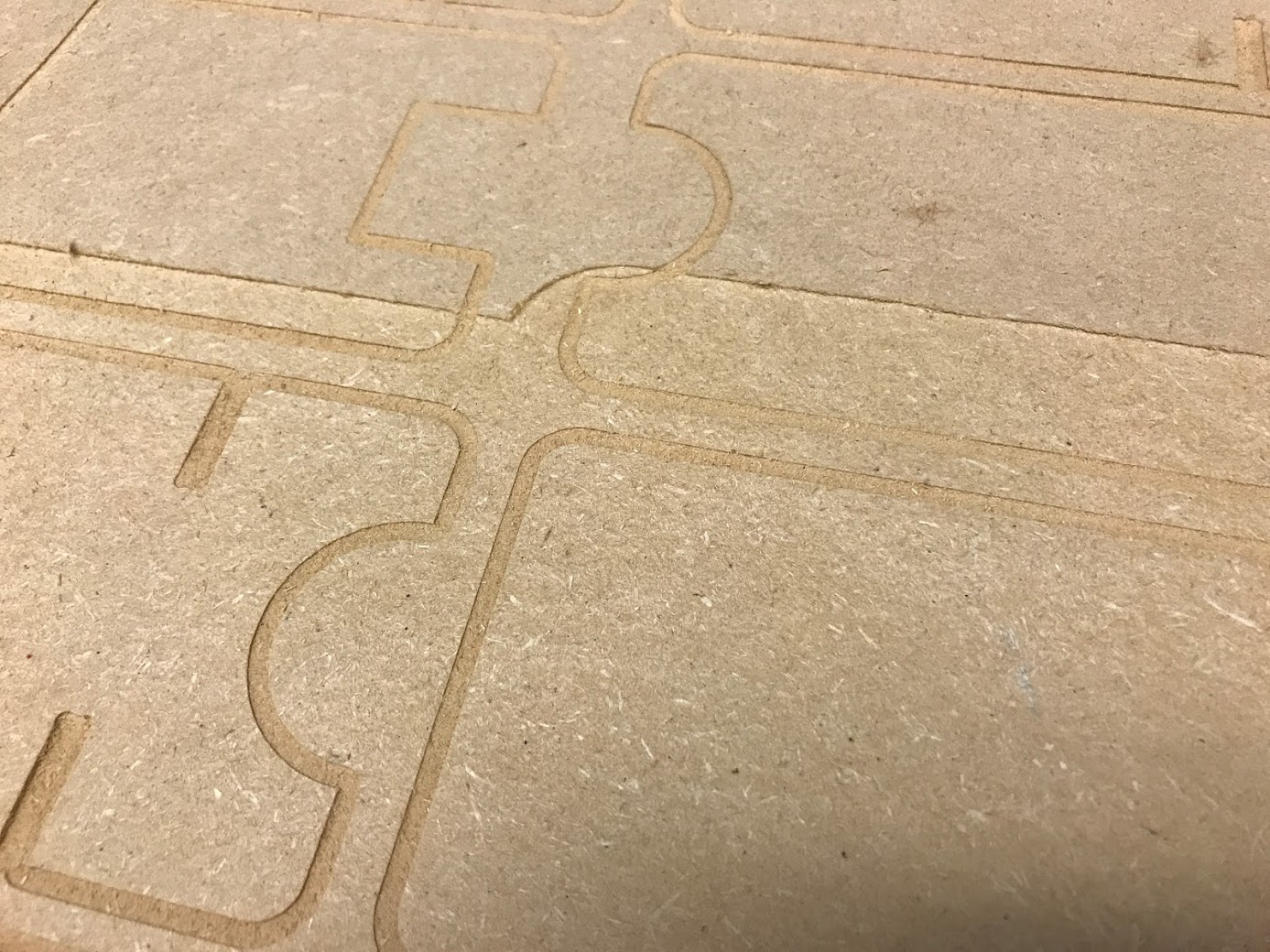

where it stopped the 1st time, 2nd time didn't get even that far..

my crappy way of holding down my spoilboard - biscuit slots & aluminum flat stock holding it down to table/t-track

Thanks for any input!

