- LinuxCNC

- General LinuxCNC Questions

- Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

21 Feb 2021 09:48 #199590

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

That's great.

I'll get right on it.

I'll get right on it.

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

21 Feb 2021 11:00 - 21 Feb 2021 11:02 #199593

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

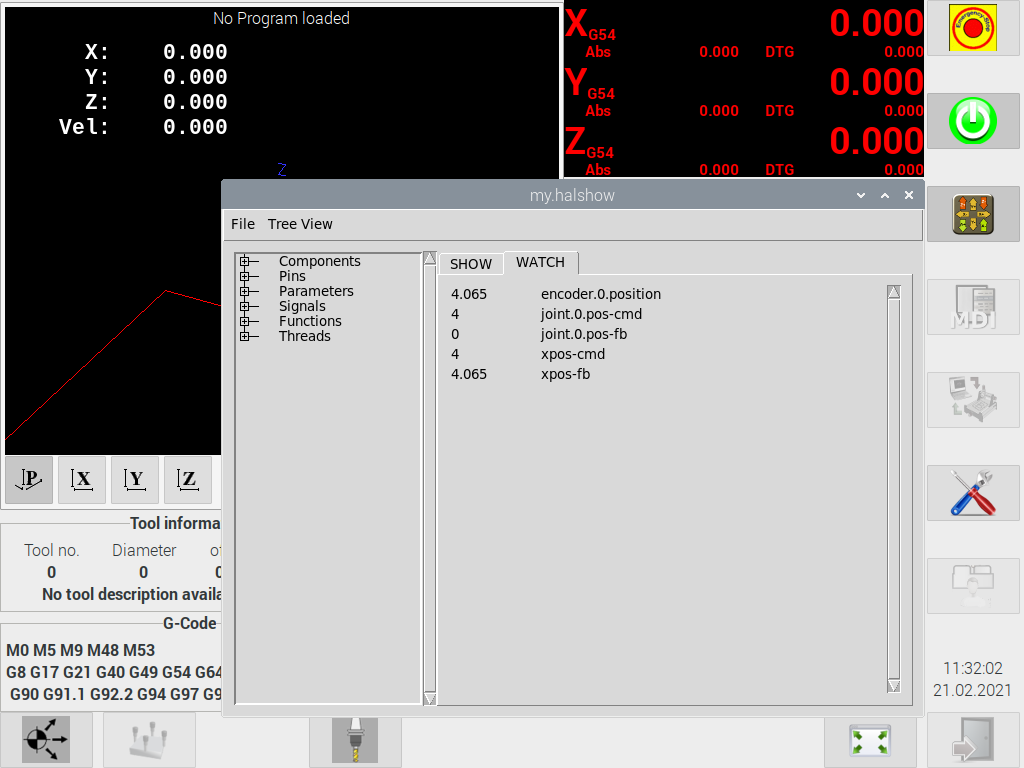

So… there were some re-declarations of things like debounce.0. but I sorted those out.

I attached an updated version of the HAL.

Went and tested but saw the same result.

But I noticed that you put in net xpos-fp => joint.0.motor-pos-fb # feedback to joint data e.g. xpos–fp. Was that on purpose or should it had been xpos-fb?

Just for kicks i changed it to xpos-fb with much greater success

It doesn’t seem to be correcting anything at this point but I’m assuming that comes down to tuning.

I attached an updated version of the HAL.

Went and tested but saw the same result.

But I noticed that you put in net xpos-fp => joint.0.motor-pos-fb # feedback to joint data e.g. xpos–fp. Was that on purpose or should it had been xpos-fb?

Just for kicks i changed it to xpos-fb with much greater success

It doesn’t seem to be correcting anything at this point but I’m assuming that comes down to tuning.

Attachments:

Last edit: 21 Feb 2021 11:02 by yagias.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

21 Feb 2021 11:58 #199595

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

But I noticed that you put in net xpos-fp => joint.0.motor-pos-fb # feedback to joint data e.g. xpos–fp. Was that on purpose or should it had been xpos-fb?

No that was a mistake. But i wonder. Your other data called

pos-cmd and so on. I thing that the Point. We have to clear this Syntax. It seems now your Feedback is working. Can you move your axis in jog? Where are your command data written?

No that was a mistake. But i wonder. Your other data called

pos-cmd and so on. I thing that the Point. We have to clear this Syntax. It seems now your Feedback is working. Can you move your axis in jog? Where are your command data written?

The following user(s) said Thank You: yagias

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

21 Feb 2021 12:00 #199596

by Hakan

Replied by Hakan on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

I see you have the position command directly to stepgen. To engage feedback the position command has to go via the pid component so it can adjust for the position deviation.

