LinuxCNC for automation

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

06 Aug 2020 18:37 - 06 Aug 2020 18:41 #177541

by Grotius

Replied by Grotius on topic LinuxCNC for automation

Hi,

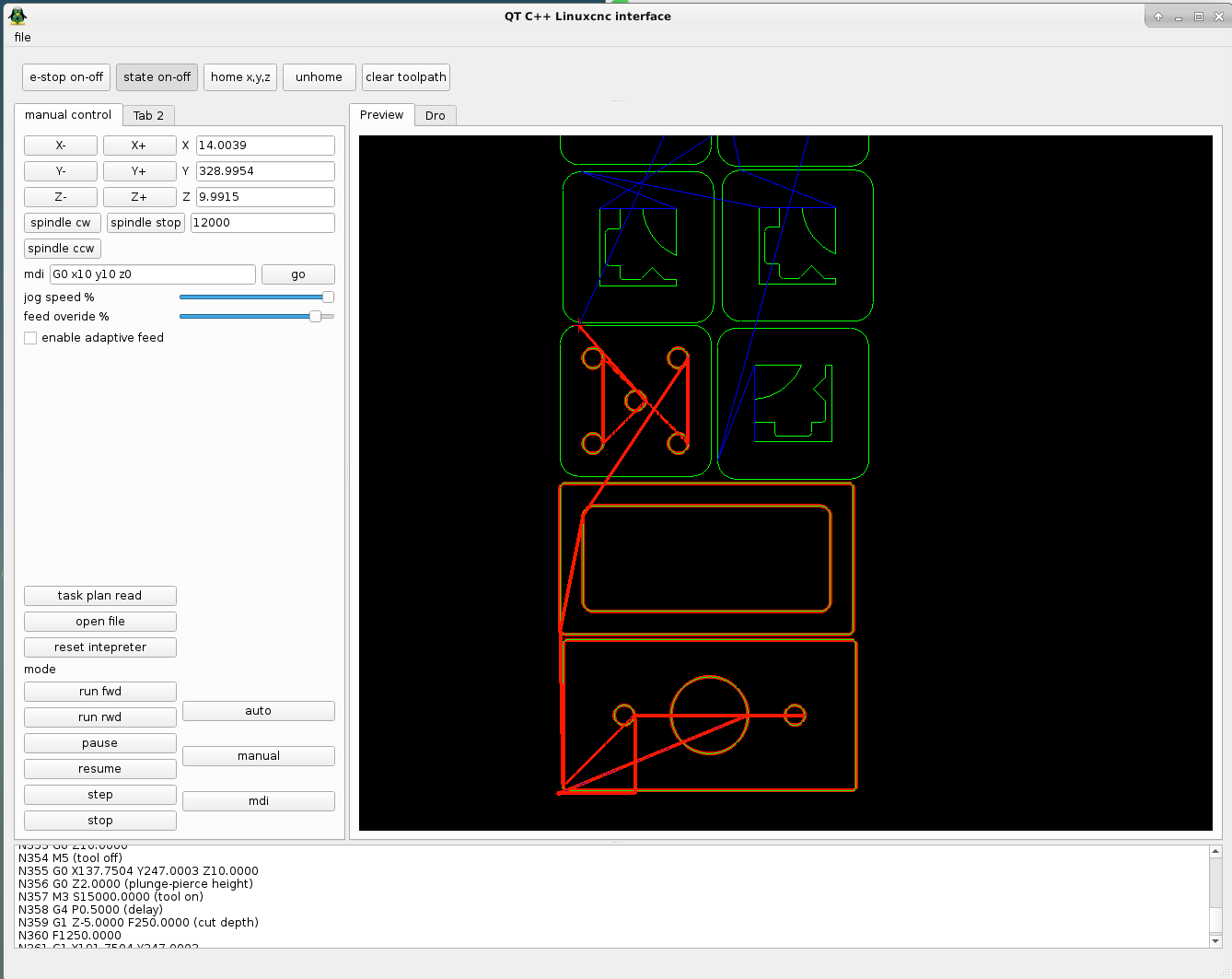

Today added the gcode preview into the opengl. I think you can call it a gcode parser. It works fine.

