- LinuxCNC

- General LinuxCNC Questions

- Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

21 Feb 2021 18:09 #199639

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Hi Mike

You´re very welcome.

Yes.. it´s one of those things. Started out fairly nice and became a mess along the way. Making a note to go and clean it up.

I have run the basic configuration without the scales which worked perfectly fine. But then again it was just about the most basic configuration you can get. Steppers in open loop.

I actually milled the bracket for the X axis in that configuration

I haven´t tried introducing the PID loop without the scales. It actually never even occurred to me that i could.

Trying to close the loop is the big pita for me at this point.

Up until now all work has been on the X axis only.

Thank you for your input on this. I think I need to go back and restart the reading. I think my basic problem is a lack of understanding of the architecture so i guess it´s time to do it again.

You´re very welcome.

Yes.. it´s one of those things. Started out fairly nice and became a mess along the way. Making a note to go and clean it up.

I have run the basic configuration without the scales which worked perfectly fine. But then again it was just about the most basic configuration you can get. Steppers in open loop.

I actually milled the bracket for the X axis in that configuration

I haven´t tried introducing the PID loop without the scales. It actually never even occurred to me that i could.

Trying to close the loop is the big pita for me at this point.

Up until now all work has been on the X axis only.

Thank you for your input on this. I think I need to go back and restart the reading. I think my basic problem is a lack of understanding of the architecture so i guess it´s time to do it again.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

21 Feb 2021 18:48 - 21 Feb 2021 21:37 #199641

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

hi,

now i am back home. I try to clean up little and hope it works.

We should get a runnig hal without encoder first. Second step connect encoder.

For test you try this hal. In your was something double.

Then comment all encoder lines + switch line 71 +72 back to open loop mode.

Check if your machine moving in correct way. If not adjust step scale best as possible.

For me its difficult to write this kind of hal. Because i use hostmot2 to and my config is different. I'm sure we can do it. corrections are welcome. I'm also just a beginner.

Finally we can do only step by step try and error.

now i am back home. I try to clean up little and hope it works.

We should get a runnig hal without encoder first. Second step connect encoder.

For test you try this hal. In your was something double.

Then comment all encoder lines + switch line 71 +72 back to open loop mode.

Check if your machine moving in correct way. If not adjust step scale best as possible.

For me its difficult to write this kind of hal. Because i use hostmot2 to and my config is different. I'm sure we can do it. corrections are welcome. I'm also just a beginner.

Finally we can do only step by step try and error.

Last edit: 21 Feb 2021 21:37 by chris@cnc.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

21 Feb 2021 18:50 #199642

by Mike_Eitel

Replied by Mike_Eitel on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

I would propose to make a sample-pncconf config with minimum axes. Learn in that how the pid is connected into the axis -> joint world. And don't forget the working glass encoders.

Then guys better than me on the closed loop question can easier help you.

m5c

Mike

Then guys better than me on the closed loop question can easier help you.

m5c

Mike

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

22 Feb 2021 06:12 - 22 Feb 2021 06:12 #199677

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

PNCConfig does not work without a mesa card and stepconf can only configure a spindle encoder.

Sorry, but I have another mistake in line 19:

loadrt stepgen step_type = 0,0,0 ctrl_type = v, v, v # +++++++++ new

ctrl_type = v, v, v must ctrl_type = v, p, p with encoder in x. Y and Z were not set yet. And the PID

net x-enable => pid.x.enable

net xpos-cmd => pid.x.command

net xvel-cmd => pid.x.command-deriv

net xpos-fb => pid.x.feedback

net x-output => pid.x.output

net xpos-cmd <= joint.0.motor-pos-cmd

net xvel-cmd <= joint.0.vel-cmd

net x-output <= stepgen.0.velocity-cmd

without encoder

net xpos-fb <= stepgen.0.position-fb

net xpos-fb => joint.0.motor-pos-fb

with encoder

net xpos-fb <= encoder.0.position

net xpos-fb => joint.0.motor-pos-fb

net x-vel-fb <= encoder.0.velocity

net x-vel-fb => pid.z.feedback-deriv

so xpos-fp and xpos-cmp are connected to PID. x-output => pid.x.output I don't quite understand yet, but it should be like this according to Hakan's example

