Making some axes independent of the motion controller

- newbynobi

-

- Offline

- Platinum Member

-

- Posts: 1930

- Thank you received: 394

Thanks for that very usefull feature, as it allows to build handling units and use separate joints for tool changers!

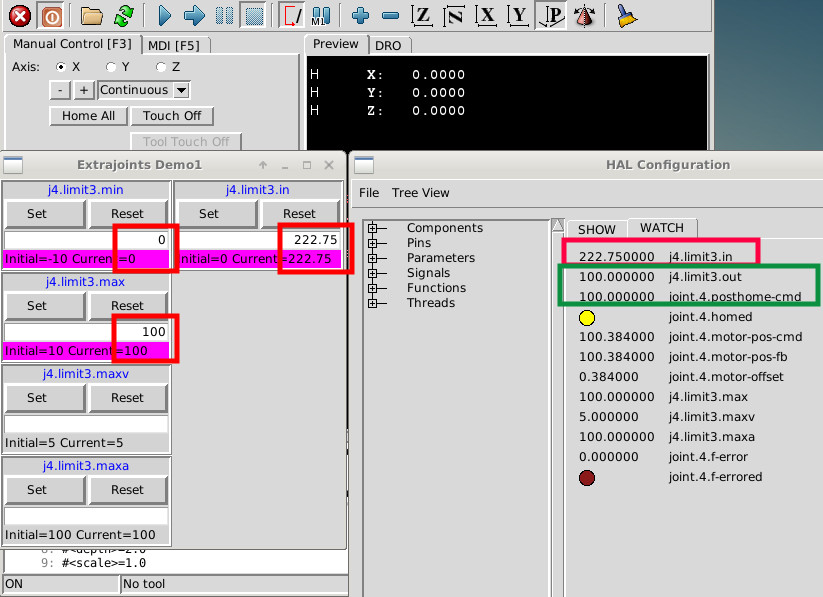

I played arround a little and I did set

j4.limit3.min = 0

j4.limit3.max = 100

Why is it possible to set:

j4.limit3.in = 222.75

That value is out of the limits. Is there a possibility to check for the limits?

Norbert

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

- Posts: 492

- Thank you received: 297

That value is out of the limits. Is there a possibility to

check for the limits?

The in pin to the limit3 component can be anything but the *output*

is limited according to the .min and .max pins (and the velocity

and acceleration of the output is limited according to the .maxv and

.maxa pin values).

The out pin of the limit3 is the input for the 'extra' joint after homing

as connected to joint.4.posthome-cmd. The usual joint.4.motor-pos-cmd

is the input to a motion controller (pid-motor-encoder or stepper system)

and includes the motor-offset resulting from the homing process.

Ref: linuxcnc.org/docs/master/html/man/man9/limit3.9.html

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Platinum Member

-

- Posts: 1930

- Thank you received: 394

That is just a GUI part, so that part is easy

Hope you will include that branch to master.

Norbert

Please Log in or Create an account to join the conversation.

- cogzoid

-

Topic Author

Topic Author

- Visitor

-

I'm not a coding guy by nature, so I'm trying to figure out how to properly install this branch. I should be able to get some help from a coworker. But, my struggles with basic github aside, I'm struggling with some syntax in your example .hal file.

Here is the demo1.hal:

