LinuxCNC S-Curve Accelerations

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

23 Mar 2023 15:46 #267366

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi,

Thanks for your kindness. It certainly gives a boost.

The plan for this year is to test the scurve on one of my machines.

Actually i build a new grotius model a year ago in the summer.

Sinds then It's still unused in storage.

It's the fastest ethercat stepper cnc i ever build.

I am tired of welding gantry machines or tube cutters myself over the years now,

In coming year's, we will see what the course will be.

That makes it excited and important to finish this scurve library.

Then the planning is to test the scurve-lib for long periods of time

on that machine, to find and fix any bug's, or improve the library.

After that is done, the planning is to build a special cnc machine,

I have not decided the exact configuration, but could be a 6 axis robot

on top of a 3 axis gantry machine.

Then i could use the kinematic library for this and expand software from there.

@ Rmu,

From now on i will do the git updates trough the command line for this project. Just updated like that.

On youtube you can find a video from Rob Ellenberg

I have seen the video of Rob. It's good this video excists. In the video Rob also referred to mach3, but

he never did a reverse engeneering on mach3. I think back then ghidra was not published yet by nsa.

Rob's position in the technology sector has it's benefits.

As I mentioned in my post, exact following is not possible, so you have to make some compromises.

I agree with that.

Thanks for your kindness. It certainly gives a boost.

The plan for this year is to test the scurve on one of my machines.

Actually i build a new grotius model a year ago in the summer.

Sinds then It's still unused in storage.

It's the fastest ethercat stepper cnc i ever build.

I am tired of welding gantry machines or tube cutters myself over the years now,

In coming year's, we will see what the course will be.

That makes it excited and important to finish this scurve library.

Then the planning is to test the scurve-lib for long periods of time

on that machine, to find and fix any bug's, or improve the library.

After that is done, the planning is to build a special cnc machine,

I have not decided the exact configuration, but could be a 6 axis robot

on top of a 3 axis gantry machine.

Then i could use the kinematic library for this and expand software from there.

@ Rmu,

From now on i will do the git updates trough the command line for this project. Just updated like that.

On youtube you can find a video from Rob Ellenberg

I have seen the video of Rob. It's good this video excists. In the video Rob also referred to mach3, but

he never did a reverse engeneering on mach3. I think back then ghidra was not published yet by nsa.

Rob's position in the technology sector has it's benefits.

As I mentioned in my post, exact following is not possible, so you have to make some compromises.

I agree with that.

The following user(s) said Thank You: itsme, Darium

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

23 Mar 2023 23:30 #267383

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi, a little project update.

Today i finished the sc_look_ahead. I renamed it to sc_optimizer.

It's now a sort of path-rules module. Wich can add extra path-rules any time.

For now it has a 5 important path-rules under the hood. This will cover the most annoying things.

The code is quite compact. Tested with 2 motion scenario's so far.

We have to decide how to use it. I guess it could be used in 2 way's :

1. Do a optimizer over the gcode when it loads.

2. Do a live optimizer, for example look ahead 20 lines of gcode.

3. Do bot'h 1 & 2.

4. A better idea?

The sc_optimzer_gui is a simple test suite to perform sc_optimizer tasks.

It has also a tiny calculator to see how gforce relates to speed, arc diameter.

I think easyest way is to make a tiny list where some value's are already printed.

To be continued.

Today i finished the sc_look_ahead. I renamed it to sc_optimizer.

It's now a sort of path-rules module. Wich can add extra path-rules any time.

For now it has a 5 important path-rules under the hood. This will cover the most annoying things.

The code is quite compact. Tested with 2 motion scenario's so far.

Warning: Spoiler!

//! The following functions are path rules. You can use them in sequence, or use a specific one.

//! Eventually you could add more path rules to the sequence.