The following user(s) said Thank You: yagias

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

21 Feb 2021 12:20 #199597

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

@ Chris You’re back early

Regarding the syntax i’m pretty much up for anything you may recommend.

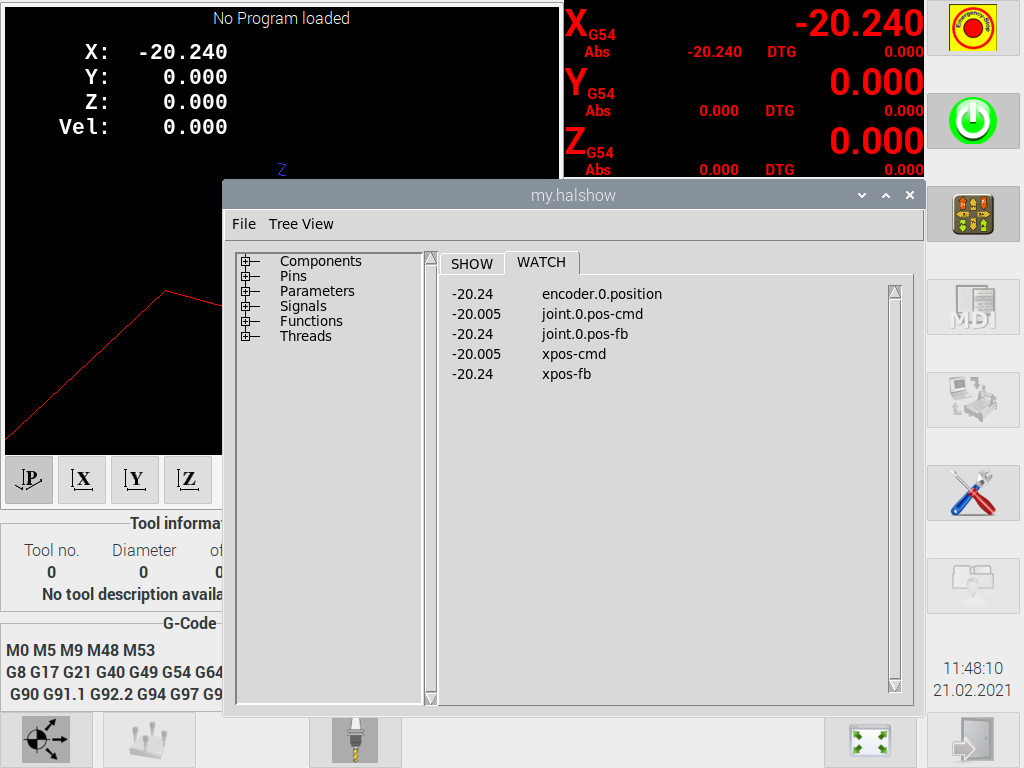

Yes. I’m able to move the axis and as long as my ferror is high enough i don’t get a joint following error.

(which is obvious even to me)

“Where are your command data written?” I’m sorry but i don’t understand the question?

(well having read Hakans post i think i do)

If i understand this right ??? commands are going to

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

@ Hakan

That would explain it and it makes sense.

BTW: I may not be right and have you mixed up with someone else but if i’m right i’m a fan of your videos.

Just want to take a second here to say thank you guys. This makes a world of difference to me.

Regarding the syntax i’m pretty much up for anything you may recommend.

Yes. I’m able to move the axis and as long as my ferror is high enough i don’t get a joint following error.

(which is obvious even to me)

“Where are your command data written?” I’m sorry but i don’t understand the question?

(well having read Hakans post i think i do)

If i understand this right ??? commands are going to

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

@ Hakan

That would explain it and it makes sense.

BTW: I may not be right and have you mixed up with someone else but if i’m right i’m a fan of your videos.

Just want to take a second here to say thank you guys. This makes a world of difference to me.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

21 Feb 2021 13:18 #199605

by Hakan

Replied by Hakan on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Yes I make some bad videos so that must be me

Here is my z-axis, it uses stepper motor and encoder for feedback. It uses hm2-components instead of the basic encoder and stepgen, but the principle is the same. Check how the pid component comes in, I think it can be the same obviously with the right naming.

Here is my z-axis, it uses stepper motor and encoder for feedback. It uses hm2-components instead of the basic encoder and stepgen, but the principle is the same. Check how the pid component comes in, I think it can be the same obviously with the right naming.

