GMOCCAPY spindle rpm issue

- santiagoe

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

28 Feb 2023 18:36 #265591

by santiagoe

GMOCCAPY spindle rpm issue was created by santiagoe

hi all, I am having an issue trying to use a folinn (fuling) BD600 VFD via RS485 with vfdmod, I copied the configuration given in this

thread

and it helped me to get it going to run the spindle CW, CCW and stopping, but I am having an issue with the set RPM, the spindle I am using is 800Hz 24000 RPM, everytime I execute Linuxcnc, the speed defaults to the maximum 800hz and it can not be modulated using the +- buttons (the bar moves but the speed is the same) and when I send a command like M03 S1000 or S10 the spindle will go to the maximum velocity and the VFD also to 800hz, lastly the feedback_bar and at_speed_led are not working not sure why, I am using 2.8.0 version on a raspberry pi 4.

vfd.hal

BD600.ini

CNC.ini

CNC.hal

custom_postgui.hal

also the VFD is configured with the correct parameters according to the next page in the thread I linked above, thank you in advance for your help.

vfd.hal

loadusr -W vfdmod BD600.ini --debug

net spindle-vel-cmd-rpm => vfdmod.spindle.rpm-in

net spindle-at-speed <= vfdmod.spindle.at-speed

net spindle-cw => vfdmod.control.run-forward

net spindle-ccw => vfdmod.control.run-reverseBD600.ini

[Common]

MaxSpeedRPM=24000

MinSpeedRPM=100

AtSpeedThreshold=0.05

[RS485]

SlaveAddress=1

SerialDevice=/dev/ttyUSB0

BaudRate=9600

LoopDelay=500

ProtocolDelay=6

IsConnectedDelay=10

ConnectionErrorList=110

ConnectionDelay=500

[Control]

Address=0x1000

RunForwardValue=0x0001

RunReverseValue=0x0002

FaultResetValue=0x0007

StopValue=0x0006

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=100

Divider=1

[SpindleRpmOut]

Address=0x3001

Multiplier=1

Divider=100

[freq-running]

FunctionCode=0x03

Address=0x3001

PinType=float

PinName=freq-running

Divider=1

[bus-voltage]

FunctionCode=0x03

Address=0x3002

PinType=float

PinName=bus-voltage

[output-voltage]

FunctionCode=0x03

Address=0x3003

PinType=float

PinName=output-voltage

[output-current]

FunctionCode=0x03

Address=0x3004

PinType=float

PinName=output-current

Divider=100

[output-torque]

FunctionCode=0x03

Address=0x3006

PinType=float

PinName=output-torque

[run-speed]

FunctionCode=0x03

Address=0x3007

PinType=float

PinName=run-speed

[spindle-load-speed]

FunctionCode=0x03

Address=0x300F

PinType=float

PinName=spindle-load-speed

[power-on-time]

FunctionCode=0x03

Address=0x301A

PinType=float

PinName=power-on-time

[spindle-run-time]

FunctionCode=0x03

Address=0x301B

PinType=float

PinName=spindle-run-time

[fault-code]

FunctionCode=0x03

Address=0x8000

PinType=float

PinName=fault-codeCNC.ini

[EMC]

MACHINE = CNC

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = gmoccapy

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.100000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/pi/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 25.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

[HAL]

HALUI = halui

HALFILE = CNC.hal

HALFILE = vfd.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000CNC.hal

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdicustom_postgui.hal

net spindle-speed-fb <= gmoccapy.spindle_feedback_bar

net spindle-at-speed <= gmoccapy.spindle_at_speed_ledalso the VFD is configured with the correct parameters according to the next page in the thread I linked above, thank you in advance for your help.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21103

- Thank you received: 7205

28 Feb 2023 18:39 #265594

by tommylight

Replied by tommylight on topic GMOCCAPY spindle rpm issue

No double posting.

The other topic deleted.

The other topic deleted.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19754

- Thank you received: 4586

03 Mar 2023 00:25 #265751

by andypugh

Replied by andypugh on topic GMOCCAPY spindle rpm issue

You have a pid for the spindle, but it seems to be unused, so it isn't that, I don't think.

Possibly the VFD expects a frequency input and you are passing RPM?

I don't know how to start Halshow ("show hal configuration") from Gnoccapy, but if there isn't a way to open it built-in, you can always start it with "halshow" at the command line.