If you replace in the axis.ini file :

# Name of display program, e.g., axis

#DISPLAY = axis

DISPLAY = QT_Lcnc_interface

It will start as stand alone gui if the QT_Lcnc_interface file is in the bin folder.

Source code is attached.

I think i can use some help. A few c++ commands are not working :

-feed rate override

-max feedrate

-adaptive feed

When calling those functions i get error : ../linuxcnc/include/emc_nml.hh:548: undefined reference to `StateTag::StateTag()'

C++ code looks like :

It looks like m.tag has to have a value and be part of above code. But wich value must the tag have?

Tag is abracadabra for me.

Any idea's?

Todo is preview current gcode line in the gcode editor.

And try to make hal connections.

Today added the gcode preview into the opengl. I think you can call it a gcode parser. It works fine.

If you replace in the axis.ini file :

# Name of display program, e.g., axis

#DISPLAY = axis

DISPLAY = QT_Lcnc_interface

It will start as stand alone gui if the QT_Lcnc_interface file is in the bin folder.

Source code is attached.

I think i can use some help. A few c++ commands are not working :

-feed rate override

-max feedrate

-adaptive feed

When calling those functions i get error : ../linuxcnc/include/emc_nml.hh:548: undefined reference to `StateTag::StateTag()'

C++ code looks like :

const char *cstr = nmlfile.c_str();

RCS_CMD_CHANNEL *c = new RCS_CMD_CHANNEL(emcFormat, "emcCommand", "xemc", cstr);

EMC_TRAJ_SET_FO_ENABLE m;

m.mode=1;

c->write(&m);It looks like m.tag has to have a value and be part of above code. But wich value must the tag have?

Tag is abracadabra for me.

Any idea's?

Todo is preview current gcode line in the gcode editor.

And try to make hal connections.

Last edit: 06 Aug 2020 18:41 by Grotius.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

07 Aug 2020 08:18 #177584

by Himarc3D

what im looking for now is the way too support multiple language like that:

www.ics.com/blog/dynamic-language-selection-qt

doc.qt.io/qt-5/qtlinguist-index.html

probably ill use gmocappy or axis at begin and after that i use qt c++ with language support when i get the machine running consistently i can work in learn qt

i wish in near future help you into your effort if not in code i can at least help translated (thank you for give to us your code) but now im reading manuals and topics here, waiting my Mesa 7i76, motors, drivers etc to start, im very busy reading many new stuff i never used ballscrew, i just used home switch until now...ill use rodw idea for limit and home switch.

forum.linuxcnc.org/38-general-linuxcnc-q...ation?start=0#124659

Replied by Himarc3D on topic LinuxCNC for automation

my background is from arduino, plc i have checked qtpyvcp but i dont know python yet and into industry they use a lot C/C++ so i think is better stay into the C/C++ path to learn. what i have wrote untill now i think my stuff is in plain C...very basic stuff.Hi Himarc,

The buckie videos on youtube are nice to follow.

If you compare buckies examples to my code style, you will see i use header only if possible.

Most of time i use a header file to do calculation's instead of a class wich contains a .h and .cpp file.

Private, public and so on don't interest me. The only thing that interest me is a compact program that does the job.

The downside of header only is, sometimes you cannot include a header twice in the same program.

Qt, look at : refractor -> rename under cursor

Qt, auto indent selection

For documentation i learned to use the standard c++ library (std) as much as possible. So when i can avoid a qt library i do so to

make program's more cross platform compatible.

If i need to know something about c++ i google for a example.

Warning: Spoiler!try to use :

std::string, double, int, bool, char, etc.

Things that are handy to use, for example :

abs or -abs

if(101%2==0){ .. } //to compare if value 101 is even or uneven.

Things to know are container types like vector :

std::vector<double>

I stay at vectors. I do not use any of the qt container types, like stringlist, linked list etc.

setting up structures and how to use them in functions :

struct POINT {

double x,y,z;

}

standard function :

void test(){

//do things here.

