Double or Triple Rotarydeltakins on Ethercat

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

30 Oct 2020 14:01 #187794

by Grotius

Replied by Grotius on topic Double or Triple Rotarydeltakins on Ethercat

Hi,

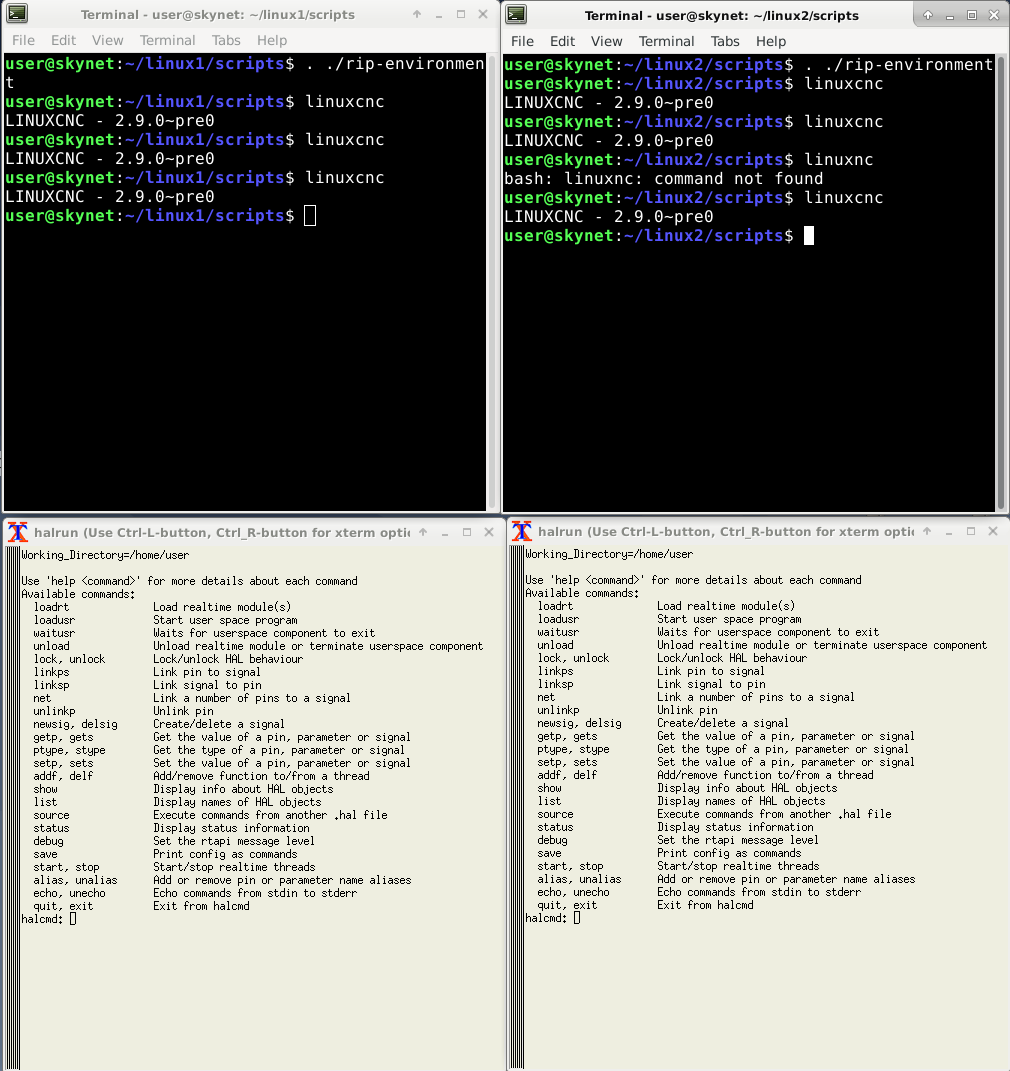

I have done some short tests.

Setup : Did a double lcnc rip install. One rip started gmocappy, the other rip started gscreen.

