Relay to turn on spindle

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

- Posts: 566

- Thank you received: 108

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

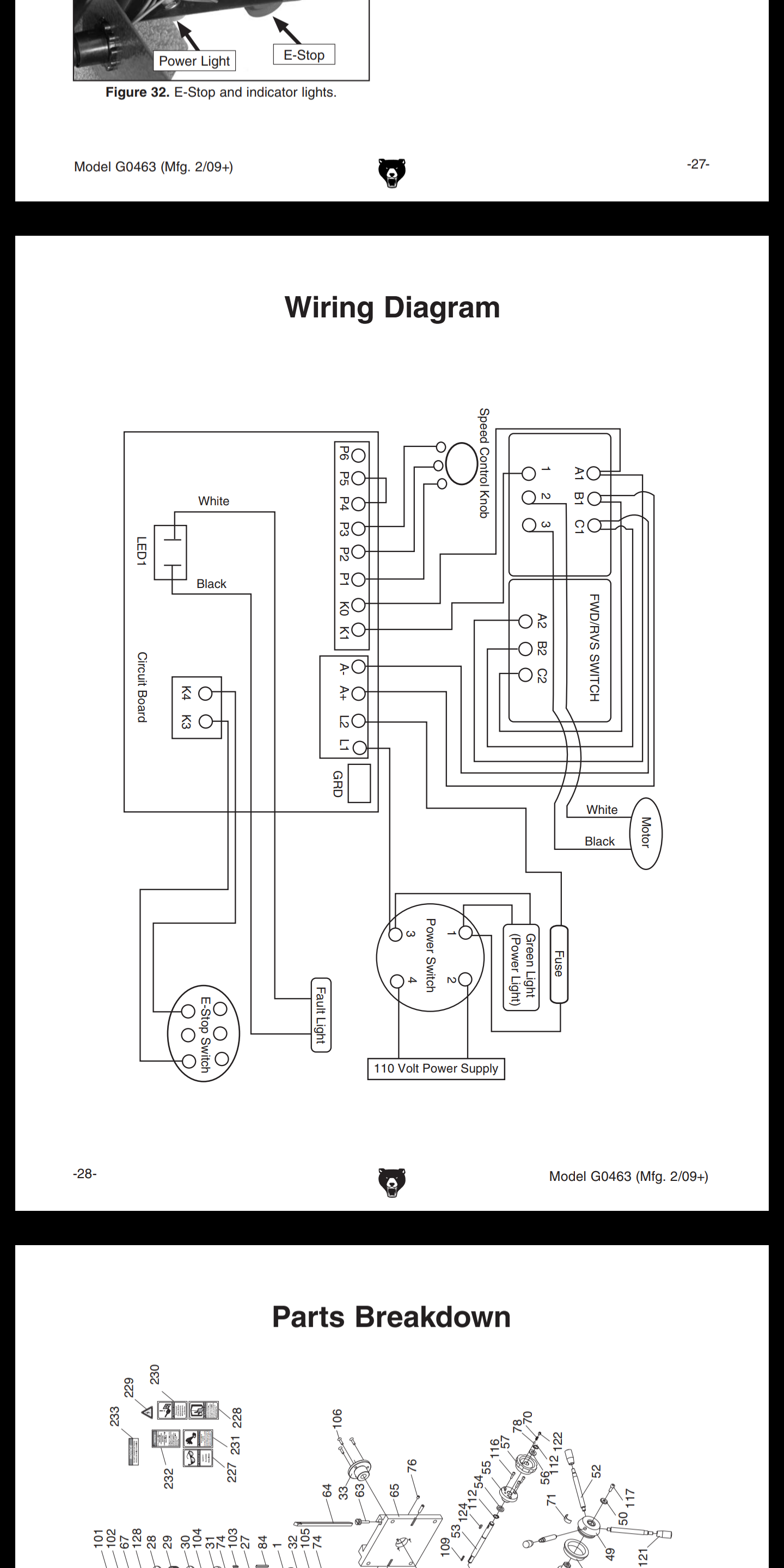

Thanks, I'll look into thatOn my X3 I used a double pole relay (Automation Direct QL2N1-D24 10A@250 VAC). One pole was used to break the connection from terminal 3 on the on/off switch to the motor. The other pole was used to open the connection between K1 on the board and terminal 1 on the on/off switch. This is so that if the motor faults or an E-Stop is activate the CNC control will need to stop the spindle (open the relay) so that the safety will be reset and then can turn the spindle back on when relay to proceed. I used this setup for about 6 months with no problems until I upgraded to a 1.8kw servo motor for my spindle motor.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