}

try to understand a function to return the point value.

POINT test(){

POINT p;

p.x=1;

return p;

}

read in the point done by above function:

void read_in(){

POINT point = test();

}

pass in values :

void test (double x, double y, double z, /*or simpler x,y,z in one point :*/ POINT p){

//here you see we pass in x,y,z or we pass in a point p.x, p.y, p.z wich is easyer and less work.

}

you can pass in iterators (kind of pointers)

void test (std::vector<POINT>::iterator it){

//how to use this you will learn by practicing and look at iterator code samples.

}

Good luck. What will you write for a program, will it contain a graphical interface with opengl?

what im looking for now is the way too support multiple language like that:

www.ics.com/blog/dynamic-language-selection-qt

doc.qt.io/qt-5/qtlinguist-index.html

probably ill use gmocappy or axis at begin and after that i use qt c++ with language support when i get the machine running consistently i can work in learn qt

i wish in near future help you into your effort if not in code i can at least help translated (thank you for give to us your code) but now im reading manuals and topics here, waiting my Mesa 7i76, motors, drivers etc to start, im very busy reading many new stuff i never used ballscrew, i just used home switch until now...ill use rodw idea for limit and home switch.

forum.linuxcnc.org/38-general-linuxcnc-q...ation?start=0#124659

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

07 Aug 2020 20:35 - 07 Aug 2020 20:49 #177650

by Grotius

Replied by Grotius on topic LinuxCNC for automation

Hi Himarc,

Very nice !

I hope you make progess with Qt c++.

.ill use rodw idea for limit and home switch. Nice. Just read and learn from others.

Mesa 7i76 On youtube there is a german guy how explain how to program a mesa. Very interesting. I like the Mesa fpga idea. but never used it.

i wish in near future help you into your effort

Are you good in mathematics? Or maybe making cool program buttons to integrate in the gui.?

