- LinuxCNC

- General LinuxCNC Questions

- 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

04 Sep 2022 17:04 #251175

by denhen89

2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations was created by denhen89

Hello again, after 2 years or so

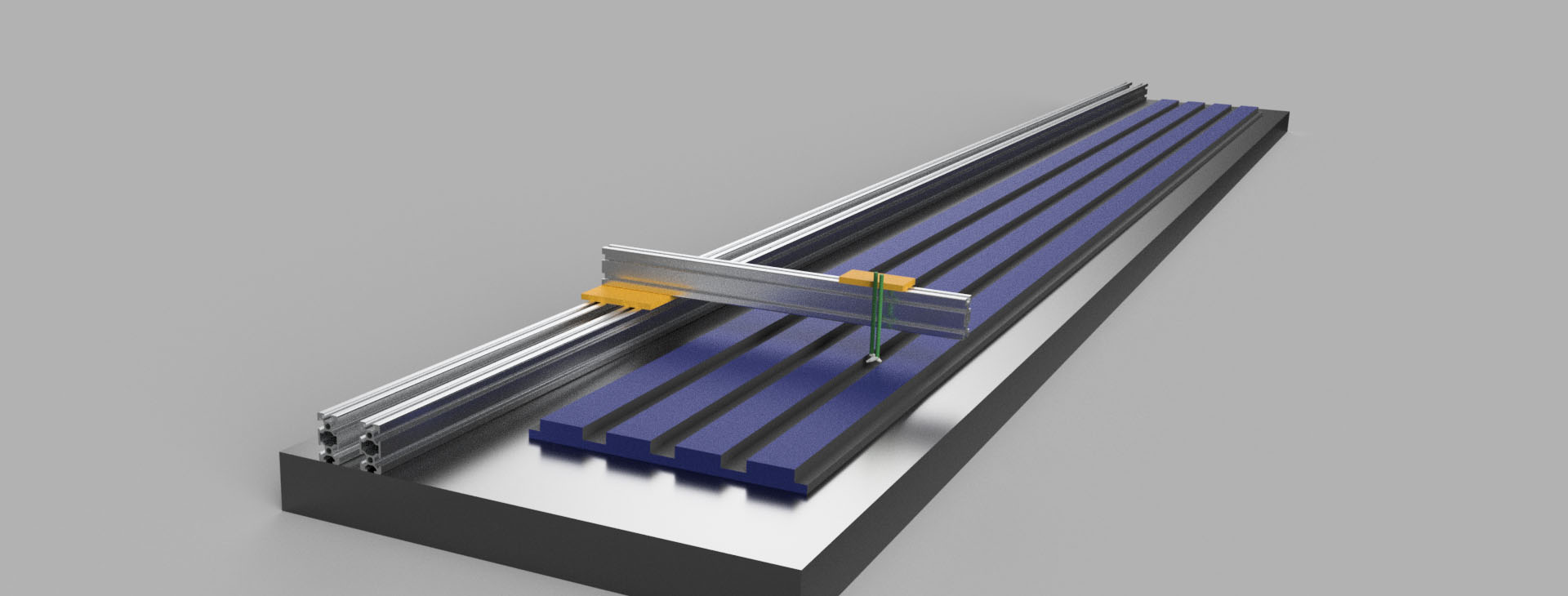

I am planning to build a very simple 2 axis machine for painting, with 2 nozzles, which i want to control seperatly or together at specific coordinates with g-code. The machine construction style will be pretty similar to the "mobile plasma cutter" cnc machines (see google pictures)

My situation in short: I will soon start to produce wood panels with 22mm wide slots over the whole length of the panel (2750 mm) that i will mill out on my cnc router. The grooves are only 22 mm wide, so there might be not enough space to locate both nozzles opposite of each other, so i might need to position the nozzles that way that one might need to stop to spray earlier than the other, and start earlier than the other.

The air supply for both nozzles i want to control with two pneumatic solenoid valves and i thought to just use the M7 and M8 command, and m9 to shut them off, but if, e.g. one nozzle should continue to spray, then i need seperate commands for start and stop for nozzle 1 and 2.

