- LinuxCNC

- General LinuxCNC Questions

- Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

- vkhargwanshi

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 6

05 Jun 2022 06:57 #244601

by vkhargwanshi

Replied by vkhargwanshi on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Yes this will be useful for low viscosity products.. Thanks

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

05 Jun 2022 14:55 - 05 Jun 2022 14:56 #244622

by smc.collins

Replied by smc.collins on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Last edit: 05 Jun 2022 14:56 by smc.collins.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

05 Jun 2022 14:59 #244624

by smc.collins

Replied by smc.collins on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

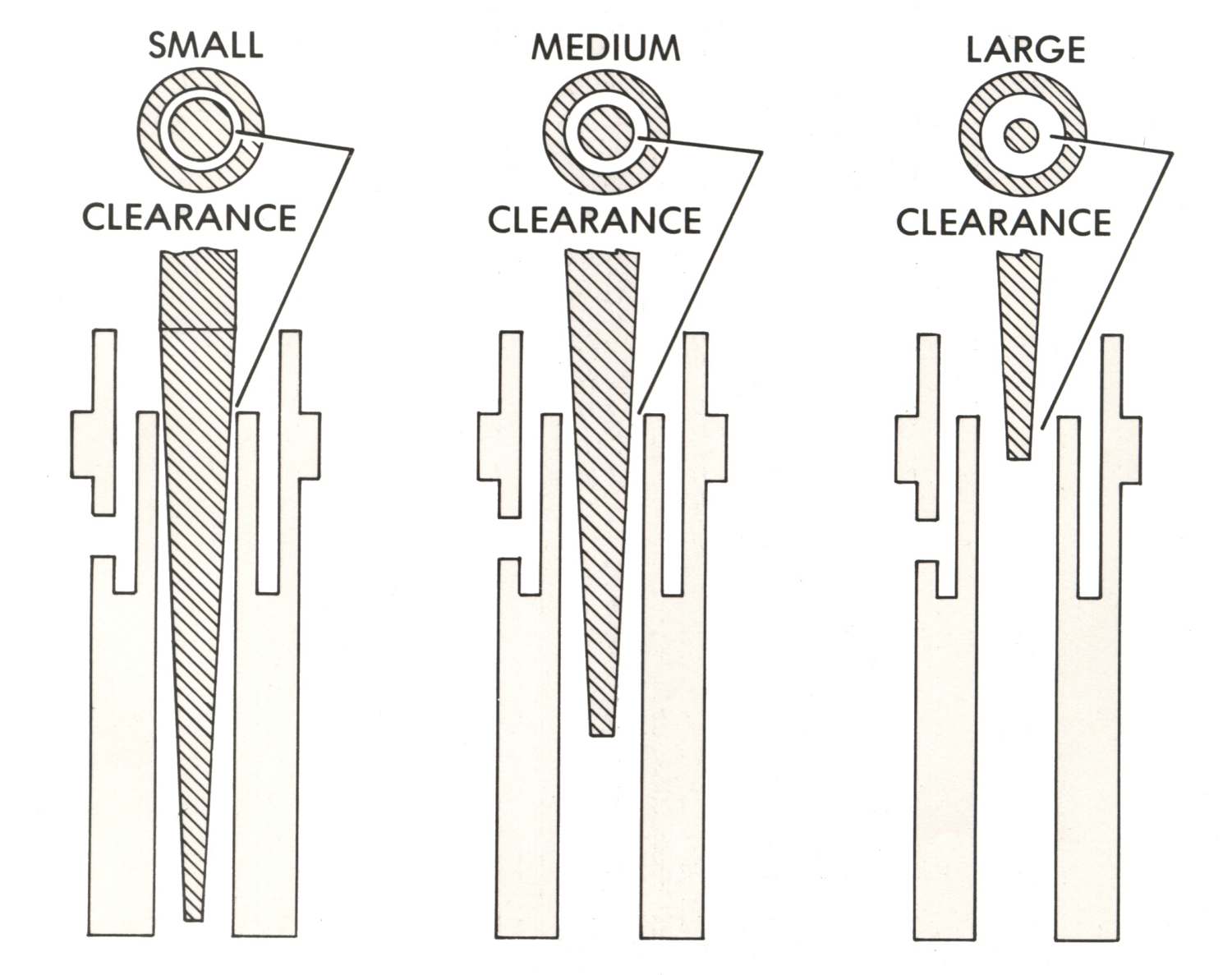

so, you would make a nozzle where the needle stops directly at the end of the nozzle, this eliminates your reservoiring issue. Conversely if you PWM the solenoid, you can meter a large orifice, and if you alter the size of the origifc and the needle you can really fine tune the delivery. Also you can run the clearance close, or you can change the nozzle geometry and spray or drizzle. I could sketch up some nozzle and valve designs in cad if you want. not very difficult to make. just need a competent lathe operator and some patience. As to how to make it operate, a spring above the needle and a basic plunger type electrical solenoid will get it done

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

05 Jun 2022 15:31 #244627

by smc.collins

Replied by smc.collins on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Please Log in or Create an account to join the conversation.

