retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

03 Dec 2022 20:34 - 03 Dec 2022 20:50 #258453

by Patrice

retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki was created by Patrice

-hitachi seiki

pin out asu40/30a

pin out asu220

le protocol de communication avec le bus asu ( comment il communique, le voltage si c en input ou output) ( modbus can rs stepdir analog ou autre

_ tour ikegai fx20n

cn1 sur velocity amplifier a06-6045-h001,h002 pin out, voltage et comment activer les pin nécessaire en low , high ou sinking ou sourced

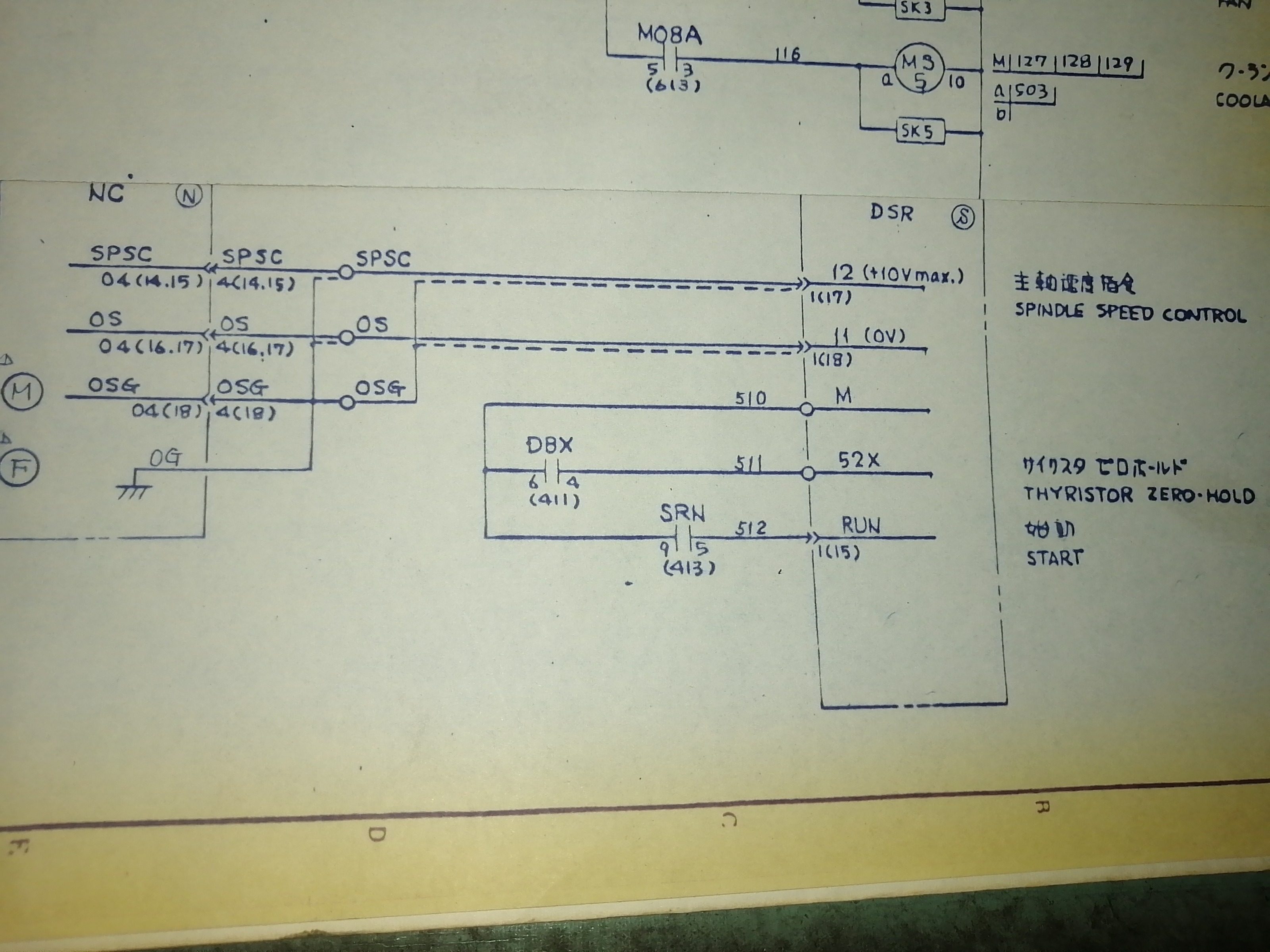

le pin out du FUJI ELECTRIC DSR COMPACT FSD-11 SN-Z for cn1 and cn2 +10v + foward and reverse

