Probe Interface Board Design (resistance switching)

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

11 Jan 2024 10:30 - 11 Jan 2024 10:33 #290415

by fletch

Probe Interface Board Design (resistance switching) was created by fletch

Hi

My 2023 'Christmas project' is a probe interface board that measures the resistance of the probe contacts. It will provide a PNP NC or NO signal to the CNC, red & green LED outputs and a buzzer output. This is an earlier version that didn't do the resistance measuring: www.youtube.com/shorts/Yk2ZmRjruxY

The resistance measuring means the CNC signal fires on initial touch rather than waiting for the contacts to fully open. It also cuts power to the contacts before they are fully open to mitigate any risk of arcing.

The design is built around my ebay bargain 21 year old Renishaw TP6 but that is a test group of one... so if any one is interested in this project, please let me know and/or if you have a probe I could borrow to increase the test group to two (it would not be used in the mill, only on the bench) please let me know! I'm based in the UK.

This is a oscilloscope trace of what happens when the probe is triggered (yellow is the voltage applied to the contacts):

I've posted this under 'Driver Boards' but not sure that's the right place (it is a driver board for a probe?) so please feel free to move it somewhere more appropriate. Also, any thoughts on sharing this to other hobby CNC forums?

Philip

My 2023 'Christmas project' is a probe interface board that measures the resistance of the probe contacts. It will provide a PNP NC or NO signal to the CNC, red & green LED outputs and a buzzer output. This is an earlier version that didn't do the resistance measuring: www.youtube.com/shorts/Yk2ZmRjruxY

The resistance measuring means the CNC signal fires on initial touch rather than waiting for the contacts to fully open. It also cuts power to the contacts before they are fully open to mitigate any risk of arcing.

The design is built around my ebay bargain 21 year old Renishaw TP6 but that is a test group of one... so if any one is interested in this project, please let me know and/or if you have a probe I could borrow to increase the test group to two (it would not be used in the mill, only on the bench) please let me know! I'm based in the UK.

This is a oscilloscope trace of what happens when the probe is triggered (yellow is the voltage applied to the contacts):

I've posted this under 'Driver Boards' but not sure that's the right place (it is a driver board for a probe?) so please feel free to move it somewhere more appropriate. Also, any thoughts on sharing this to other hobby CNC forums?

Philip

Attachments:

Last edit: 11 Jan 2024 10:33 by fletch. Reason: Dyslexic fingers

The following user(s) said Thank You: Mecanix

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

Less

More

- Posts: 447

- Thank you received: 227

11 Jan 2024 16:24 #290432

by Mecanix

Replied by Mecanix on topic Probe Interface Board Design (resistance switching)

Another significant advantage to resistance over bouncing switches is noise immunity, and ofc improved latency of which Lcnc could certainly do with. Not uncommon for a switching-probe (with debounce applied) to calibrate as much as with >0.05mm error with Lcnc. Hopefully yours can cut this by half or more.

Keep us informed of your dev. Thumbs up on the oscope trace.

Keep us informed of your dev. Thumbs up on the oscope trace.

The following user(s) said Thank You: fletch

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

Less

More

- Posts: 447

- Thank you received: 227

11 Jan 2024 16:36 - 11 Jan 2024 16:44 #290435

by Mecanix

Any chance of gutting the rennishaw and/or your retrofit? Bet some of us would fancy seeing the sort of engineering that went into this (opamps/comparators, resistors type/values, etc etc)

Replied by Mecanix on topic Probe Interface Board Design (resistance switching)

No. This should remain as a privileged and proprietary resource of Linuxcnc only, its forum and community, by rule listed in the Terms & Conditions of which I've illegally just made up. Although the folks at practicalmachinist dot com could probably endure and benefit from your expertise, since you're asking.Also, any thoughts on sharing this to other hobby CNC forums?

Any chance of gutting the rennishaw and/or your retrofit? Bet some of us would fancy seeing the sort of engineering that went into this (opamps/comparators, resistors type/values, etc etc)

Last edit: 11 Jan 2024 16:44 by Mecanix.

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

11 Jan 2024 19:45 #290450

by fletch

Hopefully I won't be dismantling my Renishaw unless it starts playing up (more) but the schematic (and probably din rail mounts) will be made available in a repository.

