toolchange protocol and manual toolchange touchoff

- frogandspanner

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 2

17 Dec 2018 18:26 #122526

by frogandspanner

Replied by frogandspanner on topic toolchange protocol and manual toolchange touchoff

> Would an automatic tool-length probe work better? It's rather easier to make work

I have though of that as an ultimate destination, but am nervous of the journey, and the number of tools broken on the way. As a CNC novice I wanted a relatively straightforward (and cheap) approach.

A little background: I got into linuxCNC by accident, never intending to work with CNC. I bought a small mini mill (Sieg SX2P) and got fed up cranking the x-axis handle, so I motorised it. I then came across linuxCNC as a way of controlling the motor, and it did away with counting how many cranks of the handle I'd made. The benefits soon led to the Y axis being modified, then the Z, and A soon followed. THEN: how to programme this kit usefully?!?!?!? I am learning, but find linuxCNC difficult to comprehend.

>The other alternative, and one that actually works pretty well

>(and is rather more flexible) is to split the G-code up into one file

>for each tool.

I am an untidy organiser, and have been unhappy about having bits of g-code for the same item in different files. I'd much rather have a single program with toolchanges. However, I have written recent projects using g-code generators I write in C, and have been using a combination of the touchoff-toolchange and (when that fails) separate files.

>This also gives you the option of using one tool on many parts, as

>sometimes it is quicker and easier to swap workpieces than tools.

I am still in nett swarf-producer mode, so am not advanced enough to be making multiple parts at a time. In fact, I am usually working on several instances of a single piece, each at a different stage of ruination.

I have though of that as an ultimate destination, but am nervous of the journey, and the number of tools broken on the way. As a CNC novice I wanted a relatively straightforward (and cheap) approach.

A little background: I got into linuxCNC by accident, never intending to work with CNC. I bought a small mini mill (Sieg SX2P) and got fed up cranking the x-axis handle, so I motorised it. I then came across linuxCNC as a way of controlling the motor, and it did away with counting how many cranks of the handle I'd made. The benefits soon led to the Y axis being modified, then the Z, and A soon followed. THEN: how to programme this kit usefully?!?!?!? I am learning, but find linuxCNC difficult to comprehend.

>The other alternative, and one that actually works pretty well

>(and is rather more flexible) is to split the G-code up into one file

>for each tool.

I am an untidy organiser, and have been unhappy about having bits of g-code for the same item in different files. I'd much rather have a single program with toolchanges. However, I have written recent projects using g-code generators I write in C, and have been using a combination of the touchoff-toolchange and (when that fails) separate files.

>This also gives you the option of using one tool on many parts, as

>sometimes it is quicker and easier to swap workpieces than tools.

I am still in nett swarf-producer mode, so am not advanced enough to be making multiple parts at a time. In fact, I am usually working on several instances of a single piece, each at a different stage of ruination.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

18 Dec 2018 09:52 #122562

by pl7i92

Replied by pl7i92 on topic toolchange protocol and manual toolchange touchoff

IT Woudt be good to tell Here How you like to Change Tool

and How does the Setup looks

Then there is a Good change to get as Best working Procedure

LIKE

""" I Got a Magazin of 6 Toolclamps/Holders for manuel Toolchange """

This woudt giveyou the Tooltable opertunity

""" I Got only one Clamp ERx and change every Tool in Manuel no ToolLength Mesurment Point"""

MAkE a Pice of PCB 1,5mm Thick Crocodile Clamp to Probe in

in G-code add your Post processor to get

MOVE UP you may know your limit 30mm+

M00

(Tool Change)

G38.2 G91Z-30 F40

G92 Z1.5

G90

G0 Z3

M00

(REMOVE Touch Plate and tool Clamp )

GO on CNC

and How does the Setup looks

Then there is a Good change to get as Best working Procedure

LIKE

""" I Got a Magazin of 6 Toolclamps/Holders for manuel Toolchange """

This woudt giveyou the Tooltable opertunity

""" I Got only one Clamp ERx and change every Tool in Manuel no ToolLength Mesurment Point"""

MAkE a Pice of PCB 1,5mm Thick Crocodile Clamp to Probe in

in G-code add your Post processor to get

MOVE UP you may know your limit 30mm+

M00

(Tool Change)

G38.2 G91Z-30 F40

G92 Z1.5

G90

G0 Z3

M00

(REMOVE Touch Plate and tool Clamp )

GO on CNC

Please Log in or Create an account to join the conversation.

- frogandspanner

- Offline

- Senior Member

-

Less

More

- Posts: 65

- Thank you received: 2

02 Jan 2019 12:51 #123322

by frogandspanner

Replied by frogandspanner on topic toolchange protocol and manual toolchange touchoff

After much research in the source code I am convinced that the bodge that I found and am using, in modified form, is the best that can be done with manual touchoff.

I'll have a look at auto-touchoff, but am concerned about the idea of using something (e.g. pcb) that results in a hard impact.

