Converting an old DMU 50, where to start?

- einarak

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 3

26 Nov 2021 09:55 #227634

by einarak

Converting an old DMU 50, where to start? was created by einarak

I am totally lost! I acquired an old DMU 50 mill, servo driven with Simodrive 611 servo drivers.

What hardware do I need to convert it to LinuxCNC? I have been looking at the mesa stuff, and it looks good and at a really good price, but I have no idea what I need. This has probably been discussed a million times before, but I just cant get my head around it...

The mill now has 3 controlled axis, and 2 manually controlled axis. I would want to have the ability to later add a stepper to at least on of the manual axisis and a rotary chuck for A-axis.

I did build my own diy cnc mill some 10-15 years ago, and have all kinds of electrical and programming knowledge.

So, can someone lay out a setup diagram for the mesa hardware I need... I know it starts with the PC --- and ends with the Simodrive 611 drivers. But all the options on how to make the PC communicate with the 611´s is a total jungle to me...

From my experience when I built the diy cnc, it was like PC--->Breakout board (serial connected)---> stepper drivers ----> stepper motors.

But It seems that the servo controling is a bit more complicated. So I am reaching out to you, fellow CNC enthusiastics for som tips and tricks

What hardware do I need to convert it to LinuxCNC? I have been looking at the mesa stuff, and it looks good and at a really good price, but I have no idea what I need. This has probably been discussed a million times before, but I just cant get my head around it...

The mill now has 3 controlled axis, and 2 manually controlled axis. I would want to have the ability to later add a stepper to at least on of the manual axisis and a rotary chuck for A-axis.

I did build my own diy cnc mill some 10-15 years ago, and have all kinds of electrical and programming knowledge.

So, can someone lay out a setup diagram for the mesa hardware I need... I know it starts with the PC --- and ends with the Simodrive 611 drivers. But all the options on how to make the PC communicate with the 611´s is a total jungle to me...

From my experience when I built the diy cnc, it was like PC--->Breakout board (serial connected)---> stepper drivers ----> stepper motors.

But It seems that the servo controling is a bit more complicated. So I am reaching out to you, fellow CNC enthusiastics for som tips and tricks

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 974

- Thank you received: 267

26 Nov 2021 15:06 #227657

by ihavenofish

Replied by ihavenofish on topic Converting an old DMU 50, where to start?

siemens 611 uses profibus most likely. it is not compatible with linuxcnc. you will need to replace the drives, and probably the motors as well.

take a picture of the label and connections on the drive, and also the motors.

take a picture of the label and connections on the drive, and also the motors.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

26 Nov 2021 18:40 #227669

by Michael

Replied by Michael on topic Converting an old DMU 50, where to start?

Servo drives don't have to be more complicated then a stepper system and often many servo systems can take the same step/dir signals that a stepper system would take. That being said you may run into proprietary equipment when doing a retrofit that requires you to replace almost all of the components.

What year is the mill? What is wrong with the original control? Before you start making purchases you should get a really good grasp of what all the machine can do and how you want to control it. This can help to make decisions for purchases.

Send some pictures of the mill and the various drives and other components that it has.

What year is the mill? What is wrong with the original control? Before you start making purchases you should get a really good grasp of what all the machine can do and how you want to control it. This can help to make decisions for purchases.

Send some pictures of the mill and the various drives and other components that it has.

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 974

- Thank you received: 267

26 Nov 2021 19:10 #227673

by ihavenofish

Replied by ihavenofish on topic Converting an old DMU 50, where to start?

siemens is proprietary profibus unfortunately. also very integrated, meaning the spindle drive will also not work as its part of the same system.

assuming nothing is broken, you'd do well selling off the old motor and drive kit and buying new ones. possibly breaking even as the old kit can be worth thousands.

the motors are big though, 2kw-3kw range, and the spindle will be 8-10kw. so not simplistic to replace.

assuming nothing is broken, you'd do well selling off the old motor and drive kit and buying new ones. possibly breaking even as the old kit can be worth thousands.

the motors are big though, 2kw-3kw range, and the spindle will be 8-10kw. so not simplistic to replace.

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

26 Nov 2021 19:52 #227678

by db1981

Replied by db1981 on topic Converting an old DMU 50, where to start?

Hello,

if this dmu has not an Sinumeric Control, there is an chance that this simodrives are with an analog io board. (Heidenhain or DMG manual mill control)

can you post a picure of the drive system, and the type plates.

if they have Profibus interface, the only option to keep them would be to interface them by ethercat with an profibus master card. But this needs electronics and plc experience or the will to learn this stuff.....

if this dmu has not an Sinumeric Control, there is an chance that this simodrives are with an analog io board. (Heidenhain or DMG manual mill control)

can you post a picure of the drive system, and the type plates.

if they have Profibus interface, the only option to keep them would be to interface them by ethercat with an profibus master card. But this needs electronics and plc experience or the will to learn this stuff.....