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror 0.0

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i76e.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i76e.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i76e.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i76e.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i76e.0.stepgen.02.step_type 0

setp hm2_7i76e.0.stepgen.02.control-type 1

setp hm2_7i76e.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# --- Z axis encoder feedback signals/setup

setp hm2_7i76e.0.encoder.02.counter-mode 0

setp hm2_7i76e.0.encoder.02.filter 1

setp hm2_7i76e.0.encoder.02.index-invert 0

setp hm2_7i76e.0.encoder.02.index-mask 0

setp hm2_7i76e.0.encoder.02.index-mask-invert 0

setp hm2_7i76e.0.encoder.02.scale 1000

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output <= hm2_7i76e.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i76e.0.encoder.02.position

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i76e.0.stepgen.02.enable

net z-vel-fb <= hm2_7i76e.0.encoder.02.velocity

net z-vel-fb => pid.z.feedback-deriv

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

21 Feb 2021 13:48 #199608

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

@ Hakan

Well… I’m a fan all the same. They feel like real life not the polished version.

Tried this out and that brings us/me back to the original problem.

I’m running position mode not velocity. And as stated in the first two replies and based on your configuration apparently i need to be in velocity mode. I have no objection to running velocity mode what so ever but i can’t figure out how to do that either.

I spent yesterday reading countless configurations and forum posts as well as the stepconf component description but none of it put me in a position to make the changes to the configuration. Well i made tons of changes but none of it worked. I’m clearly missing something here… Hence my cry for help yesterday.

Well… I’m a fan all the same. They feel like real life not the polished version.

Tried this out and that brings us/me back to the original problem.

I’m running position mode not velocity. And as stated in the first two replies and based on your configuration apparently i need to be in velocity mode. I have no objection to running velocity mode what so ever but i can’t figure out how to do that either.

I spent yesterday reading countless configurations and forum posts as well as the stepconf component description but none of it put me in a position to make the changes to the configuration. Well i made tons of changes but none of it worked. I’m clearly missing something here… Hence my cry for help yesterday.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4627

- Thank you received: 2047

21 Feb 2021 14:08 - 21 Feb 2021 14:13 #199610

by Aciera

Replied by Aciera on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

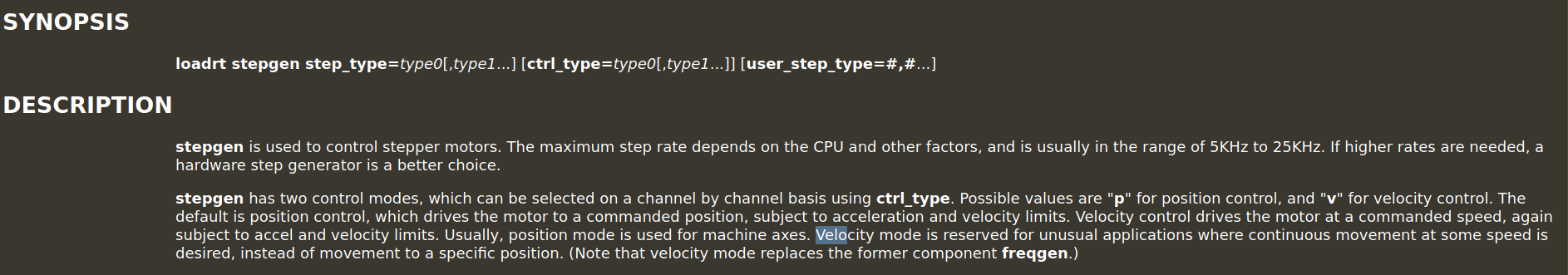

According to this:

it seems you would set the mode to velocity here:

Maybe try:

[edit]

For more information including some examples:

linuxcnc.org/docs/html/hal/rtcomps.html

it seems you would set the mode to velocity here:

loadrt stepgen step_type=0,0,0Maybe try:

loadrt stepgen step_type=0,0,0 ctrl_type=v,v,v[edit]

For more information including some examples:

linuxcnc.org/docs/html/hal/rtcomps.html

Attachments:

Last edit: 21 Feb 2021 14:13 by Aciera.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

21 Feb 2021 14:14 #199611

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

what do you want to do in velocity mode? Usually axes are in position mode and spindle in velocity mode.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

21 Feb 2021 14:20 #199614

by Hakan

Replied by Hakan on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

You can also work in position mode. I tried both and found the velocity mode worked better.

The other change needed is to set FF0=1 instead of FF1=1 for position mode if I remember right.

The other change needed is to set FF0=1 instead of FF1=1 for position mode if I remember right.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Time to create page: 0.118 seconds