Mostly 3D Printed CNC Foam cutter

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

17 May 2024 22:01 - 17 May 2024 22:03 #300871

by my1987toyota

Mostly 3D Printed CNC Foam cutter was created by my1987toyota

For over a few months now I have been building a hot wire foam cutter. First I was just trying to make a hot wire bow for cutting foam

and making an air foil for my R/C plane with 3D printed templates and metal foil tape. It sort of worked. But I could never get a

good cut without having to do a lot of sanding and even then it didn't look good. Next I tried to make a gravity actuated foam

cutter like the old Tekoa feather cut foam cutter. It worked better but I kept having problems with the hot wire snagging in unpredictable

ways and not getting a good cut. My next thought was to just build a cnc version that I have seen on YouTube by RCKieth. Lots

of good information on his channel and site by the way. I came across a Thingiverse version that used 3D printed brackets and linear

rails.

www.thingiverse.com/thing:3676825/files

For the control system I am currently using GRBL 5X with the RAMPS 1.4 board. That Said I will be switching to LinuxCNC at some point.

Mostly because I intend to use the same machine to do hot wire and hot pin style foam cutting. I am posting some pictures in later posts

.

and making an air foil for my R/C plane with 3D printed templates and metal foil tape. It sort of worked. But I could never get a

good cut without having to do a lot of sanding and even then it didn't look good. Next I tried to make a gravity actuated foam

cutter like the old Tekoa feather cut foam cutter. It worked better but I kept having problems with the hot wire snagging in unpredictable

ways and not getting a good cut. My next thought was to just build a cnc version that I have seen on YouTube by RCKieth. Lots

of good information on his channel and site by the way. I came across a Thingiverse version that used 3D printed brackets and linear

rails.

www.thingiverse.com/thing:3676825/files

For the control system I am currently using GRBL 5X with the RAMPS 1.4 board. That Said I will be switching to LinuxCNC at some point.

Mostly because I intend to use the same machine to do hot wire and hot pin style foam cutting. I am posting some pictures in later posts

.

Last edit: 17 May 2024 22:03 by my1987toyota.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19807

- Thank you received: 4613

17 May 2024 22:27 #300872

by andypugh

Replied by andypugh on topic Mostly 3D Printed CNC Foam cutter

Someone made a fun hot wire cutter some time ago. Imagine a pair of bipods like: wiki.linuxcnc.org/cgi-bin/wiki.pl?Koppi%27s_Toy bolted to the roof of the workshop, with a hot-wire "bow" hanging between them.

I thought it was clever at the time, but can't currently find any pictures.

Forum thread: forum.linuxcnc.org/10-advanced-configura...tter?lang=en&start=0

I thought it was clever at the time, but can't currently find any pictures.

Forum thread: forum.linuxcnc.org/10-advanced-configura...tter?lang=en&start=0

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

17 May 2024 22:51 #300873

by tommylight

Replied by tommylight on topic Mostly 3D Printed CNC Foam cutter

Wiki's certificate has expired!

-

A loooooong time ago i built a 1X1X2 meter cut area foam cutter, now you reminded me i never ever took any picture of it, shame on me as some 2 months ago i was there and watched it working. Over 15 years for sure...

-

What size did you go for?

And use a spring for the Nichrome wire, but do not send the power through it.

Having over 2 meters of wire dangling taught me some things the hard way!

-

A loooooong time ago i built a 1X1X2 meter cut area foam cutter, now you reminded me i never ever took any picture of it, shame on me as some 2 months ago i was there and watched it working. Over 15 years for sure...

-

What size did you go for?

And use a spring for the Nichrome wire, but do not send the power through it.

Having over 2 meters of wire dangling taught me some things the hard way!

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

17 May 2024 23:05 #300874

by my1987toyota

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

Attachments:

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

17 May 2024 23:07 #300875

by my1987toyota

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

17 May 2024 23:21 - 17 May 2024 23:53 #300876

by my1987toyota

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

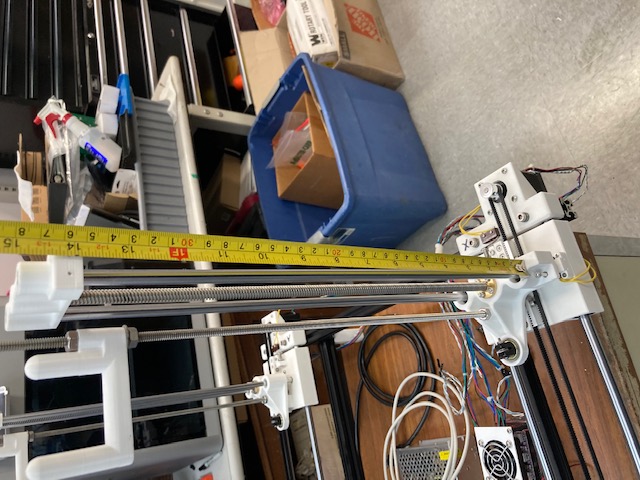

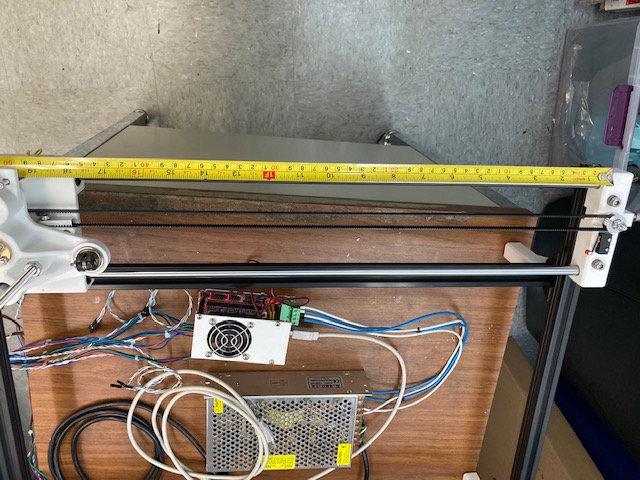

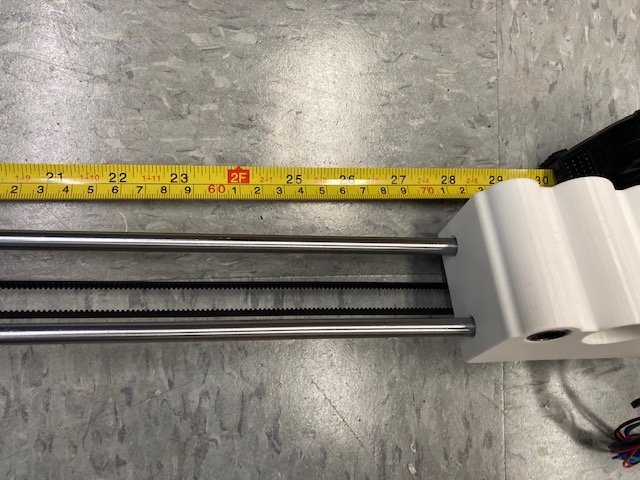

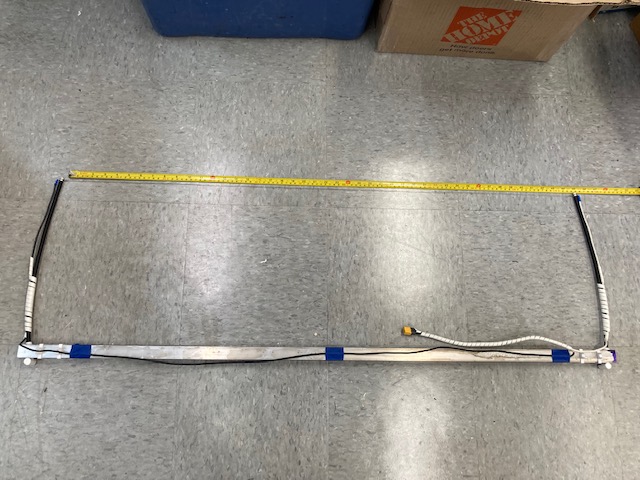

so basic travels are

450mm or 17.7in. in X travel

350mm or 13.78in. in Z travel

and when equipped

700mm or 27.56in. in Y travel

Though the photos don't show the machine in full setup configuration

it will be 1000mm wide X 600mm long x around 500mm tall.

current control is for now GRBL 5X

and RAMPS 1.4 break out board

The bow uses a 48in. long 1in. X 1in. X 0.0625 wall aluminum boom

I 3D printed the Isolator adapters out of PETG and used 2

carbon fiber arrow shafts cut in half for the tensioner posts.

I retained the threaded ends for the wire attachment and electrical

connections. I use a 22ga. nichrome wire for the hot wire.

For power supply I use a 450 watt 24 volt std power supply

and I use a 30 amp PWM brushed motor speed controller

to dial in the energy needed for the wire. That also means

I can use thinner nichrome wire if I so choose.

many changes coming soon

450mm or 17.7in. in X travel

350mm or 13.78in. in Z travel

and when equipped

700mm or 27.56in. in Y travel

Though the photos don't show the machine in full setup configuration

it will be 1000mm wide X 600mm long x around 500mm tall.

current control is for now GRBL 5X

and RAMPS 1.4 break out board

The bow uses a 48in. long 1in. X 1in. X 0.0625 wall aluminum boom

I 3D printed the Isolator adapters out of PETG and used 2

carbon fiber arrow shafts cut in half for the tensioner posts.

I retained the threaded ends for the wire attachment and electrical

connections. I use a 22ga. nichrome wire for the hot wire.

