New Build

- gregb

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 2

20 Oct 2020 04:08 #186645

by gregb

New Build was created by gregb

Hi Guys,

Short term reader, first time poster.

A few months ago I bought a CNC plasma table from China as it was the only thing that fit the budget. Not having previous experience with CNC machines, it has been a learning curve to say the least, however I have been able to make some descent parts and I have gotten quite comfortable with the machine.

The biggest limitation I have at the moment is the crappy chinese controller running it and after much research, I've decided that LINUXCNC is the best option for me.

Machine is currently running a "Fangling 2300“ controller with 400w ac servos on the x and y with yaskawa sgd7s-2r8a00a drivers and I believe it's some sort of stepper on the z which is driven by a Fangling 1628 THC which I can't get to actually work in auto mode.

I'm thinking the 7i76e is the way to go, I just want to confirm that it's fully supported in the latest stable version of Linuxcnc without any complicated install. I also note that the 6i25 with 7i76 is an alternative, if I plan on keeping it all in the same box anyway, is there a big reason to go one way or the other?

I also note that it is the 7i77 that is designed for Servo applications, is there any issue with using the 7i76? I believe the Servo drivers are currently setup for a step/dir input and the documentation for them has confused the crap out of me so I want to keep it as simple as possible and try to minimise down time.

I'd love to upload some photos of what I'm talking about but I'm on my phone and can't seem to shrink the images small enough for the forum.

Sorry if I've missed any important info. This looks like a great forum guys, hope you guys can help me out and I'll try and return the favour in the future.

Also, I'm in Sydney Australia, just wondering if there is anyone local on this forum I can support by purchasing through them.

Cheers!

Greg

Short term reader, first time poster.

A few months ago I bought a CNC plasma table from China as it was the only thing that fit the budget. Not having previous experience with CNC machines, it has been a learning curve to say the least, however I have been able to make some descent parts and I have gotten quite comfortable with the machine.

The biggest limitation I have at the moment is the crappy chinese controller running it and after much research, I've decided that LINUXCNC is the best option for me.

Machine is currently running a "Fangling 2300“ controller with 400w ac servos on the x and y with yaskawa sgd7s-2r8a00a drivers and I believe it's some sort of stepper on the z which is driven by a Fangling 1628 THC which I can't get to actually work in auto mode.

I'm thinking the 7i76e is the way to go, I just want to confirm that it's fully supported in the latest stable version of Linuxcnc without any complicated install. I also note that the 6i25 with 7i76 is an alternative, if I plan on keeping it all in the same box anyway, is there a big reason to go one way or the other?

I also note that it is the 7i77 that is designed for Servo applications, is there any issue with using the 7i76? I believe the Servo drivers are currently setup for a step/dir input and the documentation for them has confused the crap out of me so I want to keep it as simple as possible and try to minimise down time.

I'd love to upload some photos of what I'm talking about but I'm on my phone and can't seem to shrink the images small enough for the forum.

Sorry if I've missed any important info. This looks like a great forum guys, hope you guys can help me out and I'll try and return the favour in the future.

Also, I'm in Sydney Australia, just wondering if there is anyone local on this forum I can support by purchasing through them.

Cheers!

Greg

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

20 Oct 2020 07:28 #186657

by rodw

Replied by rodw on topic New Build

Welcome Greg. There are quite a few Aussies on the forum here in the Plasma Club. PhillC the developer of the awesome plasmac config is based in Melbourne, thefabricator03 (Stefan) is at Dubbo and I'm in Brisbane.

Normally we recommend the ethernet cards for plasma because of the additional galvanic isolation the ethernet cable provides. Once installed and running, there is no functional difference between the Pci/e or ethernet versions. IN fact the distinction is even more blurred now because with the recent upgrade to 2.8 as the release version, the required PREMPT_RT kernel is part of the main ISO. So yes the 7i76e is fully supported.

By the sound of it, your drives support a number of modes so step and direction via a Mesa 7i76e and closing the encoder feedback on the drives is certainly an option.

Can you let us know which plasma cutter you are using?

