Squaring machine / spindle

- danimal300

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

30 Jun 2016 18:48 #76865

by danimal300

Replied by danimal300 on topic Squaring machine / spindle

I did not check the origin after, but I will do that on the next one.

I am using a G540 V8 for my motor controller, the values that I have used were:

steplen = 1500

stepspace = 2500

dirsetup = 700

dirhold = 700

base_period = 17000

Max jitter was 11000 on my machine, but I had to keep raising up the base period from the calculated 15700 value because I kept getting a warning (don't remember the exact wording, but something about only displays once per session) and I am sure that it had to do with the base period because I raised it in increments of 100 until it went away.

The G540 minimum values are listed as:

1000

2000

200

200

I think that you are correct and this is part or all of my problem. But I am not sure which value would be the most beneficial to adjust, because I gave a 500ns buffer on all of the values, and increased the base period beyond that. This results in my machine limiting out at roughly 50ipm, but that is fine because I usually cut between 5 and 25ipm feed rates due to my slow spindle RPM of 2500.

So what you are saying is that I should increase steplen and stepspace to achieve a steps per second that results in a maximum speed of 25 - 30 ipm?

I am using a G540 V8 for my motor controller, the values that I have used were:

steplen = 1500

stepspace = 2500

dirsetup = 700

dirhold = 700

base_period = 17000

Max jitter was 11000 on my machine, but I had to keep raising up the base period from the calculated 15700 value because I kept getting a warning (don't remember the exact wording, but something about only displays once per session) and I am sure that it had to do with the base period because I raised it in increments of 100 until it went away.

The G540 minimum values are listed as:

1000

2000

200

200

I think that you are correct and this is part or all of my problem. But I am not sure which value would be the most beneficial to adjust, because I gave a 500ns buffer on all of the values, and increased the base period beyond that. This results in my machine limiting out at roughly 50ipm, but that is fine because I usually cut between 5 and 25ipm feed rates due to my slow spindle RPM of 2500.

So what you are saying is that I should increase steplen and stepspace to achieve a steps per second that results in a maximum speed of 25 - 30 ipm?

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4691

- Thank you received: 1435

30 Jun 2016 19:41 #76868

by Todd Zuercher

Replied by Todd Zuercher on topic Squaring machine / spindle

Try

steplen = 2500

stepspace = 2500

dirsetup = 1000

dirhold = 1000

You can also try inverting the parallel port pins for the step signals.

(setp parport.N.pin-NN-out-invert true)

Is the G540 connected directly to the parallel port, or through a breakout board?

steplen = 2500

stepspace = 2500

dirsetup = 1000

dirhold = 1000

You can also try inverting the parallel port pins for the step signals.

(setp parport.N.pin-NN-out-invert true)

Is the G540 connected directly to the parallel port, or through a breakout board?

The following user(s) said Thank You: danimal300

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17574

- Thank you received: 5140

30 Jun 2016 21:41 #76869

by PCW

Replied by PCW on topic Squaring machine / spindle

Lengthening the step length/spacing to even 5000 each would have no effect on your maximum speed

(this will allow 100 KHz step rates but you are limited to about 60 KHz by your base thread rate)

(this will allow 100 KHz step rates but you are limited to about 60 KHz by your base thread rate)

The following user(s) said Thank You: danimal300

Please Log in or Create an account to join the conversation.