# extrajoints demo1

# immediate homing -- jog joint4 to make a motor-offset before homing

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

addf motion-command-handler servo-thread

addf motion-controller servo-thread

net estop-loop iocontrol.0.user-enable-out iocontrol.0.emc-enable-in

net J0:loop <= joint.0.motor-pos-cmd

net J0:loop => joint.0.motor-pos-fb

net J1:loop <= joint.1.motor-pos-cmd

net J1:loop => joint.1.motor-pos-fb

net J2:loop <= joint.2.motor-pos-cmd

net J2:loop => joint.2.motor-pos-fb

net J3:loop <= joint.3.motor-pos-cmd

net J3:loop => joint.3.motor-pos-fb

#--------------------------------------------

# extra joint (joint4)

# For simulation or stepgen motor controller

# connect pos,fb:

# NOTE: For a pid motor controller (motor/encoder):

# net J4:cmd joint.4.motor-pos-cmd => pid_command

# net J4:fb joint.4.motor-prehome-fb <= encoder

net J4:loop <= joint.4.motor-pos-cmd

net J4:loop => joint.4.motor-pos-fb

#-----------------------------------------------------------

# motion planner for extra joint (joint4)

loadrt limit3 names=j4.limit3

# These constraints apply to homing managed by

# LinuxCNC and post-homing managed by the limit3 component:

setp j4.limit3.min [JOINT_4]MIN_LIMIT

setp j4.limit3.max [JOINT_4]MAX_LIMIT

setp j4.limit3.maxv [JOINT_4]MAX_VELOCITY

setp j4.limit3.maxa [JOINT_4]MAX_ACCELERATION

addf j4.limit3 servo-thread

net J4:out <= j4.limit3.out

net J4:out => joint.4.posthome-cmd

net J4:enable <= joint.4.homed

net J4:enable => j4.limit3.enableI guess I'm confused by the Joint vs. Axis differences. This link doesn't have any "joint" pins the way you use them. When do I use Joint and when do I use Axis? Is the colon in the "j0:loop" a special character or is that just another variable name? I'm going to have to understand all of this if I'm going to figure out how to merge it with the rest of my .hal file. Once again, thanks for any help. Pointing me at an example or the right documentation would be a major help.

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

- Posts: 492

- Thank you received: 297

I guess I'm confused by the Joint vs. Axis differences.

One can almost always equate joints to motors (prime

movers). Axes are world cartesian coordinates (in LinuxCNC:

XYZ ABC) (UVW are available as auxiliary coordinates usually

aligned with one of the cartesian coordinates.)

When LinuxCNC is started, only joint (motor) motion is

initially available. In operation, joints must be 'homed'

using methods provided by LinuxCNC. These methods typically

use a home-switch and perhaps an encoder index signal. Once

all joints are homed, LinuxCNC switches from joint control

to world coordinate control as specified by the loaded

kinematics module. Coordinated movements include gcode

(e.g., MDI or a GCODE program) and world jogging moves

(called 'teleop' in some places).

The experimenal branch dgarr/motion_extrajoints provides a

means to specify 'extra' joints that are homed by normal

LinuxCNC methods but do *not* participate in the kinematics

transformations employed for coordinated motion.

When using 'extra' joints, one uses existing methods to

home all joints -- joints that are kinematically transformed

to world (XYZABC) coordinates *and* the 'extra' joints that

do not participate in the kinematics transformations that

translate motor postions to/from world coordinates.

After homing, when operation is switched to coordinated

mode, the 'extra' joints must be controlled by independent

motion controllers. These motion controllers are not known

to LinuxCNC or its management of planned motion in world

space. After homing, each 'extra' joint is managed by a

single hal pin (joint.N.posthome-cmd). This pin would

typically be the driven by an independent motion planner that

uses a limit3 component to manage motion. The limit3

component provides hal pins to constrain the limit3 output

in its min/max position, its position_max_velocity, and its

position_max_acceleration. As always, the implementation must

provide a means to convert the joint.N.motor-pos-cmd

output to drive its motor (for example a step generator or a

pid-amplifier-encoder setup for a servo motor) during and

after homing.

To *use* the 'extra' joints in a GCODE program, one method

would use USER M commands to provide setpoints to the

limit3 input pin (and maybe to other limit3 pins that

limit position, velocity, and acceleration). For example,

to establish a new 'extra' joint position for the 'extra'

joint numbered 4, a bash script (M155) would be something like:

$ cat M155

#!/bin/bash

p=$1

# set new setpoint to the limit3 component for the extra joint:

halcmd setp j4.limit3.in $p

exit 0An example GCODE program excerpt could be:

F100

G1 x1 y1 z1

M155 P1.23 (move the extra joint)

G1 x2 y2 z2Note: this simple example does not show any required delays or

synchronizing steps that might be needed for a real

application.

The link is for the current release branch 2.7.x and is not appropriate forThis link doesn't have any "joint" pins the way you use them.

any experimental branch based on master.

Use the motion man page ($ man motion) for the experimental branch. Raw format:

github.com/LinuxCNC/linuxcnc/blob/dgarr/...cs/man/man9/motion.9

The raw format may be hard to read, excerpt:

The optional num_extrajoints parameter specifies

a quantity of joints that participate in homing

but are not used in kinematics transformations.

