Retrofiting Scm record 220

- jfrahm3310

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

31 Aug 2020 23:08 #180242

by jfrahm3310

Replied by jfrahm3310 on topic Retrofiting Scm record 220

So on a different note this has a stepper drive and motor for the umbrella tool changer and the input is serial, it is an ever electronica drive scm01-09. So wondering if anybody as dealt with this. The manual talks about writing and compiling programs for it in dos.maybe there is some long lost hal file somewhere.?

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

02 Sep 2020 16:59 #180447

by Todd Zuercher

Replied by Todd Zuercher on topic Retrofiting Scm record 220

I don't know. Our SCM machine's stepper drive for the tool changer is from RTA Motion Systems, and is controlled by 3 signals from the control, a direction signal, a start signal, and a stop signal (step pulses are generated internally.) The stop signal is a combination of a couple outputs from the control, some proximity sensors and (I think) the e-stop button. But there is no serial connection used.

Please Log in or Create an account to join the conversation.

- jfrahm3310

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

04 Sep 2020 20:37 #180750

by jfrahm3310

Replied by jfrahm3310 on topic Retrofiting Scm record 220

I have this idea about hacking into the drive between the logic side and the isolation to main transistor's and run off a mesa card and hal. Has anybody tried something like that. I have a fanuc robot project that would benefit from this also.

Please Log in or Create an account to join the conversation.

- anthony@breakwood.co.za

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

09 May 2022 15:27 #242385

by anthony@breakwood.co.za

Replied by anthony@breakwood.co.za on topic Retrofiting Scm record 220

Hi....I am new to this forum. I have a faulty NUM controller card for the SCM Record 220. I can get a service exchange card from NUM for about $1500. Seems a lot. Is there any other option? We believe the problem is the card because when we replaced the card with one from another machine, it worked. The part number is 0204204478

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

09 May 2022 17:36 #242397

by Todd Zuercher

Replied by Todd Zuercher on topic Retrofiting Scm record 220

While we do have an older SCM CNC machine here (and it is still running it's original control.) I am far from familiar enough with them to be able to tell you what your bad part even is just from the part number. What does the part do, what does it look like?

Also even though this thread was about helping someone retrofitting a Record 220 like yours, doesn't necessarily mean that it was the same or used the same control hardware. SCM made these machines over a long time period and offered many different options and fitted different controls over the years.

Also even though this thread was about helping someone retrofitting a Record 220 like yours, doesn't necessarily mean that it was the same or used the same control hardware. SCM made these machines over a long time period and offered many different options and fitted different controls over the years.

The following user(s) said Thank You: anthony@breakwood.co.za

Please Log in or Create an account to join the conversation.

- C0bra

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

08 Oct 2024 00:09 #311535

by C0bra

Replied by C0bra on topic Retrofiting Scm record 220

Hi there,

I recently bought very cheap record 220, but in non working condition since battery is dead in num 1040 controller.

Already have replacement BOB but now thinking why not try to fix original unit since everything is ready for it and machine also have 4th axis(that dont accept step/dir) and drilling unit.

Should I try to repair Num or take a time to connect everything with new BoB that would probably not been able to drive all in/outs and 4.axis?

I recently bought very cheap record 220, but in non working condition since battery is dead in num 1040 controller.

Already have replacement BOB but now thinking why not try to fix original unit since everything is ready for it and machine also have 4th axis(that dont accept step/dir) and drilling unit.

Should I try to repair Num or take a time to connect everything with new BoB that would probably not been able to drive all in/outs and 4.axis?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

08 Oct 2024 01:24 #311537

by tommylight

Replied by tommylight on topic Retrofiting Scm record 220

What BOB are you talking about?

Normal BOB is for parallel port with 12 outputs and 5 inputs, while this machine from what it says here needs much, much more.

Also normal BOB will not work at all for analog servo systems, and most probably the machines uses those.

Still, do upload the pictures here so we can have a look.

Normal BOB is for parallel port with 12 outputs and 5 inputs, while this machine from what it says here needs much, much more.

Also normal BOB will not work at all for analog servo systems, and most probably the machines uses those.

Still, do upload the pictures here so we can have a look.

Please Log in or Create an account to join the conversation.

- C0bra

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

08 Oct 2024 07:39 #311545

by C0bra

Replied by C0bra on topic Retrofiting Scm record 220

Its uc300eth-max, about 20output and 45input.

