Retrofit Gloria Europa 2/40 machining centre

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

21 Feb 2016 17:23 #70446

by PCW

Replied by PCW on topic Retrofit Gloria Europa 2/40 machining centre

That would use standard 7I77+7i76 firmware

The following user(s) said Thank You: backtime

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

22 Feb 2016 14:21 #70480

by andypugh

No, that will work with a stock firmware, there is one for 5i25 (the 6i25 uses 5i25 firmware) and 7i76 + 7i77. The 7i84 will be auto-detected.

You will need one of these: www.amazon.co.uk/StarTech-Profile-Bracke...parallel+port+header (or similar) to connect to the second header.

Replied by andypugh on topic Retrofit Gloria Europa 2/40 machining centre

So here we go, the boards are a 6i25 + 7i76 + 7i77 + 7i84. With this i can put my machine on service.

Now i have a question, for this combination i need a custom firmware?

No, that will work with a stock firmware, there is one for 5i25 (the 6i25 uses 5i25 firmware) and 7i76 + 7i77. The 7i84 will be auto-detected.

You will need one of these: www.amazon.co.uk/StarTech-Profile-Bracke...parallel+port+header (or similar) to connect to the second header.

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

22 Feb 2016 15:44 #70484

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Yes, even PCW had confirmed to me that the stock firmware is suitable and we already have the IDC-26 adapter, now we wait for the cards to arrive.

Thanks to everyone.

Thanks to everyone.

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

30 May 2016 16:19 #75249

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

I finally have the time to continue with the work of retrofit and I would need some information.

I bought a mini-ITX Asus H170I PLUS-D3 motherboard, very nice board, i have disabled all power

management features and audio and left enabled ethernet, integrated wifi and onboard GPU, stock

linuxcnc 2.7 is installed on SSD.

Now with this configuration and isolcpus=1 on linux command line i have very good jitter:

servo thread max jitter: 8230

base thread max jitter: 7892

even if the overall performance is not so good under heavy load.

With same configuration but without isolcpus command line option i have this jitter values:

servo thread max jitter: 24000

base thread max jitter: 28550

and the overall performance is very good

This last values are too hight for software stepper but i use mesa cards for step generation and encoder count,

so are the last values suitable for mesa or i have to go with isolcpus?

Thanks for replies.

I bought a mini-ITX Asus H170I PLUS-D3 motherboard, very nice board, i have disabled all power

management features and audio and left enabled ethernet, integrated wifi and onboard GPU, stock

linuxcnc 2.7 is installed on SSD.

Now with this configuration and isolcpus=1 on linux command line i have very good jitter:

servo thread max jitter: 8230

base thread max jitter: 7892

even if the overall performance is not so good under heavy load.

With same configuration but without isolcpus command line option i have this jitter values:

servo thread max jitter: 24000

base thread max jitter: 28550

and the overall performance is very good

This last values are too hight for software stepper but i use mesa cards for step generation and encoder count,

so are the last values suitable for mesa or i have to go with isolcpus?

Thanks for replies.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17577

- Thank you received: 5141

30 May 2016 17:00 #75252

by PCW

Replied by PCW on topic Retrofit Gloria Europa 2/40 machining centre

As a rough rule for mesa systems at 1 KHz servo thread:

50000 ns latency is OK for the standard position mode stepgen

100000 ns latency is OK if the PID stepgen setup is used in HAL

500000 ns latency is OK if a firmware with DPLL + PID stepgen are used

So I would definitely _NOT_ use isolcpus, it will do nothing but make the system slower

50000 ns latency is OK for the standard position mode stepgen

100000 ns latency is OK if the PID stepgen setup is used in HAL

500000 ns latency is OK if a firmware with DPLL + PID stepgen are used

So I would definitely _NOT_ use isolcpus, it will do nothing but make the system slower

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

30 May 2016 17:11 #75254

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Thank you for fast response PCW, i'll go without isolcpus.

Please Log in or Create an account to join the conversation.