Anyone have any input on why I'd be getting joint 0 following errors all of a sudden?

Debating on getting 3 new NEMA 34 servos/driver/power supplies, one for each axis. Looks like you can get a set for around $800. Wefixprecix had motor/encoder assembly for $550.00 a year ago, not sure if he still has any available.

I notice my PID numbers look way off compared to most posts where I read about PID tuning for SERVO motors.

Think I need to start from scratch. Odd I haven't touched my setting in months. Although the last thing I did to was lower the ferror, I was told it was too high.

error, which I am sure everyone has seen

where it stopped the 1st time, 2nd time didn't get even that far..

my crappy way of holding down my spoilboard - biscuit slots & aluminum flat stock holding it down to table/t-track

Thanks for any input!

Last edit: 13 Mar 2021 23:55 by randypetersen.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

14 Mar 2021 00:05 #202171

by jmelson

Replied by jmelson on topic Retrofit of Precix 5x10 CNC

Are these settings AFTER you reduced the error limits? Are you running with inch units or mm? If inches, then 0.1 is allowing an errot tolerance of 1/10 of an inch, which is a lot. On X and Y, that is 2080 encoder counts. You need to fire up Halscope and see what the actual error is, and what it looks like in the time domain. If your amps are running out of headroom, you will see a slowly accumulating error. If there is a bad connection (cables, worn brushes, etc.) then there will be a sudden increase in error.

