7i96 Can't get PWM output - SOLVED

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

20 Nov 2019 09:35 - 20 Nov 2019 09:53 #150729

by jools

7i96 Can't get PWM output was created by jools

Hi all

I'm having real trouble trying to sort out a PWM output on my 7I96 and have spent the last two days trying different things with no success and desperately need help.

The back story is my first configuration with the 7i96 configuration tool kindly made by John produced a working configuration but there were no manual spindle speed control buttons showing in Axis. I added some net commands in the HAL and they appeared but would still not output a PWM signal to the Mesa card. The voltage at the pins stayed at -5v.

I had added things so much to that configuration that I just deleted it and started a new configuration with the 7i96 tool.

This caused more problems. Currently LCNC refuses to load and gives the error:./io.hal:7: Pin 'motion.spindle-forward' does not exist

In the IO.hal file I found the below

net spindle-cw motion.spindle-forward => hm2_7i96.0.ssr.00.out-00

This suggests to me that I need to link some sort of button on Axis that's called motion.spindle-forward to this; I am at a loss how to do this though.

HAL

io.hal

I really need help with this please guys as I've been stuck for a couple of days now with it.

Cheers

Jools

EDIT

So I re-edited the 7i96 configuration via the tool and turned off the OUTPUTS which I had as spindle CW, CCW and ON functions mapped to them. This has let me load up LCNC.

I still have the issue that the manual control buttons do not show on AXIS.Does anyone know the correct HAL lines to add to make them show?

Also in the HAL file I don't have 'num_pwmgens=1' or an addf for pwmgen as asked for in the 2.8 documentation.

Does this matter?

I'm having real trouble trying to sort out a PWM output on my 7I96 and have spent the last two days trying different things with no success and desperately need help.

The back story is my first configuration with the 7i96 configuration tool kindly made by John produced a working configuration but there were no manual spindle speed control buttons showing in Axis. I added some net commands in the HAL and they appeared but would still not output a PWM signal to the Mesa card. The voltage at the pins stayed at -5v.

I had added things so much to that configuration that I just deleted it and started a new configuration with the 7i96 tool.

This caused more problems. Currently LCNC refuses to load and gives the error:./io.hal:7: Pin 'motion.spindle-forward' does not exist

In the IO.hal file I found the below

net spindle-cw motion.spindle-forward => hm2_7i96.0.ssr.00.out-00

This suggests to me that I need to link some sort of button on Axis that's called motion.spindle-forward to this; I am at a loss how to do this though.

HAL

# This file was created with the 7i96 Wizard on Nov 20 2019 09:23:10

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS]KINEMATICS

# motion controller

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

# standard components

loadrt pid num_chan=3

# hostmot2 driver

loadrt hostmot2

loadrt [HOSTMOT2](DRIVER) board_ip=[HOSTMOT2](IPADDRESS) config="num_encoders=[HOSTMOT2](ENCODERS)num_stepgens=[HOSTMOT2](STEPGENS)"sserial_port_0=[HOSTMOT2](SSERIAL_PORT)

setp hm2_[HOSTMOT2](BOARD).0.watchdog.timeout_ns 25000000

# THREADS

addf hm2_[HOSTMOT2](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number 1

addf pid.0.do-pid-calcs servo-thread

addf pid.1.do-pid-calcs servo-thread

addf pid.2.do-pid-calcs servo-thread

addf hm2_[HOSTMOT2](BOARD).0.write servo-thread

# Joint 0

# axis enable chain

newsig emcmot.0.enable bit

sets emcmot.0.enable FALSE

net emcmot.0.enable <= joint.0.amp-enable-out

net emcmot.0.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.00.enable pid.0.enable

# position command and feedback

net emcmot.0.pos-cmd joint.0.motor-pos-cmd => pid.0.command

net motor.0.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-fb joint.0.motor-pos-fb pid.0.feedback

net motor.0.command pid.0.output hm2_[HOSTMOT2](BOARD).0.stepgen.00.velocity-cmd

setp pid.0.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-scale [JOINT_0]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.control-type 1

setp pid.0.Pgain [JOINT_0]P

setp pid.0.Igain [JOINT_0]I

setp pid.0.Dgain [JOINT_0]D

setp pid.0.bias [JOINT_0]BIAS

setp pid.0.FF0 [JOINT_0]FF0

setp pid.0.FF1 [JOINT_0]FF1

setp pid.0.FF2 [JOINT_0]FF2

setp pid.0.deadband [JOINT_0]DEADBAND

setp pid.0.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.0.maxerror [JOINT_0]MAX_ERROR

