Losing My Way

- jorsborn

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

28 Jan 2015 08:39 - 28 Jan 2015 08:54 #55403

by jorsborn

Losing My Way was created by jorsborn

I am looking for suggestions on a problem I am having. I have a large 4'x8' gantry with two motors on the Y axis. All motors are stepper driven using G540 connected to the parallel port. I was having significant issues with the gantry racking so I've tried a bunch of things to try and nail down the source of the problem.

- I've examined the linkages on the two motors. Set screws are tight and there is no play in either.

- I've swapped drivers. What I mean by this is I have taken two other drivers (of the 4 in the G540) and substituted them in to see if it was a driver issue.

- I've changed out the external LPT card for an onboard card.

- I've changed the motherboard.

- I've changed the LPT cable so that one set of step/direction pins are now the input to both drivers. I also had to swap a phase on one of the motors to make this work.

- I've tried running at very low speeds.

- I've tried cutting air alone.

The only things I have not tried at the moment are subbing in a new power supply (48VDC 1000W), changing out the G540 and making use of some sort of breakout board which will accept the 3.3V signals from the LPT card and output at 5V so that I am not operating near the low end of the G540 input specs.

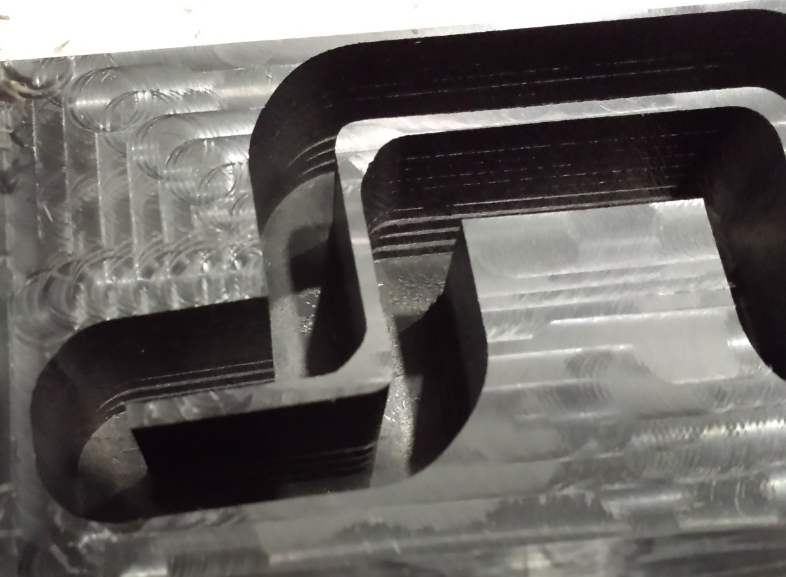

I am attaching a picture of a part which illustrates the problem.

- I've examined the linkages on the two motors. Set screws are tight and there is no play in either.

- I've swapped drivers. What I mean by this is I have taken two other drivers (of the 4 in the G540) and substituted them in to see if it was a driver issue.

- I've changed out the external LPT card for an onboard card.

- I've changed the motherboard.

- I've changed the LPT cable so that one set of step/direction pins are now the input to both drivers. I also had to swap a phase on one of the motors to make this work.

- I've tried running at very low speeds.

- I've tried cutting air alone.

The only things I have not tried at the moment are subbing in a new power supply (48VDC 1000W), changing out the G540 and making use of some sort of breakout board which will accept the 3.3V signals from the LPT card and output at 5V so that I am not operating near the low end of the G540 input specs.

I am attaching a picture of a part which illustrates the problem.

Last edit: 28 Jan 2015 08:54 by jorsborn.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Elite Member

-

Less

More

- Posts: 256

- Thank you received: 33

28 Jan 2015 09:38 #55405

by alan_3301

Replied by alan_3301 on topic Losing My Way

Looks like either spindle or Z axis needs to be trammed, or you are losing steps on the Y axis.

Are you sure the gantry is racking?

Are you sure the gantry is racking?

Please Log in or Create an account to join the conversation.

