z-axis movement via ultrasonic sensor

- saztyga

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

07 Sep 2020 22:28 - 07 Sep 2020 22:29 #181185

by saztyga

z-axis movement via ultrasonic sensor was created by saztyga

Hello !

my question is ,

can we use ultra sonic sensor to the z axis to keep it above the ground , so whenever ground have uneven surface ultrasonic sensor detect that and moves the axis upwards and downwards.

long story shorts can we keep the ground clearance (between tool and workpes) constant ?

my question is ,

can we use ultra sonic sensor to the z axis to keep it above the ground , so whenever ground have uneven surface ultrasonic sensor detect that and moves the axis upwards and downwards.

long story shorts can we keep the ground clearance (between tool and workpes) constant ?

Last edit: 07 Sep 2020 22:29 by saztyga.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20497

- Thank you received: 6975

07 Sep 2020 22:31 #181186

by tommylight

Replied by tommylight on topic z-axis movement via ultrasonic sensor

Yes, but i do not think ultrasound is precise enough.

What is the use for it ?

What is the use for it ?

Please Log in or Create an account to join the conversation.

- saztyga

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

07 Sep 2020 22:45 #181191

by saztyga

Replied by saztyga on topic z-axis movement via ultrasonic sensor

In my project precision it not a problem. .Can you please give me any hint so i can get more information about it..

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20497

- Thank you received: 6975

08 Sep 2020 11:15 #181241

by tommylight

Replied by tommylight on topic z-axis movement via ultrasonic sensor

We can not help you much if we do not know what the project or the end result should be.

But since you insist, get some car ultrasonic sensors as they are very cheap and do some tests.

Or an arduino with ultrasonic sensors should also do for testing, again very cheap.

But since you insist, get some car ultrasonic sensors as they are very cheap and do some tests.

Or an arduino with ultrasonic sensors should also do for testing, again very cheap.

Please Log in or Create an account to join the conversation.

- saztyga

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

14 Sep 2020 22:44 #182159

by saztyga

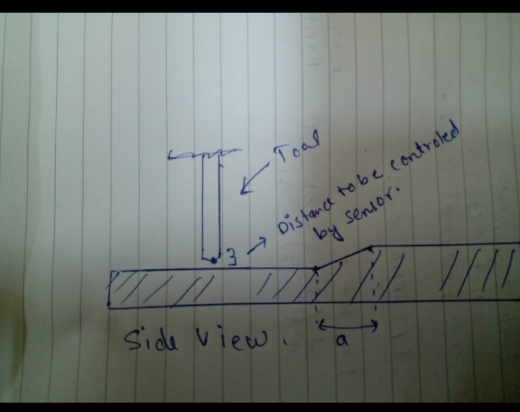

Sorry for the late response sir, i am trying to make cake decorator so there may be ups and downs on cake surface

so that's why i want to put sensor on z axis so it can move tool up and down during execution.

here is a picture

where A should be read by sensor and moves the tools accordingly ..please help me out with this.

Thank You sir

Replied by saztyga on topic z-axis movement via ultrasonic sensor

Sorry for the late response sir, i am trying to make cake decorator so there may be ups and downs on cake surface

so that's why i want to put sensor on z axis so it can move tool up and down during execution.

here is a picture

where A should be read by sensor and moves the tools accordingly ..please help me out with this.

Thank You sir

Attachments:

Please Log in or Create an account to join the conversation.

- saztyga

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

18 Sep 2020 23:33 #182690

by saztyga

Replied by saztyga on topic z-axis movement via ultrasonic sensor

?????

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

19 Sep 2020 08:08 #182717

by Himarc3D

Replied by Himarc3D on topic z-axis movement via ultrasonic sensor

I dont think its easy for cake...youll take a lot time to adjust it, for metal people use one method called breakaway, when the nozzle colide with the work material the nozzle breakaway from the support, in your case maybe it drop up the cake...i saw here one guy use wire to avoid it to drop...whats 3? 3mm, 3cm or 3 inch? why you need one machine to do it? 3cm will be more easy to implement.

The sensor work. Actually the machine dont have idea what sensor you are using, just signal and if the signal was consistent or not.

You wanna real time height adjustment?

Do you have 3D printer?

If no check bed leveling in 3D printer, someone here started talk about 3D printer but i think stopped talking about it, search here in the forum.

The sensor work. Actually the machine dont have idea what sensor you are using, just signal and if the signal was consistent or not.

You wanna real time height adjustment?

Do you have 3D printer?

If no check bed leveling in 3D printer, someone here started talk about 3D printer but i think stopped talking about it, search here in the forum.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20497

- Thank you received: 6975

19 Sep 2020 08:13 #182718

by tommylight

Replied by tommylight on topic z-axis movement via ultrasonic sensor

Ultrasonic sensors will most probably not work for that as the area they detect is quite big, or the head will move up or down way before where it is needed.

A laser range finder would be to narrow, so again not really usable.

I would still try with ultrasonic sensors but add short tubes in front of them to narrow the field, that might still work.

A laser range finder would be to narrow, so again not really usable.

I would still try with ultrasonic sensors but add short tubes in front of them to narrow the field, that might still work.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

19 Sep 2020 08:29 #182719

by Himarc3D

Replied by Himarc3D on topic z-axis movement via ultrasonic sensor

Ultrasonic sensor have mm to meters circumference range. In industry now i saw a lot people using fiber now.

Please Log in or Create an account to join the conversation.

- Himarc3D

-

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 49

19 Sep 2020 08:34 #182720

by Himarc3D

Replied by Himarc3D on topic z-axis movement via ultrasonic sensor

The material surface will be pretty trick i think using ultrasonic.

Please Log in or Create an account to join the conversation.

Time to create page: 0.079 seconds