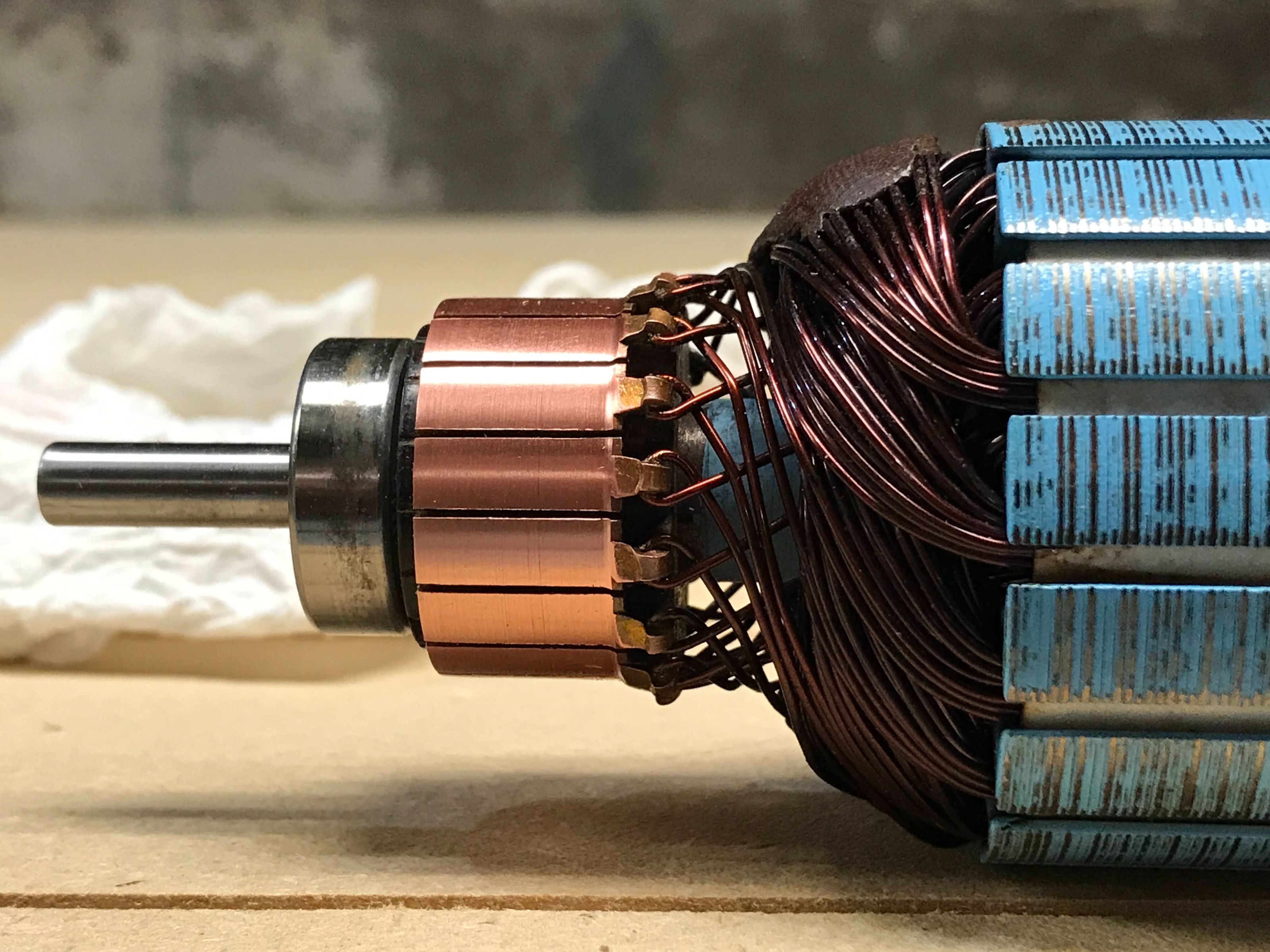

I'd pull the brushes out of the suspect motor and inspect the commutator. Either brushes or commutator could have developed wear, or the commutator slots are filled with copper dust, shorting out the armature.

Jon

I'd pull the brushes out of the suspect motor and inspect the commutator. Either brushes or commutator could have developed wear, or the commutator slots are filled with copper dust, shorting out the armature.

Jon

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

15 Mar 2021 01:33 #202289

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Thanks jmelson!

I took the servo motor apart.

Cleaned it up, but it didn't look terrible.

Putting it back together and the encoder was really hit and miss.

Then I moved the stop just a tiny amount and it was behaving much better. The encoder does seem somewhat sensitive.

I think this unit started off with some older motors, and the Y and Z axis were replaced with the magmotor units. I am thinking I could either replace the X with a magmotor or replace all the motors with some more modern units.

I have yet to connect the motor with the gears yet, hoping to test it a bit more.

Thanks again for the help!

I took the servo motor apart.

Cleaned it up, but it didn't look terrible.

Putting it back together and the encoder was really hit and miss.

Then I moved the stop just a tiny amount and it was behaving much better. The encoder does seem somewhat sensitive.

I think this unit started off with some older motors, and the Y and Z axis were replaced with the magmotor units. I am thinking I could either replace the X with a magmotor or replace all the motors with some more modern units.

I have yet to connect the motor with the gears yet, hoping to test it a bit more.

Thanks again for the help!

Attachments:

Please Log in or Create an account to join the conversation.

- GJTuck

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

15 Mar 2021 01:52 #202293

by GJTuck

Replied by GJTuck on topic Retrofit of Precix 5x10 CNC

I ended up swapping the new motor to the z axis and it had the same problem leading me to believe it’s the “new” motor. Then after looking at the wiring the encoder wires don’t match up with the old connector. The 8 active pins are not properly lined up. Hoping if I get that resolved I will be back in action.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