Sorry, but I have another mistake in line 19:

loadrt stepgen step_type = 0,0,0 ctrl_type = v, v, v # +++++++++ new

ctrl_type = v, v, v must ctrl_type = v, p, p with encoder in x. Y and Z were not set yet. And the PID

net x-enable => pid.x.enable

net xpos-cmd => pid.x.command

net xvel-cmd => pid.x.command-deriv

net xpos-fb => pid.x.feedback

net x-output => pid.x.output

net xpos-cmd <= joint.0.motor-pos-cmd

net xvel-cmd <= joint.0.vel-cmd

net x-output <= stepgen.0.velocity-cmd

without encoder

net xpos-fb <= stepgen.0.position-fb

net xpos-fb => joint.0.motor-pos-fb

with encoder

net xpos-fb <= encoder.0.position

net xpos-fb => joint.0.motor-pos-fb

net x-vel-fb <= encoder.0.velocity

net x-vel-fb => pid.z.feedback-deriv

so xpos-fp and xpos-cmp are connected to PID. x-output => pid.x.output I don't quite understand yet, but it should be like this according to Hakan's example

Last edit: 22 Feb 2021 06:12 by chris@cnc.

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

22 Feb 2021 07:18 #199682

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

This looks great. Really looking forward to trying it out.

My vacation however is over so i'm at work now.

I'll give it a shot as soon as i get home and get back to you.

My vacation however is over so i'm at work now.

I'll give it a shot as soon as i get home and get back to you.

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

22 Feb 2021 17:43 - 22 Feb 2021 18:03 #199734

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

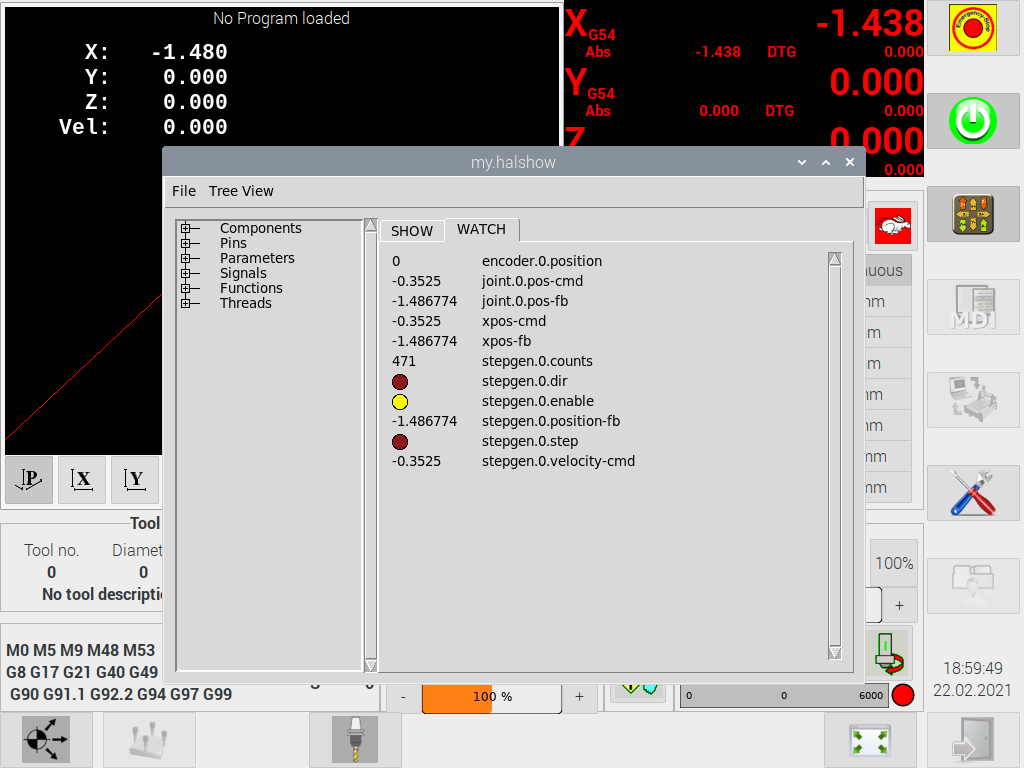

Just wanted to get the initial result back to you.

So…

Running the initial config from you but with an update line 19 yields.

loadrt stepgen step_type=0,0,0 ctrl_type=v,p,p

Fails to load and an error from line 70.

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

Then in order to try it out i updated line 70 to use:

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.velocity-cmd

Then it loads but when i order a move in X it just continues to move until i get a joint 0 error.

So…

Running the initial config from you but with an update line 19 yields.

loadrt stepgen step_type=0,0,0 ctrl_type=v,p,p

Fails to load and an error from line 70.

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.position-cmd

Then in order to try it out i updated line 70 to use:

net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.velocity-cmd

Then it loads but when i order a move in X it just continues to move until i get a joint 0 error.