Found :

- If lcnc starts there it places a lock file in /tmp/. This file is no problem. Can be erased from the source code.

- The shared memory want's to get the same adress, libnml tcp.src.cc line 280, line 281 has some problems.

- Motdot has some problems, if you comment out this at the second startup it looks a little better.

- Emcio also some problems.

Then i started something more simple. The halrun demo program.

Starting the first, and then starting the second, will terminate the first, here the solution is quite easy :

File : halrun.demo, decomment line 52.

** Result is running 2 linuxcnc programs the same time.

When i run my qtc++ program that is connected to lcnc hal and connected to ethercat i can connect as many qt apps as i want to hal.

That's because my app does not check if there is already something running. And if i use shared memory i use fixed memory names, so no interference.

Your interpolation is quite easy i see in the kins source file. With halcommand sending motor positions is easy.

Is your robot working with vision pick coordinate's and you send the coordinates trough gcode to the robot?

I have done some short tests.

Setup : Did a double lcnc rip install. One rip started gmocappy, the other rip started gscreen.

Found :

- If lcnc starts there it places a lock file in /tmp/. This file is no problem. Can be erased from the source code.

- The shared memory want's to get the same adress, libnml tcp.src.cc line 280, line 281 has some problems.

- Motdot has some problems, if you comment out this at the second startup it looks a little better.

- Emcio also some problems.

Then i started something more simple. The halrun demo program.

Starting the first, and then starting the second, will terminate the first, here the solution is quite easy :

File : halrun.demo, decomment line 52.

** Result is running 2 linuxcnc programs the same time.

When i run my qtc++ program that is connected to lcnc hal and connected to ethercat i can connect as many qt apps as i want to hal.

That's because my app does not check if there is already something running. And if i use shared memory i use fixed memory names, so no interference.

Your interpolation is quite easy i see in the kins source file. With halcommand sending motor positions is easy.

Is your robot working with vision pick coordinate's and you send the coordinates trough gcode to the robot?

Attachments:

Please Log in or Create an account to join the conversation.

- TheRoslyak

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 37

30 Oct 2020 14:57 - 30 Oct 2020 15:02 #187795

by TheRoslyak

Replied by TheRoslyak on topic Double or Triple Rotarydeltakins on Ethercat

g-code

For example

We send to 192.168.0.1 g1 X100 Y100 F100

to 192.168.0.2 g1 X200 Y200 F200

by linuxcncrsh

It's now!!!

I think With new kinematic. We send to 192.168.0.1 g1 X100 Y100 A200 B200 F100 (Feed may by same)

For example

We send to 192.168.0.1 g1 X100 Y100 F100

to 192.168.0.2 g1 X200 Y200 F200

by linuxcncrsh

It's now!!!

I think With new kinematic. We send to 192.168.0.1 g1 X100 Y100 A200 B200 F100 (Feed may by same)

Last edit: 30 Oct 2020 15:02 by TheRoslyak.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

30 Oct 2020 19:02 #187817

by Grotius

Replied by Grotius on topic Double or Triple Rotarydeltakins on Ethercat

Tommorow i will look into the current kinematics file if expanding to a total of 3x output is a easy step to do.

Have a good night ! Cheers.

Have a good night ! Cheers.

Please Log in or Create an account to join the conversation.

- TheRoslyak

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 37

30 Oct 2020 22:21 #187845

by TheRoslyak

Replied by TheRoslyak on topic Double or Triple Rotarydeltakins on Ethercat

Thank you so much

If it's easier you can start with a double. this option is also useful.

It is also worth considering the moment that the rotation of the coordinate system is used (G10 L2 P1 R30). It may not be necessary to use this command. And just write it into the variable table for XYZ and ABC.

If it's easier you can start with a double. this option is also useful.