That wll allow you to explore what values are on the various HAL pins, and you can trace the numbers through.

Possibly the VFD expects a frequency input and you are passing RPM?

I don't know how to start Halshow ("show hal configuration") from Gnoccapy, but if there isn't a way to open it built-in, you can always start it with "halshow" at the command line.

That wll allow you to explore what values are on the various HAL pins, and you can trace the numbers through.

Please Log in or Create an account to join the conversation.

- RobC

- Offline

- Junior Member

-

Less

More

- Posts: 25

- Thank you received: 5

03 Mar 2023 14:06 #265777

by RobC

Replied by RobC on topic GMOCCAPY spindle rpm issue

In BD600.ini change your rpm multipliers to 3 and 1 then 1 and 3 instead of 100. If that doesn't behave as expected try 30 instead of 100. My vfd is a 400hz / 24k rpm and my settings are 6 and 1, 1 and 6. When set correctly, the vfd at start up should show the frequency required for your minimum speed set in the ini file. I have my minimum set at 4800 rpm, so a frequency of 80 is where it starts by default.

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=3

Divider=1

[SpindleRpmOut]

Address=0x3001

Multiplier=1

Divider=3

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=3

Divider=1

[SpindleRpmOut]

Address=0x3001

Multiplier=1

Divider=3

Please Log in or Create an account to join the conversation.

- santiagoe

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

11 Mar 2023 06:54 #266378

by santiagoe

Replied by santiagoe on topic GMOCCAPY spindle rpm issue

hi, thank you for your suggestion, for example when I set like this:

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=3

Divider=1

[SpindleRpmOut]

Address=0x3001

Multiplier=1

Divider=3

the VFD goes automatically to 24 Hz, which I think would be the maximum for this values, the way I calculated multiplier and divider was that I set the value of both to 1 and saw the value the VFD went up to, in this case it showed 8 Hz on the vfd, then I divided the theoretical max with the current maximum value I am getting so I would get the number I needed, so 800/8, this is why I choose 100 as multiplier, but in my case regardless of the multiplier and divider values, the VFD always goes to the max Hz possible, not to the minimum set as you mention, not sure how to accomplish this, may be you can share your configuration files to see if something is different please.

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=3

Divider=1

[SpindleRpmOut]

Address=0x3001

Multiplier=1

Divider=3

the VFD goes automatically to 24 Hz, which I think would be the maximum for this values, the way I calculated multiplier and divider was that I set the value of both to 1 and saw the value the VFD went up to, in this case it showed 8 Hz on the vfd, then I divided the theoretical max with the current maximum value I am getting so I would get the number I needed, so 800/8, this is why I choose 100 as multiplier, but in my case regardless of the multiplier and divider values, the VFD always goes to the max Hz possible, not to the minimum set as you mention, not sure how to accomplish this, may be you can share your configuration files to see if something is different please.

Please Log in or Create an account to join the conversation.