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 974

- Thank you received: 267

26 Nov 2021 20:05 #227680

by ihavenofish

Replied by ihavenofish on topic Converting an old DMU 50, where to start?

very early dmu 50 m might have the heidenhain control, true.

the other models used 810d or 840d.

buy yeah, were just guessing til we see pics.

the other models used 810d or 840d.

buy yeah, were just guessing til we see pics.

Please Log in or Create an account to join the conversation.

- einarak

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 3

28 Nov 2021 01:46 #227794

by einarak

Replied by einarak on topic Converting an old DMU 50, where to start?

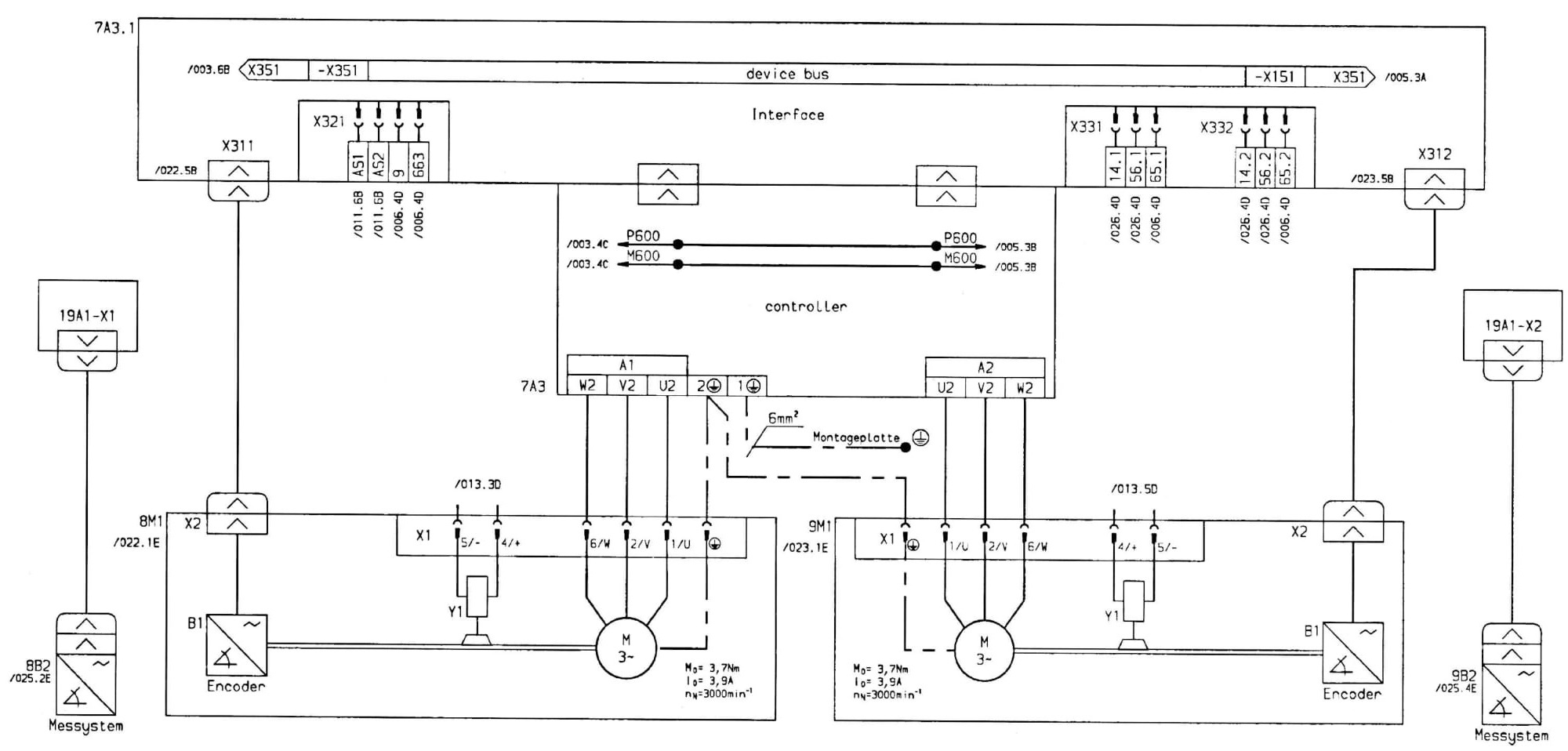

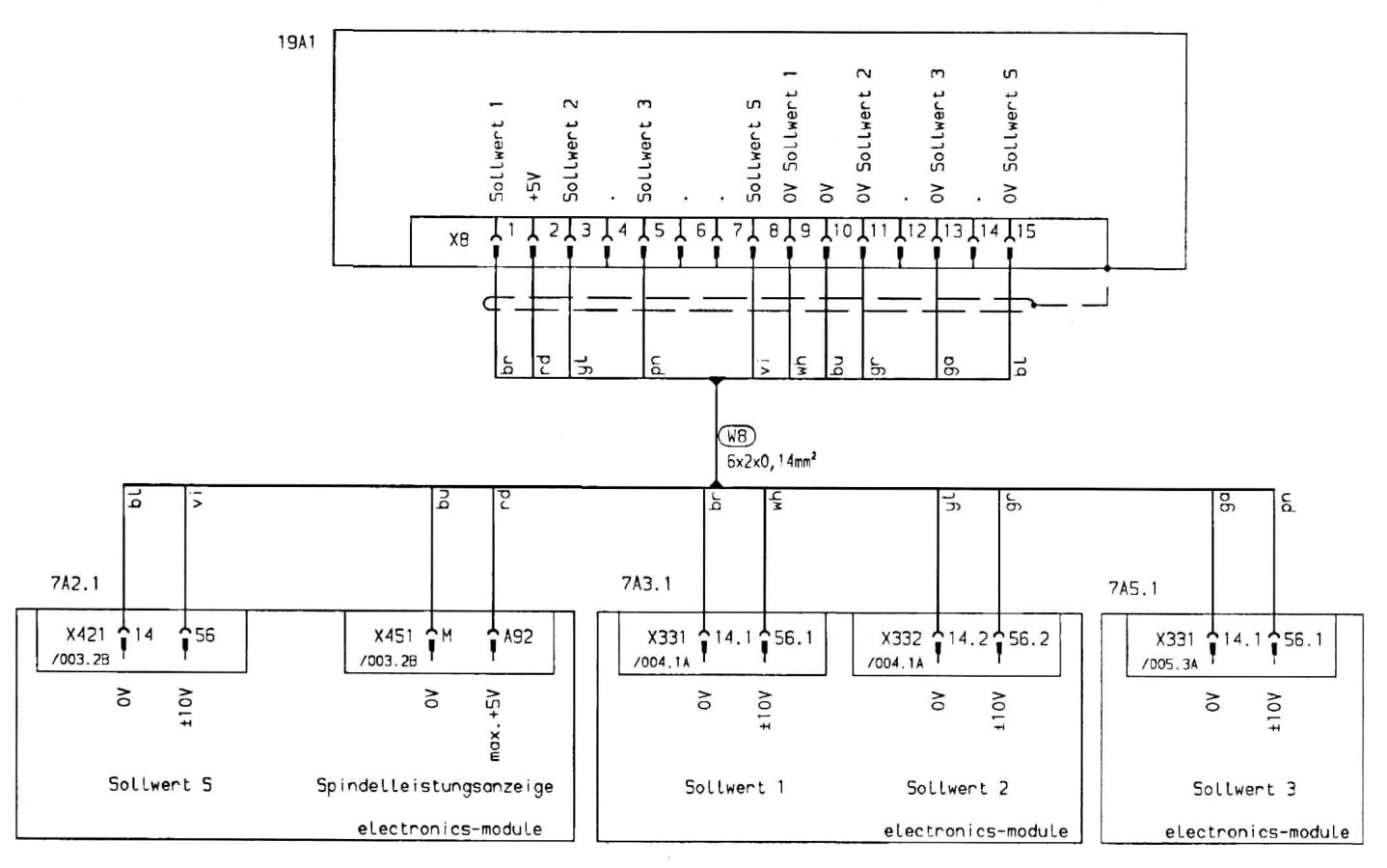

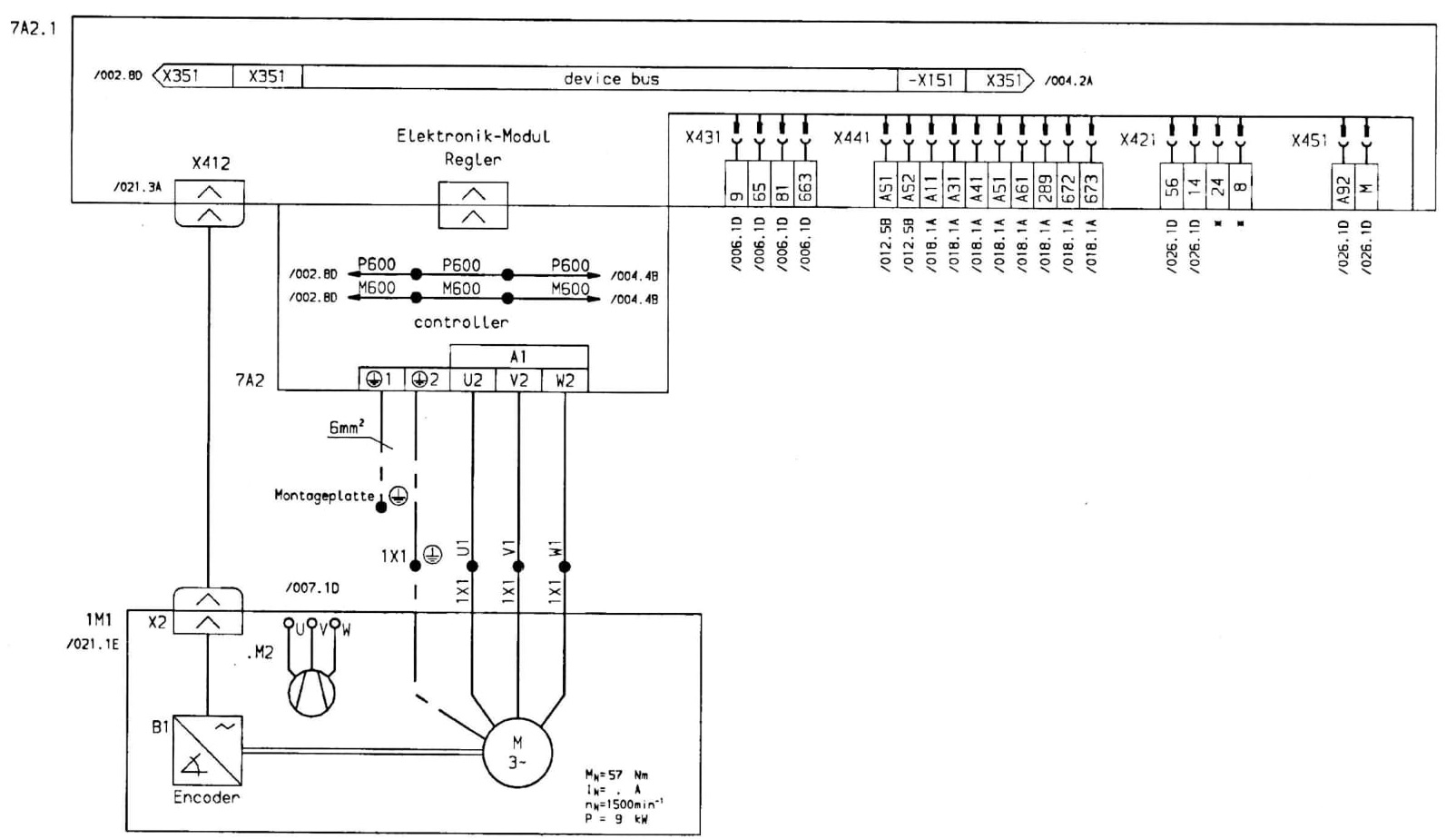

Thanks for the replies guys, If I remember correctly it is a 1998 model, and has a Heidenhain TNC 124 Controller. I think I managed to figure out in the electrical scematics it had a +-10v control, but I might be wrong... Will post pics to morrow. My final goal is to be able to add the rotary A-axis and be able to upload g-codes made in inventor-cam or mastercam

