- LinuxCNC

- General LinuxCNC Questions

- Stepper controlled servos doesnt move with Encoder feedback configured

Stepper controlled servos doesnt move with Encoder feedback configured

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

08 Jun 2022 19:02 #244774

by Faggan

Stepper controlled servos doesnt move with Encoder feedback configured was created by Faggan

Hi,

I'm stuck on configuring LinuxCNC for my new machine. I'm sure there are people here that have the experience with LinuxCNC to help me.

The Machine:

Controller hardware: MESA 7i76 + 7i89 from a 6i25

Movement hardware: ProNet servos and drivers

Control mode: Step/direction + Encoder feedback from the servos

Hal and Ini files attached.

Some background:

I have been trying to figure out the correct settings for the Hal and Ini file in relation to Step/direction control with encoder feedback for a while. To make things easier I decided to test them individually. I made a dummy Pncconfig with just step/direction control (no encoder feedback) to iron out some of the issues I had with scaling between LinuxCNC and the drivers. With that out of the way I added the encoders into the Pncconfig to test them out as well. They scale correctly and the numbers move in the desired direction when I move the machine manually.

In short. The wiring and scaling works. (i think, i will get back to scaling further down)

The issue:

When I first started LinuxCNC i had errors in relation to the hal file that Pncconfig created. This error was the same for all axis. The error seems to be related to these lines and that there are two connections to the same function:

net x-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-pos-fb <= hm2_5i25.0.encoder.01.position

net x-pos-fb => joint.0.motor-pos-fb

My assumption at the time was that because Pncconfig made too many connections to net x-pos-fb. Using all my available guessing power I commented out the top two (as you can see in the attached Hal file) and that got me past the errors and LinuxCNC started.

However. I now can not move the axis. When I try to move them they start to oscillate. Something I guess is related to the PID tuning, Or lack there of. Instead what happens is that I get a FERROR. Not surprising considering the axis doesn't move.

Raising the FERROR parameter in the hopes that i have some delay in the system that is causing this but the only change is that the error takes a little longer to show. Also not surprising.

To me it seems that the system has control over the servos since they oscillate when idle. My commands does however not cause any notable change in the position of the axis. Maybe a small one, but its hard to tell with the oscillation going on.

Maybe something:

I have seen somewhere that the scaling for steps and encoders need to be the same. I do not grasp the concept fully though, is that in relation to machine units? IE the scaling need to both come down to 1mm of movement? Or is it pulse for pulse? I don't know if this is related at all.

I am at a loss here. Can anyone help?

If you need more files or logs from the system to get a better picture of the issue just ask.

I'm stuck on configuring LinuxCNC for my new machine. I'm sure there are people here that have the experience with LinuxCNC to help me.

The Machine:

Controller hardware: MESA 7i76 + 7i89 from a 6i25

Movement hardware: ProNet servos and drivers

Control mode: Step/direction + Encoder feedback from the servos

Hal and Ini files attached.

Some background:

I have been trying to figure out the correct settings for the Hal and Ini file in relation to Step/direction control with encoder feedback for a while. To make things easier I decided to test them individually. I made a dummy Pncconfig with just step/direction control (no encoder feedback) to iron out some of the issues I had with scaling between LinuxCNC and the drivers. With that out of the way I added the encoders into the Pncconfig to test them out as well. They scale correctly and the numbers move in the desired direction when I move the machine manually.

In short. The wiring and scaling works. (i think, i will get back to scaling further down)

The issue:

When I first started LinuxCNC i had errors in relation to the hal file that Pncconfig created. This error was the same for all axis. The error seems to be related to these lines and that there are two connections to the same function:

net x-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-pos-fb <= hm2_5i25.0.encoder.01.position

net x-pos-fb => joint.0.motor-pos-fb

My assumption at the time was that because Pncconfig made too many connections to net x-pos-fb. Using all my available guessing power I commented out the top two (as you can see in the attached Hal file) and that got me past the errors and LinuxCNC started.

However. I now can not move the axis. When I try to move them they start to oscillate. Something I guess is related to the PID tuning, Or lack there of. Instead what happens is that I get a FERROR. Not surprising considering the axis doesn't move.

Raising the FERROR parameter in the hopes that i have some delay in the system that is causing this but the only change is that the error takes a little longer to show. Also not surprising.

To me it seems that the system has control over the servos since they oscillate when idle. My commands does however not cause any notable change in the position of the axis. Maybe a small one, but its hard to tell with the oscillation going on.

