Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 949

- Thank you received: 234

29 Jun 2020 15:26 #173109

by ihavenofish

Replied by ihavenofish on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Should be clarified here, you don't need linear scales, you just need the encoder on the motor.

(im doing the same with my machine)

- analogue drive mode NEEDS the motor encoder back to the control

- step and direction does NOT need the encoder to go to the control, although you can add it optionally

- BOTH setups can have linear scales added to them optionally.

My personal experience (with one set of old drives) has been that linuxcnc analogue velocity control is not super easy to deal with, so ill be using step and direction mode via a 7i76 with my encoders fed to the control optionally via a 7i77 (I just happen to already have both on hand).

What this does is let the delta drive's very advanced tuning and filtering deal with the hard stuff, and linuxcnc can read the encoder just for error checking.

There are other ways to set this up as well, using step and direction as velocity control, letting linuxcnc close the loop itself. I will experiment with that but I don't expect to use it.

(im doing the same with my machine)

- analogue drive mode NEEDS the motor encoder back to the control

- step and direction does NOT need the encoder to go to the control, although you can add it optionally

- BOTH setups can have linear scales added to them optionally.

My personal experience (with one set of old drives) has been that linuxcnc analogue velocity control is not super easy to deal with, so ill be using step and direction mode via a 7i76 with my encoders fed to the control optionally via a 7i77 (I just happen to already have both on hand).

What this does is let the delta drive's very advanced tuning and filtering deal with the hard stuff, and linuxcnc can read the encoder just for error checking.

There are other ways to set this up as well, using step and direction as velocity control, letting linuxcnc close the loop itself. I will experiment with that but I don't expect to use it.

The following user(s) said Thank You: tommylight, Aciera, Bandar

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7234

29 Jun 2020 18:04 #173116

by tommylight

Replied by tommylight on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

That is very true in the beginning it seems really hard and complicated, but once you get the hang of it it can be done in 5 to 20 minutes..... that linuxcnc analogue velocity control is not super easy to deal with,.....

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 949

- Thank you received: 234

29 Jun 2020 18:11 #173118

by ihavenofish

Replied by ihavenofish on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Cool, you got 20 mins to tune my brother tc225....

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7234

29 Jun 2020 18:26 #173120

by tommylight

Jokes aside, i would love to live there, i just hate the cold, but still i like it there, a lot.

Replied by tommylight on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Yes of course, it just takes over 20 hours and 3 planes to get there !Cool, you got 20 mins to tune my brother tc225....

Jokes aside, i would love to live there, i just hate the cold, but still i like it there, a lot.

Please Log in or Create an account to join the conversation.

- 0x2102

-

- Offline

- Elite Member

-

Less

More

- Posts: 212

- Thank you received: 76

29 Jun 2020 18:49 #173122

by 0x2102

Thanks ihavenofish, you are correct. The servo motor encoder is enough. With the Delta A2 I would probably still prefer step/dir signals to the drive.

@Bandar: It really depends on what your needs are.

- How many axis do you need?

- How is the spindle VFD controlled? 0-10V or step/dir

- How many inputs / outputs in total (limit switches, sensors, spindle etc)

- Are your sensors / switches PNP or NPN type? Is the output signal +24V (PNP) or GND (NPN)?

- Do you want isolated inputs and isolated outputs? More flexible but limited e.g. 7i95 / 7i97

etc.

Isolated inputs can have a positive or negative common for sourcing or sinking input applications. Isolated outputs allow sinking, sourcing combinations of both.

Examples:

7i76e: 5 axis step/dir, 1 spindle output 0-10v with 1 encoder, 16 outputs (sourcing, they provide 24V), 32 inputs (sinking), 2 x 25Pin expansion connectors for daughtercards (e.g. 7i85 4 channel encoder card

7i95: 6 axis step/dir with 6 encoder, no dedicate spindle output, 6 isolated ouputs, 24 isolated inputs, 1 x 25Pin expansion connector for daughtercard.

The Delta A2 and many other servo drives I know, require sinking outputs to trigger their DI (digital input). Servo On, Brake off, Alarm Reset etc. The 7i95 would allow direct wiring, but is limited to 6 outputs. The 7i76e would require relays to provide sinking outputs. There is a special 7i76ed (which has sinking outputs but they are all sinking), so if you need sourcing outputs (24V) that would required a relay as well.

