Sharp 90* turn in gcode becomes a large sweeping turn

- lumberjack_jeff

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

09 Mar 2020 20:57 #159598

by lumberjack_jeff

Replied by lumberjack_jeff on topic Sharp 90* turn in gcode becomes a large sweeping turn

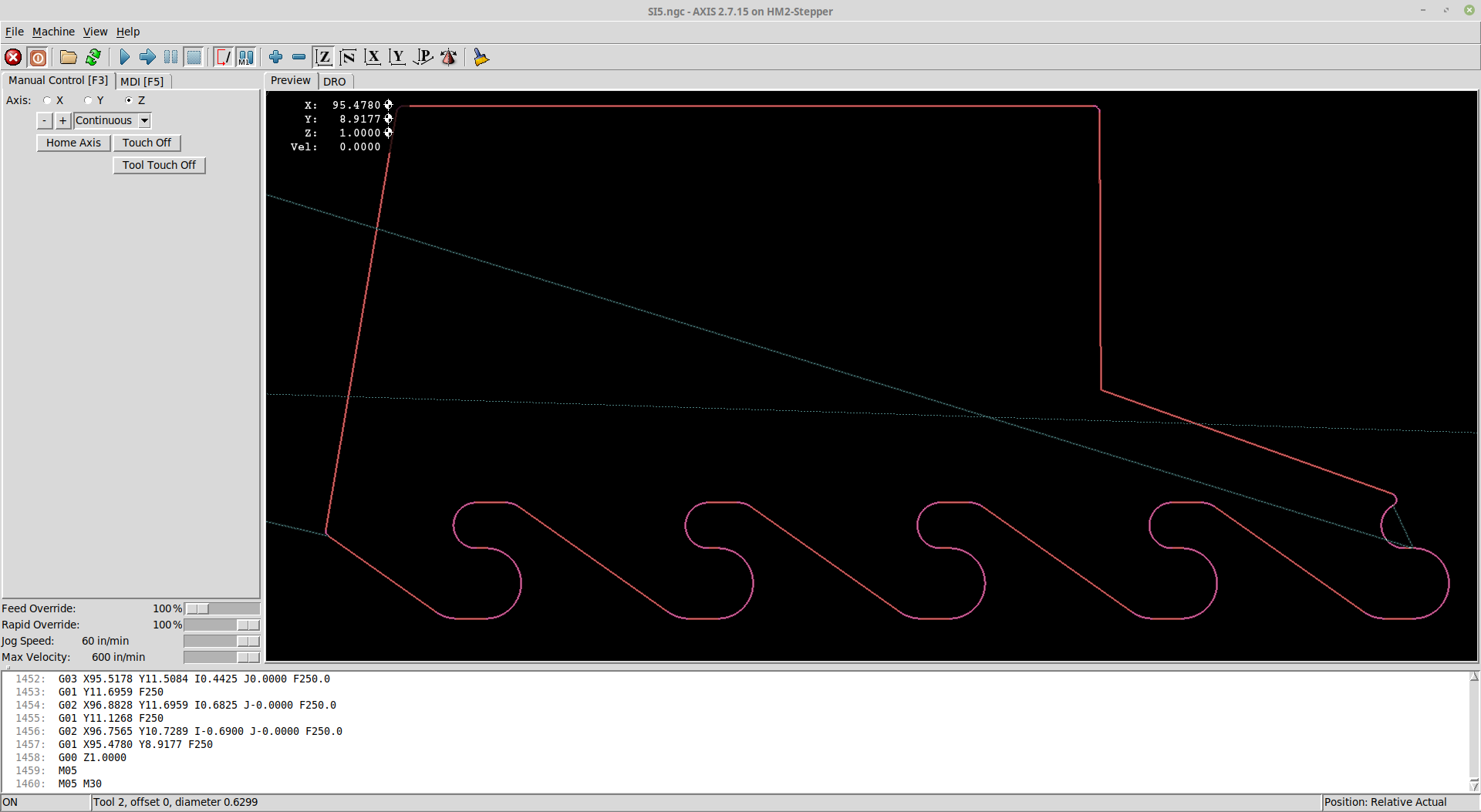

2.7.15

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17300

- Thank you received: 5035

09 Mar 2020 21:10 #159602

by PCW

Replied by PCW on topic Sharp 90* turn in gcode becomes a large sweeping turn

can you post your gcode or a portion of it that exhibits this issue?

Please Log in or Create an account to join the conversation.

- lumberjack_jeff

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

09 Mar 2020 22:23 #159608

by lumberjack_jeff

Replied by lumberjack_jeff on topic Sharp 90* turn in gcode becomes a large sweeping turn

Apologies for the fairly large file, I'm not at my controller computer, so I can't tell you exactly which lines the problem occurs on.

The toolpath is in three passes, and as the photo of the result shows, pass #1 does not superimpose pass #2 or #3.

The toolpath is in three passes, and as the photo of the result shows, pass #1 does not superimpose pass #2 or #3.

Please Log in or Create an account to join the conversation.