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 974

- Thank you received: 267

28 Nov 2021 05:37 #227799

by ihavenofish

Replied by ihavenofish on topic Converting an old DMU 50, where to start?

so dmu 50m. if the drives are analogue velocity mode, thats a good start, however the 1ft5 motors may not have encoders, they may rely on glass scales. by 1998 though i think they were standardised in a format linuxcnc might be able to use. it might also be after the transition where they used glass scales on eveyrthing - the dmu50 m was a "low cost" machine for them. good news though is you should be able to find documentations on all siemens parts.

on converting the table, NC was an option, but i dont know if it was just motors added to the same table. the table might also need a brake or have too much backlash to run as a true interpolated cnc axes.

on converting the table, NC was an option, but i dont know if it was just motors added to the same table. the table might also need a brake or have too much backlash to run as a true interpolated cnc axes.

Please Log in or Create an account to join the conversation.

- einarak

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 3

28 Nov 2021 10:34 #227808

by einarak

Replied by einarak on topic Converting an old DMU 50, where to start?

Attachments:

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 974

- Thank you received: 267

28 Nov 2021 16:29 #227818

by ihavenofish

Replied by ihavenofish on topic Converting an old DMU 50, where to start?

so they are profibus, but they have configurable analogue IO as well (looking at the drive manual) which it seems your machine is using. will be 1ft5 or 1ft6 or 1fk6 motors - likely 1fk6 as this was a lower cost machine. drawings suggest the encoders are on the motor. siemens has full manuals for everything and you can actually buy new drives still.

they are also - of course - very high performance compared to many new drives you can buy even today.

I think ill be looking for a dmu 50 M now... haha.

they are also - of course - very high performance compared to many new drives you can buy even today.

I think ill be looking for a dmu 50 M now... haha.

Please Log in or Create an account to join the conversation.

Time to create page: 0.179 seconds