Re the phone photos, I find with an Android phone, I upload my photos to Google photos and display the image there. Then I can right click on the image on my PC and download it (do not use the download button which gives the full resolution photo).

Its funny you mentioned looking to support a forum member. there is not anybody officially distributing Mesa hardware in AU. I have sold a bit via word of mouth from stuff I've bought in for my own needs. I have always wanted to offer a prebuilt plasma controller so over the weekend, I ordered a heap of stuff with this in mind including a couple of 7i76e's, single board PC's and 15.6" touch screens and some industrial wireless pendants. The intent is to build a dedicated controller package in two parts, a control box with the 7i76e, motor drives, power supplies. and a HMI module containing a touch screen, PC and all the trimmings. I wanted it to be a high end kit, not something done on the cheap. We also have a complete A axis deigned and being protoyped by an associate. If you have the usual Chinese 24v DC motor Z axis stage, you may need something like that. You can contact me on the 1300 number on my web site if you want to explore this further. www.vmn.com.au/

Normally we recommend the ethernet cards for plasma because of the additional galvanic isolation the ethernet cable provides. Once installed and running, there is no functional difference between the Pci/e or ethernet versions. IN fact the distinction is even more blurred now because with the recent upgrade to 2.8 as the release version, the required PREMPT_RT kernel is part of the main ISO. So yes the 7i76e is fully supported.

By the sound of it, your drives support a number of modes so step and direction via a Mesa 7i76e and closing the encoder feedback on the drives is certainly an option.

Can you let us know which plasma cutter you are using?

Re the phone photos, I find with an Android phone, I upload my photos to Google photos and display the image there. Then I can right click on the image on my PC and download it (do not use the download button which gives the full resolution photo).

Its funny you mentioned looking to support a forum member. there is not anybody officially distributing Mesa hardware in AU. I have sold a bit via word of mouth from stuff I've bought in for my own needs. I have always wanted to offer a prebuilt plasma controller so over the weekend, I ordered a heap of stuff with this in mind including a couple of 7i76e's, single board PC's and 15.6" touch screens and some industrial wireless pendants. The intent is to build a dedicated controller package in two parts, a control box with the 7i76e, motor drives, power supplies. and a HMI module containing a touch screen, PC and all the trimmings. I wanted it to be a high end kit, not something done on the cheap. We also have a complete A axis deigned and being protoyped by an associate. If you have the usual Chinese 24v DC motor Z axis stage, you may need something like that. You can contact me on the 1300 number on my web site if you want to explore this further. www.vmn.com.au/

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5722

- Thank you received: 2095

20 Oct 2020 09:52 #186664

by phillc54

Replied by phillc54 on topic New Build

Hey Rod, Phill is from Canberra.

And we have no breweries except for the yuppy ones that make slop that we used to call home brew back in 80s.

And we have no breweries except for the yuppy ones that make slop that we used to call home brew back in 80s.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

20 Oct 2020 10:04 #186666

by rodw

Replied by rodw on topic New Build

Geez sorry mate, I had you in the wrong state!

Please Log in or Create an account to join the conversation.

- gregb

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 2

20 Oct 2020 20:31 #186745

by gregb

Replied by gregb on topic New Build

Thanks for the feedback and great to see that there are a few locals (relatively speaking) on here.

Sounds like a 7i76e is a no brainier then, i forgot to mention that I was planning to use a THCAD 10 and I'd love to install a "MPG" I think you call them (hand held jog wheel). I saw a write up of installing an Alibaba MPG to one of the internal controllers (5i25/6i25) through the expansion port and a DB25, does that still work on a 7i76e?

Plasma cutter is a Huayuan LGK-120A, again I would have loved to go a big hyperthem but it just wasn't in the budget. Seem to have the CNC output. No mention of a HF start in the documentation. I believe it's got a voltage divider inside, what seems to be the standard as far as setting a ratio on it vs adding resistors to the THCAD circuit?

I honestly haven't had a chance to sit at the computer to play around with the photos but when I do I'll upload some.

Perfect timing for that order Rod, I might call you a little later in the week to discuss. It definitely would be great to have a local stockist for this stuff.