- santiagoe

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

29 Apr 2023 04:20 #270163

by santiagoe

Replied by santiagoe on topic GMOCCAPY spindle rpm issue

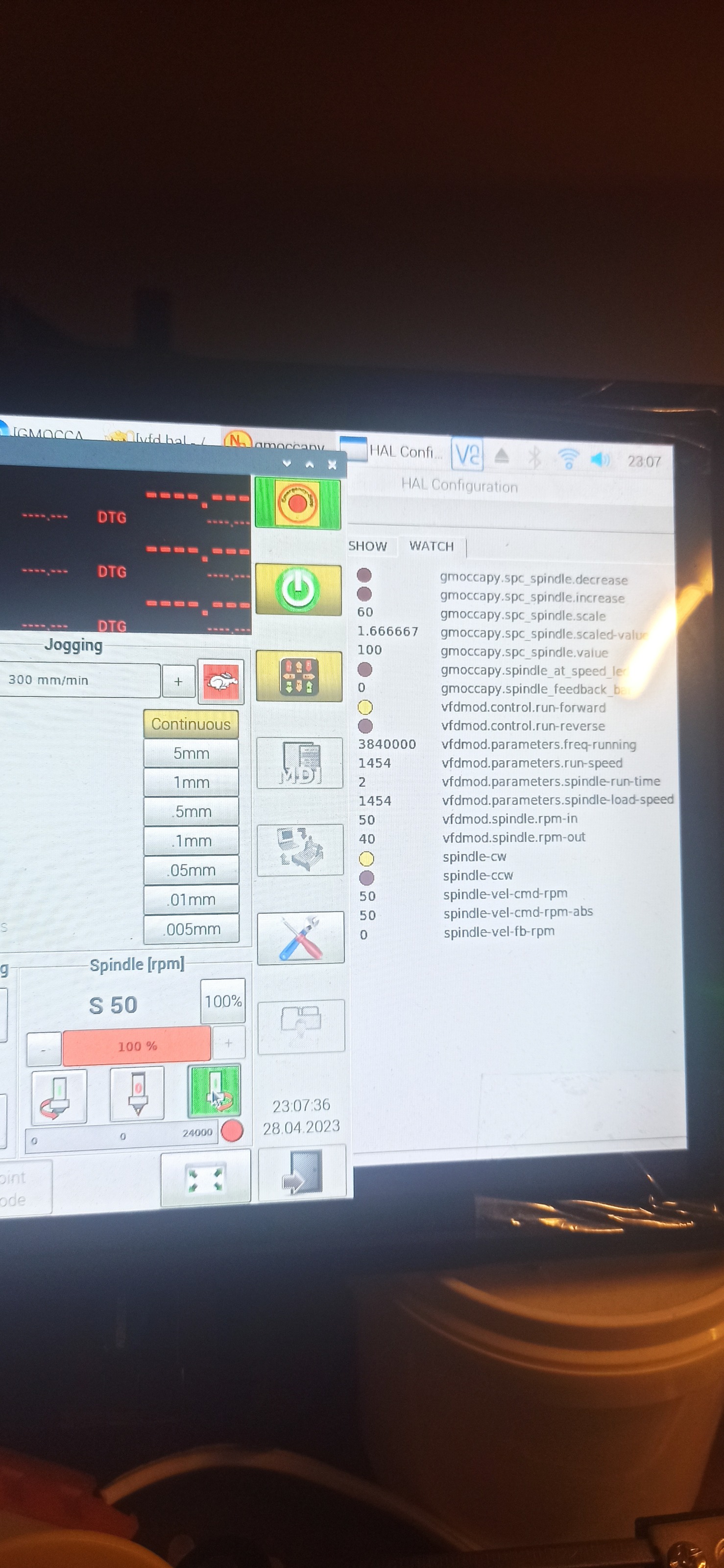

Hello again, I managed to get the right Frequency on the VFD by using this values

but I am having an issue with the displayed RPM, in the picture attached you can see that it shows s50 RPM but the spindle is currently at 24000 RPM, I have tried to take look at halshow but I was not able to figure it out, in the picture you can also see the values of some pins on the halshow, any suggestions would be greatly appreciated, thank you.

[SpindleRpmIn]

FunctionCode=0x06

Address=0x3000

Multiplier=400

Divider=2

[SpindleRpmOut]

Address=0x3001

Multiplier=2

Divider=400but I am having an issue with the displayed RPM, in the picture attached you can see that it shows s50 RPM but the spindle is currently at 24000 RPM, I have tried to take look at halshow but I was not able to figure it out, in the picture you can also see the values of some pins on the halshow, any suggestions would be greatly appreciated, thank you.

Please Log in or Create an account to join the conversation.

- santiagoe

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 0

29 Apr 2023 04:23 #270164

by santiagoe

Replied by santiagoe on topic GMOCCAPY spindle rpm issue

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11574

- Thank you received: 3887

29 Apr 2023 08:10 #270171

by rodw

Replied by rodw on topic GMOCCAPY spindle rpm issue

Part of the problem is tha linuxcnc expects the speed command in revs per sec and VFDMOD outputs RPM so you need to scale it.

Something like this.

You also need to set the vfdmod SpindleRpmOut to spindle.0.speed-in

You might need another scale component or alter your vfdmod.ini

Something like this.

# Spindle output speed

loadrt scale names=scale_to_rps

addf scale_to_rps servo-thread

setp scale_to_rps.gain 0.01666667

net spindle-rpm-out vfdmod.spindle.rpm-out => scale_to_rps.in

net spindle_rps_out scale_to_rps.out

net spindle_rps_out => spindle.0.speed-inYou also need to set the vfdmod SpindleRpmOut to spindle.0.speed-in

You might need another scale component or alter your vfdmod.ini

Please Log in or Create an account to join the conversation.

Time to create page: 0.840 seconds