My questions now are:

1. Is it possible to start a M command at a specific location? E.g. the nozzles are outside of the groove but as soon as they enter the groove, one or both nozzles should open, or when driving out of the groove to close the nozzle.

2. Do i need to create custom commands (i have never done that) in case i want to start/stop one nozzle earlier or is there a simpler way?

3. For linux cnc i would need to buy pc hardware again, so do you know any free windows software that could be good enough for what i am planning to do? (i have a laptop left that i could use)

I am currenty very much in hurry, because that idea to paint the walls came to my mind about 1 week ago, but before that i thought, i just need to finish the website and i am ready to start the sale. I have build 2 prototypes with 2 siphone-feed-style airbrushes mounted on a aluminum plate that i moved by hand to paint the walls. It works, but the speed control is not perfect, what ends in darker/brighter spots.

I am planning to build a very simple 2 axis machine for painting, with 2 nozzles, which i want to control seperatly or together at specific coordinates with g-code. The machine construction style will be pretty similar to the "mobile plasma cutter" cnc machines (see google pictures)

My situation in short: I will soon start to produce wood panels with 22mm wide slots over the whole length of the panel (2750 mm) that i will mill out on my cnc router. The grooves are only 22 mm wide, so there might be not enough space to locate both nozzles opposite of each other, so i might need to position the nozzles that way that one might need to stop to spray earlier than the other, and start earlier than the other.

The air supply for both nozzles i want to control with two pneumatic solenoid valves and i thought to just use the M7 and M8 command, and m9 to shut them off, but if, e.g. one nozzle should continue to spray, then i need seperate commands for start and stop for nozzle 1 and 2.

My questions now are:

1. Is it possible to start a M command at a specific location? E.g. the nozzles are outside of the groove but as soon as they enter the groove, one or both nozzles should open, or when driving out of the groove to close the nozzle.

2. Do i need to create custom commands (i have never done that) in case i want to start/stop one nozzle earlier or is there a simpler way?

3. For linux cnc i would need to buy pc hardware again, so do you know any free windows software that could be good enough for what i am planning to do? (i have a laptop left that i could use)

I am currenty very much in hurry, because that idea to paint the walls came to my mind about 1 week ago, but before that i thought, i just need to finish the website and i am ready to start the sale. I have build 2 prototypes with 2 siphone-feed-style airbrushes mounted on a aluminum plate that i moved by hand to paint the walls. It works, but the speed control is not perfect, what ends in darker/brighter spots.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 631

- Thank you received: 232

05 Sep 2022 06:17 #251204

by Bari

Replied by Bari on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

You can have separate M62-65 codes for each nozzle.

No custom commands needed.

We discuss LCNC not winders applications

forum.linuxcnc.org/show-your-stuff/39211...cnc-5-color-airbrush

forum.linuxcnc.org/38-general-linuxcnc-q...this?start=20#244650

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m62-m65

No custom commands needed.

We discuss LCNC not winders applications

forum.linuxcnc.org/show-your-stuff/39211...cnc-5-color-airbrush

forum.linuxcnc.org/38-general-linuxcnc-q...this?start=20#244650

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m62-m65

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

05 Sep 2022 08:00 #251215

by denhen89

Replied by denhen89 on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

Thank you very much.

Now i just need to know if i can use those commands at specific locations.

I mean, for example the nozzles are outside of the groove but the axis is driving into the groove and starts spraying as soon as it arrives at a specific location.

I actually never wrote a g-code by my self, so i dont really know what is possible, but with my knowledge i think it should be possible, but also, will it work without any delay?

Now i just need to know if i can use those commands at specific locations.

I mean, for example the nozzles are outside of the groove but the axis is driving into the groove and starts spraying as soon as it arrives at a specific location.

I actually never wrote a g-code by my self, so i dont really know what is possible, but with my knowledge i think it should be possible, but also, will it work without any delay?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

05 Sep 2022 11:03 #251224

by tommylight

Replied by tommylight on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

Pictures ? Video ? Drawing ?

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

05 Sep 2022 11:26 - 05 Sep 2022 11:30 #251226

by denhen89

Replied by denhen89 on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

hi tommylight,

do you need pictures/videos/drawings for the construction i want to build or what do you mean?