- danimal300

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

02 Jul 2016 02:54 #76912

by danimal300

Replied by danimal300 on topic Squaring machine / spindle

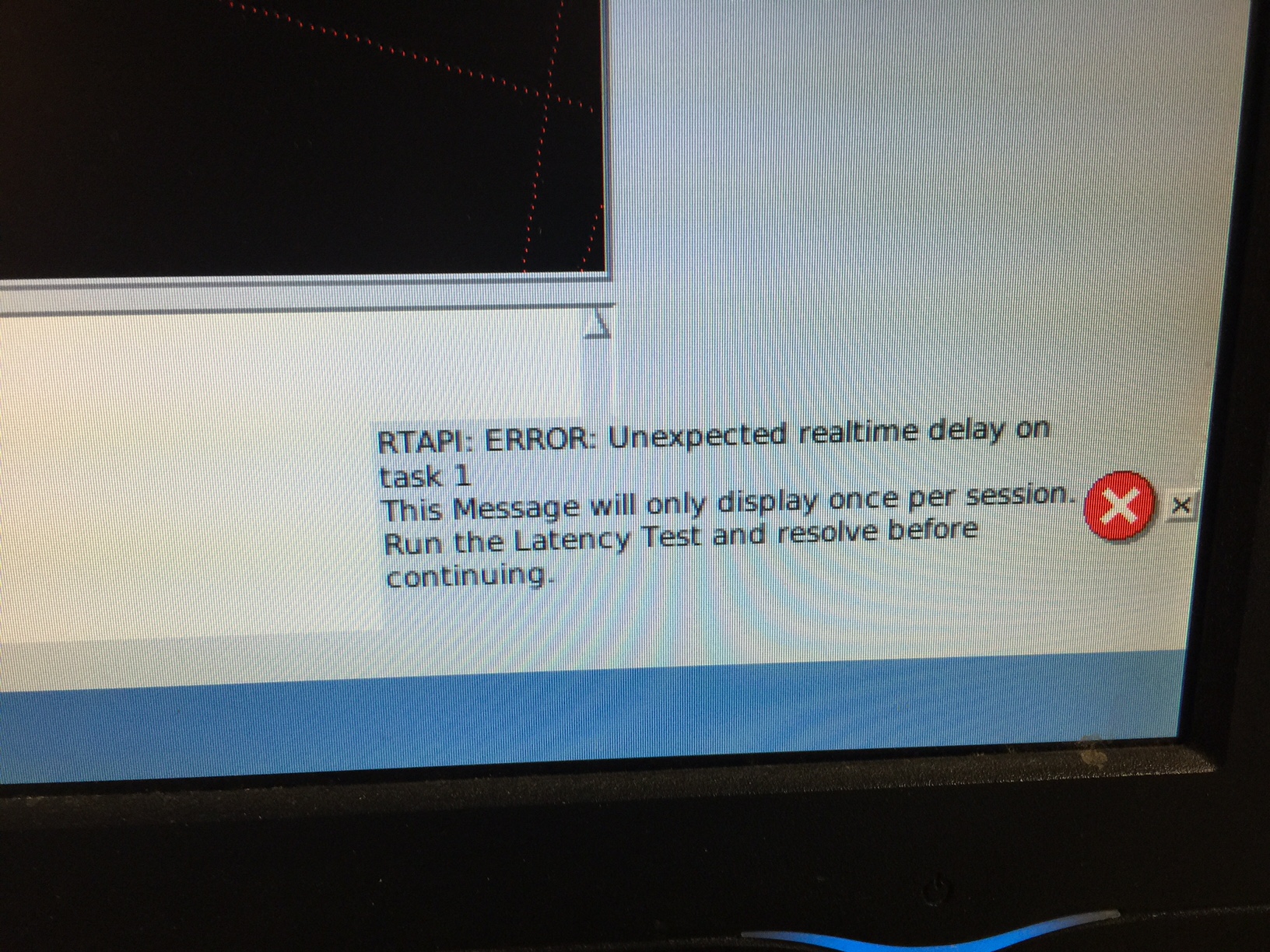

I set these values, and it seems to have helped. But I did get the error pictured below. I am still not sure what this is telling me. I increased the base period to 20000, and it happened again. The part I made turned out quite a bit better, so this must have had something to do with it. Thanks for the help.

