2 gantries with a shared work area

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

30 Jan 2018 09:21 - 30 Jan 2018 11:08 #105189

by Desertboy

2 gantries with a shared work area was created by Desertboy

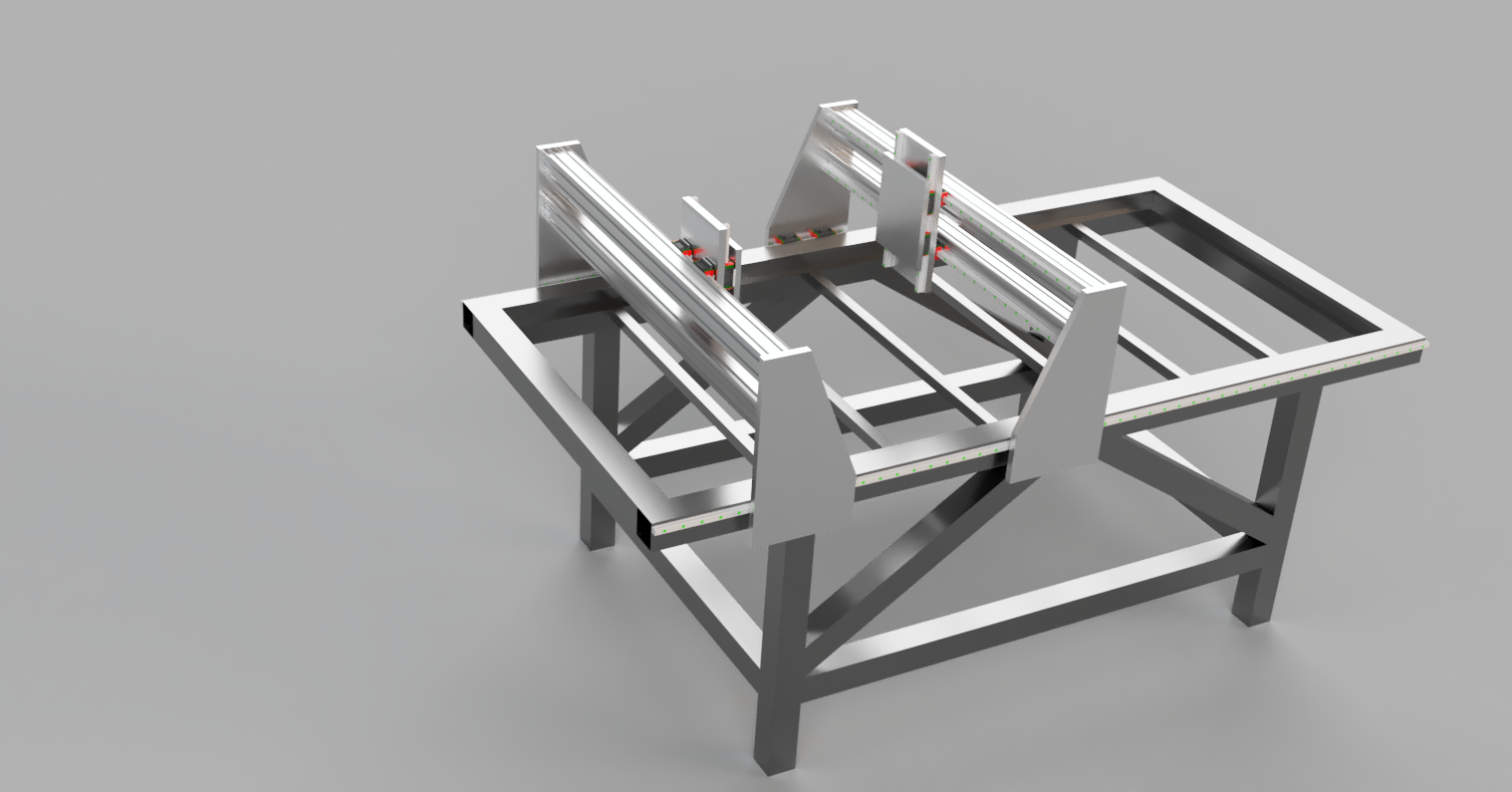

Hi I've been thinking about this for a while now a quick mockup

Not modeled the ballscrew yet and this size isn't correct but you get the idea. I cloned the gnatry on a mockup of something else I was working on.