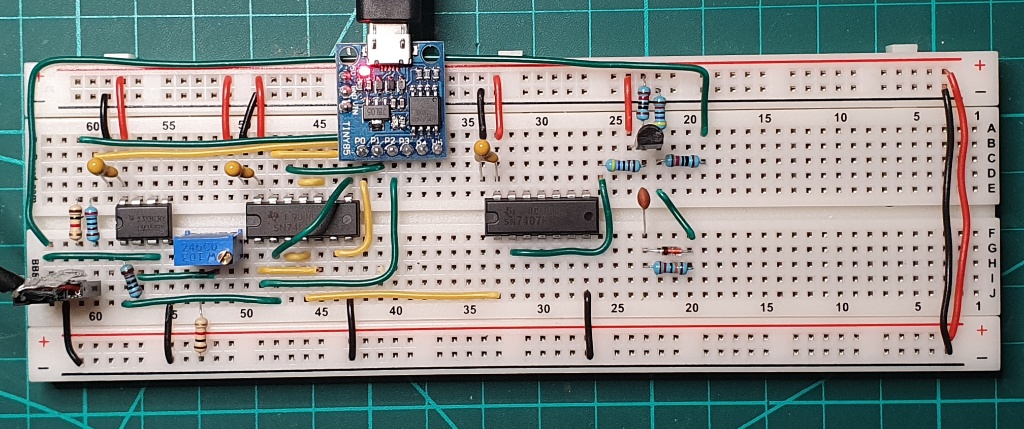

This is today's breadboard that implements the current schematic, from left to right: op-amp (but not using the second half as a comparator because it is too slow), a 74LS02 operating as a latch, an ATTiny85, a SN7407 (who knew you needed one of them?) and a PNP to switch the probe contacts off/on with (just below it) an asyncronous Miller integrator (and that bit was waaay above my pay grade ... thanks Zapper!).

And hopefully enough space to fit the CNC signal bit, the (24v to 5v) voltage regulator bit and the buzzer bit.

Philip

Replied by fletch on topic Probe Interface Board Design (resistance switching)

Absolutely, this will remain proprietary LinuxCNC confidential IP, shared (later) only on github under an open source licence...

Also, any thoughts on sharing this to other hobby CNC forums?

No. This should remain as a privileged and proprietary resource of Linuxcnc only, its forum and community, by rule listed in the Terms & Conditions of which I've illegally just made up. Although the folks at practicalmachinist dot com could probably endure and benefit from your expertise, since you're asking.

Any chance of gutting the rennishaw and/or your retrofit? Bet some of us would fancy seeing the sort of engineering that went into this (opamps/comparators, resistors type/values, etc etc)

Hopefully I won't be dismantling my Renishaw unless it starts playing up (more) but the schematic (and probably din rail mounts) will be made available in a repository.

This is today's breadboard that implements the current schematic, from left to right: op-amp (but not using the second half as a comparator because it is too slow), a 74LS02 operating as a latch, an ATTiny85, a SN7407 (who knew you needed one of them?) and a PNP to switch the probe contacts off/on with (just below it) an asyncronous Miller integrator (and that bit was waaay above my pay grade ... thanks Zapper!).

And hopefully enough space to fit the CNC signal bit, the (24v to 5v) voltage regulator bit and the buzzer bit.

Philip

Attachments:

The following user(s) said Thank You: tommylight, Mecanix

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

Less

More

- Posts: 447

- Thank you received: 227

11 Jan 2024 21:11 - 11 Jan 2024 21:12 #290455

by Mecanix

Replied by Mecanix on topic Probe Interface Board Design (resistance switching)

Clever. I like that circuit, quite inspiring. I'm one of those who makes his own personal 3d probes so please update us, I might honor your design! Never owned a renishaw (or any precision-grade), I'm one of those who perceives that tool as a "consumable" you see! (I'd never forgive myself for smashing one out of spec or worst, seeing a whole unit to hell. And so affordable probing it goes...)

Last one I did was 3 or 4 years ago. Tiny Mini Small Form Factor (26mmOD), using the pcb for ball mounts and switching. Using it with Lcnc nowadays, w/ 3 spares in the drawer for crappy days.

Last one I did was 3 or 4 years ago. Tiny Mini Small Form Factor (26mmOD), using the pcb for ball mounts and switching. Using it with Lcnc nowadays, w/ 3 spares in the drawer for crappy days.

Last edit: 11 Jan 2024 21:12 by Mecanix.

