Is there an easy way to swap axes?

- JasonF

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

13 Oct 2015 09:16 #63728

by JasonF

Is there an easy way to swap axes? was created by JasonF

Occasionally I run my mill with the spindle rotated 90 degrees on its mount, so that the spindle is oriented horizontally, making z = x and x = -z. This is when I'm working on the top of a "tall" part that need lots of clearance in the -z direction.

Is there an easy way to take the existing configuration and tell linuxcnc to just swap the axes as above, without having to individually reassign the homing switches and backlash configuration and all that?

Thanks

- J

Is there an easy way to take the existing configuration and tell linuxcnc to just swap the axes as above, without having to individually reassign the homing switches and backlash configuration and all that?

Thanks

- J

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

13 Oct 2015 15:25 #63734

by cncbasher

Replied by cncbasher on topic Is there an easy way to swap axes?

easy way is to make a second configuration ,

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

13 Oct 2015 19:13 #63745

by andypugh

I recently did this myself.

I copied the INI file to a new name in the same config directory.

My config has several HAL files, and most of those are shared. I made a renamed copy of the one that defines the axis motor setups and left the rest unchanged.

Doing it this way leaves you with two alternate configs that share tool tables, any macros and remaps, etc.

In the new INI file change the reference to the axis HAL in the [HAL] section.

In my case X remained as X, but Y and Z swapped.

In the INI I changed [AXIS_1] to [AXIS_2] and vice-versa. I then cut and pasted the sections to put them in the right order. I don't think this is necessary.

This way the limits and tuning for each motor stay with each motor.

The only thing you probably want to change inside each INI section is the homing sequence number.

Then, in the HAL file, swap the header comments for Y and Z (if any) then swap any axis.N numbers (motor-position-cmd, motor-position-fb, limit-sw-in, home-sw-in)

Leave the PID and stepgen numbers the same, _only_ change the axis.N numbers.

You can, if you want, change the signal names to match the new axis letters, but it might actually be less error-prone not to.

If you save the files and start LinuxCNC you should now have a new config that you can pick from the config picker.

The config should work just as well as the original config, except that jogs and G-code move different motors.

But... There is one remaining problem, you will have a left-handed coordinate system. You will need to swap the direction of one of your axes. In my case I swapped the new-Y (old Z) so that Y+ was table downwards.

If you have a stepper system this is just a case of negating the stepgen scale and changing the homing directions and the axis limits. For a servo system you also need to reverse the encoder scale and PWM scale. I amusing the 8i20 and Resolvers, reversing the axis took me several iterations, but if you get it wrong all that happens is a following error.

Replied by andypugh on topic Is there an easy way to swap axes?

Is there an easy way to take the existing configuration and tell linuxcnc to just swap the axes as above, without having to individually reassign the homing switches and backlash configuration and all that?

I recently did this myself.

I copied the INI file to a new name in the same config directory.

My config has several HAL files, and most of those are shared. I made a renamed copy of the one that defines the axis motor setups and left the rest unchanged.

Doing it this way leaves you with two alternate configs that share tool tables, any macros and remaps, etc.

In the new INI file change the reference to the axis HAL in the [HAL] section.

In my case X remained as X, but Y and Z swapped.

In the INI I changed [AXIS_1] to [AXIS_2] and vice-versa. I then cut and pasted the sections to put them in the right order. I don't think this is necessary.

This way the limits and tuning for each motor stay with each motor.

The only thing you probably want to change inside each INI section is the homing sequence number.

Then, in the HAL file, swap the header comments for Y and Z (if any) then swap any axis.N numbers (motor-position-cmd, motor-position-fb, limit-sw-in, home-sw-in)

Leave the PID and stepgen numbers the same, _only_ change the axis.N numbers.

You can, if you want, change the signal names to match the new axis letters, but it might actually be less error-prone not to.

If you save the files and start LinuxCNC you should now have a new config that you can pick from the config picker.

The config should work just as well as the original config, except that jogs and G-code move different motors.

But... There is one remaining problem, you will have a left-handed coordinate system. You will need to swap the direction of one of your axes. In my case I swapped the new-Y (old Z) so that Y+ was table downwards.

If you have a stepper system this is just a case of negating the stepgen scale and changing the homing directions and the axis limits. For a servo system you also need to reverse the encoder scale and PWM scale. I amusing the 8i20 and Resolvers, reversing the axis took me several iterations, but if you get it wrong all that happens is a following error.

