- LinuxCNC

- General LinuxCNC Questions

- Stepper controlled servos doesnt move with Encoder feedback configured

Stepper controlled servos doesnt move with Encoder feedback configured

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

14 Jun 2022 14:02 #245123

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

The encoders are 1048576 pulses per revolution default. (0.0003 degree resolution)

I have scaled them down to 65536 pulses per revolution. That gives me 0,000153mm resolution with 10mm per rev ball screws.

I have scaled them down to 65536 pulses per revolution. That gives me 0,000153mm resolution with 10mm per rev ball screws.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17600

- Thank you received: 5147

14 Jun 2022 14:04 - 14 Jun 2022 14:11 #245125

by PCW

Replied by PCW on topic Stepper controlled servos doesnt move with Encoder feedback configured

If the encoder and step scale are commensurate, FF1 must be 1.000

Plotting the encoder position might help as would posting the current hal/ini files

Plotting the encoder position might help as would posting the current hal/ini files

Last edit: 14 Jun 2022 14:11 by PCW.

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

14 Jun 2022 14:12 - 14 Jun 2022 14:13 #245126

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

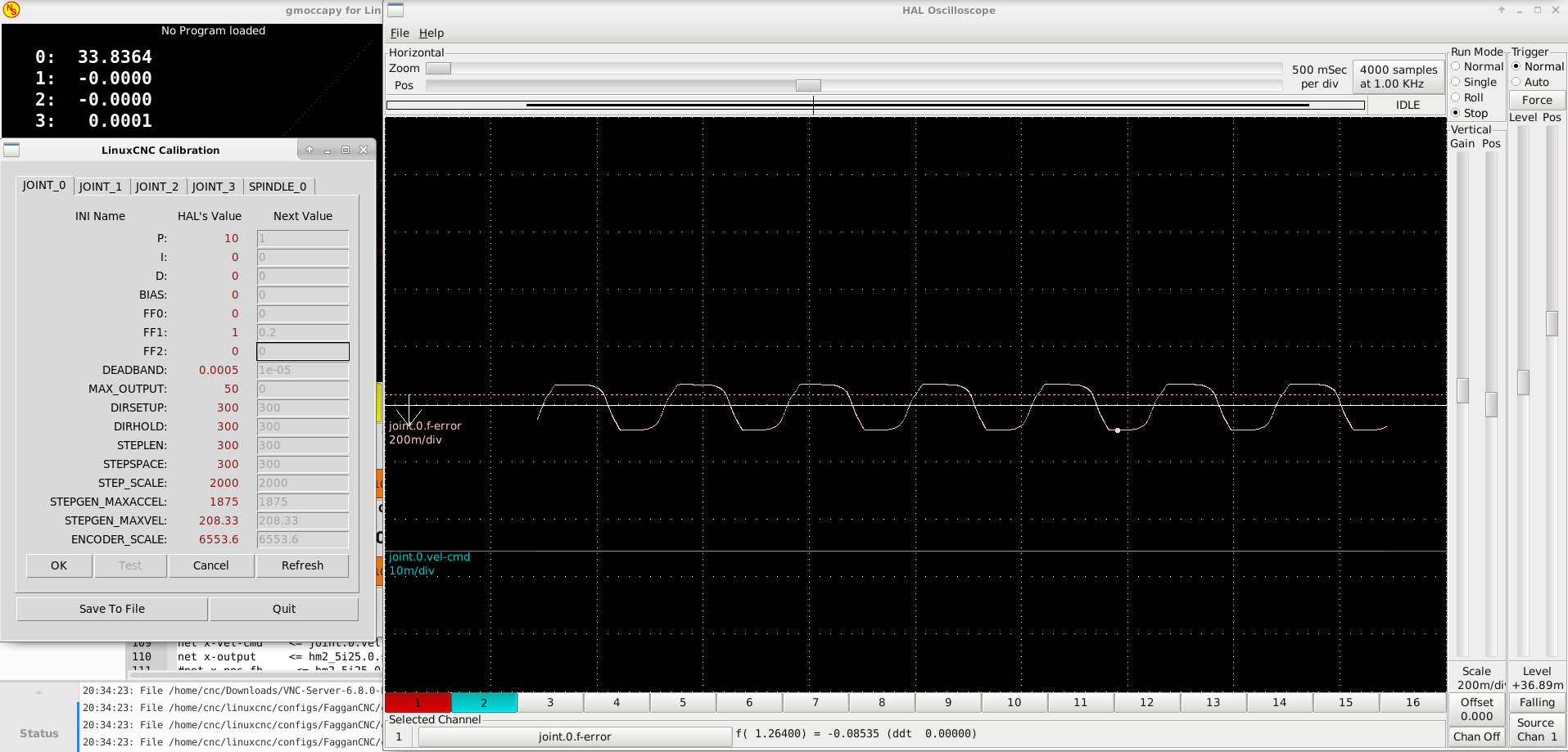

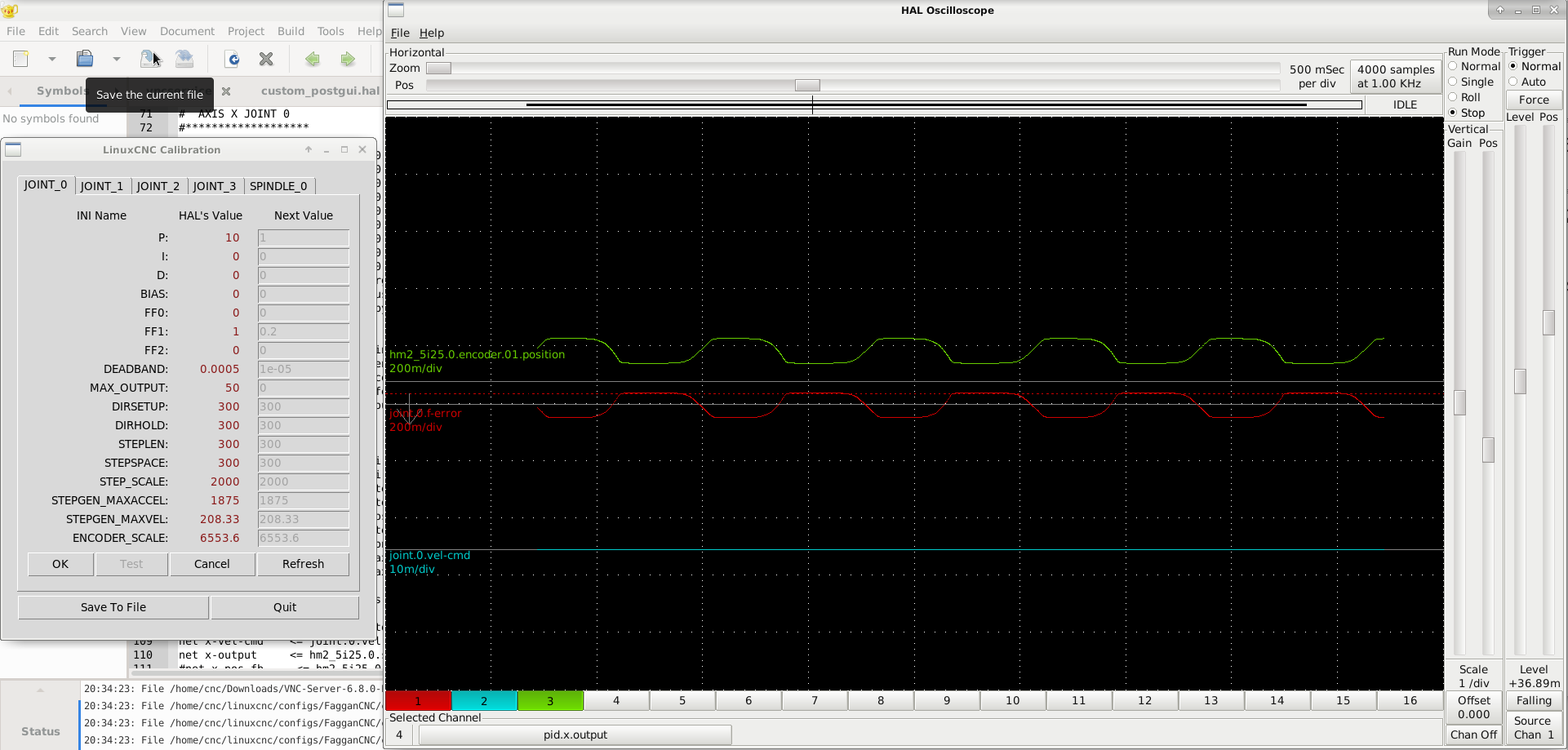

Attachments:

Last edit: 14 Jun 2022 14:13 by Faggan.