# Joint 1

# axis enable chain

newsig emcmot.1.enable bit

sets emcmot.1.enable FALSE

net emcmot.1.enable <= joint.1.amp-enable-out

net emcmot.1.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.01.enable pid.1.enable

# position command and feedback

net emcmot.1.pos-cmd joint.1.motor-pos-cmd => pid.1.command

net motor.1.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-fb joint.1.motor-pos-fb pid.1.feedback

net motor.1.command pid.1.output hm2_[HOSTMOT2](BOARD).0.stepgen.01.velocity-cmd

setp pid.1.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-scale [JOINT_1]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.control-type 1

setp pid.1.Pgain [JOINT_1]P

setp pid.1.Igain [JOINT_1]I

setp pid.1.Dgain [JOINT_1]D

setp pid.1.bias [JOINT_1]BIAS

setp pid.1.FF0 [JOINT_1]FF0

setp pid.1.FF1 [JOINT_1]FF1

setp pid.1.FF2 [JOINT_1]FF2

setp pid.1.deadband [JOINT_1]DEADBAND

setp pid.1.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.1.maxerror [JOINT_1]MAX_ERROR

# Joint 2

# axis enable chain

newsig emcmot.2.enable bit

sets emcmot.2.enable FALSE

net emcmot.2.enable <= joint.2.amp-enable-out

net emcmot.2.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.02.enable pid.2.enable

# position command and feedback

net emcmot.2.pos-cmd joint.2.motor-pos-cmd => pid.2.command

net motor.2.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-fb joint.2.motor-pos-fb pid.2.feedback

net motor.2.command pid.2.output hm2_[HOSTMOT2](BOARD).0.stepgen.02.velocity-cmd

setp pid.2.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-scale [JOINT_2]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.control-type 1

setp pid.2.Pgain [JOINT_2]P

setp pid.2.Igain [JOINT_2]I

setp pid.2.Dgain [JOINT_2]D

setp pid.2.bias [JOINT_2]BIAS

setp pid.2.FF0 [JOINT_2]FF0

setp pid.2.FF1 [JOINT_2]FF1

setp pid.2.FF2 [JOINT_2]FF2

setp pid.2.deadband [JOINT_2]DEADBAND

setp pid.2.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.2.maxerror [JOINT_2]MAX_ERROR

# Spindle

setp hm2_7i96.0.pwmgen.00.output-type 0

setp hm2_7i96.0.pwmgen.00.scale [SPINDLE]MAX_RPM

setp hm2_7i96.0.pwmgen.pwm_frequency [SPINDLE]PWM_FREQUENCY

# Standard I/O Block - EStop, Etc

# create a signal for the estop loopback

net estop-loop iocontrol.0.user-enable-out => iocontrol.0.emc-enable-in

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changedio.hal

# This file was created with the 7i96 Wizard on Nov 20 2019 09:23:10

# If you make changes to this file your screwed

net home-joint-0 joint.0.home-sw-in <= hm2_7i96.0.gpio.000.in

net home-joint-1 joint.1.home-sw-in <= hm2_7i96.0.gpio.001.in

net home-joint-2 joint.2.home-sw-in <= hm2_7i96.0.gpio.002.in

net spindle-cw motion.spindle-forward => hm2_7i96.0.ssr.00.out-00

net spindle-on motion.spindle-on => hm2_7i96.0.ssr.00.out-01

net spindle-ccw motion.spindle-reverse => hm2_7i96.0.ssr.00.out-02I really need help with this please guys as I've been stuck for a couple of days now with it.

Cheers

Jools

EDIT

So I re-edited the 7i96 configuration via the tool and turned off the OUTPUTS which I had as spindle CW, CCW and ON functions mapped to them. This has let me load up LCNC.

I still have the issue that the manual control buttons do not show on AXIS.Does anyone know the correct HAL lines to add to make them show?

Also in the HAL file I don't have 'num_pwmgens=1' or an addf for pwmgen as asked for in the 2.8 documentation.