After homing, control of an 'extra' joint is

transferred to a posthome command hal pin and the

motor feedback value is ignored. 'Extra' joints

must be managed by independent motion plan‐

ners/controllers (typically using limit3 hal com‐

ponents).

The maximum num_extrajoints value is equal to the

num_joints value. (Note that using the maximum

value would allow no operation in world coordi‐

nates). The num_joints value must be equal to

the sum of the number of joints used for kinemat‐

ics calculations plus the number of 'extra'

joints.

Joint hal pin numbering is [0 ... num_joints-1].

'Extra' joints, when specified, are assigned the

last num_extrajoints in the numbering sequence.When do I use Joint and when do I use Axis?

In addition to the brief above, please see:

linuxcnc.org/docs/master/html/motion/kinematics.html

Is the colon in the "j0:loop" a special character or is that just another variable name?

The ':' is just a character in the signal name, it makes it

easy to find in halcmd reports (for example: $ halcmd show sig|grep

Pointing me at an example or the right documentation would be a major help.

The experimental branch includes two examples:

demo1.ini uses immediate homing so a user must jog a

joint before homing to see how a motor offset

due to homing is handled.

demo2.ini uses a the library halfile (basic_sim.tcl) to make

hal components and connections based on the items

specified in the ini file. The library provides

a means to simulate home switches for many

configurations.

Step-by-step instructions for these demos are provided:

github.com/LinuxCNC/linuxcnc/blob/dgarr/...xtrajoints/demo1.txt

github.com/LinuxCNC/linuxcnc/blob/dgarr/...xtrajoints/demo2.txt

Notes:

1) all descriptions above are based on joint-axes

incorporation in the master branch (2.8~pre)

2) some guis (axis) hide the distinctions of joints and axis

coordinates when using trivial kinematics (trivkins) with

KINEMATICS_IDENTITY (the default).

3) When using trivkins with the axis gui, it is helpful to

always specify kinstype=Both to clarify the distinctions

between joints (0,1,2,...) and axis coordinates

(X,Y,Z,A,B,C...). See the trivkins (kins) man page:

linuxcnc.org/docs/master/html/man/man9/trivkins.9.html

4) Specifying extra joints in the experimental branch is a

little tricky since the branch preserves backwards

compatibility to all prior module parameters

5) User M code can receive two parameters (P

and Q) that can be used for various purposes.

linuxcnc.org/docs/master/html/gcode/m-code.html#mcode:m100-m199

6) Synchronizing 'extra' joint motion to

GCODE could be achieved with some hal logic

and GCODE reading of hal pins using M66

www.linuxcnc.org/docs/html/gcode/m-code.html#mcode:m66

7) An alternative to using user M codes for communicating to

extrajoints is to use GCODE writes to hal pins using M67 or M68

www.linuxcnc.org/docs/html/gcode/m-code.html#mcode:m67

www.linuxcnc.org/docs/html/gcode/m-code.html#mcode:m68

Note: 19mar19, branch rebased to master at commit 3f2976547

Please Log in or Create an account to join the conversation.

- cogzoid

-

Topic Author

Topic Author

- Visitor

-

I've muscled my way through installing the RunInPlace master branch and your extrajoints branch. I've managed to modify my .hal and .ini files to open linuxcnc successfully, so that feels good. Now to do some characterization tests so that everything works the way I expect before I repeat this whole process on the computer running the actual robot.

Cheers!

Please Log in or Create an account to join the conversation.

- cogzoid

-

Topic Author

Topic Author

- Visitor

-

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

It is likely that the extra joints changes have broken some of the LinuxCNC regression tests. At this point of development of that branch this is not really important.

Please Log in or Create an account to join the conversation.

- cogzoid

-

Topic Author

Topic Author

- Visitor

-

Unrelated, I'm seeing some odd behavior with homing sequences. I was testing on my 2nd system (no steppers attached to the Mesa board) so I set all of the homing sequences to -1 except for the joint that I wanted to test. After properly homing my one joint, it then proceeded to try and home all of my other joints.

Based on this: linuxcnc.org/docs/html/config/ini-homing.html that shouldn't have been the case. Is this related to the errors? I know I was able to isolate the homing sequences during testing before...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19770

- Thank you received: 4601

Please Log in or Create an account to join the conversation.