Maybe something:

I have seen somewhere that the scaling for steps and encoders need to be the same. I do not grasp the concept fully though, is that in relation to machine units? IE the scaling need to both come down to 1mm of movement? Or is it pulse for pulse? I don't know if this is related at all.

I am at a loss here. Can anyone help?

If you need more files or logs from the system to get a better picture of the issue just ask.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

08 Jun 2022 20:06 - 08 Jun 2022 20:11 #244777

by PCW

Replied by PCW on topic Stepper controlled servos doesnt move with Encoder feedback configured

Yes, the PID tuning will be very different with encoder feedback because of the delays

between command and feedback in the drive/motor/mechanics.

This will require lowering the P term by a large factor.

The step/dir and encoder scale must be set so the encoder

position and stepgen position scale are correct (in machine units)

There need be no correspondence between step counts and encoder

counts other that they are scale properly in machine units (and in the same direction)

between command and feedback in the drive/motor/mechanics.

This will require lowering the P term by a large factor.

The step/dir and encoder scale must be set so the encoder

position and stepgen position scale are correct (in machine units)

There need be no correspondence between step counts and encoder

counts other that they are scale properly in machine units (and in the same direction)

Last edit: 08 Jun 2022 20:11 by PCW.

The following user(s) said Thank You: Faggan

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

08 Jun 2022 21:02 #244781

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

When I have been testing the PID tuning I have been at around 60 in P value and even then without major instability. The frequency of the oscillation goes up with P but the axis is still stable. Would that be unreasonable with this in mind?

Ok, so no problem there then!

That doesn't solve my issue moving the axis though. Have I made an error in connecting the pins in Hal in some way then maybe?

Ok, so no problem there then!

That doesn't solve my issue moving the axis though. Have I made an error in connecting the pins in Hal in some way then maybe?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

08 Jun 2022 23:22 - 08 Jun 2022 23:22 #244788

by PCW

Replied by PCW on topic Stepper controlled servos doesnt move with Encoder feedback configured

It most likely does not move (much) because you have no FF1 and MaxError is quite small

FF1 must be 1.000 on all joints

Lack of FF1 and MaxError = 0.0127mm means very little response

I would probably set MaxError to 0

(beware of runaways if you have step/encoder directions mis-matched)

FF1 must be 1.000 on all joints

Lack of FF1 and MaxError = 0.0127mm means very little response

I would probably set MaxError to 0

(beware of runaways if you have step/encoder directions mis-matched)

Last edit: 08 Jun 2022 23:22 by PCW.

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

09 Jun 2022 20:31 #244818

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

FF1 at 1.000 works a lot better. Thank you!

MaxError? Is that the FERROR parameter?

MaxError? Is that the FERROR parameter?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

09 Jun 2022 21:17 #244820

by PCW

Replied by PCW on topic Stepper controlled servos doesnt move with Encoder feedback configured

Its settings like these in the hal file:

setp pid.x.maxerror 0.012700

I would set this to 0 (no bound) with encoder feedback

setp pid.x.maxerror 0.012700

I would set this to 0 (no bound) with encoder feedback

The following user(s) said Thank You: Faggan

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Jun 2022 22:21 #244823

by BigJohnT

Replied by BigJohnT on topic Stepper controlled servos doesnt move with Encoder feedback configured