15 Mar 2021 10:54 - 15 Mar 2021 11:42 #202325

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Good Morning GJTuck,

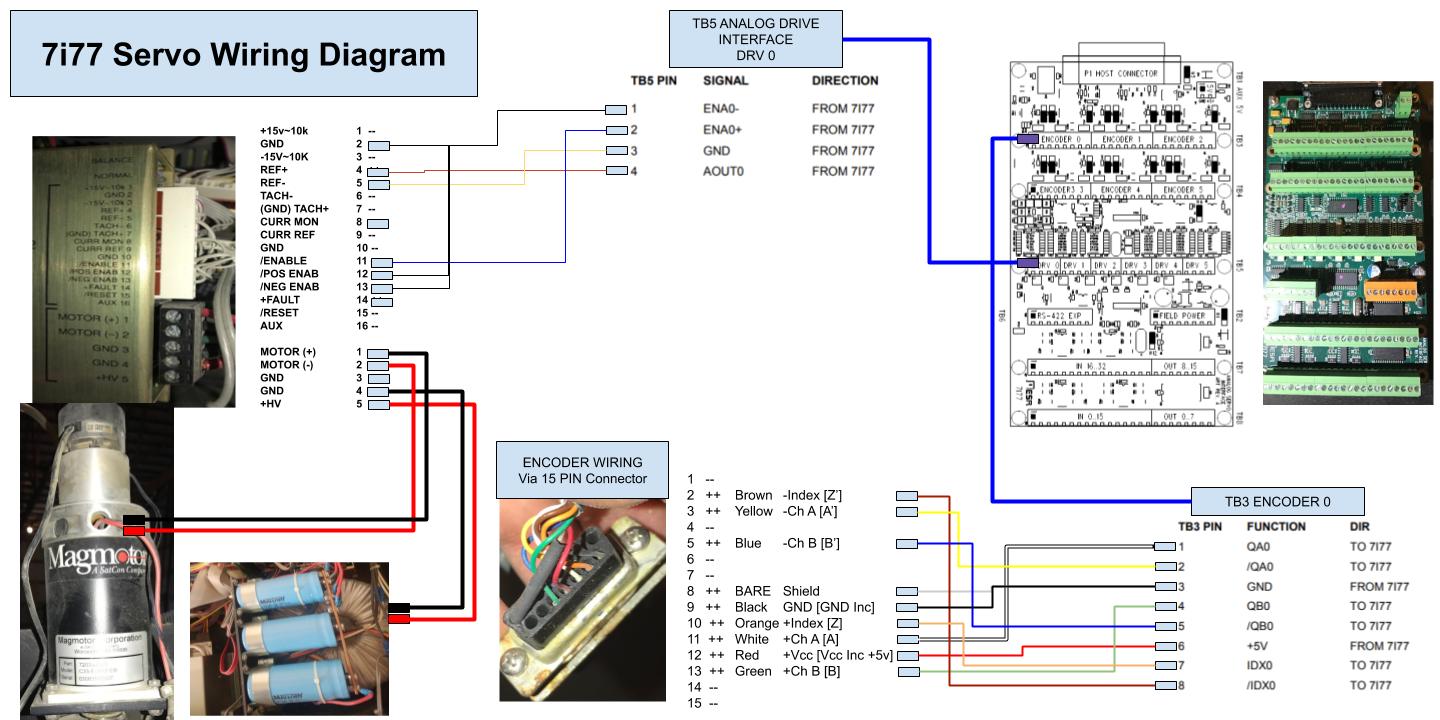

This is what I had for wiring my motors,

Which motor(s) are you using?

Magmotor was nice for sending me wiring info. I am thinking about buying a replacement MAGMOTOR for my X axis. They are $625 from them, but there was a pretty long wait, like 6-8weeks. wefixprecix has a direct replacement motor/encoder for $550 which is tested on a precix. Seems like you can get a servo nema34 motor and driver with slightly more torque for around $200 off amazon/ebay.

From my recent experience cleaning my servo motor, I found the encoder positioning on shaft is critical.

The guys here are experts, but if you ever want any info on how I got my machine working I can show you what I did (right or wrong)

When you do get your machine up and running, share your HAL/INI files, interested in seeing how they compare to mine.

This is what I had for wiring my motors,

Which motor(s) are you using?