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

14 Jun 2022 14:22 #245127

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17600

- Thank you received: 5147

14 Jun 2022 16:34 #245137

by PCW

Replied by PCW on topic Stepper controlled servos doesnt move with Encoder feedback configured

To get that kind of response I would think there must be a relatively large delay

from step command to encoder feedback, so this looks more and more

like a drive setup issue.

Are there any filters setup in the drives commanded position path?

Are there any velocity or acceleration constraints in the drive

lower than the stepgen constraints?

from step command to encoder feedback, so this looks more and more

like a drive setup issue.

Are there any filters setup in the drives commanded position path?

Are there any velocity or acceleration constraints in the drive

lower than the stepgen constraints?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

15 Jun 2022 20:54 #245227

by andypugh

Replied by andypugh on topic Stepper controlled servos doesnt move with Encoder feedback configured

If P = 1 is too high, then try P = 0.5....

I have seen P gains as high as 10,000 and as low as 0.003. It all depends on the system being controlled.

I have seen P gains as high as 10,000 and as low as 0.003. It all depends on the system being controlled.

Please Log in or Create an account to join the conversation.

- Faggan

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

16 Jun 2022 18:53 #245280

by Faggan

Replied by Faggan on topic Stepper controlled servos doesnt move with Encoder feedback configured

@PCW

You are correct. I had assumed that my servos and drives wouldn't need tuning because of a auto tune function they have. After a lot of reading manuals it turns out that the function only applies in speeds of 1000 rpm and higher (10 000mm/min for me). After some rough tuning of the X drive I have lowered the oscillation by a factor of 7. Looks like it will come into spec once I give it a bit more tuning.

Thank you so much for helping!

@andypugh

I have read that it varies greatly yes. What I don't understand fully is how a super low P value would work in practice. Lower P means slower response to errors in general. That leads us to strive for the largest stable P value if I understand correctly. But if you then have a very low value wouldn't the response be sluggish even if its stable? Or would other parameters like machine specs etc counter that?

Not really relevant to my problems, I am just trying to get a better grasp on things.

You are correct. I had assumed that my servos and drives wouldn't need tuning because of a auto tune function they have. After a lot of reading manuals it turns out that the function only applies in speeds of 1000 rpm and higher (10 000mm/min for me). After some rough tuning of the X drive I have lowered the oscillation by a factor of 7. Looks like it will come into spec once I give it a bit more tuning.

Thank you so much for helping!

@andypugh

I have read that it varies greatly yes. What I don't understand fully is how a super low P value would work in practice. Lower P means slower response to errors in general. That leads us to strive for the largest stable P value if I understand correctly. But if you then have a very low value wouldn't the response be sluggish even if its stable? Or would other parameters like machine specs etc counter that?

Not really relevant to my problems, I am just trying to get a better grasp on things.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

17 Jun 2022 23:29 #245357

by andypugh

So if you are at 50,000 counts per second and want to be at 51,000 CPS that's a 0.1% change required in the output voltage, so a gain of 0.001 volts / count would be about right.

Replied by andypugh on topic Stepper controlled servos doesnt move with Encoder feedback configured

It depends on what the inputs and outputs are. One theoretical example might be a very high count encoder feeding back counts / second that is being controlled with a 0 to 10V analogue voltage for speed control.I have read that it varies greatly yes. What I don't understand fully is how a super low P value would work in practice.

So if you are at 50,000 counts per second and want to be at 51,000 CPS that's a 0.1% change required in the output voltage, so a gain of 0.001 volts / count would be about right.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Stepper controlled servos doesnt move with Encoder feedback configured

Time to create page: 0.303 seconds