It is also worth considering the moment that the rotation of the coordinate system is used (G10 L2 P1 R30). It may not be necessary to use this command. And just write it into the variable table for XYZ and ABC.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

31 Oct 2020 08:57 #187873

by Mike_Eitel

Replied by Mike_Eitel on topic Double or Triple Rotarydeltakins on Ethercat

One question also ivm convinced that you know what you are doing.

Why not using a cheepo rpi4 for every delta. Having thereon macros to trigger like

Go to pos xyz, lift and trow at position, go to start point.

And use a pc for sending thos submodules only the parameters for the macros. U could easily augment the numbers of deltas too.

Mike

Why not using a cheepo rpi4 for every delta. Having thereon macros to trigger like

Go to pos xyz, lift and trow at position, go to start point.

And use a pc for sending thos submodules only the parameters for the macros. U could easily augment the numbers of deltas too.

Mike

Please Log in or Create an account to join the conversation.

- TheRoslyak

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 37

31 Oct 2020 09:48 - 31 Oct 2020 09:49 #187878

by TheRoslyak

Replied by TheRoslyak on topic Double or Triple Rotarydeltakins on Ethercat

Let me explain. This is not a garage project. There is no task here to collect a cheap product. These robots work 24/7 365 days non-stop.

It's all the same what to do spaceships base on Arduino.

It's all the same what to do spaceships base on Arduino.

Last edit: 31 Oct 2020 09:49 by TheRoslyak.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

31 Oct 2020 10:07 #187879

by Mike_Eitel

Replied by Mike_Eitel on topic Double or Triple Rotarydeltakins on Ethercat

Maybe i missexpressed.

Also, or especially, if we talk bussines, I'm a huge fan of modularity.

I would like to understand why do you wan't to have a one controller solution.

Also, or especially, if we talk bussines, I'm a huge fan of modularity.

I would like to understand why do you wan't to have a one controller solution.

Please Log in or Create an account to join the conversation.

- TheRoslyak

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 37

31 Oct 2020 10:31 #187882

by TheRoslyak

Replied by TheRoslyak on topic Double or Triple Rotarydeltakins on Ethercat

I don't quite understand what you said. I also want to use one controller for 2/3 robots. If you mean the main computer, then it performs mathematical calculations using tensorflow

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

31 Oct 2020 10:59 #187886

by Mike_Eitel

Replied by Mike_Eitel on topic Double or Triple Rotarydeltakins on Ethercat

Yes i see a 1 to n modular solution.

Seeing your picture i guess you wan't to have some kind of sorting mecanism.

I see optical (part recognition) and 3x handling (delta arms). In my opinion your deltas have a clear duty: grab parts on positions given from the vision controlled "master". You have that "grapping" three times.

I would judge such a delta as an autonomous module. I would give such a "slave" his own controller. And i think rpi4 are nowadays good with lcnc for such a duty.

So on a glance i see one pc plus 3x rpi4 as mcu's. I even could give that job to two different engineers.

That's my thinking. And i just wonder why you wan't to have all in one.

Mike

Seeing your picture i guess you wan't to have some kind of sorting mecanism.

I see optical (part recognition) and 3x handling (delta arms). In my opinion your deltas have a clear duty: grab parts on positions given from the vision controlled "master". You have that "grapping" three times.

I would judge such a delta as an autonomous module. I would give such a "slave" his own controller. And i think rpi4 are nowadays good with lcnc for such a duty.

So on a glance i see one pc plus 3x rpi4 as mcu's. I even could give that job to two different engineers.

That's my thinking. And i just wonder why you wan't to have all in one.

Mike

Please Log in or Create an account to join the conversation.

- TheRoslyak

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 37

31 Oct 2020 11:20 - 31 Oct 2020 11:21 #187888

by TheRoslyak

Replied by TheRoslyak on topic Double or Triple Rotarydeltakins on Ethercat

I'm going to make such a system on NVIDIA Jetson AGX (with my own motherboard) + Codesys. But this is already the next stage.

Last edit: 31 Oct 2020 11:21 by TheRoslyak.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.091 seconds