2 gantries driven by 4 ballscrews in total 2 for each gantry so I can work it as 2 seperate machines which is how it would spend most of it's life. But would it be possible to have a shared area so they could work 1 piece? An 8 Axis router does Linuxcnc support this sort of setup?

My biggest worry of all is the gantries crashing into each other but when using them as 2 routers I can easily use different profiles in Linuxcnc (2 seperate machines, etc) so they no longer share a work area. I can see it will be hassle to wire it through switches so I can connect to 2 linuxcnc machines in one mode and 1 machine in 8 axis mode but not rocket science. The software side is a different matter.

Is this just a stupid idea.

Not modeled the ballscrew yet and this size isn't correct but you get the idea. I cloned the gnatry on a mockup of something else I was working on.

2 gantries driven by 4 ballscrews in total 2 for each gantry so I can work it as 2 seperate machines which is how it would spend most of it's life. But would it be possible to have a shared area so they could work 1 piece? An 8 Axis router does Linuxcnc support this sort of setup?

My biggest worry of all is the gantries crashing into each other but when using them as 2 routers I can easily use different profiles in Linuxcnc (2 seperate machines, etc) so they no longer share a work area. I can see it will be hassle to wire it through switches so I can connect to 2 linuxcnc machines in one mode and 1 machine in 8 axis mode but not rocket science. The software side is a different matter.

Is this just a stupid idea.

Last edit: 30 Jan 2018 11:08 by Desertboy.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

30 Jan 2018 16:01 #105195

by Todd Zuercher

Replied by Todd Zuercher on topic 2 gantries with a shared work area

Yes and no. Linuxcnc does support up to 9 axis (you would be using 6 (with 8 joints). The UVW axis represent parallel axis to XYZ, so it would make sense to use them for your 2ndary gantry.

Problems I can see,

1. working out how to prevent interference. (I don't think moving soft limits is currently possible)

2. The new trajectory planner only does blending and look a head for XYZ movements, it reverts to the old system for moves with any other axis.

3. Programming G-code for both would be a chore. You would need to find a CAM program that could program the code for this Siamese-twin machine.

4, Fully independent operation would require two separate Linuxcnc controls (2 computers), Making switching between independent and integrated operation difficult.

5. G-code operations are limited for the UVW axis. For example; I don't think arc movements (G2,G3) work for UVW.

For number 1 an alarm to prevent a crash during a move or a run should not be too hard, but predicting those situations when loading a g-code file like the soft limits do for an ordinary machine might be difficult.

It doesn't seem like such a good idea, when you consider that 2 separate machines would be more functional, and not cost significantly more. (The down side being needing twice as much space.)

Problems I can see,

1. working out how to prevent interference. (I don't think moving soft limits is currently possible)

2. The new trajectory planner only does blending and look a head for XYZ movements, it reverts to the old system for moves with any other axis.

3. Programming G-code for both would be a chore. You would need to find a CAM program that could program the code for this Siamese-twin machine.

4, Fully independent operation would require two separate Linuxcnc controls (2 computers), Making switching between independent and integrated operation difficult.

5. G-code operations are limited for the UVW axis. For example; I don't think arc movements (G2,G3) work for UVW.

For number 1 an alarm to prevent a crash during a move or a run should not be too hard, but predicting those situations when loading a g-code file like the soft limits do for an ordinary machine might be difficult.

It doesn't seem like such a good idea, when you consider that 2 separate machines would be more functional, and not cost significantly more. (The down side being needing twice as much space.)