The following user(s) said Thank You: fletch

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

11 Jan 2024 21:27 #290456

by fletch

Replied by fletch on topic Probe Interface Board Design (resistance switching)

Nice! Is the design published any where? Crashing the probe is one of my biggest concerns - I once crashed three 6mm end mills in less than 10 minutes - all for different lessons that I have hopefully now learnt. Would be interesting to test the oscilloscope traces on your contacts - I have often wondered if the Renishaw (and other OEMs) are 'special' in terms of resistance or if there is a semi-conductive 'grease' in there.

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

Less

More

- Posts: 447

- Thank you received: 227

11 Jan 2024 21:46 - 11 Jan 2024 22:07 #290458

by Mecanix

Replied by Mecanix on topic Probe Interface Board Design (resistance switching)

Unpublished however I'm more than happy to get in touch and send it over, no commercial affection whatsoever attached, just a dumb (but essential) tool. Mind you there isn't any space-tech to it, easy to replicate on a cloudy sunday afternoon (see visuals).

I'm all-in for trying your circuit when you feel it's ready though (oscope to share for sure). ps. screw renishaw and their secret magic... diy +/-0.01mm is enough!

edit; added a few visuals, you'll get the idea. Fun weekend cad...

I'm all-in for trying your circuit when you feel it's ready though (oscope to share for sure). ps. screw renishaw and their secret magic... diy +/-0.01mm is enough!

edit; added a few visuals, you'll get the idea. Fun weekend cad...

Last edit: 11 Jan 2024 22:07 by Mecanix.

The following user(s) said Thank You: pommen, besriworld, fletch

Please Log in or Create an account to join the conversation.

- fletch

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 139

- Thank you received: 70

11 Jan 2024 21:58 #290460

by fletch

Replied by fletch on topic Probe Interface Board Design (resistance switching)

That's a very clean design! Not sure how DMs work here but my email is on the github page.

The frustrating thing about the Renishaw (and other OEM) probe interfaces is they are still £££ second hand (and ££££ new) but based on last century tech!

The frustrating thing about the Renishaw (and other OEM) probe interfaces is they are still £££ second hand (and ££££ new) but based on last century tech!

The following user(s) said Thank You: Mecanix

Please Log in or Create an account to join the conversation.

- Mecanix

- Offline

- Platinum Member

-

Less

More

- Posts: 447

- Thank you received: 227

11 Jan 2024 22:37 - 11 Jan 2024 22:45 #290463

by Mecanix

Replied by Mecanix on topic Probe Interface Board Design (resistance switching)

I've STEP the entire assembly for you (proprietary LinuxCNC confidential IP and all lol). You should be able to unpack that lot using any half-decent CAD. If that doesn't work, let me know and I'll find another way.

Good luck with your project in a meantime, looking forward. Github bookmarked - Thanks for the link up, Philip (subscribed)

Good luck with your project in a meantime, looking forward. Github bookmarked - Thanks for the link up, Philip (subscribed)

Last edit: 11 Jan 2024 22:45 by Mecanix.

The following user(s) said Thank You: fletch

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

12 Jan 2024 01:18 #290465

by jmelson

Replied by jmelson on topic Probe Interface Board Design (resistance switching)

Well, totally unrelated, but I got a Blum TC50 3-axis probe on eBay a couple years ago. This is a battery-powered probe that uses bidirectional IR to communicate.

IR pulses from the CNC control turn the probe on and off, and the probe sends low-battery, probe deflected and first time the probe has been deflected. It sends immediately when the probe changes state and then at 50 Hz when there is no change. I built a controller to communicate with the probe using an FPGA and some IR interface chips. It works great, I have made up a bunch of G-code routines to find all corners and edges of parts, and also the center of holes. I created the hal code to show probe status, and also put the machine in feed hold if the IR communication fails (like obstruction in the IR path).

Jon

IR pulses from the CNC control turn the probe on and off, and the probe sends low-battery, probe deflected and first time the probe has been deflected. It sends immediately when the probe changes state and then at 50 Hz when there is no change. I built a controller to communicate with the probe using an FPGA and some IR interface chips. It works great, I have made up a bunch of G-code routines to find all corners and edges of parts, and also the center of holes. I created the hal code to show probe status, and also put the machine in feed hold if the IR communication fails (like obstruction in the IR path).

Jon

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.269 seconds