I'll have a look at auto-touchoff, but am concerned about the idea of using something (e.g. pcb) that results in a hard impact.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

02 Jan 2019 13:40 #123328

by andypugh

Something spring-loaded is likely to be safest.

There are specific devices available for the job. Though making your own would be cheaper.

www.ebay.co.uk/itm/Werkzeuglangensensor-...4:g:S7gAAOxy3yNTfQx3

Replied by andypugh on topic toolchange protocol and manual toolchange touchoff

I'll have a look at auto-touchoff, but am concerned about the idea of using something (e.g. pcb) that results in a hard impact.

Something spring-loaded is likely to be safest.

There are specific devices available for the job. Though making your own would be cheaper.

www.ebay.co.uk/itm/Werkzeuglangensensor-...4:g:S7gAAOxy3yNTfQx3

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 566

- Thank you received: 108

03 Jan 2019 03:02 #123385

by JohnnyCNC

Replied by JohnnyCNC on topic toolchange protocol and manual toolchange touchoff

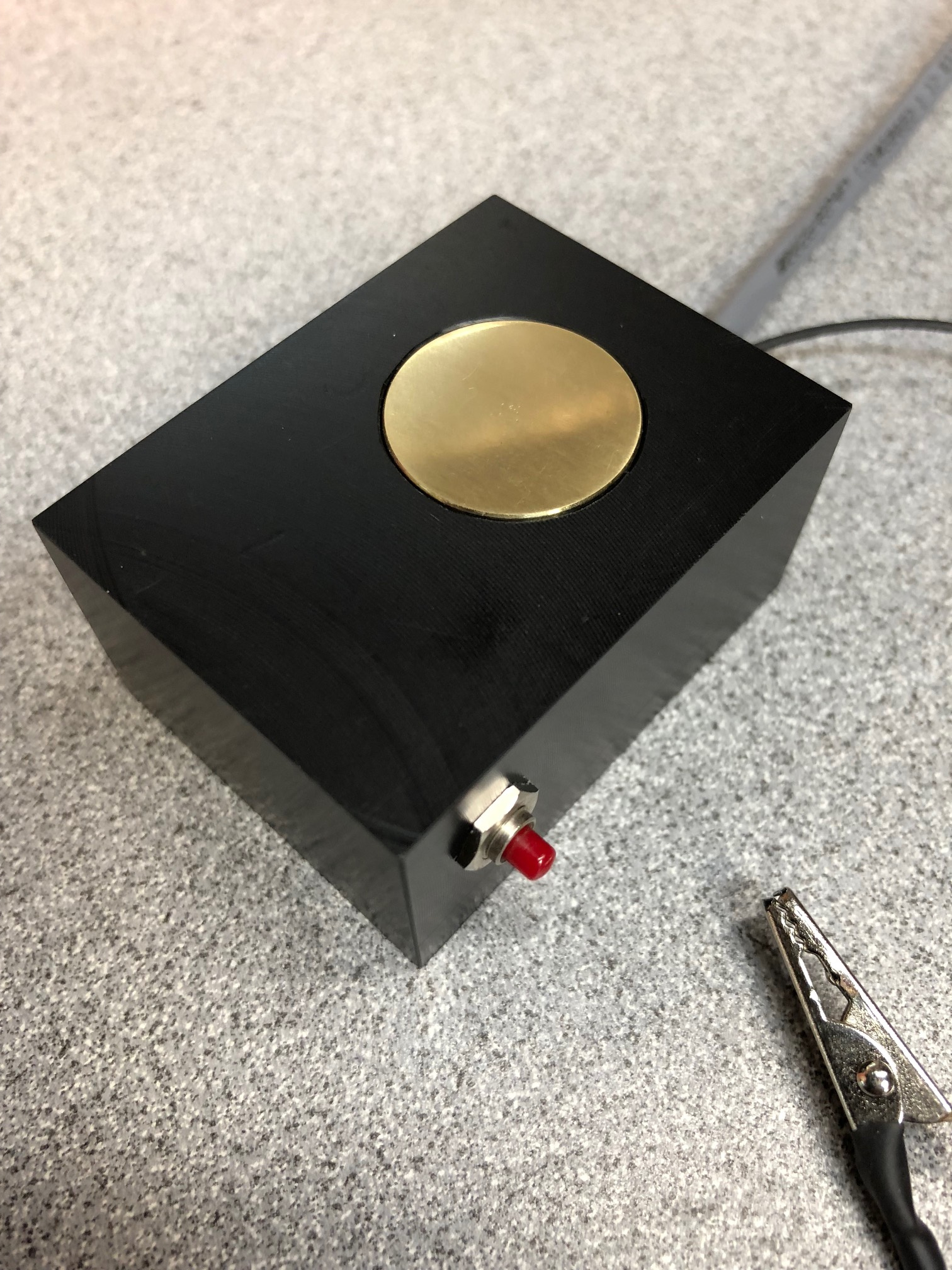

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.121 seconds