et la derniere question changer mon index pulse coder pour un encoder abs je devrait acheter une carte ssi pour interfacer avec mon encoder, c pour une tourrette hydraulique 6 position avec un index pour le milieu de la course, ou l'autre option envisager est de prendre une carte arduino pour convertir mon signal en output et réserver 7 input pour le positionnement de tourret, ou d'utiliser une table binaire pour sauver des input, j'aimerai de quoi de simple et d'économique vos recommandation svp j'ai voulu mettre des swith individuellle mais manque un peut de place, si je trouve pas mes information je me tournerait surment sur des drive et moteur dyn4 de DMM , surment avec une carte 7i76+ 7i92 + usb mpg, je me demande si je vais en closed loop sur la mesa ou directement dans la drive, j'avais pensé a acorn mais j'aime bien l'idée de mesa et de linux, mais ethercat sa seras quand les drive seront moins dispendieuse,

Merci a tous réponder en anglais en francais ou tout autre, thanks a lot and good day

pin out asu40/30a

pin out asu220

le protocol de communication avec le bus asu ( comment il communique, le voltage si c en input ou output) ( modbus can rs stepdir analog ou autre

_ tour ikegai fx20n

cn1 sur velocity amplifier a06-6045-h001,h002 pin out, voltage et comment activer les pin nécessaire en low , high ou sinking ou sourced

le pin out du FUJI ELECTRIC DSR COMPACT FSD-11 SN-Z for cn1 and cn2 +10v + foward and reverse

et la derniere question changer mon index pulse coder pour un encoder abs je devrait acheter une carte ssi pour interfacer avec mon encoder, c pour une tourrette hydraulique 6 position avec un index pour le milieu de la course, ou l'autre option envisager est de prendre une carte arduino pour convertir mon signal en output et réserver 7 input pour le positionnement de tourret, ou d'utiliser une table binaire pour sauver des input, j'aimerai de quoi de simple et d'économique vos recommandation svp j'ai voulu mettre des swith individuellle mais manque un peut de place, si je trouve pas mes information je me tournerait surment sur des drive et moteur dyn4 de DMM , surment avec une carte 7i76+ 7i92 + usb mpg, je me demande si je vais en closed loop sur la mesa ou directement dans la drive, j'avais pensé a acorn mais j'aime bien l'idée de mesa et de linux, mais ethercat sa seras quand les drive seront moins dispendieuse,

Merci a tous réponder en anglais en francais ou tout autre, thanks a lot and good day

Last edit: 03 Dec 2022 20:50 by Patrice.

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

03 Dec 2022 21:11 - 05 Dec 2022 03:03 #258454

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

I have the following for the 6m DC velocity unit (CN1)

You may have to decode the mnemonics but some seem obvious.

Pin

1-PRDYA

2-ENBLA

3-OVLA

4-*VRDYA

5-

6-tsb signal tach 7v/1000rpm voici ce qui me manquait

7-VCMD (ANALOG COMMAND?)

8-*ALM10

9-*ALM11

10-*ALM12

11-

12-

13-*COM

14-PRDYB

15-ENBLB

16-OVLB

17-*VRDYB

18-

19-tsb signal tach 7v/1000rpm (groud commun) la suite de ce qui mem manquait

20-EC

The (*) usually means the common or complement or active low.

Al.

that's is what i found on drive 6047 but not sure its the same of 6045-h001?!

You may have to decode the mnemonics but some seem obvious.