//! Calculates block angles, then set's a corner ve.

std::vector<sc_block> sc_optimize_block_angles_ve(std::vector<sc_block> blockvec);

//! Calculates arc's vm trough a max defined gforce impact value in [g].

std::vector<sc_block> sc_optimize_gforce_arcs(std::vector<sc_block> blockvec);

//! Sets vo=0, ve=0 when motion is of type: G0

std::vector<sc_block> sc_optimize_G0_ve(std::vector<sc_block> blockvec);

//! Sets vo. ve when motions are of type: G0, G1, G2.

std::vector<sc_block> sc_optimize_G123_ve_backward(std::vector<sc_block> blockvec);

std::vector<sc_block> sc_optimize_G123_ve_forward(std::vector<sc_block> blockvec);We have to decide how to use it. I guess it could be used in 2 way's :

1. Do a optimizer over the gcode when it loads.

2. Do a live optimizer, for example look ahead 20 lines of gcode.

3. Do bot'h 1 & 2.

4. A better idea?

The sc_optimzer_gui is a simple test suite to perform sc_optimizer tasks.

It has also a tiny calculator to see how gforce relates to speed, arc diameter.

I think easyest way is to make a tiny list where some value's are already printed.

To be continued.

The following user(s) said Thank You: Darium

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11727

- Thank you received: 3972

24 Mar 2023 01:55 #267393

by rodw

x 2

Replied by rodw on topic LinuxCNC S-Curve Accelerations

Grotius = T1000 Terminator

He does not give up, ever.

x 2

No we need you around lurking in the shadows to keep the T1000 Terminator on track...rodw: I didn't intend to sound negative. back to lurk mode for now.

The following user(s) said Thank You: tommylight, Grotius, Darium

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

24 Mar 2023 14:26 - 24 Mar 2023 14:28 #267408

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi,

He does not give up, ever.

Have to confess sometimes it's better to give up in sometimes

for your own health and mental state.

Otherwise you can make your own live very hard,

and you can become angry on yourself, because things do not

succeed.

the algo of cavalier contours & auto nesting was going to far for me.

Cavalier contours is like magic. Really hard to design such a algo.

A nesting algo idem dito. Also magic, haha.

I guess we are lucky today.

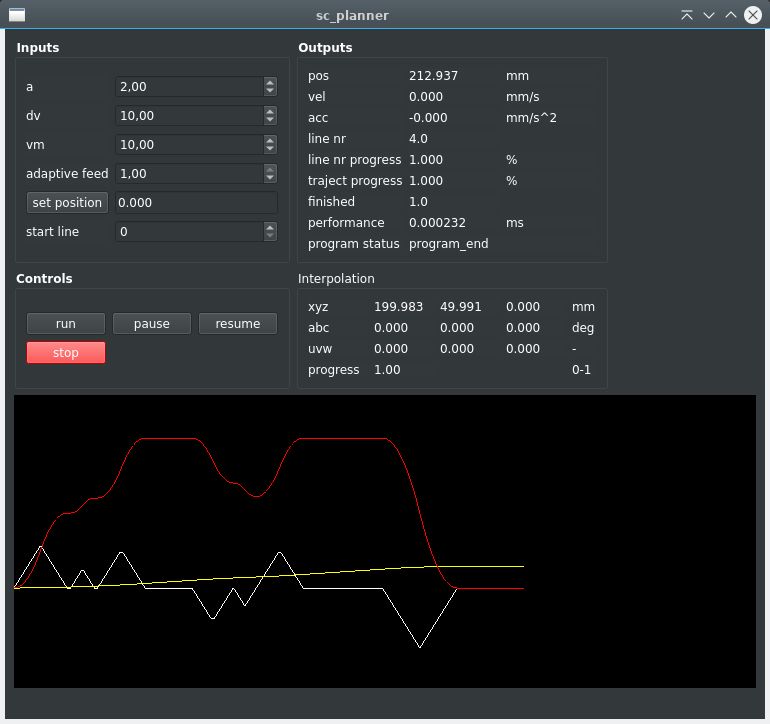

I tested the planner with the optimizer attached, cq look ahead function. It looks ahead 20 lines.

If user is at program line 50, the optimizer takes 50 as start & 50+20 as end range.

So far so good.

The testcase was done with multiple short lines after each other.

The motion:

Example without sc_optimizer :

Example with sc_optimizer :

Mention:

Half way the motion, the red curve has a dip. This is because there is a corner angle at that point. The last motion has

a y-value of 50.

You can also mention the first 4 motion's are fused together, because they are of type G1.