Machine still have much more but its certanly enough if make connections more simply.

Thing is am not sure should I mess up factory instalations or maybe its better to get controller fixed and just threw it in and go, would benefit from 4.axis which motor is driven analog (tool turret maybe too) and I guess its professional nc. and is probably better quality and reliability that of diy approach.

On the other hand with new bob would have more possibility, like 4.axis on table rotation and add diode laser or plasma torch.

Have already tried those Yaskawa servos and are working with step/dir signal, just had some problem with endless motor vibration on X axis with smallest move of shaft.

Have swap it with Y drive and they work fine, its only happening with X drive on X servo.

Am not worried about tools turret since if cant work with step/dir its a small motor and probably have some stepper laying around that can replace it.

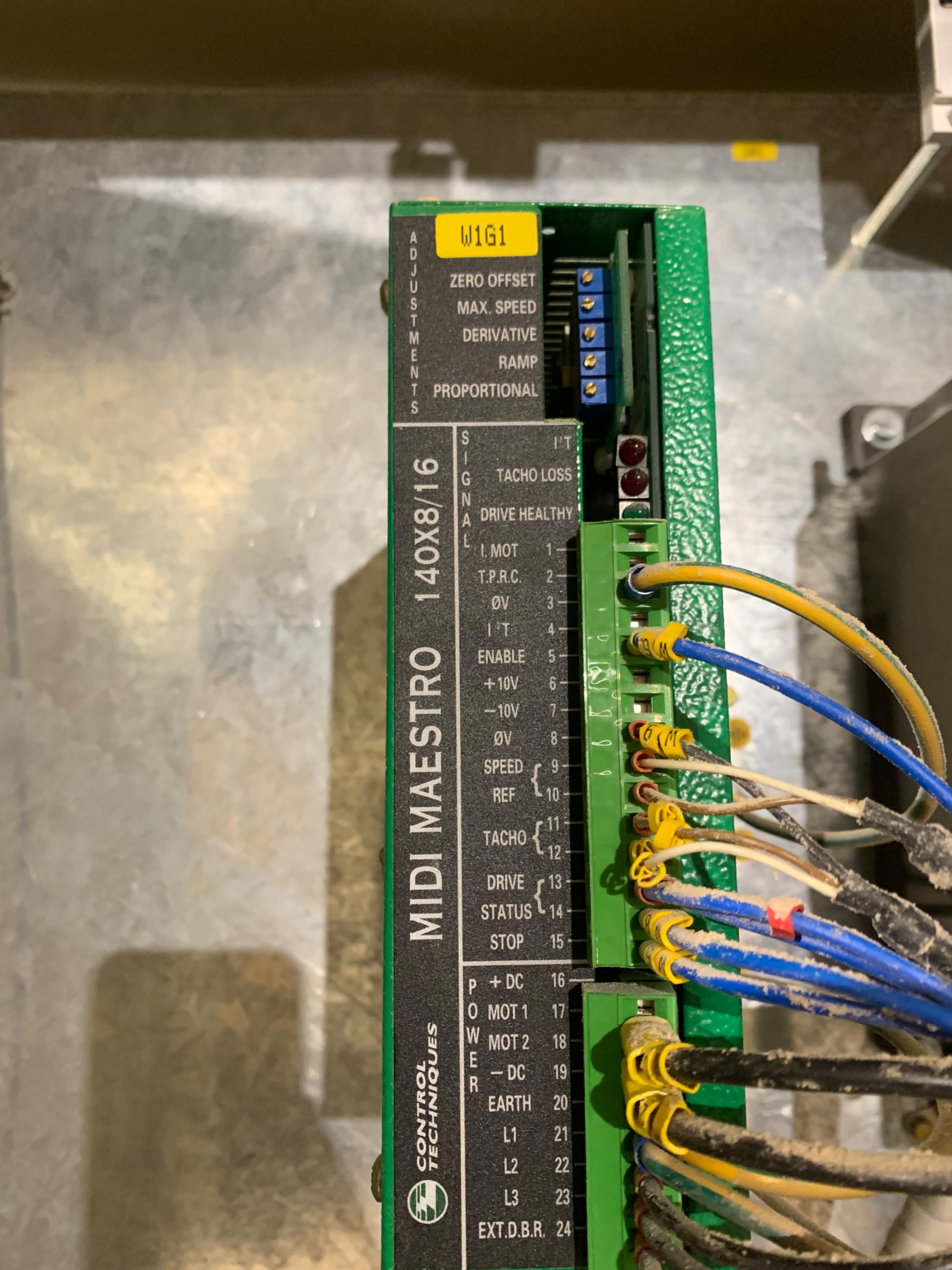

Here is pic of the drive for the 4.axis (tilting spindle head on sides).