Magmotor was nice for sending me wiring info. I am thinking about buying a replacement MAGMOTOR for my X axis. They are $625 from them, but there was a pretty long wait, like 6-8weeks. wefixprecix has a direct replacement motor/encoder for $550 which is tested on a precix. Seems like you can get a servo nema34 motor and driver with slightly more torque for around $200 off amazon/ebay.

From my recent experience cleaning my servo motor, I found the encoder positioning on shaft is critical.

The guys here are experts, but if you ever want any info on how I got my machine working I can show you what I did (right or wrong)

When you do get your machine up and running, share your HAL/INI files, interested in seeing how they compare to mine.

Attachments:

Last edit: 15 Mar 2021 11:42 by randypetersen.

Please Log in or Create an account to join the conversation.

- GJTuck

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

16 Mar 2021 03:09 #202442

by GJTuck

Replied by GJTuck on topic Retrofit of Precix 5x10 CNC

The motor is a Dynetic Motor. I am working on getting a quote from Magmotor but they want torque/speed and encoder resolution. Can anyone help me with these three questions? Sorry I’m new to this I got this machine from my Grandpa. I would not recommend wefixprecix unless you have to go that route. They sold me the motor replacement for $550 and then the wires weren’t even lined up and no info on the motor. When I requested specs on the motor his reply was it’s a “standard replacement”, that’s it. Currently working with PayPal to try and get my money back. When I told him it didnt work and I was asking for a refund he got very angry and swore at me. Also told me I couldn’t have my refund and I wouldn’t win the PayPal dispute. I asked him to help me figure out what was up after it wouldn’t work and he said I needed to pay him 200 dollars a hour for diagnostics. I guess I figured after spending 550 there was included service. Like Magmotor sent you that wiring diagram for free 20 years later. This is all after he told me it was probably a $300 amplifier that I ordered and Didn’t fix it but at least I have a spare. Also after a week and half of not receiving the motor I called him and asked where it was and he said he had to order some more encoders. I didn’t even know what a encoder was when I called him a month ago. Very frustrated to say the least. Unfortunately they have you over a barrel when your machine is obsolete. Anyways torque, speed and encoder resolution for a 5x10 table. Also the old motor works when I connect it to dc, is there some way I have to line up the old encoder to put it back together? I took the cap off and blew it out with air thinking dust may have got in there just making sure I can’t get that one to work again. Thanks again for all the help. Also that wiring diagram is really helpful.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

16 Mar 2021 19:03 #202499

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Sorry to hear that GJTuck,

I am considering buying from wefixprecix just because he'd be providing a direct replacement for a precix router that would be plug and play. Being a seller on paypal, we often lose the dispute, even if we can provide proof of delivery. We have even lost a dispute when the customer realized he made a mistake and contacted paypal saying they did indeed get the package. Hopefully he will help you get things up and running, or take the motor back.

Magmotor was great to work with, and their offer of selling me an exact same model for $625 was more than fair. Great people from my experience.

I had to rewire my encoder, how do you have things connected to a MESA product? These guys on this forum are really intelligent people, but if we don't do our part and layout exactly the problem then they can't do much to help. I have to run now, but I will re-read your post and it seems that the problem followed your cabling right? So it's not a motor problem? When you changed the motor, did you change your encoder as well?

This machine is my first servo machine, using stepper motors on previous machines was easier for me to wrap my head around.

I am considering buying from wefixprecix just because he'd be providing a direct replacement for a precix router that would be plug and play. Being a seller on paypal, we often lose the dispute, even if we can provide proof of delivery. We have even lost a dispute when the customer realized he made a mistake and contacted paypal saying they did indeed get the package. Hopefully he will help you get things up and running, or take the motor back.

Magmotor was great to work with, and their offer of selling me an exact same model for $625 was more than fair. Great people from my experience.

I had to rewire my encoder, how do you have things connected to a MESA product? These guys on this forum are really intelligent people, but if we don't do our part and layout exactly the problem then they can't do much to help. I have to run now, but I will re-read your post and it seems that the problem followed your cabling right? So it's not a motor problem? When you changed the motor, did you change your encoder as well?