Without the path optimizer, the machine would stop every motion line.

He does not give up, ever.

Have to confess sometimes it's better to give up in sometimes

for your own health and mental state.

Otherwise you can make your own live very hard,

and you can become angry on yourself, because things do not

succeed.

the algo of cavalier contours & auto nesting was going to far for me.

Cavalier contours is like magic. Really hard to design such a algo.

A nesting algo idem dito. Also magic, haha.

I guess we are lucky today.

I tested the planner with the optimizer attached, cq look ahead function. It looks ahead 20 lines.

If user is at program line 50, the optimizer takes 50 as start & 50+20 as end range.

So far so good.

The testcase was done with multiple short lines after each other.

The motion:

Warning: Spoiler!

vo=0, ve=0;

planner->sc_add_line_motion(vo,ve,acs,ace,{0,0,0},{10,0,0},sc_type::sc_G1);

vo=0, ve=0;

planner->sc_add_line_motion(vo,ve,acs,ace,{10,0,0},{20,0,0},sc_type::sc_G1);

vo=0, ve=0;

planner->sc_add_line_motion(vo,ve,acs,ace,{20,0,0},{100,0,0},sc_type::sc_G1);

vo=0, ve=0;

planner->sc_add_line_motion(vo,ve,acs,ace,{100,0,0},{110,0,0},sc_type::sc_G1);

vo=0, ve=0;

planner->sc_add_line_motion(vo,ve,acs,ace,{110,0,0},{200,50,0},sc_type::sc_G1);Example without sc_optimizer :

Example with sc_optimizer :

Mention:

Half way the motion, the red curve has a dip. This is because there is a corner angle at that point. The last motion has

a y-value of 50.

You can also mention the first 4 motion's are fused together, because they are of type G1.

Without the path optimizer, the machine would stop every motion line.

Last edit: 24 Mar 2023 14:28 by Grotius.

The following user(s) said Thank You: tommylight, Darium

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

24 Mar 2023 20:34 #267420

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi,

I first looked into the comments of Mr Garret this evening. Its on page 30 of this topic.

Was able to halcompile a custom tp.comp and was able to replace a tp.c file for a copy named sc_tp.c

Lcnc started and loaded the sc_tp.so succesfully. Jogging was ok.

Now the next thing i want to try is play a little bit around with the function list in the sc_tp.c file.

What happens if we empty the pause function? I must get an idea how the tp.c works and reacts.

Here are my notes, how the procedure went exactly :

I first looked into the comments of Mr Garret this evening. Its on page 30 of this topic.

Was able to halcompile a custom tp.comp and was able to replace a tp.c file for a copy named sc_tp.c

Lcnc started and loaded the sc_tp.so succesfully. Jogging was ok.

Now the next thing i want to try is play a little bit around with the function list in the sc_tp.c file.

What happens if we empty the pause function? I must get an idea how the tp.c works and reacts.

Here are my notes, how the procedure went exactly :

Warning: Spoiler!

- Renamed tpcomp.comp to sc_tp.comp.

- Edit sc_tp.comp file, at first line:

component sc_tp "Trajectory Planning (tp) module skeleton";

- In file sc_tp.comp, line 51, set path to your lcnc dir.

#define TOPDIR /home/user/linuxcnc-dev

- Copy and rename file:

~/home/user/linuxcnc-dev/src/emc/tp/tp.c

into

~/home/user/linuxcnc-dev/src/emc/tp/sc_tp.c

- In sc_tp.comp outcomment : // #include USE_TOPDIR(src/emc/tp/tp.c)

- In sc_tp.comp add : #include "/home/user/linuxcnc-dev/src/emc/tp/sc_tp.c"

- ~/linuxcnc-dev/scripts/$ . ./rip-environment

- ~/linuxcnc-dev/scripts/$ halcompile --install /home/user/linuxcnc-dev/src/hal/components/sc_tp.comp

/components/sc_tp.comp

Compiling realtime sc_tp.c

Linking sc_tp.so

cp sc_tp.so /home/user/linuxcnc-dev/rtlib/

//! This did not load the sc_tp.

- ~/home/user/linuxcnc-dev/configs/sim/axis/axis_mm.ini

# Trajectory planner section --------------------------------------------------

[TRAJ]

TPMOD=sc_tp

//! This worked.