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

02 Jul 2016 10:28 #76916

by Rick G

Replied by Rick G on topic Squaring machine / spindle

Looks like you need to re run the latency test, be sure to load the computer with appropriate programs, such as running glxgears and run it for an extended period.

Rick G

Rick G

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

02 Jul 2016 10:31 #76917

by BigJohnT

Replied by BigJohnT on topic Squaring machine / spindle

Open a terminal and run latency-histogram for a while.

JT

JT

Please Log in or Create an account to join the conversation.

- danimal300

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

03 Jul 2016 05:56 #76934

by danimal300

Replied by danimal300 on topic Squaring machine / spindle

I am going to let the latency program run overnight, and I will have a bunch of stuff open while it does it. When that is done, the only thing that it affects is the Base_period, correct?

So I should run the latency test, use various programs, then take the highest value, add it to the steplen and step space and make that the base period.

Are there any other values that need to be changed for this error?

I have:

2500

2500

1000

1000

with a base period of 20,000. Up to now the latency has been 11,000 ish.

So I should run the latency test, use various programs, then take the highest value, add it to the steplen and step space and make that the base period.

Are there any other values that need to be changed for this error?

I have:

2500

2500

1000

1000

with a base period of 20,000. Up to now the latency has been 11,000 ish.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4691

- Thank you received: 1435

03 Jul 2016 17:20 #76942

by Todd Zuercher

Replied by Todd Zuercher on topic Squaring machine / spindle

Only the base period timing (and to some extent servo period when latency is really bad) have any effect on the real time errors. The other timings only have to do with the step generation signals.

Increasing your base period time may not be the best answer to your real time alarm error. There may be settings that you can change for your system that could improve latency, fixing your real time alarm, and possibly allowing you to run a faster base thread. Have you turned off hyperthreading, and any power saving or wait states settings in the bios?

Increasing your base period time may not be the best answer to your real time alarm error. There may be settings that you can change for your system that could improve latency, fixing your real time alarm, and possibly allowing you to run a faster base thread. Have you turned off hyperthreading, and any power saving or wait states settings in the bios?

Please Log in or Create an account to join the conversation.

- danimal300

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

05 Jul 2016 15:36 #77040

by danimal300

Replied by danimal300 on topic Squaring machine / spindle

I ran the latency test for a few days while using the computer, and it came back with a maximum of 14,000. I kept it on and just used it for everything that I could think of aside from running the CNC. The machine is a

Gigabyte GA-E350N

with an intel 32GB SSD and 1600mHz memory. The memory was also low latency if I remember correctly, but I do not have the exact type with me.

What I do not understand is how LinuxCNC handles the steplen and stepspace values in the context of the error that I received. Is the error telling me that one of those values are too short and it missed information due to those values, or is it saying that the Base Period was too short and regardless of the len and space values (up to the point where the sum would exceeding the base period) needs to be adjusted. I would just like to know what the error really means so my testing and adjusting can have more meaning.

Thanks for all the help guys.

What I do not understand is how LinuxCNC handles the steplen and stepspace values in the context of the error that I received. Is the error telling me that one of those values are too short and it missed information due to those values, or is it saying that the Base Period was too short and regardless of the len and space values (up to the point where the sum would exceeding the base period) needs to be adjusted. I would just like to know what the error really means so my testing and adjusting can have more meaning.

Thanks for all the help guys.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4691

- Thank you received: 1435

05 Jul 2016 16:09 #77042

by Todd Zuercher

Replied by Todd Zuercher on topic Squaring machine / spindle

The RTAPI error alarm means that the computer could not meet the time requirement for task 1 (probably the Base Period)

You can look at the actual base thread time while Linuxcnc is running with the hal pin "base-thread.time" and see the maximum time with the parameter "base-thread.tmax"

You can look at the actual base thread time while Linuxcnc is running with the hal pin "base-thread.time" and see the maximum time with the parameter "base-thread.tmax"

Please Log in or Create an account to join the conversation.

Time to create page: 0.114 seconds