Please Log in or Create an account to join the conversation.

- JasonF

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

13 Oct 2015 20:25 #63752

by JasonF

Replied by JasonF on topic Is there an easy way to swap axes?

That's the approach I started to take, but it just seemed like too much work.

I was hoping there was a 5 minute solution instead of a few hour solution.

I was hoping there was a 5 minute solution instead of a few hour solution.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

14 Oct 2015 00:20 #63757

by andypugh

It shouldn't take more than 15 minutes to get the left-handed config. It is just text-editor work.

Replied by andypugh on topic Is there an easy way to swap axes?

That's the approach I started to take, but it just seemed like too much work.

I was hoping there was a 5 minute solution instead of a few hour solution.

It shouldn't take more than 15 minutes to get the left-handed config. It is just text-editor work.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

26 Aug 2024 15:12 #308711

by RotarySMP

Replied by RotarySMP on topic Is there an easy way to swap axes?

Hi Guys,

A bit of serious thread necro here

I have my Maho MH400E configured as a vertical mill, and am trying to set up a second INI and HAL with it configured to use the horizontal spindle. For this I need to switch Z and Y, and negate one.

I have something messed up, and spent a couple of evenings trying to trouble shoot it, but cant see the issue. The MH400E HAL and ini work fine, the Horizontal hal and Ini load without error, but cause a Y axis error as son as I push the start button.

I would appreciate if anyone can spot my (probably dumb) mistake. Thanks.

Cheers,

Mark

A bit of serious thread necro here

I have my Maho MH400E configured as a vertical mill, and am trying to set up a second INI and HAL with it configured to use the horizontal spindle. For this I need to switch Z and Y, and negate one.

I have something messed up, and spent a couple of evenings trying to trouble shoot it, but cant see the issue. The MH400E HAL and ini work fine, the Horizontal hal and Ini load without error, but cause a Y axis error as son as I push the start button.

I would appreciate if anyone can spot my (probably dumb) mistake. Thanks.

Cheers,

Mark

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1968

- Thank you received: 803

27 Aug 2024 01:12 - 27 Aug 2024 01:25 #308751

by spumco

Replied by spumco on topic Is there an easy way to swap axes?

Mark - you're running a LCNC version pre-joint/axis?

EDIT:

I'm not familiar with pre-joint/axis configs, but one thing I noticed in your HAL files is that it looks like there's a mismatch between the INI and HAL axis numbers.

Vertical:

INI - Y is axis_1

INI - Z is axis_2

HAL - Y is axis_1

HAL - Z is axis_2

Horizontal

INI - Z is axis_1

INI - Y is axis_2

HAL - Z is axis_2

HAL - Y is axis_1

Make sense?

EDIT:

I'm not familiar with pre-joint/axis configs, but one thing I noticed in your HAL files is that it looks like there's a mismatch between the INI and HAL axis numbers.

Vertical:

INI - Y is axis_1

INI - Z is axis_2

HAL - Y is axis_1

HAL - Z is axis_2

Horizontal

INI - Z is axis_1

INI - Y is axis_2

HAL - Z is axis_2

HAL - Y is axis_1

Make sense?

Last edit: 27 Aug 2024 01:25 by spumco.

Please Log in or Create an account to join the conversation.

- hmnijp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 45

27 Aug 2024 03:06 - 27 Aug 2024 03:12 #308755

by hmnijp

Replied by hmnijp on topic Is there an easy way to swap axes?