Attachments:

Last edit: 22 Feb 2021 18:03 by yagias.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

22 Feb 2021 18:22 #199745

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

yes, there is the missing point with pid

line 70 new two lines

x-output <= stepgen.0.velocity-cmd # velocity to PID

xpos-cmd <= joint.0.motor-pos-cmd # new calculatet back to xpos-cmd

xvel-cmd <= joint.0.vel-cmd #is missing to

to compare. finaly is this our target. we have to rename all hm2_7i76e.0 and z- words.

line 70 new two lines

x-output <= stepgen.0.velocity-cmd # velocity to PID

xpos-cmd <= joint.0.motor-pos-cmd # new calculatet back to xpos-cmd

xvel-cmd <= joint.0.vel-cmd #is missing to

to compare. finaly is this our target. we have to rename all hm2_7i76e.0 and z- words.

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

setp pid.z.maxerror 0.0

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i76e.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i76e.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i76e.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i76e.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i76e.0.stepgen.02.step_type 0

setp hm2_7i76e.0.stepgen.02.control-type 1

setp hm2_7i76e.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# --- Z axis encoder feedback signals/setup

setp hm2_7i76e.0.encoder.02.counter-mode 0

setp hm2_7i76e.0.encoder.02.filter 1

setp hm2_7i76e.0.encoder.02.index-invert 0

setp hm2_7i76e.0.encoder.02.index-mask 0

setp hm2_7i76e.0.encoder.02.index-mask-invert 0

setp hm2_7i76e.0.encoder.02.scale 1000

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output <= hm2_7i76e.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i76e.0.encoder.02.position

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i76e.0.stepgen.02.enable

net z-vel-fb <= hm2_7i76e.0.encoder.02.velocity

net z-vel-fb => pid.z.feedback-deriv

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

22 Feb 2021 18:37 #199749

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Trying it out.

Sorry about the delay. Was buried in a manual

Sorry about the delay. Was buried in a manual

Please Log in or Create an account to join the conversation.

- yagias

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

22 Feb 2021 18:57 - 22 Feb 2021 19:10 #199753

by yagias

Replied by yagias on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

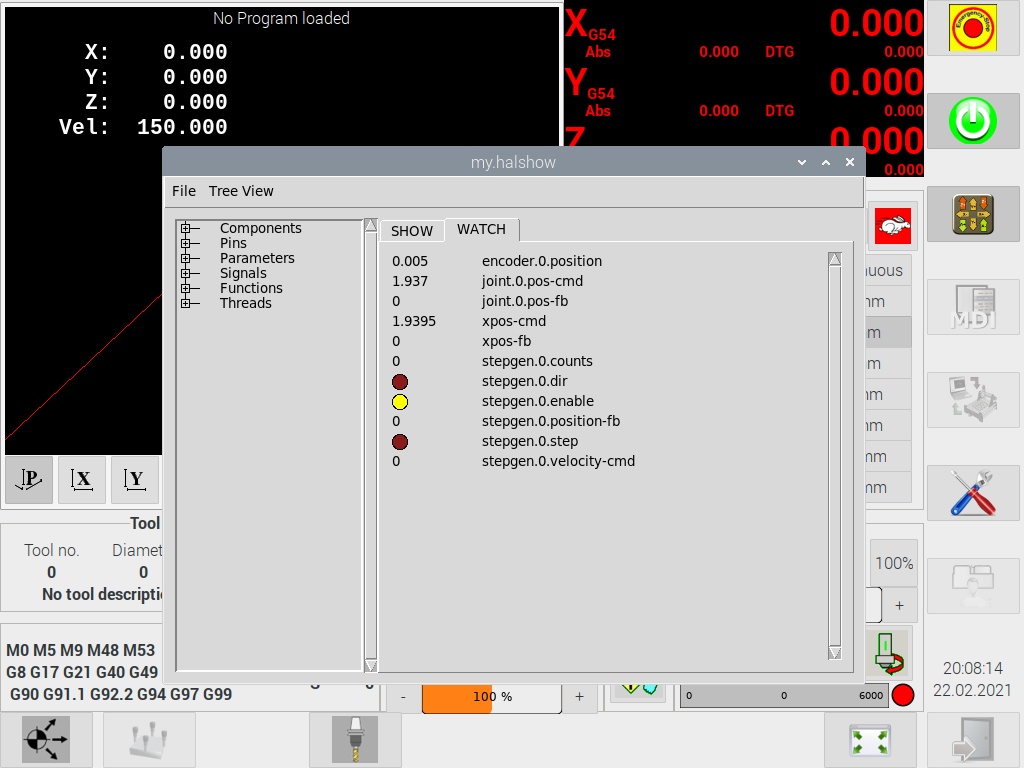

ok. currently i added the three lines starting from line 70:

And it now looks like this.