Please Log in or Create an account to join the conversation.

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

30 Jan 2018 16:38 #105198

by Desertboy

Replied by Desertboy on topic 2 gantries with a shared work area

Hooking them up needn't be a chore

www.moddiy.com/products/Maituo-2-Port-DB...2EAQYASABEgLo8PD_BwE

I could use parallel port BOB to simplify the wiring and connect to a mesa controller this solves scenario 1 & 2.

scenario 3 I can see the problem lol, you could use an inductive prob on one of the gantries hooked to an emergency stop to deal with crashing into each other but as you say the cam software, planners, etc. Need to be aware.

www.moddiy.com/products/Maituo-2-Port-DB...2EAQYASABEgLo8PD_BwE

I could use parallel port BOB to simplify the wiring and connect to a mesa controller this solves scenario 1 & 2.

scenario 3 I can see the problem lol, you could use an inductive prob on one of the gantries hooked to an emergency stop to deal with crashing into each other but as you say the cam software, planners, etc. Need to be aware.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

01 Feb 2018 16:06 #105286

by Todd Zuercher

Replied by Todd Zuercher on topic 2 gantries with a shared work area

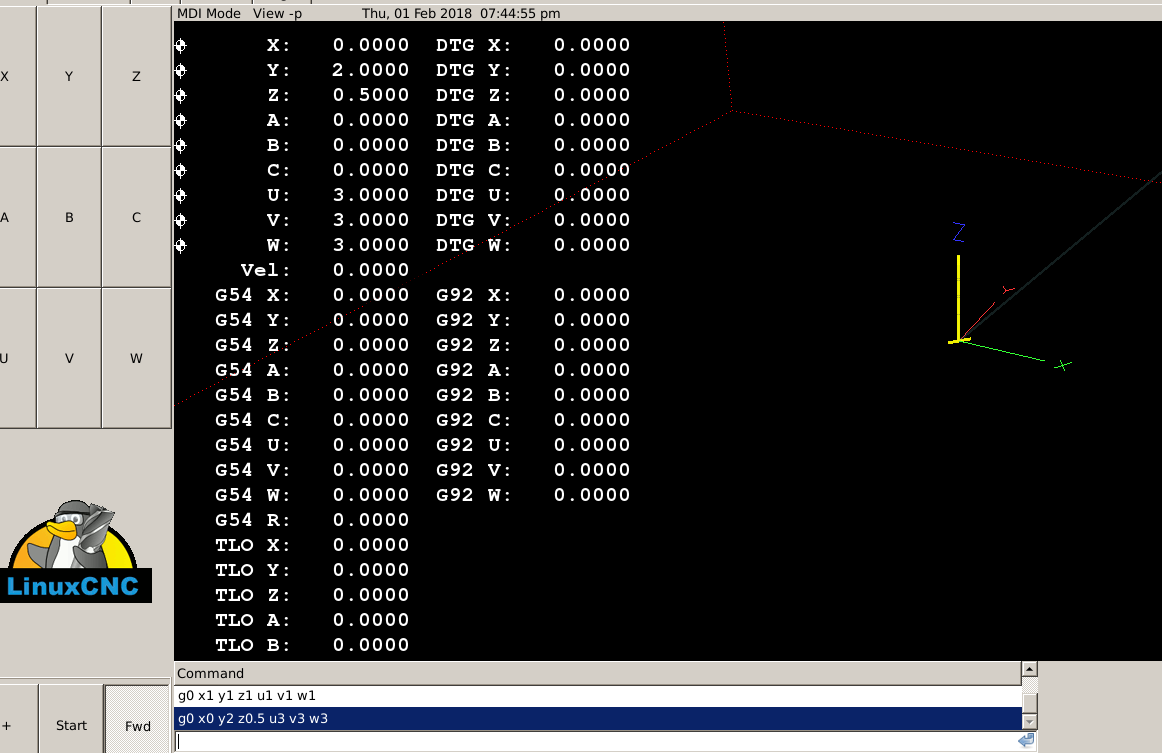

Here is another idea of a way to configure the two parallel axis that I think might allow Linuxcnc to predict and prevent interference.