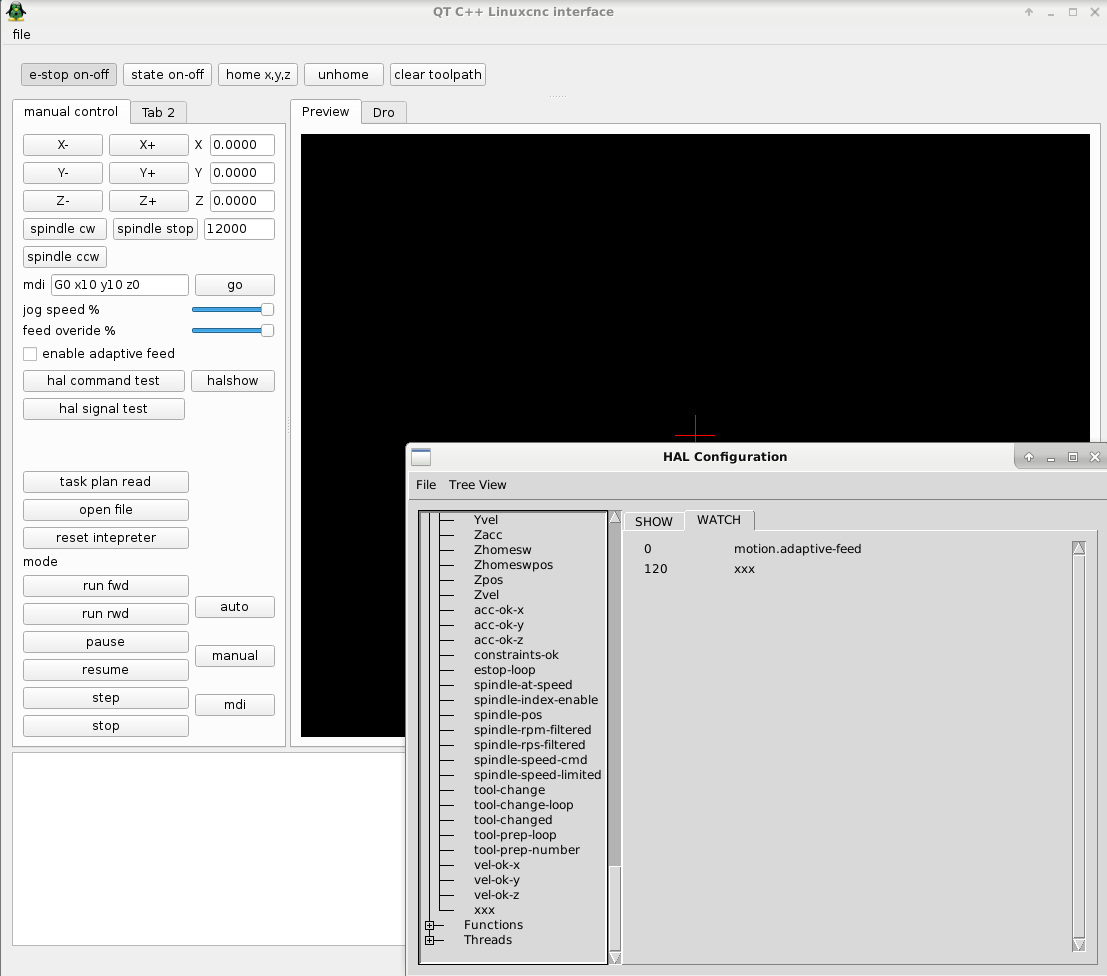

Today i did some work to try to connect the c++ app to hal.

I got no luck the first hours.

Then i decided to copy parts of the c++ halcommand code into my app to see if we can get lucky.

And that worked.

Now we can set pins, signals and parameters, etc very easy from c++

Look in the attachment, for hal/halsextion.h, the code is still raw, but is working.

Here we fill in the "name" and the "value" of the component and we are done !

//sets means set signal

int do_sets_cmd(char *name, char *value)

//setp means set parameter

int do_setp_cmd(char *name, char *value)

To save copy time i did make a symbolic link to the linuxcnc/bin folder from my qt compile directory.

Otherwise i had to copy the new compiled executable every time to the linuxcnc/bin folder.

Also added halshow to the app, so we can check the port and pins.

Tested 2 signals, set parameter motion.adaptive-feed from 1 to 0.

Set up a signal in c++ code, named xxx, change value from 0 to 120.

Source code attached.

Very nice !

I hope you make progess with Qt c++.

.ill use rodw idea for limit and home switch. Nice. Just read and learn from others.

Mesa 7i76 On youtube there is a german guy how explain how to program a mesa. Very interesting. I like the Mesa fpga idea. but never used it.

i wish in near future help you into your effort

Are you good in mathematics? Or maybe making cool program buttons to integrate in the gui.?

Today i did some work to try to connect the c++ app to hal.

I got no luck the first hours.

Then i decided to copy parts of the c++ halcommand code into my app to see if we can get lucky.

And that worked.

Now we can set pins, signals and parameters, etc very easy from c++

Look in the attachment, for hal/halsextion.h, the code is still raw, but is working.

Here we fill in the "name" and the "value" of the component and we are done !

//sets means set signal

int do_sets_cmd(char *name, char *value)

//setp means set parameter

int do_setp_cmd(char *name, char *value)

To save copy time i did make a symbolic link to the linuxcnc/bin folder from my qt compile directory.

Otherwise i had to copy the new compiled executable every time to the linuxcnc/bin folder.

Also added halshow to the app, so we can check the port and pins.

Tested 2 signals, set parameter motion.adaptive-feed from 1 to 0.

Set up a signal in c++ code, named xxx, change value from 0 to 120.

Source code attached.

Last edit: 07 Aug 2020 20:49 by Grotius.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

08 Aug 2020 01:22 - 08 Aug 2020 01:51 #177673

by Himarc3D

Replied by Himarc3D on topic LinuxCNC for automation

Im average in mathematics. I think i can make buttons but usually i make HMI very simple, very basic, very boring...i try to follow SCADA/HMI standards.

www.asee.org/public/conferences/8/papers/3605/download

www.controleng.com/articles/how-to-best-design-an-hmi-system/

www.hmicons.com/2019/07/27/using-color-in-hmi-graphics-design/

after i send my machine to the client (total 8) the next one ill focus work into the HMI, customise it so i think i can help making buttons for you, i can use basic inkscape and gimp for my needs.