Thanks Again!!

Greg

Sounds like a 7i76e is a no brainier then, i forgot to mention that I was planning to use a THCAD 10 and I'd love to install a "MPG" I think you call them (hand held jog wheel). I saw a write up of installing an Alibaba MPG to one of the internal controllers (5i25/6i25) through the expansion port and a DB25, does that still work on a 7i76e?

Plasma cutter is a Huayuan LGK-120A, again I would have loved to go a big hyperthem but it just wasn't in the budget. Seem to have the CNC output. No mention of a HF start in the documentation. I believe it's got a voltage divider inside, what seems to be the standard as far as setting a ratio on it vs adding resistors to the THCAD circuit?

I honestly haven't had a chance to sit at the computer to play around with the photos but when I do I'll upload some.

Perfect timing for that order Rod, I might call you a little later in the week to discuss. It definitely would be great to have a local stockist for this stuff.

Thanks Again!!

Greg

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

20 Oct 2020 21:32 #186755

by rodw

Replied by rodw on topic New Build

The 7i76e has two MPG inputs onboard which are enabled in Mode 2 ( a software setting in hal). If you search for my "Spaceship Plasma" thread on about page 3, its all fully documented how to install on a 7i76e. There is also a USB pendant option. I just did not want to go down the USB path. I've used a 433 MHz wireless pendant which is hard wired in (and uses one of the 7i76e's MPG input). This is what I am planning and have ordered a couple of pendants.

Hopefully your divider settings are documented or available from the supplier. If you can get behind the voltage divider boards inside the plasma cutter, you can add a known voltage ( I used 96v eg. 2 x 48 volt power supplies) and measure the output and calculate it accordingly. But being accurate here is not important if you auto sample the volts with plasmac. You'd just need to make sure the THCAD does not go to full scale while cutting.

Hopefully your divider settings are documented or available from the supplier. If you can get behind the voltage divider boards inside the plasma cutter, you can add a known voltage ( I used 96v eg. 2 x 48 volt power supplies) and measure the output and calculate it accordingly. But being accurate here is not important if you auto sample the volts with plasmac. You'd just need to make sure the THCAD does not go to full scale while cutting.

Please Log in or Create an account to join the conversation.

- gregb

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 2

12 Nov 2020 07:47 #189091

by gregb

Replied by gregb on topic New Build

Hey guys,

Sorry for the delayed reply (mainly to Rod), I have had a hectic couple of weeks at work.

Thanks for all the reply and again to Rod for the phone calls.

Looks like I need to upgrade my z axis as it's currently running a DC motor. Just wondering everyone's thoughts on Servo vs Stepper. The machine has 400w yaskawa servos on x and y (2 on y, 1 on y). I've done a bit of research and I feel like nema 23 sized servo's would have to be up to the task. Looks like Gecko is the best for a stepper driver, but I can't seem to figure out the whole motor situation.

Are all nema 23's the same or is there a particular brand I should be looking at. I've noticed 'sure step' which seems to be a quality motor, does anyone have experience with them and a gecko driver? I'm after as many opinions as possible so please feel free to share what you think.

I will post some pic's tonight when I'm in front of my computer.

Cheers,

Greg

Sorry for the delayed reply (mainly to Rod), I have had a hectic couple of weeks at work.

Thanks for all the reply and again to Rod for the phone calls.

Looks like I need to upgrade my z axis as it's currently running a DC motor. Just wondering everyone's thoughts on Servo vs Stepper. The machine has 400w yaskawa servos on x and y (2 on y, 1 on y). I've done a bit of research and I feel like nema 23 sized servo's would have to be up to the task. Looks like Gecko is the best for a stepper driver, but I can't seem to figure out the whole motor situation.

Are all nema 23's the same or is there a particular brand I should be looking at. I've noticed 'sure step' which seems to be a quality motor, does anyone have experience with them and a gecko driver? I'm after as many opinions as possible so please feel free to share what you think.

I will post some pic's tonight when I'm in front of my computer.