If the long axis that caries the two gantries is the Y axis and V axis. Rather than configure the V as an independent axis, set it up as the sum of the Y joints and the V joints. When set up this way a command of the Y axis would move both gantries in parallel and a command of the V axis would change the spacing between them. Set up like this I believe all of the soft limits should work. (I think)

The main downside to this set up would be possibly putting a larger and more unusual demand on your CAM software for programing independent movement of your V axis. A simple parametric find and replace of the standard V position could give you the needed command. (Could even be done on the fly with a sript when loading the file.)

For example if you wanted to move the Y axis 10 inches from 5 to 15 but have the V move -10 from 65 to 55. The parameterized g-code could look something like this.

G90G0 Y5 V[65-#5421]

G1 Y15 V[55-#5421]

parameter #5421 = the absolute potion of the Y joint including all offsets.

I am not certain what this might do to feed rates, and that could be a problem.

If the long axis that caries the two gantries is the Y axis and V axis. Rather than configure the V as an independent axis, set it up as the sum of the Y joints and the V joints. When set up this way a command of the Y axis would move both gantries in parallel and a command of the V axis would change the spacing between them. Set up like this I believe all of the soft limits should work. (I think)

The main downside to this set up would be possibly putting a larger and more unusual demand on your CAM software for programing independent movement of your V axis. A simple parametric find and replace of the standard V position could give you the needed command. (Could even be done on the fly with a sript when loading the file.)

For example if you wanted to move the Y axis 10 inches from 5 to 15 but have the V move -10 from 65 to 55. The parameterized g-code could look something like this.

G90G0 Y5 V[65-#5421]

G1 Y15 V[55-#5421]

parameter #5421 = the absolute potion of the Y joint including all offsets.

I am not certain what this might do to feed rates, and that could be a problem.

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

02 Feb 2018 00:51 #105304

by Grotius

Replied by Grotius on topic 2 gantries with a shared work area

@hi Desertboy,

I think it work. I did a test with gscreen, it works.

But there is a problem when you do one line of g-code for 2 gantry's with different movement's.

You know the interpolation effects end's on the same time in one g-code line.

So that must be a seperated g-code if you want do different

things on the double portal machine.

Linux can only be started one time at the moment. Maybe if you start it two times, it will work independent.

At the moment you can only use it as a slave with one pc.

I think it work. I did a test with gscreen, it works.

But there is a problem when you do one line of g-code for 2 gantry's with different movement's.

You know the interpolation effects end's on the same time in one g-code line.

So that must be a seperated g-code if you want do different

things on the double portal machine.

Linux can only be started one time at the moment. Maybe if you start it two times, it will work independent.

At the moment you can only use it as a slave with one pc.

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

02 Feb 2018 13:20 #105324

by Todd Zuercher

Replied by Todd Zuercher on topic 2 gantries with a shared work area

At one point I thought Machinekit either had the ability to run multiple instances (of their version of Linuxcnc) or they were working on it. I don't know any more than that as I don't follow or use Machinekit. (a fork of Linuxcnc)

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

02 Feb 2018 13:38 - 02 Feb 2018 13:39 #105325

by Desertboy

Replied by Desertboy on topic 2 gantries with a shared work area

Is there an advantage to running multiple instances of linuxcnc on 1 pc over 2 pc's? Apart from space of course.

I'm really digging the dual gantry idea now, I keep talking myself out of it but then the next day I'm talking myself back into it lol.

There has to be a point to it since it's going to cost at least an extra £1k to implement and maybe more but I have quite a few ideas on how this could be implemented to make it a worthwhile endeavour.