Pin

1-PRDYA

2-ENBLA

3-OVLA

4-*VRDYA

5-

6-tsb signal tach 7v/1000rpm voici ce qui me manquait

7-VCMD (ANALOG COMMAND?)

8-*ALM10

9-*ALM11

10-*ALM12

11-

12-

13-*COM

14-PRDYB

15-ENBLB

16-OVLB

17-*VRDYB

18-

19-tsb signal tach 7v/1000rpm (groud commun) la suite de ce qui mem manquait

20-EC

The (*) usually means the common or complement or active low.

Al.

that's is what i found on drive 6047 but not sure its the same of 6045-h001?!

Last edit: 05 Dec 2022 03:03 by Patrice.

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

06 Dec 2022 21:33 #258748

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

The CN1 connectors have these signals:

PRDY: CNC sends contact closure between CN1 pin 1 and CN1 pin 14

ENBL: CNC sends contact closure between CN1 pin 2 and CN1 pin 15

OVL: Servo sends contact closure betwen CN1 pin 3 and CN1 pin 16

VRDY: Servo sends contact closure between CN1 pin 4 and CN1 pin 17

Tach signal - analog input to servo between CN1 pin 6 and CN1 pin 19

VCMD signal - analog input to servo between CN1 pin 7 and CN1 pin 20

All other pins are unused.

The contact closure OVL from the servo to the CNC is from the motor overload sensor (the current sensor on the motor armature current that has the little red reset button).

The contact closure VRDY is from a small set of contacts on the side of the big MCC contactor.

Pins 19 and 20 are both tied to ground on the board, so the the tach signal on pin 6 and the Velocity command signal on pin 7 are both measured relative to the same ground reference. The check pins CH3 and CH4 are both grounded also, so you should see continuity between pins 19 & 20 and CH3 and CH4

Pins 14 and 15 are both tied to +24vdc on the board, so when the relay contacts on the CNC close for the signals PRDY and ENBL, the +24v from the servo board is put on pins 1 and 2, respectively. This +24v is from the little power supply on the X axis servo board, which also appears at CH15. The Z servo board usually does no have a power supply, since it shares power with the X board through a ribbon cable.

PRDY: CNC sends contact closure between CN1 pin 1 and CN1 pin 14

ENBL: CNC sends contact closure between CN1 pin 2 and CN1 pin 15

OVL: Servo sends contact closure betwen CN1 pin 3 and CN1 pin 16

VRDY: Servo sends contact closure between CN1 pin 4 and CN1 pin 17

Tach signal - analog input to servo between CN1 pin 6 and CN1 pin 19

VCMD signal - analog input to servo between CN1 pin 7 and CN1 pin 20

All other pins are unused.

The contact closure OVL from the servo to the CNC is from the motor overload sensor (the current sensor on the motor armature current that has the little red reset button).

The contact closure VRDY is from a small set of contacts on the side of the big MCC contactor.

Pins 19 and 20 are both tied to ground on the board, so the the tach signal on pin 6 and the Velocity command signal on pin 7 are both measured relative to the same ground reference. The check pins CH3 and CH4 are both grounded also, so you should see continuity between pins 19 & 20 and CH3 and CH4

Pins 14 and 15 are both tied to +24vdc on the board, so when the relay contacts on the CNC close for the signals PRDY and ENBL, the +24v from the servo board is put on pins 1 and 2, respectively. This +24v is from the little power supply on the X axis servo board, which also appears at CH15. The Z servo board usually does no have a power supply, since it shares power with the X board through a ribbon cable.

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

06 Dec 2022 21:45 - 08 Dec 2022 00:49 #258752

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

Attachments:

Last edit: 08 Dec 2022 00:49 by Patrice.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21054

- Thank you received: 7181

06 Dec 2022 21:49 #258753

by tommylight

Replied by tommylight on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

Pictures would help more, not sure if what you wrote for pins is a 0-zero or an o-word

And, do not buy DYN4 drives, they are to slow for velocity control and might, might be ok for step/dir control but i would not count on it.