Can you show to me what is cool buttons for you?

Probably i will use you GUI and put one tab for camera and in all tabs one button to switch language, no need logout, here at the client fabric floor the operator and the supervisor dont have the same native language, for the operator is very simple layout to use, something you just need little time to understand, minimalist, simple because the operator rotation is high...usually they just take and put the work piece into the machine.

www.asee.org/public/conferences/8/papers/3605/download

www.controleng.com/articles/how-to-best-design-an-hmi-system/

www.hmicons.com/2019/07/27/using-color-in-hmi-graphics-design/

after i send my machine to the client (total 8) the next one ill focus work into the HMI, customise it so i think i can help making buttons for you, i can use basic inkscape and gimp for my needs.

Can you show to me what is cool buttons for you?

Probably i will use you GUI and put one tab for camera and in all tabs one button to switch language, no need logout, here at the client fabric floor the operator and the supervisor dont have the same native language, for the operator is very simple layout to use, something you just need little time to understand, minimalist, simple because the operator rotation is high...usually they just take and put the work piece into the machine.

Last edit: 08 Aug 2020 01:51 by Himarc3D.

The following user(s) said Thank You: Grotius

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

09 Aug 2020 19:56 - 12 Aug 2020 11:33 #177774

by Grotius

Replied by Grotius on topic LinuxCNC for automation

Hi,

I think i can make buttons but usually i make HMI very simple, very basic, very boring

Perfect for this job. We don't like HMI cristmass tree's.

Can you show to me what is cool buttons for you?

If you can do it like this. You are the men, you got 2 fish !

Probably i will use you GUI and put one tab for camera

Do you want to integrate camara logic into the app? Then i need more info.

and in all tabs one button to switch language

Nice !