Cheers,

Greg

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

12 Nov 2020 10:30 - 12 Nov 2020 10:31 #189097

by rodw

Replied by rodw on topic New Build

I'm sorry. I've been a bit the same. I would not get a Gecko servo driver as Stefan had a lot of problems with one and gave up.

If you went with a stepper, I would recommend a Lam Technologies LS1073a driver I can source, and a

Sanyo Denki NEMA24 (60mm frame) motor which I have in stock. I bought about 20 of them so ignore the price shown on that page. For a power supply, I would suggest a 50V 3.2 amp toroid which I have a source for..

I've got a matched pair ESTUN EDC servo driver (step/dir) and a matching 400 W servo motor with a 60mm frame on hold for you with a trusted Aussie supplier. The power is a good match for a Z axis based on our stepper model. The advantage of using a servo is that it will run on mains power so you do not need to buy an additional power supply to drive a stepper. It will cost a bit more but be a cleaner setup with the existing yaskawas

A question for the others. This servo motor has max torque through to about 3600 rpm. I did not think it would need a gearbox reduction, so what do others think?

If you went with a stepper, I would recommend a Lam Technologies LS1073a driver I can source, and a

Sanyo Denki NEMA24 (60mm frame) motor which I have in stock. I bought about 20 of them so ignore the price shown on that page. For a power supply, I would suggest a 50V 3.2 amp toroid which I have a source for..

I've got a matched pair ESTUN EDC servo driver (step/dir) and a matching 400 W servo motor with a 60mm frame on hold for you with a trusted Aussie supplier. The power is a good match for a Z axis based on our stepper model. The advantage of using a servo is that it will run on mains power so you do not need to buy an additional power supply to drive a stepper. It will cost a bit more but be a cleaner setup with the existing yaskawas

A question for the others. This servo motor has max torque through to about 3600 rpm. I did not think it would need a gearbox reduction, so what do others think?

Last edit: 12 Nov 2020 10:31 by rodw.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1944

- Thank you received: 338

12 Nov 2020 12:45 #189103

by bevins

Is it for the Z with a ballscrew? If so then direct drive should be ok. Rack and pinion forget it. I already went through hat and had to buy planetary gears becasue my pinion was too big and I have 750 ac servo's with a load of no more than 25lbs.

Replied by bevins on topic New Build

I'm sorry. I've been a bit the same. I would not get a Gecko servo driver as Stefan had a lot of problems with one and gave up.

If you went with a stepper, I would recommend a Lam Technologies LS1073a driver I can source, and a

Sanyo Denki NEMA24 (60mm frame) motor which I have in stock. I bought about 20 of them so ignore the price shown on that page. For a power supply, I would suggest a 50V 3.2 amp toroid which I have a source for..

I've got a matched pair ESTUN EDC servo driver (step/dir) and a matching 400 W servo motor with a 60mm frame on hold for you with a trusted Aussie supplier. The power is a good match for a Z axis based on our stepper model. The advantage of using a servo is that it will run on mains power so you do not need to buy an additional power supply to drive a stepper. It will cost a bit more but be a cleaner setup with the existing yaskawas

A question for the others. This servo motor has max torque through to about 3600 rpm. I did not think it would need a gearbox reduction, so what do others think?

Is it for the Z with a ballscrew? If so then direct drive should be ok. Rack and pinion forget it. I already went through hat and had to buy planetary gears becasue my pinion was too big and I have 750 ac servo's with a load of no more than 25lbs.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11311