- lumberjack_jeff

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

10 Mar 2020 02:24 #159621

by lumberjack_jeff

Replied by lumberjack_jeff on topic Sharp 90* turn in gcode becomes a large sweeping turn

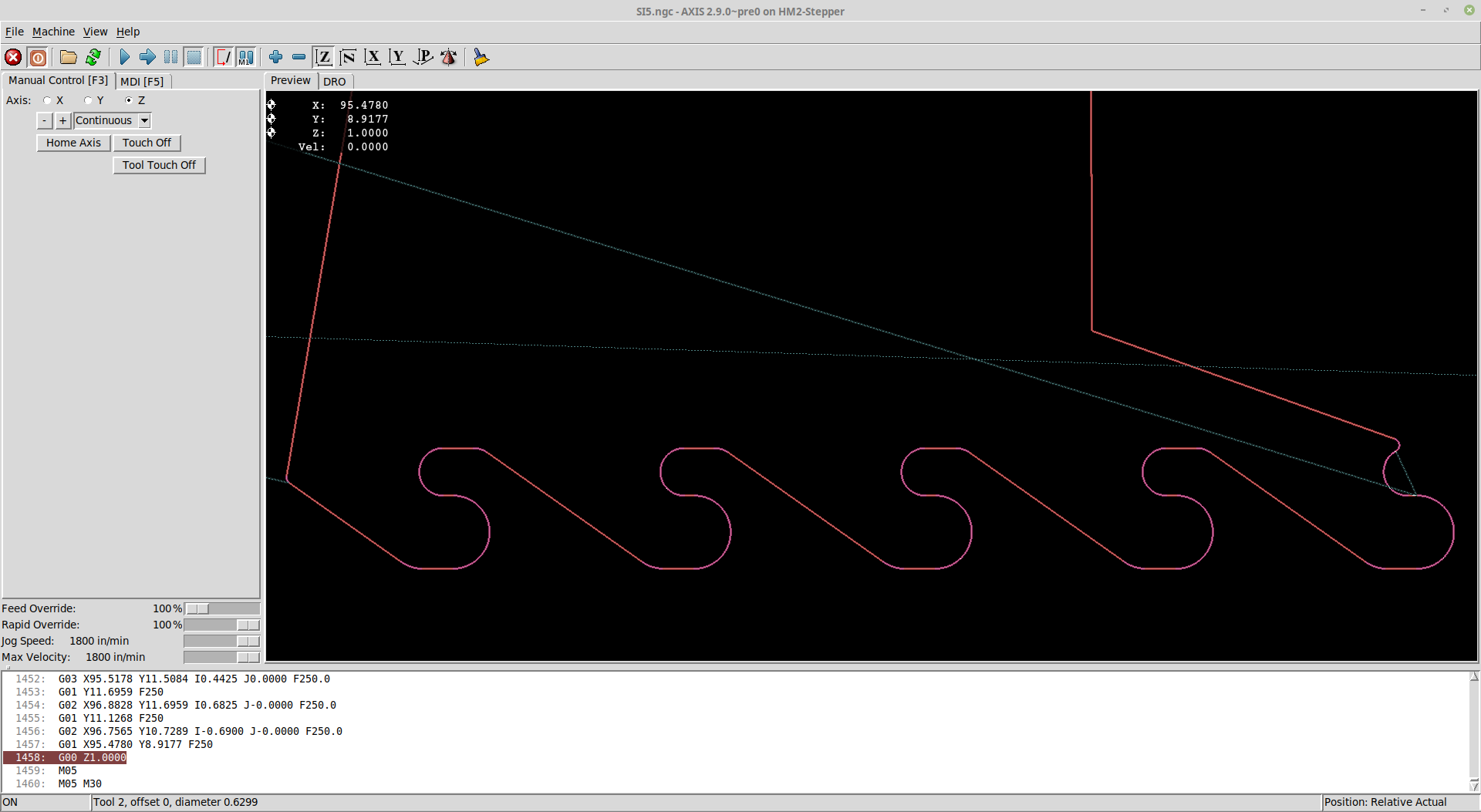

I changed the max acceleration value to 17. Re-ran the file (no load). The track shown in the preview window conformed to the path plotted (i.e performed as expected)

It would be nice to know if that was the problem, or if it's still lurking.

I have also been getting frequent random shutdowns ("estop reset" is the status) with no error messages. I had written it off as a loose connection... Could it be related?

It would be nice to know if that was the problem, or if it's still lurking.

I have also been getting frequent random shutdowns ("estop reset" is the status) with no error messages. I had written it off as a loose connection... Could it be related?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17300

- Thank you received: 5035

10 Mar 2020 03:16 - 10 Mar 2020 03:23 #159623

by PCW

Replied by PCW on topic Sharp 90* turn in gcode becomes a large sweeping turn

Attachments:

Last edit: 10 Mar 2020 03:23 by PCW.

The following user(s) said Thank You: lumberjack_jeff

Please Log in or Create an account to join the conversation.