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

14 Jun 2022 11:25 #245108

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

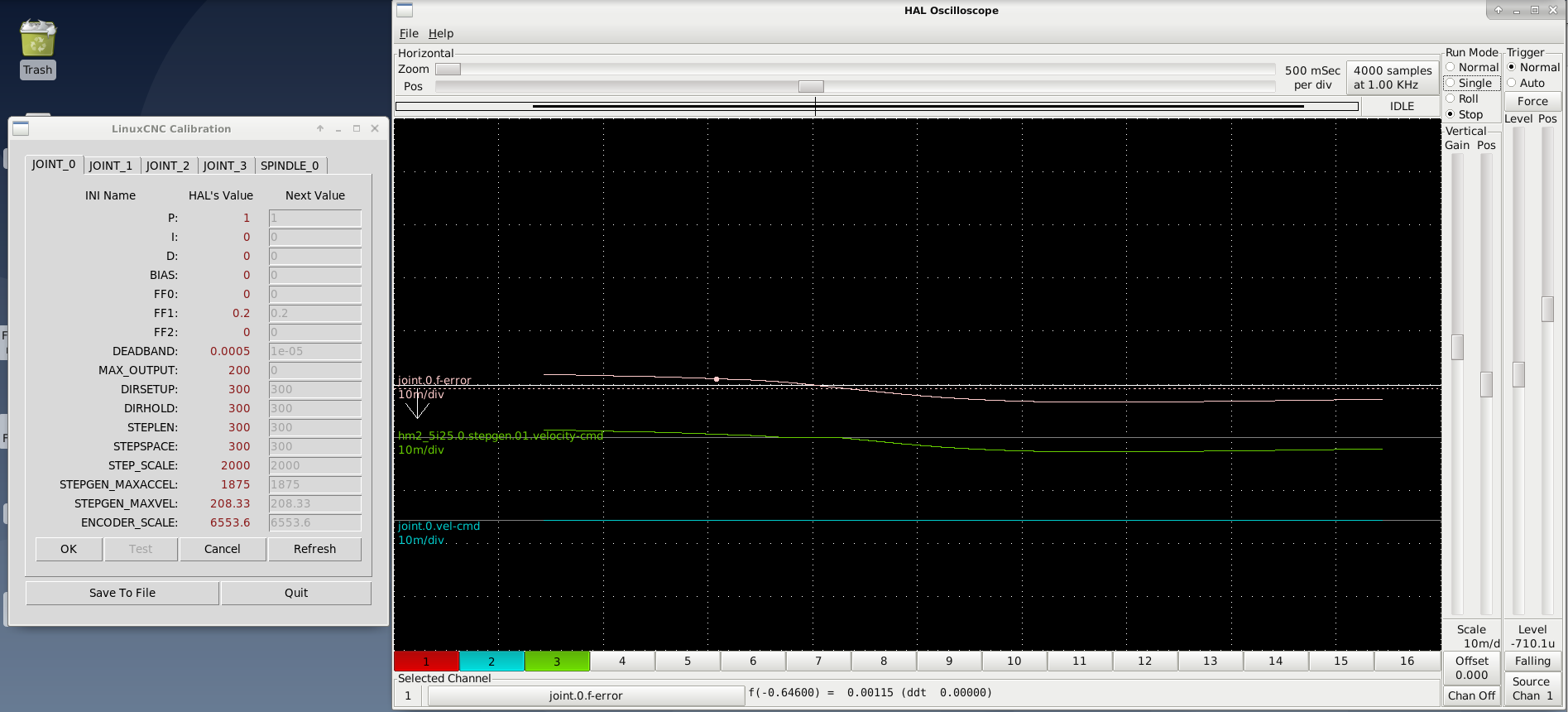

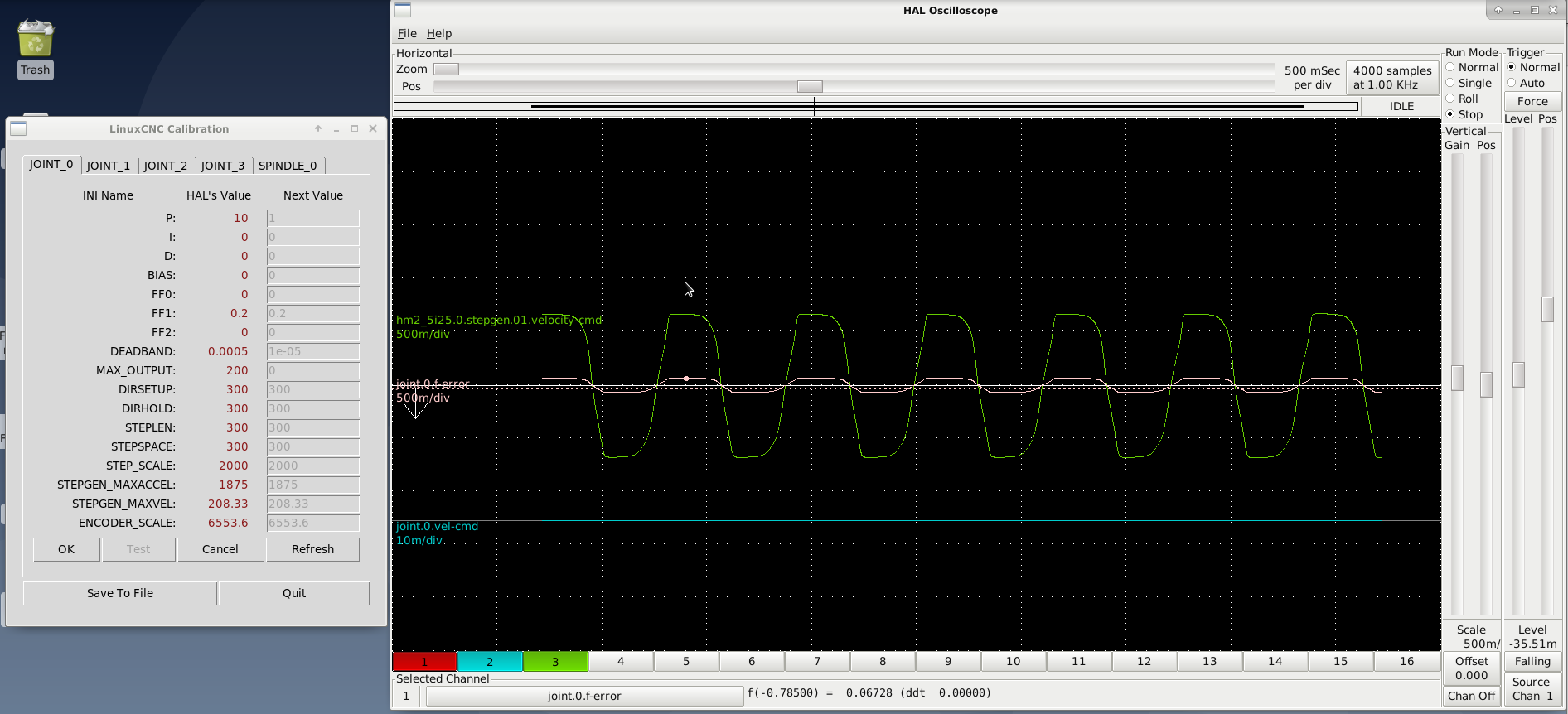

Changing the parameters you mentioned PCW worked. Thank you.

I now find myself with other issues related to PID tuning (I think)

All guides I have seen (if I understood them correctly) tells you to start to increase P until there is vibration on the axis and then back off.

My issue is that from extremely low P values I have oscillation on the axis after a short move. During a move the oscillation is very small.

I don't know how to get around this. If I try to use D gain to get rid of the "idle" oscillation I need to put so much D value on there that the axis now stutters when I do a commanded move.

Increasing P gain only results in a higher frequency oscillation with higher amplitude. At P1 the amplitude is about 0,003mm. At P10 its around 0,06mm.

Is there any way of dampening the "idle" oscillation?

I now find myself with other issues related to PID tuning (I think)

All guides I have seen (if I understood them correctly) tells you to start to increase P until there is vibration on the axis and then back off.

My issue is that from extremely low P values I have oscillation on the axis after a short move. During a move the oscillation is very small.

I don't know how to get around this. If I try to use D gain to get rid of the "idle" oscillation I need to put so much D value on there that the axis now stutters when I do a commanded move.