On my X3 I used a double pole relay (Automation Direct QL2N1-D24 10A@250 VAC). One pole was used to break the connection from terminal 3 on the on/off switch to the motor. The other pole was used to open the connection between K1 on the board and terminal 1 on the on/off switch. This is so that if the motor faults or an E-Stop is activate the CNC control will need to stop the spindle (open the relay) so that the safety will be reset and then can turn the spindle back on when relay to proceed. I used this setup for about 6 months with no problems until I upgraded to a 1.8kw servo motor for my spindle motor.

Is that relay just for the interlock?

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

- Posts: 566

- Thank you received: 108

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

No. One pole of the relay disconnects the motor. It is in series with the manual on/off switch. The other pole is in series with the connection which goes from the on/off switch to the K1 on the board.

I think I understand.

So I would sent 24 volt to that relay( it says 24v coil), and close the contacts thru my Bob spindle relay to actuate that relay.

And it would complete the circuit to the motor and k1? And since they are both closed the fault saftey would still work.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

- Posts: 566

- Thank you received: 108

You could probably find a 12 volt version of that relay if you need it to be rather than 24volt.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

Yes. If the motor faults or the E-Stop I activated you must open the connection between K1 and K0 to reset the fault. By having K1 and the motor run the same switch/relay you have to turn off the power to the motor to do the reset. You wouldn't want the motor to start as soon as you reset the E-Stop switch.

You could probably find a 12 volt version of that relay if you need it to be rather than 24volt.

Thanks. I looked quick, they have a 120volt coil one. That would probably be the easiest and my Bob relay can handle 10 amps ac.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

- Posts: 592

- Thank you received: 79

It works good and the interlock works.

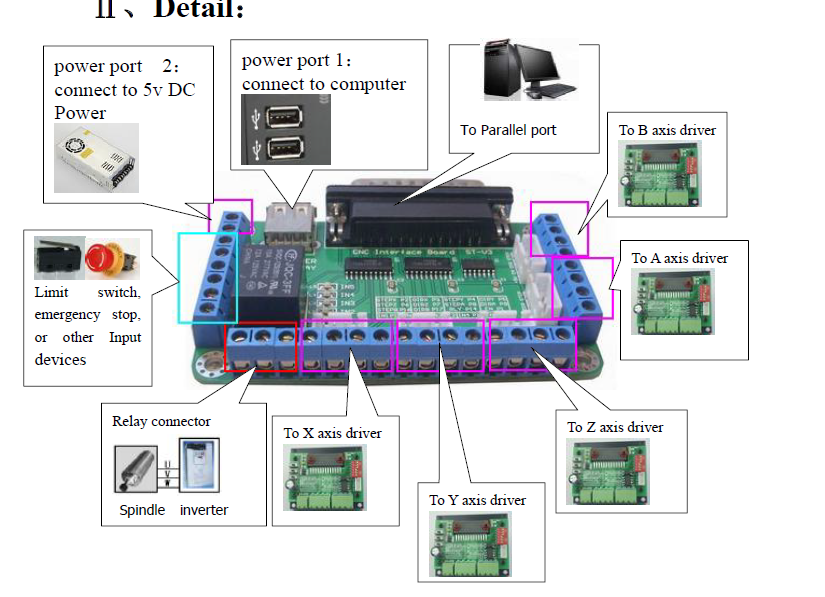

But the relay in my breakout board is kind of dumb.

I hooked it up to the normally open side and as soon as I turned the power on the mill the spindle started. After I booted into linux cnc the relay opened and the spindle stopped. The normally open side is closed untill there is power. And I don't see any jumpers on it anywhere

If I hit the CW button it starts and stops when I hit the stop button.

So I am going to have to put a switch, or I can run the low voltage wire thru my estop on the open when latched side.yhis will break the connection as I estop it when it's off

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

- Posts: 615

- Thank you received: 75

I hooked it up to the normally open side and as soon as I turned the power on the mill the spindle started. After I booted into linux cnc the relay opened and the spindle stopped. The normally open side is closed untill there is power. And I don't see any jumpers on it anywhere

That sounds like you wired it normally closed? Try the other terminal on that BOB. Maybe it's mis-labeled. Is this your board?? I would check with a volt meter to confirm the state of that relay when everything is powered off.

Please Log in or Create an account to join the conversation.