Result:

Now nothing moves

Haven't begun aligning to hakans example yet.

# JOINT_0

setp stepgen.0.position-scale [JOINT_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 15200 #If motor not turn increase time

setp stepgen.0.dirsetup 15200

setp stepgen.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

#net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.velocity-cmd

net x-output <= stepgen.0.velocity-cmd # velocity to PID

net xpos-cmd <= joint.0.motor-pos-cmd # new calculatet back to xpos-cmd

net xvel-cmd <= joint.0.vel-cmd

net xpos-fb <= stepgen.0.position-fb #Without encoder feedback from stepgen

net xpos-fb => joint.0.motor-pos-fb #Without encoder feedback to joint data

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable joint.0.amp-enable-out => stepgen.0.enable

# Encoder Stuff.

#

net xa encoder.0.phase-A <= hal_pi_gpio.pin-11-in

net xb encoder.0.phase-B <= hal_pi_gpio.pin-12-in

net xvel-cmd <= joint.0.vel-cmd

net xvel-fb <= encoder.0.velocity

net xvel-fb => pid.x.feedback-deriv # not sure what is it

#net xpos-fb <= encoder.0.position # Encoderdata feedback

net xpos-fb => joint.0.motor-pos-fb # feedback to joint data

addf encoder.update-counters base-thread

addf encoder.capture-position servo-thread

setp encoder.0.position-scale 200

net rawPhaseA hal_pi_gpio.pin-16-in debounce.0.0.in # check wiring

net rawPhaseB hal_pi_gpio.pin-18-in debounce.0.1.in #

And it now looks like this.

Result:

Now nothing moves

Haven't begun aligning to hakans example yet.

# JOINT_0

setp stepgen.0.position-scale [JOINT_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 15200 #If motor not turn increase time

setp stepgen.0.dirsetup 15200

setp stepgen.0.maxaccel [JOINT_0]STEPGEN_MAXACCEL

#net xpos-cmd joint.0.motor-pos-cmd => stepgen.0.velocity-cmd

net x-output <= stepgen.0.velocity-cmd # velocity to PID

net xpos-cmd <= joint.0.motor-pos-cmd # new calculatet back to xpos-cmd

net xvel-cmd <= joint.0.vel-cmd

net xpos-fb <= stepgen.0.position-fb #Without encoder feedback from stepgen

net xpos-fb => joint.0.motor-pos-fb #Without encoder feedback to joint data

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable joint.0.amp-enable-out => stepgen.0.enable

# Encoder Stuff.

#

net xa encoder.0.phase-A <= hal_pi_gpio.pin-11-in

net xb encoder.0.phase-B <= hal_pi_gpio.pin-12-in

net xvel-cmd <= joint.0.vel-cmd

net xvel-fb <= encoder.0.velocity

net xvel-fb => pid.x.feedback-deriv # not sure what is it

#net xpos-fb <= encoder.0.position # Encoderdata feedback

net xpos-fb => joint.0.motor-pos-fb # feedback to joint data

addf encoder.update-counters base-thread

addf encoder.capture-position servo-thread

setp encoder.0.position-scale 200

net rawPhaseA hal_pi_gpio.pin-16-in debounce.0.0.in # check wiring

net rawPhaseB hal_pi_gpio.pin-18-in debounce.0.1.in #

Attachments:

Last edit: 22 Feb 2021 19:10 by yagias.

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

22 Feb 2021 19:24 - 22 Feb 2021 19:50 #199755

by chris@cnc

Replied by chris@cnc on topic Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

well done.

this line is double

net xpos-fb => joint.0.motor-pos-fb # feedback to joint data

if you switch to open loop you schould comment this line to

Next step check in open loop your movement. Maybe we can trust the encoder data and travel 200mm end of your table.

Compare encoder position with stepgen.0.position-fb postion.

Adjust SCALE = -320 in ini File to min difference.

last step switch encoder on and cross finger

this line is double

net xpos-fb => joint.0.motor-pos-fb # feedback to joint data

if you switch to open loop you schould comment this line to

Next step check in open loop your movement. Maybe we can trust the encoder data and travel 200mm end of your table.

Compare encoder position with stepgen.0.position-fb postion.

Adjust SCALE = -320 in ini File to min difference.

last step switch encoder on and cross finger

Last edit: 22 Feb 2021 19:50 by chris@cnc.

The following user(s) said Thank You: yagias

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Need a bit of help with a Raspberry PI 4 GPIO Glass scales control loop

Time to create page: 0.125 seconds