Linuxcnc on Debian Stretch 9 32 bit preempt rt

- richard123

- Offline

- New Member

-

- Posts: 11

- Thank you received: 0

At first, I was running my cnc machine through LPT port by using the debian wheezy live install with the rtai. My motors can rotates either in clockwise or counter clockwise.

Right now, I am trying to control my cnc machine through lpt port using the live install with Debian stretch 32 bit with preempt rt kernel. When i arrived at the stepconfig, I set my lpt address to become 0x378 (as usual) but then I couldn't continue. After changing the parallel port mode from 'Bidirectional' to 'Normal' in my BIOS, i can put 0x378 as my lpt port address. But, turns out that my stepper motors can only move in 1 direction (CCW). Can anyone please help me with this?

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4690

- Thank you received: 1434

Make sure your step and direction signals are not switched.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

It's more compatible with today's given program's.

If you look at the x axis :

pin 2 = step

pin 3 = direction (your issue)

remove pin wire 3 and put it on nothing. Move the machine....

Oke it moves in one direction. Then put pin 3 on a 5 volt power supply. Machine will move in other direction. If so yes, your hardware is in shape, if not check your machine (hardware).

If your software is the problem. Connect your pin with a multimeter. Maybe your pc port is blown out in the past. That is possible.

To test fast, you can use a ltp pci card.

if you type in terminal : sudo grep pci ( it will not responce ) maybe "lspci -v" check's the pci card adress for you !

linuxcnc.org/docs/2.4/html/examples_pci_parallel_port.html

Please Log in or Create an account to join the conversation.

- richard123

- Offline

- New Member

-

- Posts: 11

- Thank you received: 0

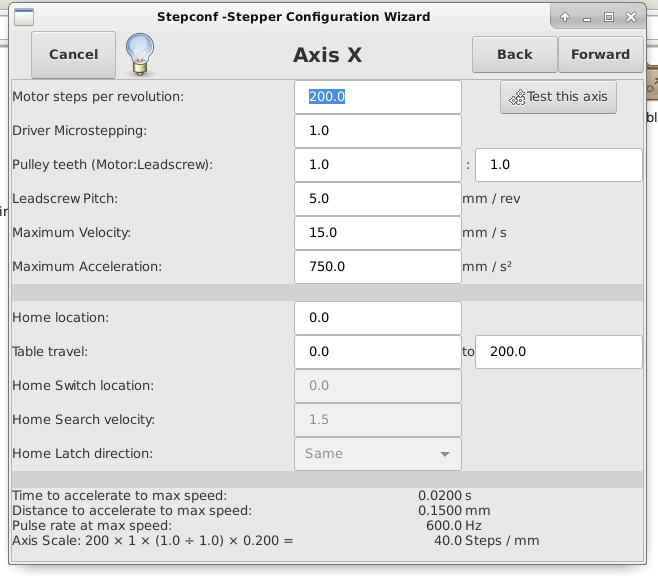

Right now I'm about to create a new step configuration for my machine. For this machine, the X and Y axis will be controlled using nema 17 stepper motor and timing pulley GT2. What I want to ask is, what should I put in the "Lead Screw Pitch" column for the stepconf?

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

Right now I'm about to create a new step configuration for my machine. For this machine, the X and Y axis will be controlled using nema 17 stepper motor and timing pulley GT2. What I want to ask is, what should I put in the "Lead Screw Pitch" column

Exactly what it states . what it means is if you rotate the screw one revolution how far would the axis (table) move. So in the example it shows 5mm/rev. that means the axis will move 5mm for one rev.

If you are using screwed rod as a lead screw say 10mm it could be 1.25mm pitch (ie one rev would be 1.25mm travel)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21131

- Thank you received: 7219

10mm or M10 would be 1.5mmIf you are using screwed rod as a lead screw say 10mm it could be 1.25mm pitch (ie one rev would be 1.25mm travel)

M8 is 1.25mm

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

10mm or M10 would be 1.5mmIf you are using screwed rod as a lead screw say 10mm it could be 1.25mm pitch (ie one rev would be 1.25mm travel)

M8 is 1.25mm

I agree but you can also get 10mm rod with 1.25mm pitch. steel and brass www.ebay.co.uk/itm/M3-M4-M5-M6-M8-M10-Fi...-500mm-/272714083192 B)

Please Log in or Create an account to join the conversation.

- AnnoyingMutt

-

- Visitor

-

Metric Fine Thread

www.newmantools.com/tech/threadmf.htm

Metric Coarse Thread

www.newmantools.com/tech/threadm.htm

Just to be a smarty pants

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

Or you could cut just about any pitch thread you want with a lathe

Metric Fine Thread

www.newmantools.com/tech/threadmf.htm

Metric Coarse Thread

www.newmantools.com/tech/threadm.htm

Just to be a smarty pants

Yes but that is not what the op wanted to do. He was asking what numbers to put in stepconf

Please Log in or Create an account to join the conversation.

- AnnoyingMutt

-

- Visitor

-

Please Log in or Create an account to join the conversation.