Increasing P gain only results in a higher frequency oscillation with higher amplitude. At P1 the amplitude is about 0,003mm. At P10 its around 0,06mm.

Is there any way of dampening the "idle" oscillation?

Attachments:

Please Log in or Create an account to join the conversation.

- strahlensauger

-

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 66

14 Jun 2022 13:43 - 14 Jun 2022 13:55 #245119

by strahlensauger

Replied by strahlensauger on topic Stepper controlled servos doesnt move with Encoder feedback configured

I just added scales to my machine, so I know this can be frustrating, and there can be errors in the mechanical, in the electronics and in the hal and INI files...

Last edit: 14 Jun 2022 13:55 by strahlensauger.

Please Log in or Create an account to join the conversation.

- strahlensauger

-

- Offline

- Elite Member

-

Less

More

- Posts: 195

- Thank you received: 66

14 Jun 2022 13:51 - 14 Jun 2022 13:59 #245122

by strahlensauger

Replied by strahlensauger on topic Stepper controlled servos doesnt move with Encoder feedback configured

I use 5 um scales, the encoder scale is 200.

your encoder scale looks pretty high, maybe that is the reason your axis don't move.

200 means 200 scratches on the glass on 1 mm.

your encoder scale looks pretty high, maybe that is the reason your axis don't move.

200 means 200 scratches on the glass on 1 mm.

Last edit: 14 Jun 2022 13:59 by strahlensauger.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Stepper controlled servos doesnt move with Encoder feedback configured

Time to create page: 0.118 seconds