- aventtini

-

- Visitor

-

11 Jun 2016 11:22 #75813

by aventtini

Replied by aventtini on topic Retrofit Gloria Europa 2/40 machining centre

hello see my topick you have the configuration on 6i25 and 7i77 if you want . THe bosch drives work perfect with mesa

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

11 Jun 2016 16:27 #75824

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Which topic? I can not see any link. However the bosh original drives have been replaced.

Please Log in or Create an account to join the conversation.

- aventtini

-

- Visitor

-

11 Jun 2016 16:32 #75825

by aventtini

Replied by aventtini on topic Retrofit Gloria Europa 2/40 machining centre

forum.linuxcnc.org/forum/38-general-linu...etrofit?limitstart=0

Its a good machine for aluminium and steel drilling . Make it a liniar scales you will get a perfect machine on this . if you want the panel with buttons i still have it . If you want the machanical schematics i can give you.

Its a good machine for aluminium and steel drilling . Make it a liniar scales you will get a perfect machine on this . if you want the panel with buttons i still have it . If you want the machanical schematics i can give you.

Please Log in or Create an account to join the conversation.

- backtime

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 0

11 Jun 2016 18:10 #75829

by backtime

Replied by backtime on topic Retrofit Gloria Europa 2/40 machining centre

Ah I see, the same as our machine, you did a great job, congratulations, I hope to operate our in the coming days and start doing some work.

Thanks for the info, the machine is in our workshop for many years and has always worked well. We decided to retrofit because the CC100 had failed and taking advantage of an offer I replaced drives, eliminated the high voltage power supplies and simplified scheme.

In the workshop we have the complete electrical and mechanical schemes, but by now the electrical system has been completely redone.

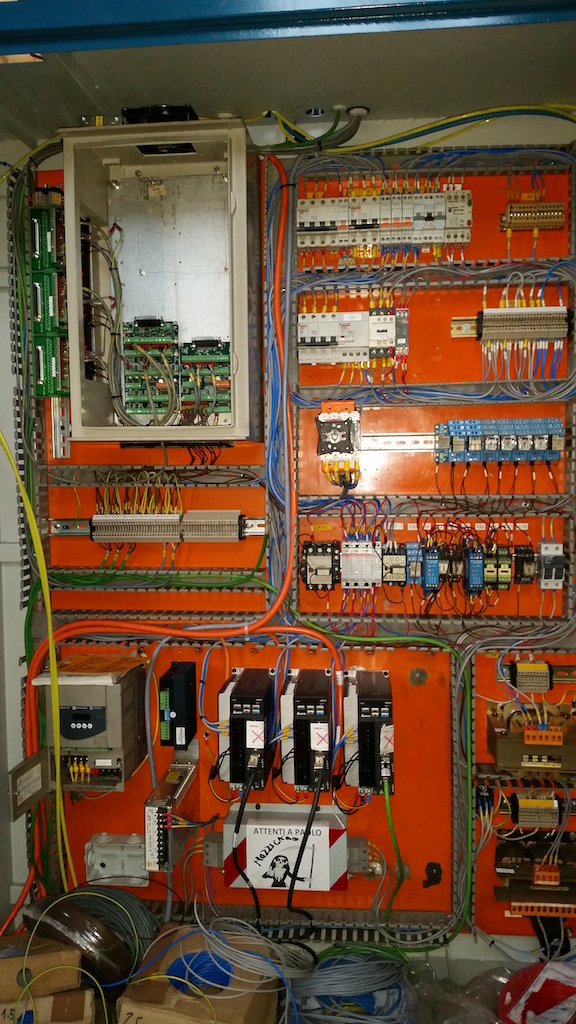

This is the cabinet today.

Thanks for the info, the machine is in our workshop for many years and has always worked well. We decided to retrofit because the CC100 had failed and taking advantage of an offer I replaced drives, eliminated the high voltage power supplies and simplified scheme.

In the workshop we have the complete electrical and mechanical schemes, but by now the electrical system has been completely redone.

This is the cabinet today.

Please Log in or Create an account to join the conversation.

Time to create page: 0.186 seconds