I hope I didn't confuse you, but as you can see .... it all depends on what you need. There are quite a few Mesa card combinations to accomplish what you need.

I would write down answers to all the questions above and try to find a Mesa card that matches the majority of our requirements. The rest can be done via relays or expansion cards (25 Pin or Smart Serial).

Replied by 0x2102 on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Should be clarified here, you don't need linear scales, you just need the encoder on the motor.

Thanks ihavenofish, you are correct. The servo motor encoder is enough. With the Delta A2 I would probably still prefer step/dir signals to the drive.

@Bandar: It really depends on what your needs are.

- How many axis do you need?

- How is the spindle VFD controlled? 0-10V or step/dir

- How many inputs / outputs in total (limit switches, sensors, spindle etc)

- Are your sensors / switches PNP or NPN type? Is the output signal +24V (PNP) or GND (NPN)?

- Do you want isolated inputs and isolated outputs? More flexible but limited e.g. 7i95 / 7i97

etc.

Isolated inputs can have a positive or negative common for sourcing or sinking input applications. Isolated outputs allow sinking, sourcing combinations of both.

Examples:

7i76e: 5 axis step/dir, 1 spindle output 0-10v with 1 encoder, 16 outputs (sourcing, they provide 24V), 32 inputs (sinking), 2 x 25Pin expansion connectors for daughtercards (e.g. 7i85 4 channel encoder card

7i95: 6 axis step/dir with 6 encoder, no dedicate spindle output, 6 isolated ouputs, 24 isolated inputs, 1 x 25Pin expansion connector for daughtercard.

The Delta A2 and many other servo drives I know, require sinking outputs to trigger their DI (digital input). Servo On, Brake off, Alarm Reset etc. The 7i95 would allow direct wiring, but is limited to 6 outputs. The 7i76e would require relays to provide sinking outputs. There is a special 7i76ed (which has sinking outputs but they are all sinking), so if you need sourcing outputs (24V) that would required a relay as well.

I hope I didn't confuse you, but as you can see .... it all depends on what you need. There are quite a few Mesa card combinations to accomplish what you need.

I would write down answers to all the questions above and try to find a Mesa card that matches the majority of our requirements. The rest can be done via relays or expansion cards (25 Pin or Smart Serial).

The following user(s) said Thank You: Bandar

Please Log in or Create an account to join the conversation.

- Bandar

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

30 Jun 2020 13:27 - 30 Jun 2020 15:39 #173191

by Bandar

Replied by Bandar on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Thanks guys for the support you are giving me based on your experiences. This way I feel I can do it. (For clarification: this build is new build not a retrofit).

@ihavenofish, thank you for clearing that up. I was completely confused about which encoder it should be connected to the Mesa card. However, there is one thing that bothers me, why do I have to connect the motors encoders in the Mesa board? The Delta Servo drive has a motor encoder input in the drive itself. If I used 7i76 step/dir do I have to connect the motor's encoder in the 7i76?

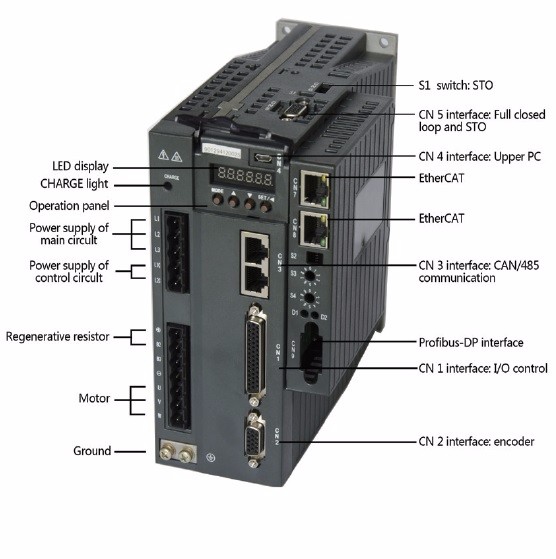

Here is an example for the ASDA-A2

This is another Servo drive company called INVT (I like this servo motor drive because they has the same price as DELTA servo drive price, except that the DELTA motor has 20bit encoder and the INVT has 23bit motor encoder) If you could give me your opinion on those two drivers that would be nice.