Does this matter?

Last edit: 20 Nov 2019 09:53 by jools. Reason: adding further investgative results

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17687

- Thank you received: 5172

20 Nov 2019 13:05 - 20 Nov 2019 13:07 #150749

by PCW

Replied by PCW on topic 7i96 Can't get PWM output

You don't need the addf pwmgen as that creates a software PWMgen.

With correct firmware, the 7I96 will replace 1 or more step generators

with PWM generators, you can enable one PWM generator with

'num_pwmgens=1' though its not needed as the default is to enable

all modules (pwmgens, stepgens etc) if not specified

Once you have enabled the PWM generator you must setup its operating mode,

frequency and scaling and link the PWM generator pins to the corresponding

LinuxCNC spindle control pins.

This should have been done by the 7I96 setup utility

( so you might ask what's needed to setup the spindle in the 7I96 setup utility thread )

To do it by hand, You need to know the names and functions of the PWM generators

pins and parameters. You can get a list of the pin and parameter names

( and their current values ) by launching LinuxCNC and then in a separate

terminal typing this command:

halcmd show all *pwm*

The hostmot2 manual page describes the pin and parameter functions:

man hostmot2

With correct firmware, the 7I96 will replace 1 or more step generators

with PWM generators, you can enable one PWM generator with

'num_pwmgens=1' though its not needed as the default is to enable

all modules (pwmgens, stepgens etc) if not specified

Once you have enabled the PWM generator you must setup its operating mode,

frequency and scaling and link the PWM generator pins to the corresponding

LinuxCNC spindle control pins.

This should have been done by the 7I96 setup utility

( so you might ask what's needed to setup the spindle in the 7I96 setup utility thread )

To do it by hand, You need to know the names and functions of the PWM generators

pins and parameters. You can get a list of the pin and parameter names

( and their current values ) by launching LinuxCNC and then in a separate

terminal typing this command:

halcmd show all *pwm*

The hostmot2 manual page describes the pin and parameter functions:

man hostmot2

Last edit: 20 Nov 2019 13:07 by PCW.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

20 Nov 2019 13:33 #150753

by jools

Thank you for this.

I ran the command and this is the output

Loaded HAL Components:

ID Type Name PID State

Component Pins:

Owner Type Dir Value Name

Pin Aliases:

Alias Original Name

Signals:

Type Value Name (linked to)

Parameters:

Owner Type Dir Value Name

Parameter Aliases:

Alias Original Name

Exported Functions:

Owner CodeAddr Arg FP Users Name

Realtime Threads:

Period FP Name ( Time, Max-Time )

Replied by jools on topic 7i96 Can't get PWM output

You don't need the addf pwmgen as that creates a software PWMgen.

With correct firmware, the 7I96 will replace 1 or more step generators

with PWM generators, you can enable one PWM generator with

'num_pwmgens=1' though its not needed as the default is to enable

all modules (pwmgens, stepgens etc) if not specified

Once you have enabled the PWM generator you must setup its operating mode,

frequency and scaling and link the PWM generator pins to the corresponding

LinuxCNC spindle control pins.

This should have been done by the 7I96 setup utility

( so you might ask what's needed to setup the spindle in the 7I96 setup utility thread )

To do it by hand, You need to know the names and functions of the PWM generators

pins and parameters. You can get a list of the pin and parameter names

( and their current values ) by launching LinuxCNC and then in a separate

terminal typing this command:

halcmd show all *pwm*

The hostmot2 manual page describes the pin and parameter functions:

man hostmot2

Thank you for this.

I ran the command and this is the output

Loaded HAL Components:

ID Type Name PID State

Component Pins:

Owner Type Dir Value Name

Pin Aliases:

Alias Original Name

Signals:

Type Value Name (linked to)

Parameters:

Owner Type Dir Value Name

Parameter Aliases:

Alias Original Name

Exported Functions:

Owner CodeAddr Arg FP Users Name

Realtime Threads:

Period FP Name ( Time, Max-Time )

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17687

- Thank you received: 5172

20 Nov 2019 14:11 #150756

by PCW

Replied by PCW on topic 7i96 Can't get PWM output

That means you are not running a linuxCNC configuration with enabled pwmgen hardware