- jorsborn

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

28 Jan 2015 09:43 #55406

by jorsborn

Replied by jorsborn on topic Losing My Way

The Z axis may need to be trammed (it is close) but I would think if that was the problem I'd see a very gradual progression of the offset. Here the offset is created in an instant. In this particular instance the gantry did not "rack" as it typically does with a large pop. This appears, like you say, that the y axis is losing steps. The depth of cut here was about 0.100" and the overall stock height was 0.944". So, it was ok until about the last 0.300".

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Elite Member

-

Less

More

- Posts: 256

- Thank you received: 33

28 Jan 2015 19:39 #55415

by alan_3301

Replied by alan_3301 on topic Losing My Way

I would have a feature somewhere on the table that you can verify if you have lost steps or not.

Set up your job, zero part origin, then jog / probe to feature edges and record coordinates.

Then when the job is finished, or you think you missed steps at some point, go back to check if the coordinates match as before.

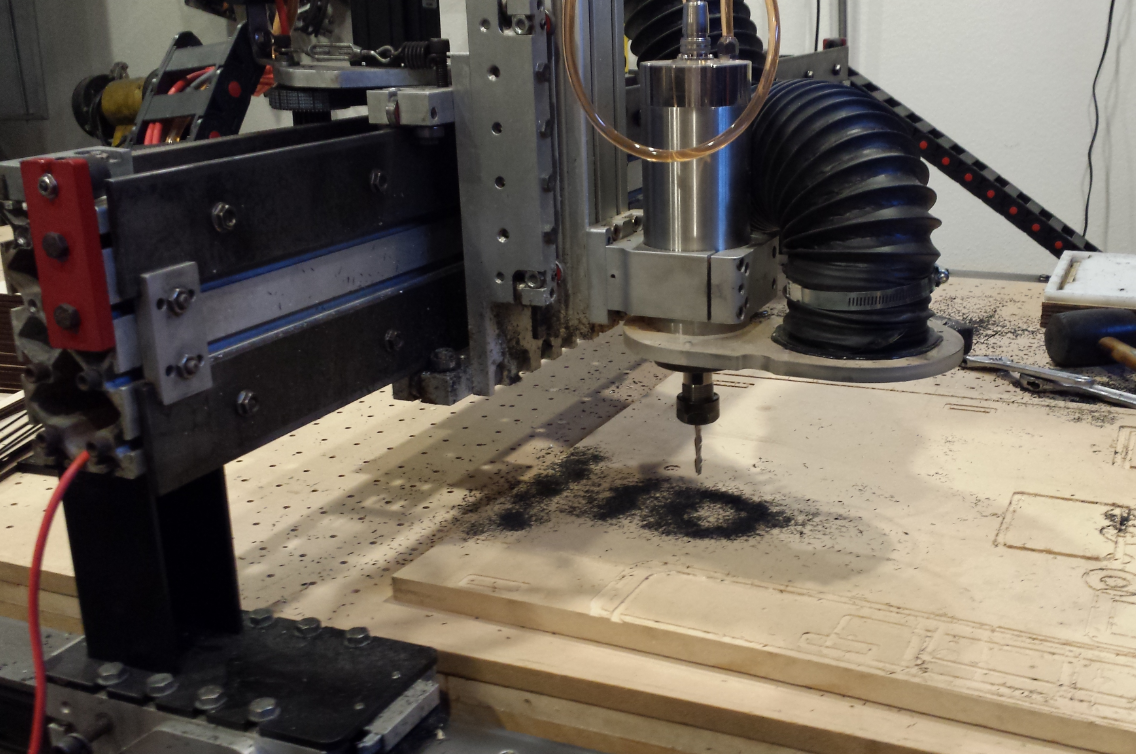

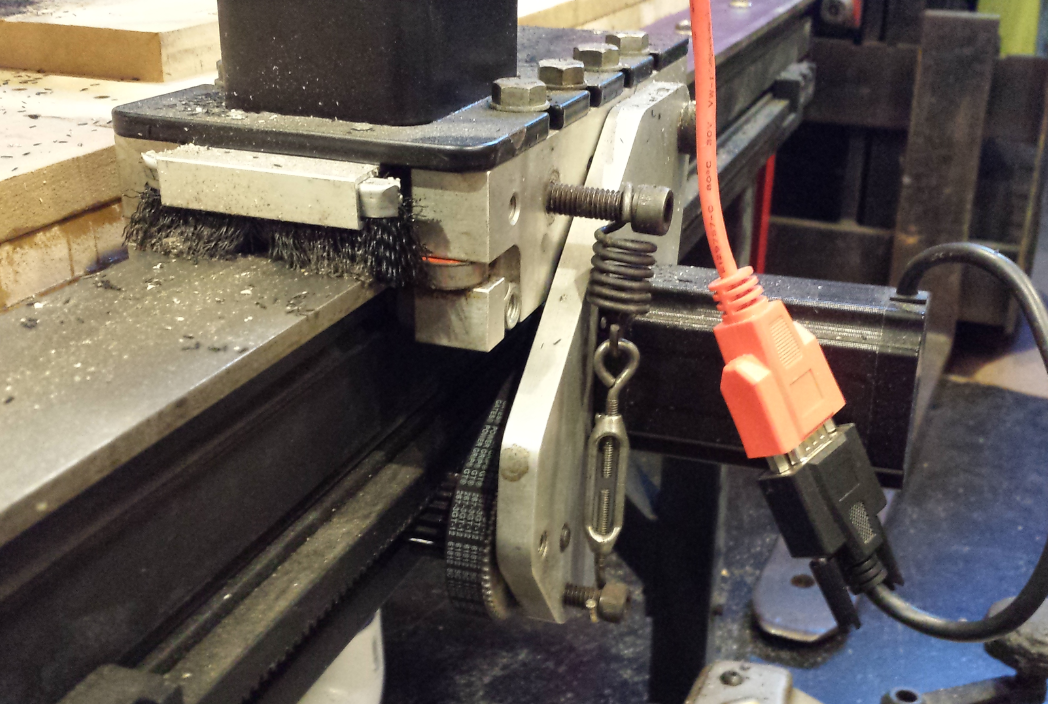

Can you describe your machine motion and drive? or post a picture?

I know you said you checked the motor linkages, but if you have timing pulleys, or shaft couplers that use a set screw,

they can shift at totally inconsistent times, and be difficult to see.

I would recommend getting a fine tip paint pen, and putting witness marks on all rotating components that join to another.

On the motor shaft, coupler, and leadscrew for example.

or if you have belt reduction, on all the pulleys and shafts.

The key is to get a pen tip that is as narrow as possible, and draw the lines exactly co-linear.

So if it does slip, you wil be able to see clearly.

Set up your job, zero part origin, then jog / probe to feature edges and record coordinates.