- ~/linuxcnc-dev/scripts/$ linuxcnc -t sc_tp /home/user/linuxcnc-dev/configs/sim/axis/axis_mm.ini

linuxcnc -t sc_tp /home/user/linuxcnc-dev/configs/sim/axis/axis_mm.ini

LINUXCNC - 2.10.0~pre0

Machine configuration directory is '/home/user/linuxcnc-dev/configs/sim/axis'

Machine configuration file is 'axis_mm.ini'

Starting LinuxCNC...

linuxcnc TPMOD=sc_tp HOMEMOD=homemod EMCMOT=motmod

Lcnc started ok, jogging ok.

At this stage, we have a tp componenent, and a custom tp.c file wich we can try to edit and see what happens.

The following user(s) said Thank You: tommylight, Darium

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

25 Mar 2023 23:10 #267510

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi,

Today i worked on mr. Garrets comments.

I emptied all functions in the tp.c file. The file was around 3000 lines. I lost overview.

After compiling with empty functions, lcnc would startup slowly, but no errors.

Then i pasted function's back into the code, that i found relevant for now.

After that, lcnc started up nice. Jogging and homing are working all the time,

it seems the tp.c file is only active when program run is pressed. I did'nt know that.

Then tested to get the lcnc tool moving on the screen. This worked !

I noticed a slow delay of about 5 sec. when motion would start to move, but no problem for now. I think it could

be something with the gcode list (Queue), wich is empty for now.

I started to getting the idea i know how it works. That's a good sign.

The next thing i am programming now is loading the gcode list, "Queue". This is the list of gcode coordinates to do.

So from here on, i think we can integrate the scurve lib quite easy into the tp.c file.

I have good feelings about this.

For testing i have lcnc repository with cmake build system. We have bird eye view, works perfect :

lcnc repository

This is the component that is starting with lcnc with the command:

$ . ./rip-environment

$ linuxcnc -t sc_tp /home/user/linuxcnc/configs/sim/axis/axis_mm.ini

The component that mr. Garret has provided as example, i have created a .c file component wich is a little simpler in the end:

theComponent

This is the modified tp.c file wich does the realtime motion planning, in progress :

TheScurveTp

Today i worked on mr. Garrets comments.

I emptied all functions in the tp.c file. The file was around 3000 lines. I lost overview.

After compiling with empty functions, lcnc would startup slowly, but no errors.

Then i pasted function's back into the code, that i found relevant for now.

After that, lcnc started up nice. Jogging and homing are working all the time,

it seems the tp.c file is only active when program run is pressed. I did'nt know that.

Then tested to get the lcnc tool moving on the screen. This worked !

I noticed a slow delay of about 5 sec. when motion would start to move, but no problem for now. I think it could

be something with the gcode list (Queue), wich is empty for now.

I started to getting the idea i know how it works. That's a good sign.

The next thing i am programming now is loading the gcode list, "Queue". This is the list of gcode coordinates to do.

So from here on, i think we can integrate the scurve lib quite easy into the tp.c file.

I have good feelings about this.

For testing i have lcnc repository with cmake build system. We have bird eye view, works perfect :

lcnc repository

This is the component that is starting with lcnc with the command:

$ . ./rip-environment

$ linuxcnc -t sc_tp /home/user/linuxcnc/configs/sim/axis/axis_mm.ini

The component that mr. Garret has provided as example, i have created a .c file component wich is a little simpler in the end:

theComponent

This is the modified tp.c file wich does the realtime motion planning, in progress :

TheScurveTp

The following user(s) said Thank You: zack, Darium

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

27 Mar 2023 13:17 - 27 Mar 2023 13:21 #267599

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi,

I have question.

Yesterday tried to find out how tp->done exactly works.

What happens to me is:

1. I want to recieve a new gcode line, so i set : tp->done=1

- Then from somewhere the function tpaddline or tpaddarc is triggered and i recieve one line of gcode.

- I could not see in the project wich module or code is sending this signal to activate the function.

2. If i want to recieve another line of gcode, i repeat 1.

- Then the whole gcode is dumped at once.