This machine is my first servo machine, using stepper motors on previous machines was easier for me to wrap my head around.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

16 Mar 2021 22:36 #202534

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

So I am sure you now know that the encoder signals back to the controller the rotation/speed of the motor.

So without powering or homing your machine, you should be able to see if the encoder is functioning and connected. If you manually move your X axis and your Y values change on your Digital Read Out then you know something isn't correct. I spent a lot of time working on the machine, before even powering up the motors, to make sure my encoders were working properly and I had the settings correct.

Are you using LinuxCNC or just the software that came with it?

There is a lot to learn, since I haven't even scratched the surface, but it's rewarding experience.

So without powering or homing your machine, you should be able to see if the encoder is functioning and connected. If you manually move your X axis and your Y values change on your Digital Read Out then you know something isn't correct. I spent a lot of time working on the machine, before even powering up the motors, to make sure my encoders were working properly and I had the settings correct.

Are you using LinuxCNC or just the software that came with it?

There is a lot to learn, since I haven't even scratched the surface, but it's rewarding experience.

Please Log in or Create an account to join the conversation.

- randypetersen

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 15

08 Apr 2021 14:24 - 08 Apr 2021 18:42 #205325

by randypetersen

Replied by randypetersen on topic Retrofit of Precix 5x10 CNC

Generic Motor Amplifier / Voltage question.

I am talking with MagMotor about replacing the Astromec motor I have with a MagMotor and new encoder.

This is what they recommended: 500280454 (model S28-F2-300FX) motor and 290000203 encoder. ($494.00 + $227.00 = $721.00)

Only thing that has me a bit worried, I know my power supply is 48v (meter says 51v) and the motor is 24V. I am guessing that the servo amplifier takes 48V and only applies a certain amount of voltage to each motor? They tell me the other servo motors (Magmotor C33-E-300FEB and C33-E-300FE) are 24V although I am not sure.

I have 3 servo amplifiers -

2 Copley 800-760 connected to the magmotors and

1 AMC connected to this Astromec motor that i'd like to switch to the new MagMotor.

You guys told me they were "standard analog drives" so I am thinking I can continue to use the AMC to drive the new MagMotor.

Just wanted to ask you experts if that makes sense and I won't fry my new $721 motor.

Also, wanted to share my research to anyone who is updating a machine like this.

**UPDATE - MagMotor got back with me and explained that these motors will operate at 24volts as well as 48volts. So my concern was unwarranted. Still concerned about the odd amplifier, but I am thinking it should work ok.

Thanks,

Randy

I am talking with MagMotor about replacing the Astromec motor I have with a MagMotor and new encoder.

This is what they recommended: 500280454 (model S28-F2-300FX) motor and 290000203 encoder. ($494.00 + $227.00 = $721.00)

Only thing that has me a bit worried, I know my power supply is 48v (meter says 51v) and the motor is 24V. I am guessing that the servo amplifier takes 48V and only applies a certain amount of voltage to each motor? They tell me the other servo motors (Magmotor C33-E-300FEB and C33-E-300FE) are 24V although I am not sure.

I have 3 servo amplifiers -

2 Copley 800-760 connected to the magmotors and

1 AMC connected to this Astromec motor that i'd like to switch to the new MagMotor.

You guys told me they were "standard analog drives" so I am thinking I can continue to use the AMC to drive the new MagMotor.

Just wanted to ask you experts if that makes sense and I won't fry my new $721 motor.

Also, wanted to share my research to anyone who is updating a machine like this.

**UPDATE - MagMotor got back with me and explained that these motors will operate at 24volts as well as 48volts. So my concern was unwarranted. Still concerned about the odd amplifier, but I am thinking it should work ok.

Thanks,

Randy

Last edit: 08 Apr 2021 18:42 by randypetersen.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.322 seconds