Then when the job is finished, or you think you missed steps at some point, go back to check if the coordinates match as before.

Can you describe your machine motion and drive? or post a picture?

I know you said you checked the motor linkages, but if you have timing pulleys, or shaft couplers that use a set screw,

they can shift at totally inconsistent times, and be difficult to see.

I would recommend getting a fine tip paint pen, and putting witness marks on all rotating components that join to another.

On the motor shaft, coupler, and leadscrew for example.

or if you have belt reduction, on all the pulleys and shafts.

The key is to get a pen tip that is as narrow as possible, and draw the lines exactly co-linear.

So if it does slip, you wil be able to see clearly.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1744

- Thank you received: 288

28 Jan 2015 19:58 #55416

by cncbasher

Replied by cncbasher on topic Losing My Way

looks to me more mechanical , as the gantry is not stable , and either or the gantry is flexing under load or weight , have you a picture of the machine handy , showing it'sa build ?

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

28 Jan 2015 22:17 - 28 Jan 2015 22:21 #55418

by BigJohnT

Replied by BigJohnT on topic Losing My Way

A 4' x 8' gantry running steppers with a G540 and cutting metal does not seem like a good fit. Voltage = Power when talking steppers and your at 50v or less so you don't have much power. I run my plasma (54" aluminum gantry) with G203v's that can take 80v. I'm running 68v but I'm not cutting metal. I don't know what rpm your steppers are turning when you cut but as rpm increases torque decreases.

If the problem is the stair stepping seen at the bottom of the pocket you could be loosing steps from side loads while cutting. What voltage is your power supply now?

JT

If the problem is the stair stepping seen at the bottom of the pocket you could be loosing steps from side loads while cutting. What voltage is your power supply now?