- BobsGotCnc

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

10 Mar 2020 05:07 #159635

by BobsGotCnc

Replied by BobsGotCnc on topic Sharp 90* turn in gcode becomes a large sweeping turn

My ini file settings. I will be re-doing this shortly as I move to new DM542T drivers. The settings below were from the previous owner.

Y

MAX_VELOCITY = 3

MAX_ACCELERATION = 4.0

STEPGEN_MAXVEL = 7.21

STEPGEN_MAXACCEL = 5.00

Z

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 5.0

STEPGEN_MAXVEL = 1.25

STEPGEN_MAXACCEL = 6.25

X

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 10.0

STEPGEN_MAXVEL = 2.92

STEPGEN_MAXACCEL = 12.50

Y

MAX_VELOCITY = 3

MAX_ACCELERATION = 4.0

STEPGEN_MAXVEL = 7.21

STEPGEN_MAXACCEL = 5.00

Z

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 5.0

STEPGEN_MAXVEL = 1.25

STEPGEN_MAXACCEL = 6.25

X

MAX_VELOCITY = 2.5

MAX_ACCELERATION = 10.0

STEPGEN_MAXVEL = 2.92

STEPGEN_MAXACCEL = 12.50

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17300

- Thank you received: 5035

10 Mar 2020 13:08 - 10 Mar 2020 13:09 #159649

by PCW

Replied by PCW on topic Sharp 90* turn in gcode becomes a large sweeping turn

Unless you are using G64 Pxxx, rounded corners are _expected_ so its not likely your INI

settings are involved (other that the fact that you have very low acceleration settings so you

will get very large radius blends with plain G64). Did you try G64 P0.0005 as cmorely suggested?

settings are involved (other that the fact that you have very low acceleration settings so you

will get very large radius blends with plain G64). Did you try G64 P0.0005 as cmorely suggested?

Last edit: 10 Mar 2020 13:09 by PCW.

The following user(s) said Thank You: BobsGotCnc

Please Log in or Create an account to join the conversation.

- lumberjack_jeff

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

10 Mar 2020 20:52 #159699

by lumberjack_jeff

Replied by lumberjack_jeff on topic Sharp 90* turn in gcode becomes a large sweeping turn

Thank you for the troubleshooting help.

Can you please advise me about debouncing pin 10?

I think I need to replace this wscnc.hal code

with

Can you please advise me about debouncing pin 10?

I think I need to replace this wscnc.hal code

...

net estop-ext <= parport.0.pin-10-in

...

#limits debounce to stop false triggers

loadrt debounce cfg=2 #change to the number you want

setp debounce.0.delay 100 #this sets the delay 100 iterations of the base thread

addf debounce.0 base-thread

net deb-probe-in debounce.0.0.in <= parport.0.pin-12-in-not

net probe-in debounce.0.0.out...

loadrt debounce cfg=2 #I think I only need two

setp debounce.0.delay 100

setp debounce.1.delay 100

addf debounce.0 base-thread

addf debounce.1 base-thread

net deb-probe-in debounce.0.0.in <= parport.0.pin-12-in-not

net deb-estop-ext debounce.1.0.in <= parport.0.pin-10-in

net probe-in debounce.0.0.out

net estop-ext debounce.1.0.outPlease Log in or Create an account to join the conversation.

- BobsGotCnc

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

11 Mar 2020 01:05 #159729

by BobsGotCnc

Replied by BobsGotCnc on topic Sharp 90* turn in gcode becomes a large sweeping turn

G64 P0.0005 resolved the sweeping 90* turn.

So I am still a CNC newb. When I am in the CAM phase, how would I detect such an issue in the future as to reduce the likelihood that I destroy valuable material when running the gcode? At this point in my learning (about 4 months in), I feel like every other new design I take to the CNC destroys a piece of material. Each time I learn something new, but it is getting a bit discouraging that it feel rare to generate gcode, execute it, and have the piece I designed. Maybe this is part of the hobby cnc router process?

So I am still a CNC newb. When I am in the CAM phase, how would I detect such an issue in the future as to reduce the likelihood that I destroy valuable material when running the gcode? At this point in my learning (about 4 months in), I feel like every other new design I take to the CNC destroys a piece of material. Each time I learn something new, but it is getting a bit discouraging that it feel rare to generate gcode, execute it, and have the piece I designed. Maybe this is part of the hobby cnc router process?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17300

- Thank you received: 5035

11 Mar 2020 02:22 #159738

by PCW

Replied by PCW on topic Sharp 90* turn in gcode becomes a large sweeping turn

Probably best way is to have your CAM program insert a gcode preamble that includes

important modal gcodes like G64 Pxxx.

Also with new code and expensive material, take time to study the preview,

or run it in simulation to see if its doing what you expect or perhaps

do an run on scrap material

important modal gcodes like G64 Pxxx.

Also with new code and expensive material, take time to study the preview,

or run it in simulation to see if its doing what you expect or perhaps

do an run on scrap material

The following user(s) said Thank You: BobsGotCnc

Please Log in or Create an account to join the conversation.

Time to create page: 0.225 seconds