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

20 Nov 2019 14:49 #150760

by jools

Replied by jools on topic 7i96 Can't get PWM output

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17687

- Thank you received: 5172

20 Nov 2019 15:06 - 20 Nov 2019 15:10 #150763

by PCW

Replied by PCW on topic 7i96 Can't get PWM output

Sorry the command is

halcmd show all *pwmgen*

or

halcmd show all | grep pwm

I forgot that halcmd does not do a simple text match like vanilla grep

but seems to search only for complete tokens

halcmd show all *pwmgen*

or

halcmd show all | grep pwm

I forgot that halcmd does not do a simple text match like vanilla grep

but seems to search only for complete tokens

Last edit: 20 Nov 2019 15:10 by PCW.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

20 Nov 2019 15:10 #150764

by tommylight

Replied by tommylight on topic 7i96 Can't get PWM output

That is a software PWM there, not hardware.

From the beginning:

What firmware do you have on your 7i96, what does readhmi report ?

You will most probably need to flash it with firmware that has hardware PWM, as noted by PCW.

After you flash it, reload and check readhmi again, it has to say PWM somewhere in it's output . Only after this continue setting up the config.

From the beginning:

What firmware do you have on your 7i96, what does readhmi report ?

You will most probably need to flash it with firmware that has hardware PWM, as noted by PCW.

After you flash it, reload and check readhmi again, it has to say PWM somewhere in it's output . Only after this continue setting up the config.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