- Thank you received: 3792

12 Nov 2020 13:33 - 12 Nov 2020 13:33 #189106

by rodw

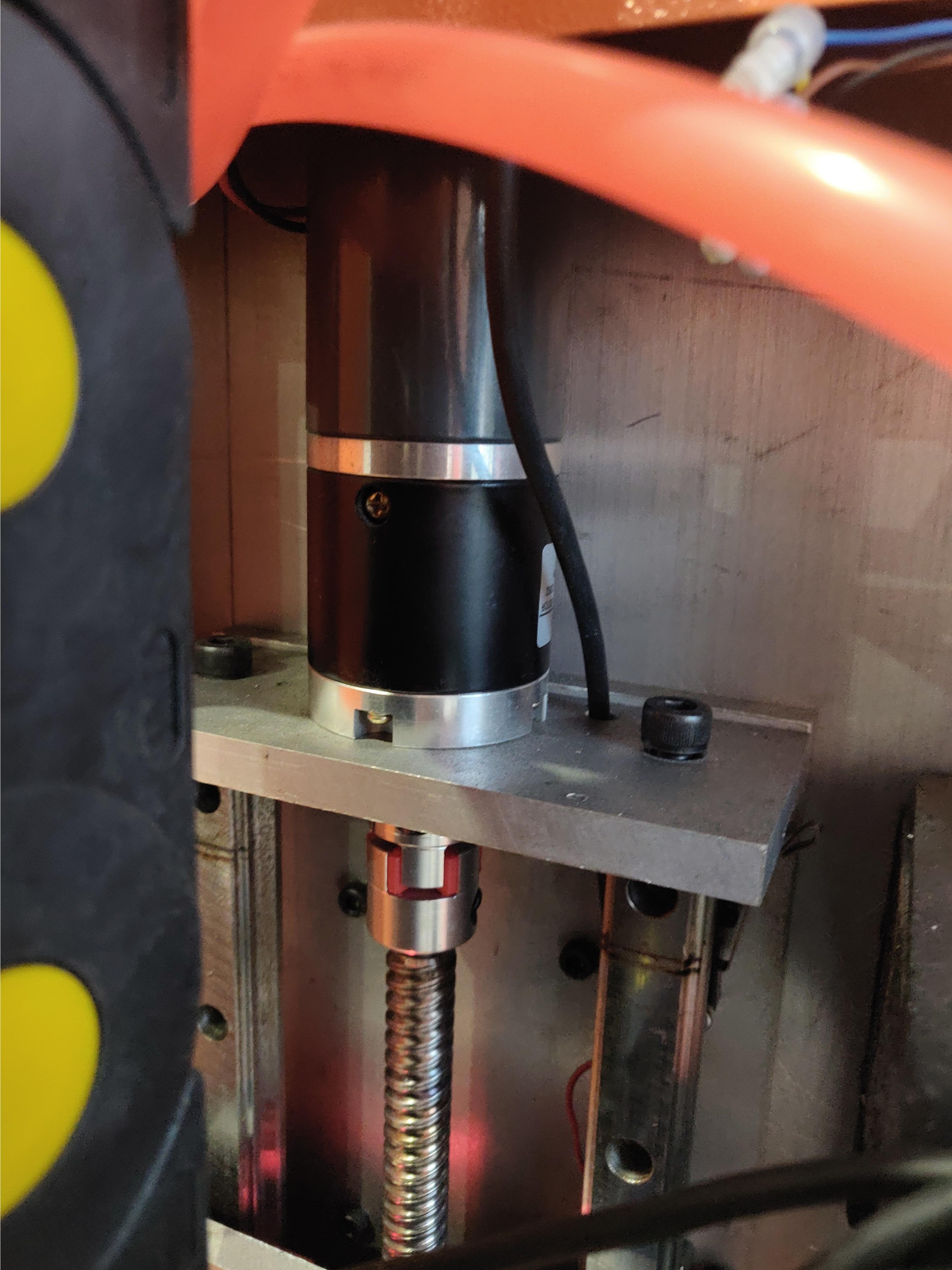

Yeh, Greg has a Ballscrew on the Z axis

I thought it would be OK direct drive but would have been reaching for a gearbox for a rack and pinion

Replied by rodw on topic New Build

Is it for the Z with a ballscrew? If so then direct drive should be ok. Rack and pinion forget it. I already went through hat and had to buy planetary gears becasue my pinion was too big and I have 750 ac servo's with a load of no more than 25lbs.

Yeh, Greg has a Ballscrew on the Z axis

I thought it would be OK direct drive but would have been reaching for a gearbox for a rack and pinion

Attachments:

Last edit: 12 Nov 2020 13:33 by rodw.

Please Log in or Create an account to join the conversation.

Time to create page: 0.088 seconds