I just want to know if its possible to use the M commands at a specific location/coordinates.

For example: The nozzles are outside of the groove and are not spraying yet. Then the long axis (Y) starts to drive in the direction of the groove but the nozzles are still not spraying, but at a specific point where the nozzles enter that groove/slot, the spraying should start and stop at a specific location when the nozzles drive out of that groove. Then after driving out of the groove when not anymore spraying, the x axis drives to the next groove, then starts driving into the groove and starts spraying again.

The panels are only 250mm wide with max 4 grooves, so i will build the machine as simple as possible, like the "mobile plasma cutter" machines. It has not a full gantry (with steppers on both sides), but a "crane style gantry" if i can say so.

Just 2 axis, Y and X, without Z, because the height will never change - it will always drive inside grooves.

In general, i am trying to find the cheapest and simplest solution, because i will just start the business and cannot tell yet how it will go. I dont want to invest a lot of time to plan the build with a perfect drawing and also i dont want invest a lot of money, because first i want to have a setup that will work so that i can start the business asap. Later, if any changes are needed (e.g. better construction and high quality parts) i can still do it when i know that it works as i wish when it comes to the function.

do you need pictures/videos/drawings for the construction i want to build or what do you mean?

I just want to know if its possible to use the M commands at a specific location/coordinates.

For example: The nozzles are outside of the groove and are not spraying yet. Then the long axis (Y) starts to drive in the direction of the groove but the nozzles are still not spraying, but at a specific point where the nozzles enter that groove/slot, the spraying should start and stop at a specific location when the nozzles drive out of that groove. Then after driving out of the groove when not anymore spraying, the x axis drives to the next groove, then starts driving into the groove and starts spraying again.

The panels are only 250mm wide with max 4 grooves, so i will build the machine as simple as possible, like the "mobile plasma cutter" machines. It has not a full gantry (with steppers on both sides), but a "crane style gantry" if i can say so.

Just 2 axis, Y and X, without Z, because the height will never change - it will always drive inside grooves.

In general, i am trying to find the cheapest and simplest solution, because i will just start the business and cannot tell yet how it will go. I dont want to invest a lot of time to plan the build with a perfect drawing and also i dont want invest a lot of money, because first i want to have a setup that will work so that i can start the business asap. Later, if any changes are needed (e.g. better construction and high quality parts) i can still do it when i know that it works as i wish when it comes to the function.

Last edit: 05 Sep 2022 11:30 by denhen89.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

05 Sep 2022 13:06 #251227

by tommylight

Here is a bit of info on using the M67 code for the "scratchers" i build:

forum.linuxcnc.org/10-advanced-configura...-superimposing-a-pic

Replied by tommylight on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

Whatever helps get a better grasp at what exactly you need so we can allow ourselfs to bombard you with ideas!do you need pictures/videos/drawings for the construction i want to build or what do you mean?

Yes it is, and as far as i could tell from our description, it will be easier to manually write the gcode for it as you will be doing multiple of the same thing.I just want to know if its possible to use the M commands at a specific location/coordinates.

Here is a bit of info on using the M67 code for the "scratchers" i build:

forum.linuxcnc.org/10-advanced-configura...-superimposing-a-pic

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

05 Sep 2022 17:12 - 05 Sep 2022 17:13 #251238

by denhen89

Replied by denhen89 on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

I wrote a quiet a lot earlier, but when i sended the message i got an error and now i have to write it again, so i will try to make it as short as possible.

@tommylight: Thanks for that. I hope it will be not that difficult to set it up in Linuxcnc. From the hardware side, it shouldnt be a problem for me, because i have a fog mister on my cnc router with a solenoid relai valve. Setting up 2 of these should not be difficult for me.