20 Nov 2019 15:24 #150765

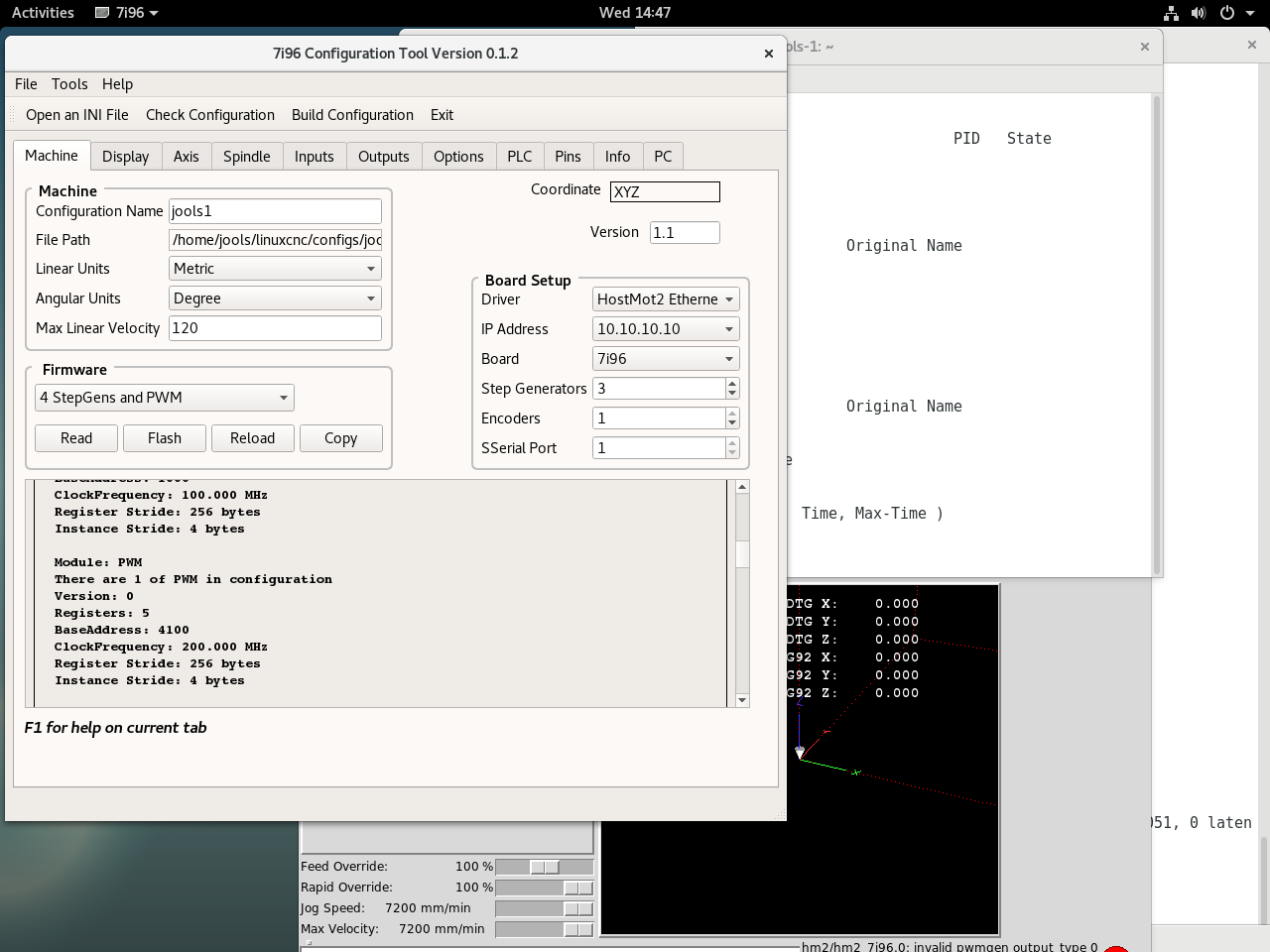

by jools

readhmid produces

This is using an old version of mesaflash hence the segmentation fault but I actually used the 7i96 configuration tool to flash it. When I use the same tool to read it there is no segmentation fault.

Code from 7i96 tool

Jools

Replied by jools on topic 7i96 Can't get PWM output

That is a software PWM there, not hardware.

From the beginning:

What firmware do you have on your 7i96, what does readhmi report ?

You will most probably need to flash it with firmware that has hardware PWM, as noted by PCW.

After you flash it, reload and check readhmi again, it has to say PWM somewhere in it's output . Only after this continue setting up the config.

readhmid produces

jools@jools-1:~$ sudo mesaflash --device 7i96 --addr 10.10.10.10 --readhmid

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I96

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 3

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 3 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 1 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 200.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 4 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 1 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: SSerial

There are 1 of SSerial in configuration

Version: 0

Registers: 6

BaseAddress: 5B00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 64 bytes

Module: Transformer

There are 1 of Transformer in configuration

Version: 0

Registers: 2

BaseAddress: 7D00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P1

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort None

14 1 IOPort None

2 2 IOPort None

15 3 IOPort None

3 4 IOPort None

16 5 IOPort None

4 6 IOPort None

17 7 IOPort None

5 8 IOPort None

6 9 IOPort None

7 10 IOPort None

8 11 IOPort Transformer 0 Drive (Out)

9 12 IOPort Transformer 0 Ref (Out)

10 13 IOPort Transformer 0 Null3 (Out)

11 14 IOPort Transformer 0 Null4 (Out)

12 15 IOPort Transformer 0 Null5 (Out)

13 16 IOPort Transformer 0 Null6 (Out)

IO Connections for TB1

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 17 IOPort StepGen 0 Step/Table1 (Out)

14 18 IOPort StepGen 0 Dir/Table2 (Out)

2 19 IOPort StepGen 1 Step/Table1 (Out)

15 20 IOPort StepGen 1 Dir/Table2 (Out)

3 21 IOPort StepGen 2 Step/Table1 (Out)

16 22 IOPort StepGen 2 Dir/Table2 (Out)

4 23 IOPort StepGen 3 Step/Table1 (Out)

17 24 IOPort StepGen 3 Dir/Table2 (Out)

5 25 IOPort PWM 0 PWM (Out)

6 26 IOPort PWM 0 Dir (Out)

7 27 IOPort QCount 0 Quad-A (In)

8 28 IOPort QCount 0 Quad-B (In)

9 29 IOPort QCount 0 Quad-IDX (In)

10 30 IOPort SSerial 0 RXData1 (In)

11 31 IOPort SSerial 0 TXData1 (Out)

12 32 IOPort SSerial 0 TXEn1 (Out)

Segmentation fault

jools@jools-1:~$ This is using an old version of mesaflash hence the segmentation fault but I actually used the 7i96 configuration tool to flash it. When I use the same tool to read it there is no segmentation fault.