How could we recieve one line of gcode each time?

Or better, recieve a gcode from a given line nr on request.

Currently converting the sc_engine c++ code into pure c, to be used in realtime.

In the mean time, i hope someone know more about this fenomen.

The attached file is just for info.

The question is related to this code : scurve_tp.c

I have question.

Yesterday tried to find out how tp->done exactly works.

What happens to me is:

1. I want to recieve a new gcode line, so i set : tp->done=1

- Then from somewhere the function tpaddline or tpaddarc is triggered and i recieve one line of gcode.

- I could not see in the project wich module or code is sending this signal to activate the function.

2. If i want to recieve another line of gcode, i repeat 1.

- Then the whole gcode is dumped at once.

How could we recieve one line of gcode each time?

Or better, recieve a gcode from a given line nr on request.

Currently converting the sc_engine c++ code into pure c, to be used in realtime.

In the mean time, i hope someone know more about this fenomen.

The attached file is just for info.

The question is related to this code : scurve_tp.c

Last edit: 27 Mar 2023 13:21 by Grotius.

The following user(s) said Thank You: Darium

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

27 Mar 2023 21:31 #267626

by spumco

Replied by spumco on topic LinuxCNC S-Curve Accelerations

@Grotius:

I've been trying to follow this from the sidelines for quite some time - understanding perhaps 5% of the discussion. I've had nothing to contribute other than a belated 'thank you.'

Your latest post discussing 'one line of gcode' prompted me me to respond, however. I don't understand how 'everything' in LCNC works, but I do know there is an issue - or at least I and some others perceive it as such - with how LCNC works regarding execution of of g-code lines.

Forgive me if I get this wildly wrong, but I believe individual lines of g-code are not passed to (or from?) the trajectory planner. Rather, it's been explained to me that messages are sent which contain a 'bundle' of instructions. If a single line of g-code has movement, then that is all that's passed in the message.

However, if there are non-movement lines - G4's, M7/M8/M9, etc - those get 'bundled' in a single message with the next movement line. I'm quite sure I'm being dense or inexact (at best) in the terminology.

The end result is that LCNC's single-step function doesn't work like industrial CNC controls. In other controls there is a single-block mode, and when enabled that mode results in a single line of g-code being executed for each cycle-start command (or MFGR's equivalent). Doesn't matter if the line has motion or not... only one line is executed.

In LCNC a single step will blow through (execute) all lines of g-code until the next motion line. And there is no built-in single-block 'mode' - LCNC's step function is just another 'cycle-start' button. Somewhat disconcerting coming from other control systems.

I don't know if not having a single-block 'mode' has anything to do with the non-movement commands being 'bundled' with the next movement line. They may be related - or not. I've no clue, but both are a significant deviation from 'standard' CNC control behavior.

I mention all this because I'm hoping you can keep it in mind while you work on the s-curve TP project. If you have the chance to change how LCNC behaves regarding lines of g-code being 'bundled' I would urge you to see if it's possible without derailing the core project of a working s-curve tp.

Again, thank you for your efforts.

I've been trying to follow this from the sidelines for quite some time - understanding perhaps 5% of the discussion. I've had nothing to contribute other than a belated 'thank you.'

Your latest post discussing 'one line of gcode' prompted me me to respond, however. I don't understand how 'everything' in LCNC works, but I do know there is an issue - or at least I and some others perceive it as such - with how LCNC works regarding execution of of g-code lines.

Forgive me if I get this wildly wrong, but I believe individual lines of g-code are not passed to (or from?) the trajectory planner. Rather, it's been explained to me that messages are sent which contain a 'bundle' of instructions. If a single line of g-code has movement, then that is all that's passed in the message.

However, if there are non-movement lines - G4's, M7/M8/M9, etc - those get 'bundled' in a single message with the next movement line. I'm quite sure I'm being dense or inexact (at best) in the terminology.

The end result is that LCNC's single-step function doesn't work like industrial CNC controls. In other controls there is a single-block mode, and when enabled that mode results in a single line of g-code being executed for each cycle-start command (or MFGR's equivalent). Doesn't matter if the line has motion or not... only one line is executed.