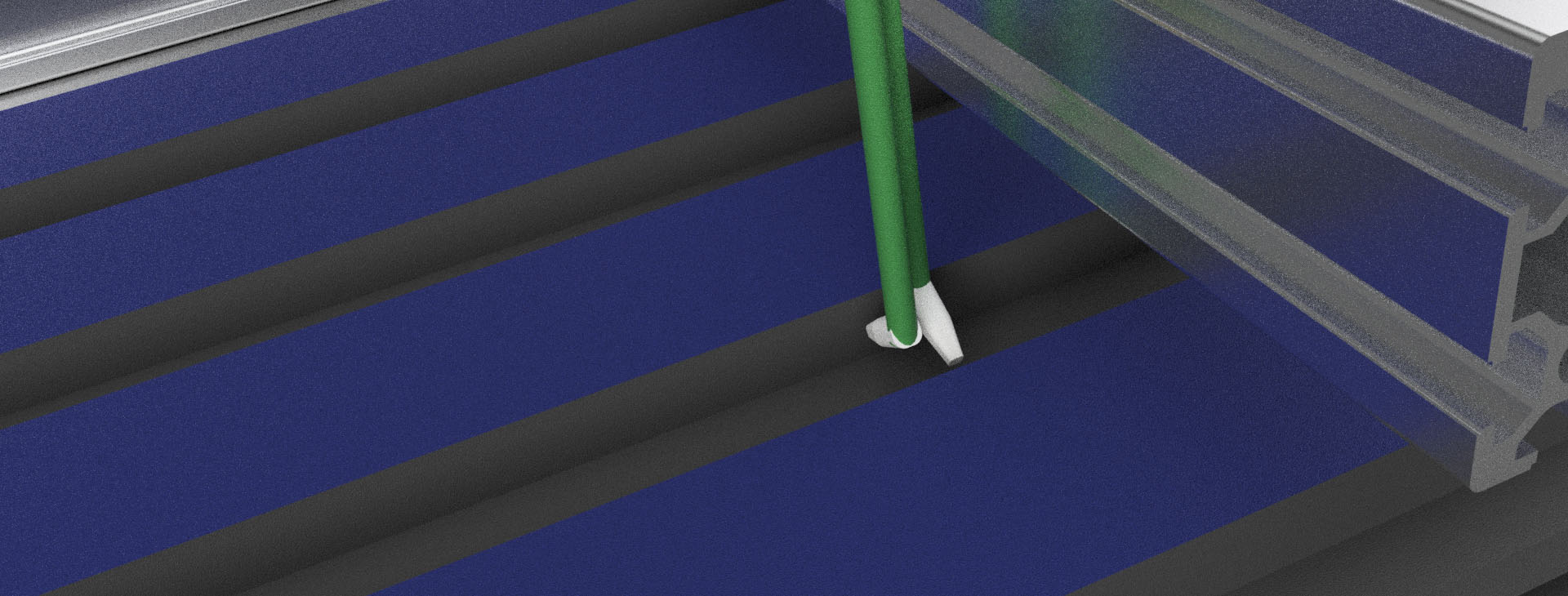

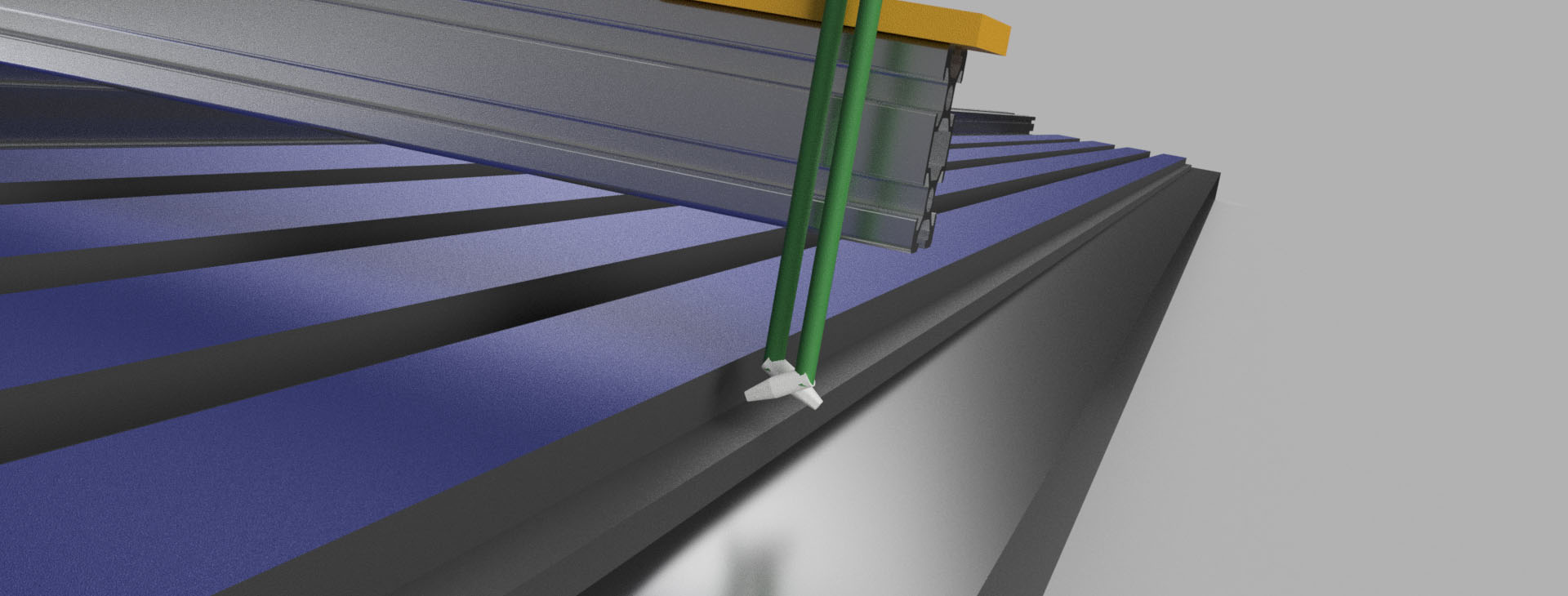

Here the simple drawing i made. I hope that is enough to understand what i am planning to do.

You can see on the pictures, the nozzles are not on the same position, so one nozzle has to start and stop spraying earlier than the other nozzle.

On the last picture you can see that when spraying the side-ends (if i can say so) of the panel, only one nozzle has to be activated.

PS: I will use the "siphon feed" type painting technic, so there will be actually 1 paint nozzle and one air nozzle for one side to paint. The paint nozzle is always "open", and the paint gets pulled by the air from the air nozzle. Its the venturi effect if i remember correct. You can type "airbrush siphon feed" in google to see that type of airbrush and how it works. The only disadvantage with this technic is that the paint nozzle has to be above the paint lowest point of the paint in the tank, otherwise the paint will just flow out of the nozzle until the tank is empty.

I hope now everything important is clear. If not, just let me know. I always got help here, but first time i am really in a hurry, so if you have any good ideas, please let me know it. I need to get that machine done within 2 weeks and i havent even started the drawing and ordering components.

@tommylight: Thanks for that. I hope it will be not that difficult to set it up in Linuxcnc. From the hardware side, it shouldnt be a problem for me, because i have a fog mister on my cnc router with a solenoid relai valve. Setting up 2 of these should not be difficult for me.

Here the simple drawing i made. I hope that is enough to understand what i am planning to do.

You can see on the pictures, the nozzles are not on the same position, so one nozzle has to start and stop spraying earlier than the other nozzle.

On the last picture you can see that when spraying the side-ends (if i can say so) of the panel, only one nozzle has to be activated.

PS: I will use the "siphon feed" type painting technic, so there will be actually 1 paint nozzle and one air nozzle for one side to paint. The paint nozzle is always "open", and the paint gets pulled by the air from the air nozzle. Its the venturi effect if i remember correct. You can type "airbrush siphon feed" in google to see that type of airbrush and how it works. The only disadvantage with this technic is that the paint nozzle has to be above the paint lowest point of the paint in the tank, otherwise the paint will just flow out of the nozzle until the tank is empty.

I hope now everything important is clear. If not, just let me know. I always got help here, but first time i am really in a hurry, so if you have any good ideas, please let me know it. I need to get that machine done within 2 weeks and i havent even started the drawing and ordering components.