For power supply I use a 450 watt 24 volt std power supply

and I use a 30 amp PWM brushed motor speed controller

to dial in the energy needed for the wire. That also means

I can use thinner nichrome wire if I so choose.

many changes coming soon

Last edit: 17 May 2024 23:53 by my1987toyota. Reason: adding info

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

18 May 2024 00:00 #300879

by tommylight

Replied by tommylight on topic Mostly 3D Printed CNC Foam cutter

Do you need it to cut 4 axis or just 2 axis?

If 4 how did you solve the wire length changing issue?

I used 2 bearings so the wire dips in between them and also connected the power to those bearings mount, the the spring is set some 25CM/10" to the side. Spring was from some type very thin (8-10mm?) of car bonnet shock absorber, had good linearity for about 20cm of stretch then it would start to harden.

If 4 how did you solve the wire length changing issue?

I used 2 bearings so the wire dips in between them and also connected the power to those bearings mount, the the spring is set some 25CM/10" to the side. Spring was from some type very thin (8-10mm?) of car bonnet shock absorber, had good linearity for about 20cm of stretch then it would start to harden.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

18 May 2024 00:49 - 18 May 2024 00:51 #300882

by my1987toyota

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

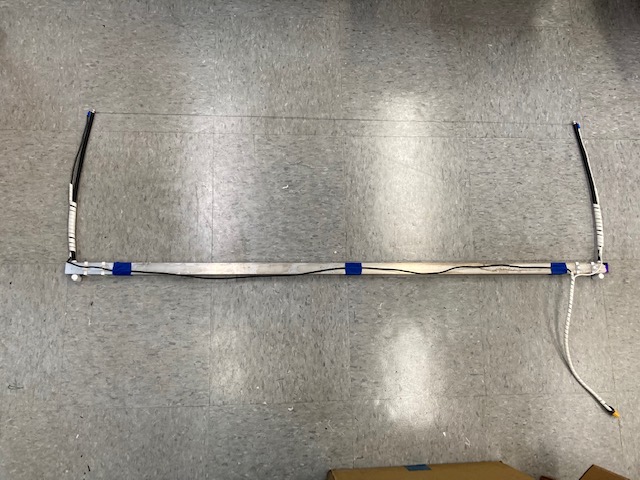

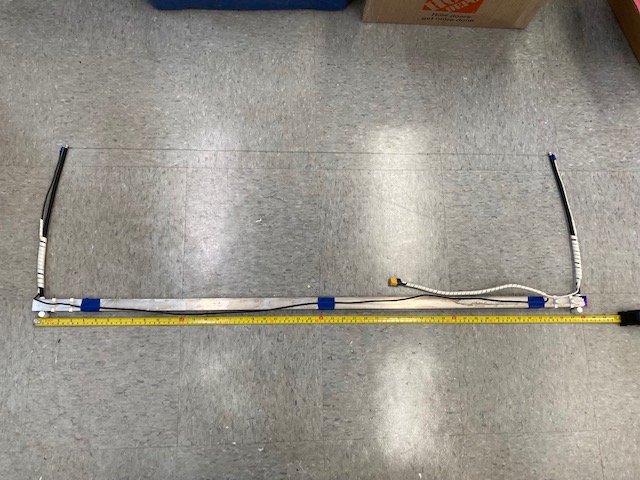

I actually will be using it in 4 axis configuration. Though my Slow ultra stick will be using straight wing cuts.

That's why I am using a bow to handle the wire tension. The attached picture shows the wire yoke. It's designed

to keep the wire mostly in place but will allow it to slide between the two metal washers and also deal with the angular

alignment when the two Z axis are not parallel to each other . the bearings will also allow

for angular misalignment of the two X axis. As I am typing this I am starting to realize that I may need to do a video

showing the misalignment capabilities of how the system works. Fortunately I have time this weekend to do it.

That's why I am using a bow to handle the wire tension. The attached picture shows the wire yoke. It's designed

to keep the wire mostly in place but will allow it to slide between the two metal washers and also deal with the angular

alignment when the two Z axis are not parallel to each other . the bearings will also allow

for angular misalignment of the two X axis. As I am typing this I am starting to realize that I may need to do a video

showing the misalignment capabilities of how the system works. Fortunately I have time this weekend to do it.

Attachments:

Last edit: 18 May 2024 00:51 by my1987toyota.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

18 May 2024 01:00 #300883

by tommylight

Replied by tommylight on topic Mostly 3D Printed CNC Foam cutter

Yes, videos !

Leme see if i can find any of my smaller foam cutter made some 12 years ago...

Leme see if i can find any of my smaller foam cutter made some 12 years ago...

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 975

- Thank you received: 430

18 May 2024 11:11 #300905

by my1987toyota

Replied by my1987toyota on topic Mostly 3D Printed CNC Foam cutter

Please Log in or Create an account to join the conversation.

Time to create page: 0.251 seconds