Try to use existing ones, if they are +-10V then you would need a Mesa 7i97 or a combination of 7i92/7i77 for ethernet or 5i25/7i77 for PCI or 6i25/7i77 for PCI-E. There are other combos that i am not sure of so leaving that to someone with more info.

As for the turret encoder, i can not figure out from the translation what the actual question is. If it has an encoder, probably it can work with LinuxCNC.

And, do not buy DYN4 drives, they are to slow for velocity control and might, might be ok for step/dir control but i would not count on it.

Try to use existing ones, if they are +-10V then you would need a Mesa 7i97 or a combination of 7i92/7i77 for ethernet or 5i25/7i77 for PCI or 6i25/7i77 for PCI-E. There are other combos that i am not sure of so leaving that to someone with more info.

As for the turret encoder, i can not figure out from the translation what the actual question is. If it has an encoder, probably it can work with LinuxCNC.

The following user(s) said Thank You: Patrice

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

06 Dec 2022 21:50 #258754

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

fot velocity amplifier These Fanuc drives do accept analog inputs. The small motors (00,0,5) use a 3.5v per 1000 RPM command signal, and the larger motors (10,20,30) use a 7v per 1000 rpm signal. The inputs can go to 10v without losing linearity. The gain is adjustable on the board, so you could use a +/- 10v analog signal if you need to.

The biggest problem with trying to use the Fanuc drives in a retrofit is that the tach signals are usually generated by the CNC using the pulse coder feedback. The pulses are put through a "frequency to velocity" converter so that an analog tach signal is generated for the servo drives, and the need for a real tach generator is eliminated. The tach signals are always 6v per 1000 rpm of the motor. There are some Fanuc motors out there that have tachs in them, and the pulse coders are separately coupled to the ballscrews. Most of the time, however, there are no tachs in the motors and the pulse coder is mounted inside the back cover of the motor. This works fine if your motor is directly coupled to the ballscrew. A few machines have motors with tachs driving the ballscrew with a Gilmer belt, and the pulse coder is directly coupled to the screw.

If you have motors with tachs and separate pulse coders, you should be able to use the servos, motors and pulse coders in almost any kind of retrofit. If the pulse coders are inside the motors, you would need to make some kind of F/V circuit to generate the tach signals, or mount a separate tach generator that's driven at the same speed as the motor.

The CN1 connectors on the Fanuc servo boards have an analog VCMD (velocity command) signal and also a TSA/TSB signal for the tach input. There are also some relay closure signals from the CNC that pull in the servo contactor (PRDY) and enable the firing circuit (ENBL), and there is a contact closure on the servo to confirm that the drive is ready (VRDY).

The sequence is pretty simple. The CNC boots up and closes a contact to send the PRDY (Power ready) signal to the servo. The servo pulls in the big MCC contactor and sends back a contact closure signal to confirm that the velocity unit is ready (VRDY), then the CNC closes the enable signal (ENBL) and you're off and running. The VCMD velocity command analog signal should be clamped to 0v until the servo is enabled, and your tach signal should be live before the ENBL signal is sent. A tach that's missing or backwards polarity will cause a motor to runaway (fast!). A missing phase will cause the motor to run rough and have little power.

Maybe one of the other forum members has cooked up a little F/V converter for generating tach signals for these servos. How about it guys?

The biggest problem with trying to use the Fanuc drives in a retrofit is that the tach signals are usually generated by the CNC using the pulse coder feedback. The pulses are put through a "frequency to velocity" converter so that an analog tach signal is generated for the servo drives, and the need for a real tach generator is eliminated. The tach signals are always 6v per 1000 rpm of the motor. There are some Fanuc motors out there that have tachs in them, and the pulse coders are separately coupled to the ballscrews. Most of the time, however, there are no tachs in the motors and the pulse coder is mounted inside the back cover of the motor. This works fine if your motor is directly coupled to the ballscrew. A few machines have motors with tachs driving the ballscrew with a Gilmer belt, and the pulse coder is directly coupled to the screw.

If you have motors with tachs and separate pulse coders, you should be able to use the servos, motors and pulse coders in almost any kind of retrofit. If the pulse coders are inside the motors, you would need to make some kind of F/V circuit to generate the tach signals, or mount a separate tach generator that's driven at the same speed as the motor.