Attachments:

Last edit: 05 Sep 2022 17:13 by denhen89.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

05 Sep 2022 19:25 #251249

by tommylight

Replied by tommylight on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

That is simple enough, so you might be overthinking it.

What is the distance between nozzles?

Why not have the nozzles to paint everything at once ?

So, for having one nozzle stop before the other, use an M code that does is not syncronised with motion as the speed of painting will not change, or was it one that does not brake blending ? Getting rusty!

Or do some tests with acceleration if you get jerky motion when the first nozzle stops.

Either way, it should be doable and it should work.

What is the distance between nozzles?

Why not have the nozzles to paint everything at once ?

So, for having one nozzle stop before the other, use an M code that does is not syncronised with motion as the speed of painting will not change, or was it one that does not brake blending ? Getting rusty!

Or do some tests with acceleration if you get jerky motion when the first nozzle stops.

Either way, it should be doable and it should work.

Please Log in or Create an account to join the conversation.

- denhen89

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 298

- Thank you received: 26

05 Sep 2022 19:53 - 05 Sep 2022 19:55 #251252

by denhen89

Replied by denhen89 on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

*it seems that when i Quote your text i get a error message and the text is deleted. It happend now again, so i need to start from 0.

@What is the distance between nozzles?

--- The distance between the nozzles should be max. 10mm.

@Why not have the nozzles to paint everything at once ?

--- What do you mean exactly? Like having as many nozzles as there are grooves? If thats what you mean, i thought about the idea, but not sure if the air pressure can keep up and actually the painting of one panel should not take longer than 2-3 minutes, so its fast enough when painting one groove, then next one..

@So, for having one nozzle stop before the other, use an M code that does is not syncronised with motion as the speed of painting will not change, or was it one that does not brake blending ? Getting rusty!

Or do some tests with acceleration if you get jerky motion when the first nozzle stops.

Either way, it should be doable and it should work.

--- Good to know that its doable

Actually, i had first a other idea: Instead of controlling the solenoids, to use mechanical valve switches, one for each nozzle.

Thats just a idea, but of course it could work if setup correctly and i even think to try it.

I mean this kind of switches: www.smcpneumatics.com/VM830-01-13W.html

Unfortunately they seem to be pretty expensive, but i will check if there are cheaper ones.

What do you think, good or bad idea?

Thanks in advance

@What is the distance between nozzles?

--- The distance between the nozzles should be max. 10mm.

@Why not have the nozzles to paint everything at once ?

--- What do you mean exactly? Like having as many nozzles as there are grooves? If thats what you mean, i thought about the idea, but not sure if the air pressure can keep up and actually the painting of one panel should not take longer than 2-3 minutes, so its fast enough when painting one groove, then next one..

@So, for having one nozzle stop before the other, use an M code that does is not syncronised with motion as the speed of painting will not change, or was it one that does not brake blending ? Getting rusty!

Or do some tests with acceleration if you get jerky motion when the first nozzle stops.

Either way, it should be doable and it should work.

--- Good to know that its doable

Actually, i had first a other idea: Instead of controlling the solenoids, to use mechanical valve switches, one for each nozzle.

Thats just a idea, but of course it could work if setup correctly and i even think to try it.

I mean this kind of switches: www.smcpneumatics.com/VM830-01-13W.html

Unfortunately they seem to be pretty expensive, but i will check if there are cheaper ones.

What do you think, good or bad idea?

Thanks in advance

Last edit: 05 Sep 2022 19:55 by denhen89.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

05 Sep 2022 21:26 #251255

by tommylight

Or use a DC motor with speed regulation ...

I would still use LinuxCNC and electric valves, just to have everything automated and whenever something else comes along it is just a gcode change.

Replied by tommylight on topic 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

Also very usable, and can be controlled from a single arduino, just to have some electronics there.Actually, i had first a other idea: Instead of controlling the solenoids, to use mechanical valve switches, one for each nozzle.

Or use a DC motor with speed regulation ...

I would still use LinuxCNC and electric valves, just to have everything automated and whenever something else comes along it is just a gcode change.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- 2 Axis machine - Controlling 2 solenoid valves seperatly at specific locations

Time to create page: 0.139 seconds