Code from 7i96 tool

Configuration Name: HOSTMOT2

General configuration information:

BoardName : MESA7I96

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 3

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 3 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 1 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 200.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 4 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 1 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: SSerial

There are 1 of SSerial in configuration

Version: 0

Registers: 6

BaseAddress: 5B00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 64 bytes

Module: SSR

There are 1 of SSR in configuration

Version: 0

Registers: 2

BaseAddress: 7D00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for TB3

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort None

14 1 IOPort None

2 2 IOPort None

15 3 IOPort None

3 4 IOPort None

16 5 IOPort None

4 6 IOPort None

17 7 IOPort None

5 8 IOPort None

6 9 IOPort None

7 10 IOPort None

8 11 IOPort SSR 0 Out-00 (Out)

9 12 IOPort SSR 0 Out-01 (Out)

10 13 IOPort SSR 0 Out-02 (Out)

11 14 IOPort SSR 0 Out-03 (Out)

12 15 IOPort SSR 0 Out-04 (Out)

13 16 IOPort SSR 0 Out-05 (Out)

IO Connections for TB1/TB2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 17 IOPort StepGen 0 Step/Table1 (Out)

14 18 IOPort StepGen 0 Dir/Table2 (Out)

2 19 IOPort StepGen 1 Step/Table1 (Out)

15 20 IOPort StepGen 1 Dir/Table2 (Out)

3 21 IOPort StepGen 2 Step/Table1 (Out)

16 22 IOPort StepGen 2 Dir/Table2 (Out)

4 23 IOPort StepGen 3 Step/Table1 (Out)

17 24 IOPort StepGen 3 Dir/Table2 (Out)

5 25 IOPort PWM 0 PWM (Out)

6 26 IOPort PWM 0 Dir (Out)

7 27 IOPort QCount 0 Quad-A (In)

8 28 IOPort QCount 0 Quad-B (In)

9 29 IOPort QCount 0 Quad-IDX (In)

10 30 IOPort SSerial 0 RXData0 (In)

11 31 IOPort SSerial 0 TXData0 (Out)

12 32 IOPort SSerial 0 TXEn0 (Out)

13 33 IOPort SSR 0 AC Ref (Out)

IO Connections for P1

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 34 IOPort None

14 35 IOPort None

2 36 IOPort None

15 37 IOPort None

3 38 IOPort None

16 39 IOPort None

4 40 IOPort None

17 41 IOPort None

5 42 IOPort None

6 43 IOPort None

7 44 IOPort None

8 45 IOPort None

9 46 IOPort None

10 47 IOPort None

11 48 IOPort None

12 49 IOPort None

13 50 IOPort None Jools

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

20 Nov 2019 15:28 #150766

by jools

I flashed it via tool then reloaded and then started to set it up in the config tool.

Should this set up a manual PWM or is it a PWM only from the MDI commands?

Replied by jools on topic 7i96 Can't get PWM output

That is a software PWM there, not hardware.

From the beginning:

What firmware do you have on your 7i96, what does readhmi report ?

You will most probably need to flash it with firmware that has hardware PWM, as noted by PCW.

After you flash it, reload and check readhmi again, it has to say PWM somewhere in it's output . Only after this continue setting up the config.

I flashed it via tool then reloaded and then started to set it up in the config tool.

Should this set up a manual PWM or is it a PWM only from the MDI commands?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21276

- Thank you received: 7265

20 Nov 2019 15:45 #150769

by tommylight

Replied by tommylight on topic 7i96 Can't get PWM output

Add the num_pwm = 1 to loadrt line for Mesa 7i76, or see if there is a provision for setting that in tool.

If not, after adding pwm to loadrt, there are some more lines to add to hal file that i do not know for sure, like scale, frequency and some other stuff that again i think PCW mentioned somewhere. There are 3 topics with this same problem so hard to keep track.

Another way of making this work is to create a config for 5i25 with hardware pwm and copy/paste the hal entries to your config, and just change the 5i25 to 7i96 in those lines.

If not, after adding pwm to loadrt, there are some more lines to add to hal file that i do not know for sure, like scale, frequency and some other stuff that again i think PCW mentioned somewhere. There are 3 topics with this same problem so hard to keep track.

Another way of making this work is to create a config for 5i25 with hardware pwm and copy/paste the hal entries to your config, and just change the 5i25 to 7i96 in those lines.

Please Log in or Create an account to join the conversation.

Time to create page: 0.152 seconds