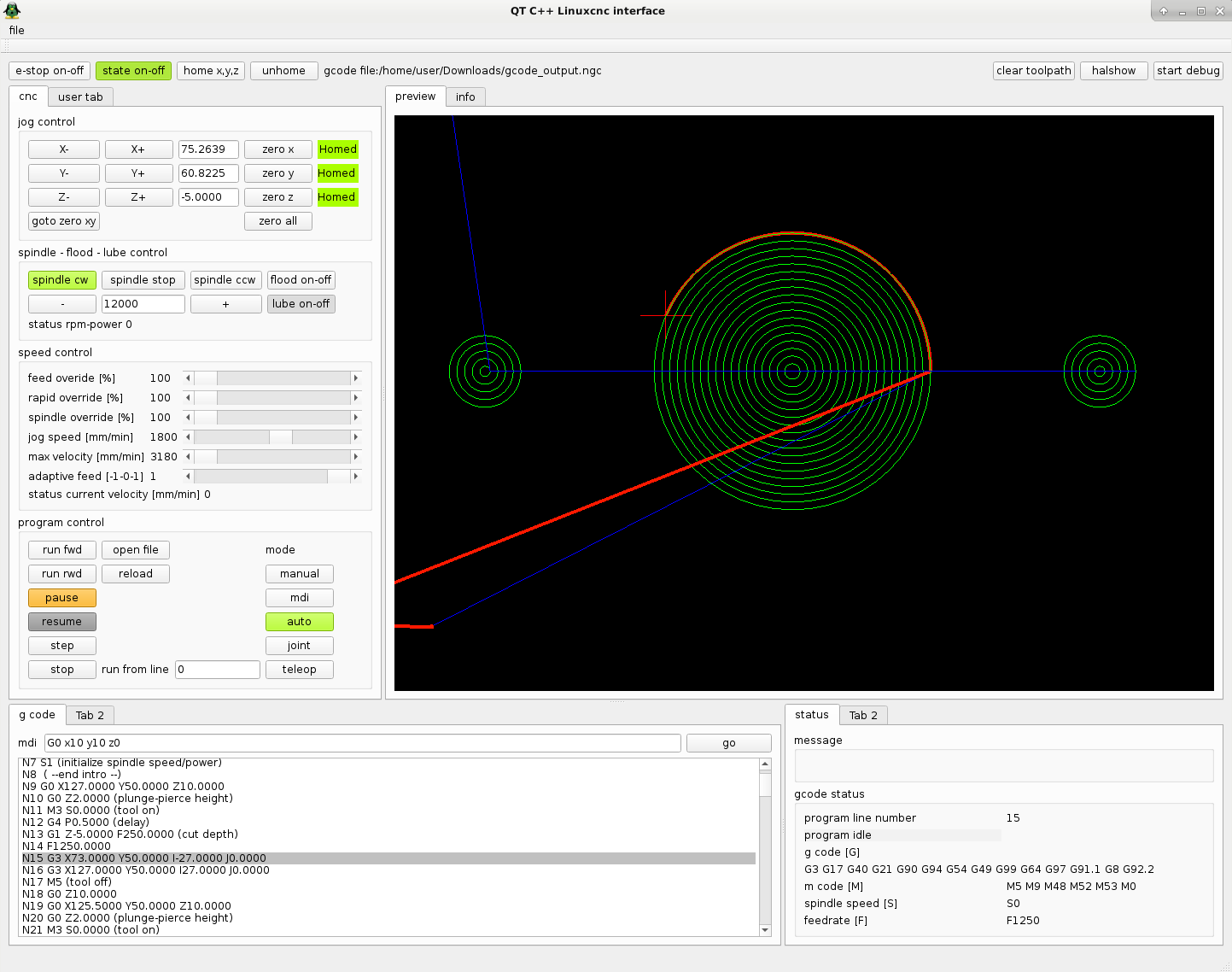

Okey i did write some code today.

1. The gcode preview is now interactive with the program.

2. We got several status connections now.

3. The most of the gui buttons and sliders are working except : spindle + and -, program reload.

4. The c++ code i refined some bit to make it usefull for beginning c++ users.

For every linux command or call i made a function. So for mdi command you simple write in c++:

mdi("G0 X0 Y0");

Just take a look at the code. If you want to try the app. You have to download QT c++ and open the project file.

When compiled place the executable file into the linuxcnc bin folder. Change display in the ini file to executable name and

you are done!

Result for today.

Source code attached.

Edit : For latest code update :

github.com/grotius-cnc/QT_C-_Linuxcnc_in...ithub_screenshot.png

The most of code is done. Read the readme file for my comments.

I think i can make buttons but usually i make HMI very simple, very basic, very boring

Perfect for this job. We don't like HMI cristmass tree's.

Can you show to me what is cool buttons for you?

If you can do it like this. You are the men, you got 2 fish !

Probably i will use you GUI and put one tab for camera

Do you want to integrate camara logic into the app? Then i need more info.

and in all tabs one button to switch language

Nice !

Okey i did write some code today.

1. The gcode preview is now interactive with the program.

2. We got several status connections now.

3. The most of the gui buttons and sliders are working except : spindle + and -, program reload.

4. The c++ code i refined some bit to make it usefull for beginning c++ users.

For every linux command or call i made a function. So for mdi command you simple write in c++:

mdi("G0 X0 Y0");

Just take a look at the code. If you want to try the app. You have to download QT c++ and open the project file.

When compiled place the executable file into the linuxcnc bin folder. Change display in the ini file to executable name and

you are done!

Result for today.

Source code attached.

Edit : For latest code update :

github.com/grotius-cnc/QT_C-_Linuxcnc_in...ithub_screenshot.png

The most of code is done. Read the readme file for my comments.

Last edit: 12 Aug 2020 11:33 by Grotius.

The following user(s) said Thank You: tommylight, Clive S, Himarc3D

Please Log in or Create an account to join the conversation.

Time to create page: 0.328 seconds