- vkhargwanshi

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 6

06 Jun 2022 03:11 #244646

by vkhargwanshi

Replied by vkhargwanshi on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Thank you so much for so detailed information. This is surely going to be a part of our work going forward..

You can say fortunately or unfortunately we have started working with, specialized dispenser already available and used by people for dispensing specialized high viscous material available in particular packages manually. The demand came as using the same dispenser for dispensing but on a benchtop automation. So effectively we are unable to play around with the dispenser..

You can say fortunately or unfortunately we have started working with, specialized dispenser already available and used by people for dispensing specialized high viscous material available in particular packages manually. The demand came as using the same dispenser for dispensing but on a benchtop automation. So effectively we are unable to play around with the dispenser..

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 631

- Thank you received: 232

06 Jun 2022 04:55 - 06 Jun 2022 05:24 #244650

by Bari

Replied by Bari on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

I've built several types of fluid/paste/gel dispensers using LCNC. It's not really LCNC but the valve design that matters. If you are stuck with a given pneumatic valve and syringe type dispenser the viscosity of the fluid won't vary much over time at the same temperature, so you can predict how long the nozzle will still expel the fluid after the valve is closed.

imgur.com/hQsE2h7 this example used a high viscosity epoxy that we would draw or write directly to surfaces using small diameter needles. The epoxy was in a pneumatically driven syringe that could have positive or negative pressure. We could stop the flow near instantly and draw numbers and text onto surfaces without whiskers.

www.nordson.com/en/divisions/efd/product...tips/plastic-nozzles

www.pmdcorp.com/hs-fs/hubfs/Diagrams/Fig...ame=Fig-Air-Pump.png

Off the shelf fuel injectors handle low viscosity fluids as is. They require some mods for higher viscosity fluids like honey. Cantilever piezo dispensers work with fluids up to ~1,000 cPs and run up to ~1k drops per second.

imgur.com/hQsE2h7 this example used a high viscosity epoxy that we would draw or write directly to surfaces using small diameter needles. The epoxy was in a pneumatically driven syringe that could have positive or negative pressure. We could stop the flow near instantly and draw numbers and text onto surfaces without whiskers.

www.nordson.com/en/divisions/efd/product...tips/plastic-nozzles

www.pmdcorp.com/hs-fs/hubfs/Diagrams/Fig...ame=Fig-Air-Pump.png

Off the shelf fuel injectors handle low viscosity fluids as is. They require some mods for higher viscosity fluids like honey. Cantilever piezo dispensers work with fluids up to ~1,000 cPs and run up to ~1k drops per second.

Last edit: 06 Jun 2022 05:24 by Bari.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 631

- Thank you received: 232

06 Jun 2022 05:31 #244653

by Bari

Replied by Bari on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Oh I just remembered that one version used the M-codes for real time ON/OFF of the valves. You could turn on the valve in realtime synchronized with motion and then turn off the valve and have a small delay until the motion stops.

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m62-m65

linuxcnc.org/docs/html/gcode/m-code.html#mcode:m62-m65

Please Log in or Create an account to join the conversation.

- vkhargwanshi

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 6

06 Jun 2022 12:30 #244662

by vkhargwanshi

Replied by vkhargwanshi on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Looks interesting.. this means while motion is on, the valve can be closed without stopping the motion.., but I think, this command is not part of GRBL which I am using currently.

I quickly tried to find any example of same, but couldn't find.. Will check more and if fails to find, will get back.

Thanks for your input..

I quickly tried to find any example of same, but couldn't find.. Will check more and if fails to find, will get back.

Thanks for your input..

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

10 Jun 2022 00:07 #244834

by andypugh

Replied by andypugh on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

I think that with LinuxCNC you might be able to turn off the valve early using the "motion.distance-to-go" pin.

linuxcnc.org/docs/stable/html/man/man9/motion.9.html

Though you would need to flag "last move" to avoid it shutting the valve before the end of _every_ move.

linuxcnc.org/docs/stable/html/man/man9/motion.9.html

Though you would need to flag "last move" to avoid it shutting the valve before the end of _every_ move.

Please Log in or Create an account to join the conversation.

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 631

- Thank you received: 232

10 Jun 2022 04:39 - 10 Jun 2022 04:39 #244844

by Bari

Replied by Bari on topic Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

M63 and then the next line is a short segment that lasts as long as the last bit of material leaves the nozzle.

With GRBL it's similar, you just stop the flow at the end of the second to the last segment of movement and then add a final motion segment with the nozzle OFF that lasts as long as the flow does.

With GRBL it's similar, you just stop the flow at the end of the second to the last segment of movement and then add a final motion segment with the nozzle OFF that lasts as long as the flow does.

Last edit: 10 Jun 2022 04:39 by Bari.

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Adhesive dispensing machine forming adhesive bead, can LinuxCNC solve this?

Time to create page: 0.096 seconds