The CN1 connectors on the Fanuc servo boards have an analog VCMD (velocity command) signal and also a TSA/TSB signal for the tach input. There are also some relay closure signals from the CNC that pull in the servo contactor (PRDY) and enable the firing circuit (ENBL), and there is a contact closure on the servo to confirm that the drive is ready (VRDY).

The sequence is pretty simple. The CNC boots up and closes a contact to send the PRDY (Power ready) signal to the servo. The servo pulls in the big MCC contactor and sends back a contact closure signal to confirm that the velocity unit is ready (VRDY), then the CNC closes the enable signal (ENBL) and you're off and running. The VCMD velocity command analog signal should be clamped to 0v until the servo is enabled, and your tach signal should be live before the ENBL signal is sent. A tach that's missing or backwards polarity will cause a motor to runaway (fast!). A missing phase will cause the motor to run rough and have little power.

Maybe one of the other forum members has cooked up a little F/V converter for generating tach signals for these servos. How about it guys?

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

06 Dec 2022 22:08 #258759

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

what a pine do you talk, cn2 it's tacho with temperature sensor,, i have 7192/ 7i77d (siniking), the spindle drive have 0 to +10v need pin to reverse i will dig this wk-end For Cn-1 pin 18 its os, i think it's a word, i will check my electrical diagram but not all info in there. and the manual i pick it with a lathe it s 6t model b not a, the turret it's hydraulic ,its is old pulse coder 6 position with index in midle stoke of each position , i will check for new, abz (360,600 or other , need to index(homing) want wake it up and generate a pulse in middle on tool position and split 360 in 6 for 60 degree to check parity (slow down the turret and whent hit the synthetique pulse, stop in place and clamp) do you have suggest for adapteur brand 6mm encoder shaft to 10mm on the machine ?! tkx Tom

Please Log in or Create an account to join the conversation.

- Patrice

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 0

06 Dec 2022 22:21 #258761

by Patrice

Replied by Patrice on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

i think 400 it's 0v

437,512 and 546 it's for run , forward and reverse , 3 magentic contactor (run give the power, and after f or r its activing not 2 in same time ,

i will confirm that

437,512 and 546 it's for run , forward and reverse , 3 magentic contactor (run give the power, and after f or r its activing not 2 in same time ,

i will confirm that

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

08 Dec 2022 22:58 #258924

by andypugh

Replied by andypugh on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

Maybe the bldc component could have a velocity output pin for synthesising a tach signal.

Do the drives work in torque mode if the tach signal input is shorted to zero? I would rather expect them to either do that, or to fault out.

Basically the output is the difference between commanded velocity and tach velocity. So if the tach is zero you just have a current / torque mode drive.

Anyway, I don't think V/F analogue hardware is the way to go, it can be worked out in HAL and generated with a D-to-A converter (maybe even a spare analogue output on the control board...)

Do the drives work in torque mode if the tach signal input is shorted to zero? I would rather expect them to either do that, or to fault out.

Basically the output is the difference between commanded velocity and tach velocity. So if the tach is zero you just have a current / torque mode drive.

Anyway, I don't think V/F analogue hardware is the way to go, it can be worked out in HAL and generated with a D-to-A converter (maybe even a spare analogue output on the control board...)

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

08 Dec 2022 23:00 #258925

by andypugh

Replied by andypugh on topic retrofit ikegai fx20n 6t, probleme nec drive sur hitachi seiki

This only makes sense if the drives absolutely need a tach signal. If they don't then it makes no sense to synthesise a tach and sum the voltages in the drive. At that point move the velocity loop in to HAL and reduce the analogue output once at-speed (or in-position)Anyway, I don't think V/F analogue hardware is the way to go, it can be worked out in HAL and generated with a D-to-A converter (maybe even a spare analogue output on the control board...)

The following user(s) said Thank You: Patrice

Please Log in or Create an account to join the conversation.

Time to create page: 0.097 seconds