@0x2102 , thanks for giving me some idea. To answer your questions:

- How many axis do you need?

I need 4 axis for now. Two for the Y-axis (one is slave), one for the X-axis and one for the Z-axis. later (in the future) I would like to make 4th and 5th axis table.

- How is the spindle VFD controlled? 0-10V or step/dir

About the spindle. I will buy the ATC JGL-80/2.2R30-20 (I will be using rack with tools holder) The manual for the ATC spindle is attached. The VFD is simphoenix e550 VFD (it has 0-10v and modbus)

- How many inputs / outputs in total (limit switches, sensors, spindle etc)

I haven't bought any limit switches yet. But one limit switch for Y-axis , X-axis and Z-axis

Also, I bought MARPOOS touch probe T25G

- Are your sensors / switches PNP or NPN type? Is the output signal +24V (PNP) or GND (NPN)?

I'm open for suggestions

- Do you want isolated inputs and isolated outputs? More flexible but limited e.g. 7i95 / 7i97

Not sure.

I hope that answer most of it

Regards,

@ihavenofish, thank you for clearing that up. I was completely confused about which encoder it should be connected to the Mesa card. However, there is one thing that bothers me, why do I have to connect the motors encoders in the Mesa board? The Delta Servo drive has a motor encoder input in the drive itself. If I used 7i76 step/dir do I have to connect the motor's encoder in the 7i76?

Here is an example for the ASDA-A2

This is another Servo drive company called INVT (I like this servo motor drive because they has the same price as DELTA servo drive price, except that the DELTA motor has 20bit encoder and the INVT has 23bit motor encoder) If you could give me your opinion on those two drivers that would be nice.

@0x2102 , thanks for giving me some idea. To answer your questions:

- How many axis do you need?

I need 4 axis for now. Two for the Y-axis (one is slave), one for the X-axis and one for the Z-axis. later (in the future) I would like to make 4th and 5th axis table.

- How is the spindle VFD controlled? 0-10V or step/dir

About the spindle. I will buy the ATC JGL-80/2.2R30-20 (I will be using rack with tools holder) The manual for the ATC spindle is attached. The VFD is simphoenix e550 VFD (it has 0-10v and modbus)

- How many inputs / outputs in total (limit switches, sensors, spindle etc)

I haven't bought any limit switches yet. But one limit switch for Y-axis , X-axis and Z-axis

Also, I bought MARPOOS touch probe T25G

- Are your sensors / switches PNP or NPN type? Is the output signal +24V (PNP) or GND (NPN)?

I'm open for suggestions

- Do you want isolated inputs and isolated outputs? More flexible but limited e.g. 7i95 / 7i97

Not sure.

I hope that answer most of it

Regards,

Last edit: 30 Jun 2020 15:39 by Bandar. Reason: misspelling

Please Log in or Create an account to join the conversation.

- Bandar

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

30 Jun 2020 15:58 #173194

by Bandar

Replied by Bandar on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21171

- Thank you received: 7234

30 Jun 2020 16:34 #173196

by tommylight

So aluminium extrusion is to weak for those parts, as the ballscrew alone will weigh more than the extrusion.

Still, very nice parts, for sure.

Replied by tommylight on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

Those are parts you buy when building a 5 ton machine, and a fast one at that!1) I bought so far HIWIN linear guides for all my axis.

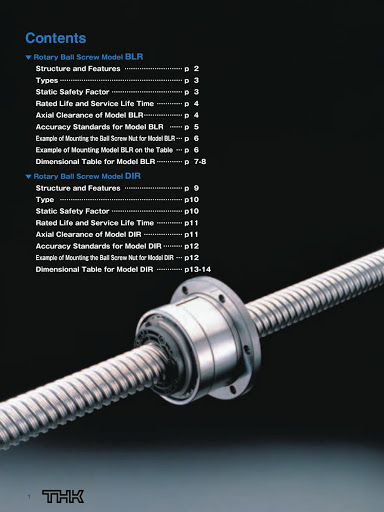

I bought THK Ball screw:

2) For Y-axis THK BLR3232 rotary ball screw.