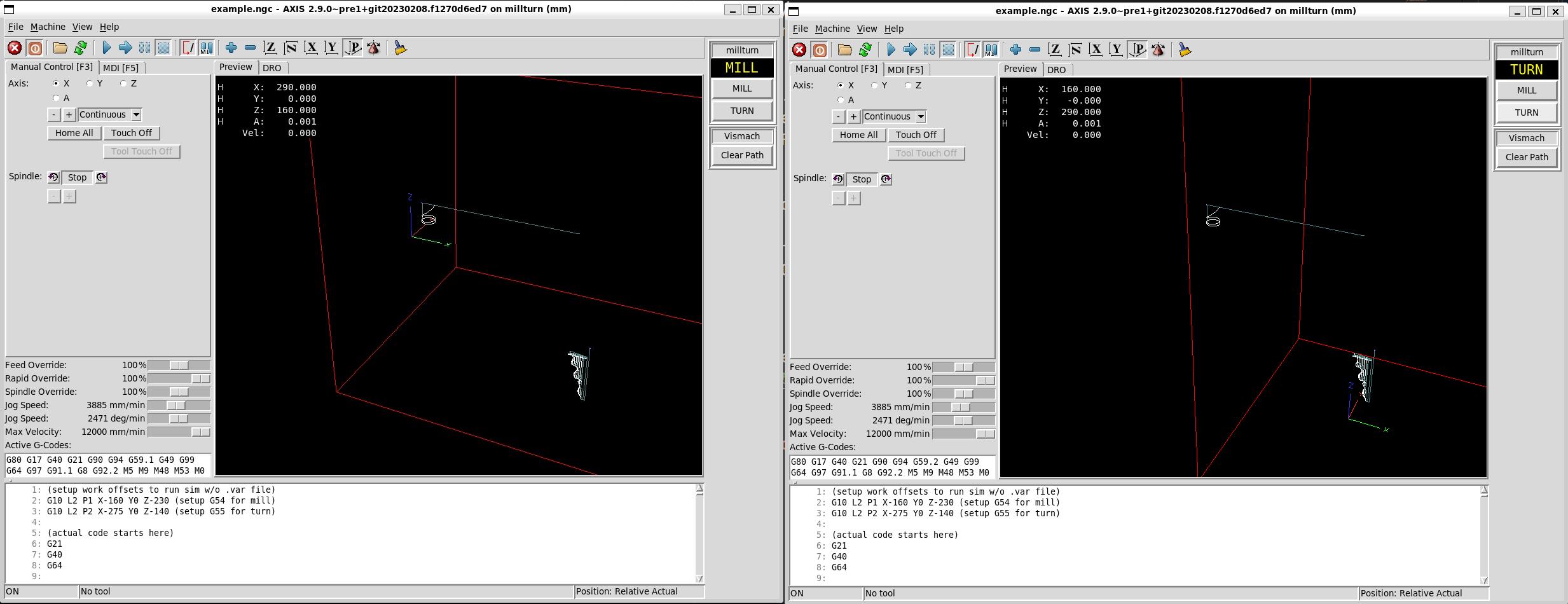

could you use Switchable kinematics ?

for example you can run the millturn configuration - it rotates the Z axis on 90 degrees.

linuxcnc.org/docs/html/motion/switchkins.html

linuxcnc.org/docs/html/man/man9/millturn.9.html

for example you can run the millturn configuration - it rotates the Z axis on 90 degrees.

linuxcnc.org/docs/html/motion/switchkins.html

linuxcnc.org/docs/html/man/man9/millturn.9.html

Attachments:

Last edit: 27 Aug 2024 03:12 by hmnijp.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11653

- Thank you received: 3921

27 Aug 2024 08:20 #308778

by rodw

Replied by rodw on topic Is there an easy way to swap axes?

Using separate configs, the only thing needed is to change the coordinates statement in the ini file eg XYYZ to YXXZ which I did on a machine yesterday.

But stupidly, pncconf and stepconf set all of the signals to axes instead of joints.What I do is to relabel the signals to avoid confusion eg x-home becomes 0-home. I made 162 changes.

I have thought of modifying pncconf to select between joint based and axes based configs.

But stupidly, pncconf and stepconf set all of the signals to axes instead of joints.What I do is to relabel the signals to avoid confusion eg x-home becomes 0-home. I made 162 changes.

I have thought of modifying pncconf to select between joint based and axes based configs.

The following user(s) said Thank You: RotarySMP, Masiwood123

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

27 Aug 2024 16:01 - 27 Aug 2024 16:10 #308821

by RotarySMP

Replied by RotarySMP on topic Is there an easy way to swap axes?

Thanks guys. I was following Andys instructions, and didn't rename all the signals names, as I figured the more I changed the more I would screw up, but it didn't help and I still ended up tied in knots.

Is switchkins useable with LinuxCNC 2.7? I have never updated the Maho to a Joints based version, as I am afraid of breaking a working system. I have that gearbox comp working and am loath risking bricking the machine.

Cheers,

Mark

Is switchkins useable with LinuxCNC 2.7? I have never updated the Maho to a Joints based version, as I am afraid of breaking a working system. I have that gearbox comp working and am loath risking bricking the machine.

Cheers,

Mark

Last edit: 27 Aug 2024 16:10 by RotarySMP.

Please Log in or Create an account to join the conversation.

Time to create page: 0.100 seconds