I can do the hardware and to some extent I can sort cloning and individual operation out myself but shared work area is far beyond me lol.

I'm really digging the dual gantry idea now, I keep talking myself out of it but then the next day I'm talking myself back into it lol.

There has to be a point to it since it's going to cost at least an extra £1k to implement and maybe more but I have quite a few ideas on how this could be implemented to make it a worthwhile endeavour.

I can do the hardware and to some extent I can sort cloning and individual operation out myself but shared work area is far beyond me lol.

Last edit: 02 Feb 2018 13:39 by Desertboy.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

02 Feb 2018 14:10 - 02 Feb 2018 14:17 #105326

by Todd Zuercher

Replied by Todd Zuercher on topic 2 gantries with a shared work area

Independent control would still be possible, the real trick would be generating the G-code to do it. It would take some rather powerful and configurable CAM program. (can't name one off the top of my head that could do it, but I'm sure there is one, and that it's probably very expensive.)

To get around possible feed rate issues, you might have to use inverse time feeds. (adding yet another layer of complexity to the g-code and making it even less handy to code by hand.)

I'll try to give you a very simple example, to move in a 3x3 square with XY and a 4x4x4 triangle with UV with a feed rate of F100 simultaneously using inverse time.

To get around possible feed rate issues, you might have to use inverse time feeds. (adding yet another layer of complexity to the g-code and making it even less handy to code by hand.)

I'll try to give you a very simple example, to move in a 3x3 square with XY and a 4x4x4 triangle with UV with a feed rate of F100 simultaneously using inverse time.

G90G93

G0X1Y1U1V[21-#5421]

G1X4U3.5981V[22.5-#5421]F0.03

Y2U4.4681V[23.0-#5421]F0.01

Y4U2.7321V[24-#5421]F0.02

X2U1V[25.0-#5421]F0.02

X1V[24.0-#5421]F0.01

Y1V[21.0-#5421]F0.03

Last edit: 02 Feb 2018 14:17 by Todd Zuercher. Reason: I really should proof read before posting.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

02 Feb 2018 14:33 #105327

by Todd Zuercher

Replied by Todd Zuercher on topic 2 gantries with a shared work area

I say this knowing nothing about Machinekits implementation of this if it even exists. But it may make the integration of duel gantries and their interaction with each other easier, on one computer with shared resources rather than two separate computers and trying to transmit position info between the two.

One place you may be able to save some cash and combine items. Rather than having 4 ball screw assemblies just for the gantry axis, use just 2 fixed screws (one on each side) with 2 nuts on each screw and rotate the nuts instead of the whole screw. It often makes more sense to rotate the nut rather than the screw on really long screws like you're going to have there anyway.

As far as the shared work area, you could always just not worry about predicting interference with soft limits and simply rely on hard limit switches to prevent crashes as they happen.

One place you may be able to save some cash and combine items. Rather than having 4 ball screw assemblies just for the gantry axis, use just 2 fixed screws (one on each side) with 2 nuts on each screw and rotate the nuts instead of the whole screw. It often makes more sense to rotate the nut rather than the screw on really long screws like you're going to have there anyway.

As far as the shared work area, you could always just not worry about predicting interference with soft limits and simply rely on hard limit switches to prevent crashes as they happen.

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

02 Feb 2018 21:57 #105340

by Grotius

Replied by Grotius on topic 2 gantries with a shared work area

@Todd,

If you have a git link for me, i can look and compare the code with latest linux version.

I have also future machines for this option. Also one client wanted a milling machine with 2 saw blades on double portal.

Normally i would do this on 2 pc's, but if possible i would do it on a I7 processor on one pc.

If you have a git link for me, i can look and compare the code with latest linux version.

I have also future machines for this option. Also one client wanted a milling machine with 2 saw blades on double portal.

Normally i would do this on 2 pc's, but if possible i would do it on a I7 processor on one pc.

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

Time to create page: 0.119 seconds