In LCNC a single step will blow through (execute) all lines of g-code until the next motion line. And there is no built-in single-block 'mode' - LCNC's step function is just another 'cycle-start' button. Somewhat disconcerting coming from other control systems.

I don't know if not having a single-block 'mode' has anything to do with the non-movement commands being 'bundled' with the next movement line. They may be related - or not. I've no clue, but both are a significant deviation from 'standard' CNC control behavior.

I mention all this because I'm hoping you can keep it in mind while you work on the s-curve TP project. If you have the chance to change how LCNC behaves regarding lines of g-code being 'bundled' I would urge you to see if it's possible without derailing the core project of a working s-curve tp.

Again, thank you for your efforts.

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

27 Mar 2023 22:35 #267634

by Grotius

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

Hi Spumco,

From user perspective it's a logic explanation from you.

If you look into the previous linked c file, you can see functions like : tp_addline or tp_addcircle or tp_isdone.

In the original tp.c file there is a queue vector that has a size of about 10 lines of gcode.

I speak in therms of gcode to keep it simple. It's actually line, arc data, some speed and acc data etc.

It comes close to a actual gcode line.

Every time tp_done=1, the queue may be updated with new gcode line. It works like a c++ vector operation.

It can add a line, remove a old line from the bucket. The queue is like a tiny program that feeds the component.

For me it's not clear if i don't use the queue bucket to hold the gcode lines, why it's dumping the whole gcode file at once

if i do a tp_isdone request.

The first request goes ok, second request is dump mode.

And it's not clear to me where the tp_addline, tp_addarc requests actually came from?

With the bird eye view, i can search for the functions, but these 2 appear only once.

The goal is to clean up the original tp.c file to something minimal that is working, even without vel,acc etc.

It just has to do a working cycle. May even be without moving the tp itself.

From there i have a nice and clean starting point to integrate the scurve code.

From user perspective it's a logic explanation from you.

If you look into the previous linked c file, you can see functions like : tp_addline or tp_addcircle or tp_isdone.

In the original tp.c file there is a queue vector that has a size of about 10 lines of gcode.

I speak in therms of gcode to keep it simple. It's actually line, arc data, some speed and acc data etc.

It comes close to a actual gcode line.

Every time tp_done=1, the queue may be updated with new gcode line. It works like a c++ vector operation.

It can add a line, remove a old line from the bucket. The queue is like a tiny program that feeds the component.

For me it's not clear if i don't use the queue bucket to hold the gcode lines, why it's dumping the whole gcode file at once

if i do a tp_isdone request.

The first request goes ok, second request is dump mode.

And it's not clear to me where the tp_addline, tp_addarc requests actually came from?

With the bird eye view, i can search for the functions, but these 2 appear only once.

The goal is to clean up the original tp.c file to something minimal that is working, even without vel,acc etc.

It just has to do a working cycle. May even be without moving the tp itself.

From there i have a nice and clean starting point to integrate the scurve code.

The following user(s) said Thank You: spumco, Darium

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11727

- Thank you received: 3972

27 Mar 2023 22:38 #267636

by rodw

Replied by rodw on topic LinuxCNC S-Curve Accelerations

Just to highlight that the correct way to build a custom tp is to use a component based on this skeleton

github.com/LinuxCNC/linuxcnc/blob/master...mponents/tpcomp.comp

Docs: linuxcnc.org/docs/2.9/html/man/man9/tpcomp.9.html

I don't see the code yet following this template.

This is also how custom homing modules are created.

Spumco, I don't think this code touches the gcode parsing code but it is also modular too.

There is so much flexibility built into the linuxcnc framework, yet nobody has really attempted to make custom modules

github.com/LinuxCNC/linuxcnc/blob/master...mponents/tpcomp.comp

Docs: linuxcnc.org/docs/2.9/html/man/man9/tpcomp.9.html

I don't see the code yet following this template.

This is also how custom homing modules are created.

Spumco, I don't think this code touches the gcode parsing code but it is also modular too.

There is so much flexibility built into the linuxcnc framework, yet nobody has really attempted to make custom modules

The following user(s) said Thank You: spumco, Darium

Please Log in or Create an account to join the conversation.

Time to create page: 0.191 seconds