JT

Last edit: 28 Jan 2015 22:21 by BigJohnT.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Elite Member

-

Less

More

- Posts: 256

- Thank you received: 33

28 Jan 2015 23:13 #55422

by alan_3301

Replied by alan_3301 on topic Losing My Way

I cut aluminum on my diy machine with nema 34 steppers w/ g201x's @ 48v with a 1/4" 2 flute carbide @ 0.080" DOC and 50ipm

I have done the same with a nema 23 g540 driven machine, but with a smaller DOC.

I have cut as deep as 1.125"

In both cases, the finish isn't great, you can see some ripples and variations, but nothing like in the pictures posted.

I didn't realize the g201's were good for 80v, Now you have me thinking about upgrading my power supply!

Thanks alot BigJohnT

I have done the same with a nema 23 g540 driven machine, but with a smaller DOC.

I have cut as deep as 1.125"

In both cases, the finish isn't great, you can see some ripples and variations, but nothing like in the pictures posted.

I didn't realize the g201's were good for 80v, Now you have me thinking about upgrading my power supply!

Thanks alot BigJohnT

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Elite Member

-

Less

More

- Posts: 256

- Thank you received: 33

28 Jan 2015 23:14 #55423

by alan_3301

Replied by alan_3301 on topic Losing My Way

jorsborn are you good about clearing chips out of the slot?

Maybe the bit is getting gummed up at the lower depths and causing increased effort on the axis motors leading to lost steps?

Maybe the bit is getting gummed up at the lower depths and causing increased effort on the axis motors leading to lost steps?

Please Log in or Create an account to join the conversation.

- jorsborn

- Offline

- Junior Member

-

Less

More

- Posts: 35

- Thank you received: 0

29 Jan 2015 01:05 - 29 Jan 2015 01:13 #55425

by jorsborn

Replied by jorsborn on topic Losing My Way

Thanks all for the responses. I am attaching a picture of the gantry as well as the linkage. The build is mostly based on the structure developed by CNC router parts.

Alan, in this particular instance I am not good about clearing the chips as it gets deep into that slot. I can't say for sure that this is not a contributing factor but I do know that the gantry racks when simply cutting air on some files. There must be particular moves which exacerbates the problem because some files are really problematic. The pen idea is a smart one and I think I'll have a go with that. I'll report back.

The material being cut here is delrin. I am running at approximately 800 SFM (0.25" diameter carbide cutter, 12,000 RPM). My feed rate is set to 30 ipm.

My ini configuration file is below:

Alan, in this particular instance I am not good about clearing the chips as it gets deep into that slot. I can't say for sure that this is not a contributing factor but I do know that the gantry racks when simply cutting air on some files. There must be particular moves which exacerbates the problem because some files are really problematic. The pen idea is a smart one and I think I'll have a go with that. I'll report back.

The material being cut here is delrin. I am running at approximately 800 SFM (0.25" diameter carbide cutter, 12,000 RPM). My feed rate is set to 30 ipm.

My ini configuration file is below:

# Generated by stepconf at Sun Jul 28 22:35:21 2013

# If you make changes to this file, they will be

# overwritten when you run stepconf again

[EMC]

MACHINE = router

DEBUG = 0

[DISPLAY]

DISPLAY = axis

#PREFERENCE_FILE_PATH = gmoccapy_preferences

EDITOR = mousepad

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 10.0

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/jorsborn/linuxcnc/nc_files

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

EMBED_TAB_NAME = Camera

EMBED_TAB_LOCATION = ntb_user_tabs

#EMBED_TAB_COMMAND = ./camview-emc-f1oat.py -v 1280x720 -C camview.cfg -g cam.ui -H campins.hal -w {XID}

#PYVCP = custompanel.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

COMM_WAIT = 0.010

BASE_PERIOD = 30000

SERVO_PERIOD = 1000000

[HAL]

HALUI = halui

HALFILE = router.hal

HALFILE = xhc-hb04.hal

#HALFILE = joypad.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

[HALUI]