Midi Maestro 140x8/16

Machine still have much more but its certanly enough if make connections more simply.

Thing is am not sure should I mess up factory instalations or maybe its better to get controller fixed and just threw it in and go, would benefit from 4.axis which motor is driven analog (tool turret maybe too) and I guess its professional nc. and is probably better quality and reliability that of diy approach.

On the other hand with new bob would have more possibility, like 4.axis on table rotation and add diode laser or plasma torch.

Have already tried those Yaskawa servos and are working with step/dir signal, just had some problem with endless motor vibration on X axis with smallest move of shaft.

Have swap it with Y drive and they work fine, its only happening with X drive on X servo.

Am not worried about tools turret since if cant work with step/dir its a small motor and probably have some stepper laying around that can replace it.

Here is pic of the drive for the 4.axis (tilting spindle head on sides).

Midi Maestro 140x8/16

Attachments:

Please Log in or Create an account to join the conversation.

- C0bra

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

08 Oct 2024 10:17 #311550

by C0bra

Replied by C0bra on topic Retrofiting Scm record 220

Would like to add that I dont see too much use of tilting spindle axis anyway, maybe am wrong?

But have idea.. What if could just tilt it with one potentiometer to desired angle, in that case could still use it to drill holes at angle with drilling unit and cut board at angle.

Also could cut fully at edge of the table since my Y axis now has longer travel than width of the table.

Machine came with 3.2m x 1.55m travel but there was some distancer on Y that has limit travel to about 1.25m which is width of the table.

Now I took off that distancer and its free to go, just need to move that limit switch but it already have a place designed at 1.25m and other at 1.55m.

So think I will use both limits with a switch to chose between them so sometimes can have better travel.

But have idea.. What if could just tilt it with one potentiometer to desired angle, in that case could still use it to drill holes at angle with drilling unit and cut board at angle.

Also could cut fully at edge of the table since my Y axis now has longer travel than width of the table.

Machine came with 3.2m x 1.55m travel but there was some distancer on Y that has limit travel to about 1.25m which is width of the table.

Now I took off that distancer and its free to go, just need to move that limit switch but it already have a place designed at 1.25m and other at 1.55m.

So think I will use both limits with a switch to chose between them so sometimes can have better travel.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

08 Oct 2024 10:58 #311554

by tommylight

Replied by tommylight on topic Retrofiting Scm record 220

The servo drive in the picture has analog inputs that are not used, the speed ref pins are used, so might be quadrature or up/down signals?

That would have to be confirmed, so a manual would help.

If all other drives are step/dir, that makes things a bit easier, but the X issue must be fixed in the drive or it might just be interference from dangling cables.

I do not know what uc300eth is, but if it is for use with mach3/4 i would really, really avoid using it, seen to many machines left crippled by such retrofits.

Get Mesa boards, namely 7i96S with 7i85 and add 7i84 as required for IO, they use a single network cable so you can mount those on the gantry or near the spindles, makes wiring much easier.

Fixing old controllers is ok if something small is gone, but anything bigger and it costs much more than retrofitting it.

Also, do not solder the battery to the controller board without a properly grounded soldering iron.

That would have to be confirmed, so a manual would help.

If all other drives are step/dir, that makes things a bit easier, but the X issue must be fixed in the drive or it might just be interference from dangling cables.

I do not know what uc300eth is, but if it is for use with mach3/4 i would really, really avoid using it, seen to many machines left crippled by such retrofits.

Get Mesa boards, namely 7i96S with 7i85 and add 7i84 as required for IO, they use a single network cable so you can mount those on the gantry or near the spindles, makes wiring much easier.

Fixing old controllers is ok if something small is gone, but anything bigger and it costs much more than retrofitting it.

Also, do not solder the battery to the controller board without a properly grounded soldering iron.

Please Log in or Create an account to join the conversation.

Time to create page: 0.104 seconds