3) For X-axis HWIN 2020 ball screw

4) For the Z-axis THK SBK 1616 ball screw

5) Aluminium 4080 extrusion profile and 80160 for my gantry.

6)MARPOSS

So aluminium extrusion is to weak for those parts, as the ballscrew alone will weigh more than the extrusion.

Still, very nice parts, for sure.

The following user(s) said Thank You: Bandar

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 949

- Thank you received: 234

30 Jun 2020 17:42 - 30 Jun 2020 18:02 #173197

by ihavenofish

Replied by ihavenofish on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

With step and direction position control, you do NOT need to connect the encoder to the mesa card. The control is telling the motor to got x many steps, like with a stepper motor, and "assumes" the motor went the correct distance without checking.

With analogue speed or torque control, you need to connect the encoder PASS THROUGH from the drive to the mesa board. The encoder from the MOTOR still goes to the drive. The drive then outputs an emulated quadrature signal that the mesa can read. the control is only giving the servo a speed, and therefore needs to read the encoder to know where it is and to then give it a new speed.

Ideally, you'd want the control to close the loop and always know where the motor is - this is how siemens, fanuc etc do it, but linuxcnc is easier to use with plain step and direction and not all drives (like my sanyo) play happily with it.

Linear scales a re separate additional system - a secondary encoder that the control can read in addition or instead of the motors encoder.

With analogue speed or torque control, you need to connect the encoder PASS THROUGH from the drive to the mesa board. The encoder from the MOTOR still goes to the drive. The drive then outputs an emulated quadrature signal that the mesa can read. the control is only giving the servo a speed, and therefore needs to read the encoder to know where it is and to then give it a new speed.

Ideally, you'd want the control to close the loop and always know where the motor is - this is how siemens, fanuc etc do it, but linuxcnc is easier to use with plain step and direction and not all drives (like my sanyo) play happily with it.

Linear scales a re separate additional system - a secondary encoder that the control can read in addition or instead of the motors encoder.

Last edit: 30 Jun 2020 18:02 by ihavenofish.

The following user(s) said Thank You: Bandar

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 949

- Thank you received: 234

30 Jun 2020 17:54 #173198

by ihavenofish

Replied by ihavenofish on topic Best Mesa Cards/ Combo for DELTA ASD-A2 drive/motor

On the 20 bit vs 23 bit... the new delta B3 drives and motors are 24 bit, and cheaper. That's what im using.

The Bit depth isn't very relevant directly - your machine wont be more precise for it. What it does is allow the drive to respond with much higher dynamics and inertia handling - simply because it can scan the encoder for movement much faster. The delta B3 for example has a 3khz velocity loop, vs 1khz on the A2, and 500hz on the B2 (and 100hz on my 1990 sanyo drives that I couldn't tune). Many of the low cost Chinese 'brand" drives are in the 200-500hz range. as a result, they wont have the dynamics ability of the delta B3 or A2. If your machine isn't going to accelerate fast, it's not a big deal, buy what's cheapest with the right power. If you want 0.5G acceleration and 2000ipm, then the B3 will be better than the A2, and the A2 better than the B2 by a noticeable margin.

Like tommy though, you lost me at 4080 extrusion, I don't know what your design is, but that extrusion is what you get on a $299 mini tabletop router frame.

The Bit depth isn't very relevant directly - your machine wont be more precise for it. What it does is allow the drive to respond with much higher dynamics and inertia handling - simply because it can scan the encoder for movement much faster. The delta B3 for example has a 3khz velocity loop, vs 1khz on the A2, and 500hz on the B2 (and 100hz on my 1990 sanyo drives that I couldn't tune). Many of the low cost Chinese 'brand" drives are in the 200-500hz range. as a result, they wont have the dynamics ability of the delta B3 or A2. If your machine isn't going to accelerate fast, it's not a big deal, buy what's cheapest with the right power. If you want 0.5G acceleration and 2000ipm, then the B3 will be better than the A2, and the A2 better than the B2 by a noticeable margin.

Like tommy though, you lost me at 4080 extrusion, I don't know what your design is, but that extrusion is what you get on a $299 mini tabletop router frame.

The following user(s) said Thank You: tommylight, Bandar

Please Log in or Create an account to join the conversation.

Time to create page: 0.254 seconds