# add halui MDI commands here (max 64)

MDI_COMMAND = G38.2 Z-2 f16

MDI_COMMAND = G10 L20 P0 Z.062

MDI_COMMAND = G0 Z2

MDI_COMMAND = G0 X0 Y0 Z0

MDI_COMMAND = G0

MDI_COMMAND = G0

MDI_COMMAND=G10 L20 P1 X0

MDI_COMMAND=G10 L20 P1 Y0

MDI_COMMAND=G10 L20 P1 Z0

MDI_COMMAND=G0 X0 Y0 Z0

[TRAJ]

AXES = 4

COORDINATES = X Y Z Y

MAX_ANGULAR_VELOCITY = 360.00

DEFAULT_ANGULAR_VELOCITY = 36.00

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

CYCLE_TIME = 0.010

DEFAULT_VELOCITY = 100.00

MAX_LINEAR_VELOCITY = 300.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[AXIS_0]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 120

MAX_ACCELERATION = 40

STEPGEN_MAXACCEL = 80

SCALE = 1736.237

FERROR = 1

MIN_FERROR = 0.01

MIN_LIMIT = -.5

MAX_LIMIT = 49.5

BACKLASH = 0.005

HOME_OFFSET = 0.0

[AXIS_1]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 120

MAX_ACCELERATION = 40

STEPGEN_MAXACCEL = 80

SCALE = 1736.237

FERROR = 1

MIN_FERROR = 0.01

MIN_LIMIT = -.5

MAX_LIMIT = 99.0

BACKLASH = 0.005

HOME_OFFSET = 0.0

[AXIS_2]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 3

MAX_ACCELERATION = 10

STEPGEN_MAXACCEL = 25

SCALE = 4000

FERROR = 1

MIN_FERROR = 0.01

MIN_LIMIT = -6.0

MAX_LIMIT = 6.0

HOME_OFFSET = 0.0

[AXIS_3]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 120

MAX_ACCELERATION = 40

STEPGEN_MAXACCEL = 80

SCALE = 1736.237

FERROR = 1

MIN_FERROR = 0.01

MIN_LIMIT = -.5

MAX_LIMIT = 99.0

BACKLASH = 0.005

HOME_OFFSET = 0.0

Last edit: 29 Jan 2015 01:13 by jorsborn.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Elite Member

-

Less

More

- Posts: 256

- Thank you received: 33

29 Jan 2015 01:28 - 29 Jan 2015 01:30 #55426

by alan_3301

Replied by alan_3301 on topic Losing My Way

That looks almost identical to my machine. I have a 4x4' cncrouterparts machine.

The #1 problem people have is with the motor pulleys slipping.

as you know, the set screw is tiny, and you may not have a flat on the motor shaft for it to rest against.

I used loctite on the interface between the motor shaft and the belt pulley, then with a dab of loctite on the threads, tightened the set screw until almost rounding the hex off.

I haven't had a problem yet. If I ever need to dissassemble it, I will most likely need a gear puller, and will probably damage the belt pulley, but I can live with that, as long as it isn't slipping.

one more thing, you won't be able to see where it slipped, unless you mark it, or take it apart and see the gouges where the set screw was rubbing on the motor shaft.

They are usually tight and secure, up until they slip, change direction and get jammed up again, until it all happens again at some point.

Is your accel a little high for Y at 40? I think I run like 75 for Z, 50 for X and 25 for Y

The #1 problem people have is with the motor pulleys slipping.

as you know, the set screw is tiny, and you may not have a flat on the motor shaft for it to rest against.

I used loctite on the interface between the motor shaft and the belt pulley, then with a dab of loctite on the threads, tightened the set screw until almost rounding the hex off.

I haven't had a problem yet. If I ever need to dissassemble it, I will most likely need a gear puller, and will probably damage the belt pulley, but I can live with that, as long as it isn't slipping.

one more thing, you won't be able to see where it slipped, unless you mark it, or take it apart and see the gouges where the set screw was rubbing on the motor shaft.

They are usually tight and secure, up until they slip, change direction and get jammed up again, until it all happens again at some point.

Is your accel a little high for Y at 40? I think I run like 75 for Z, 50 for X and 25 for Y

Last edit: 29 Jan 2015 01:30 by alan_3301. Reason: 50 --> 40

Please Log in or Create an account to join the conversation.

Time to create page: 0.121 seconds