[SOLVED] Rotary axis homin on index not working

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

21 May 2023 16:36 #271849

by PCW

and not the stepgen and you still have an issue?

Replied by PCW on topic Rotary axis homin on index not working

So you are saying you made the change so that feedback on the rotary axis is coming from the encoderSo far I have not found a solution for the homing offset issue I'm having with the encoder feedback.

and not the stepgen and you still have an issue?

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

21 May 2023 18:35 #271860

by Aciera

Replied by Aciera on topic Rotary axis homin on index not working

Yes, the problem with encoder feedback is that after homing the DRO (absolute and relative ) position is not zero but a value proportional to the homing-latch-velocity. Somewhere around 1.0 for a really slow latch-velocity.

I'll recheck that tomorrow and will post the current state of affairs.

I'll recheck that tomorrow and will post the current state of affairs.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

21 May 2023 18:39 #271864

by PCW

Replied by PCW on topic Rotary axis homin on index not working

Sounds like you are not actually using encoder feedback as the encoder position

is zeroed at index

is zeroed at index

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

22 May 2023 08:57 - 22 May 2023 09:07 #271908

by Aciera

Replied by Aciera on topic Rotary axis homin on index not working

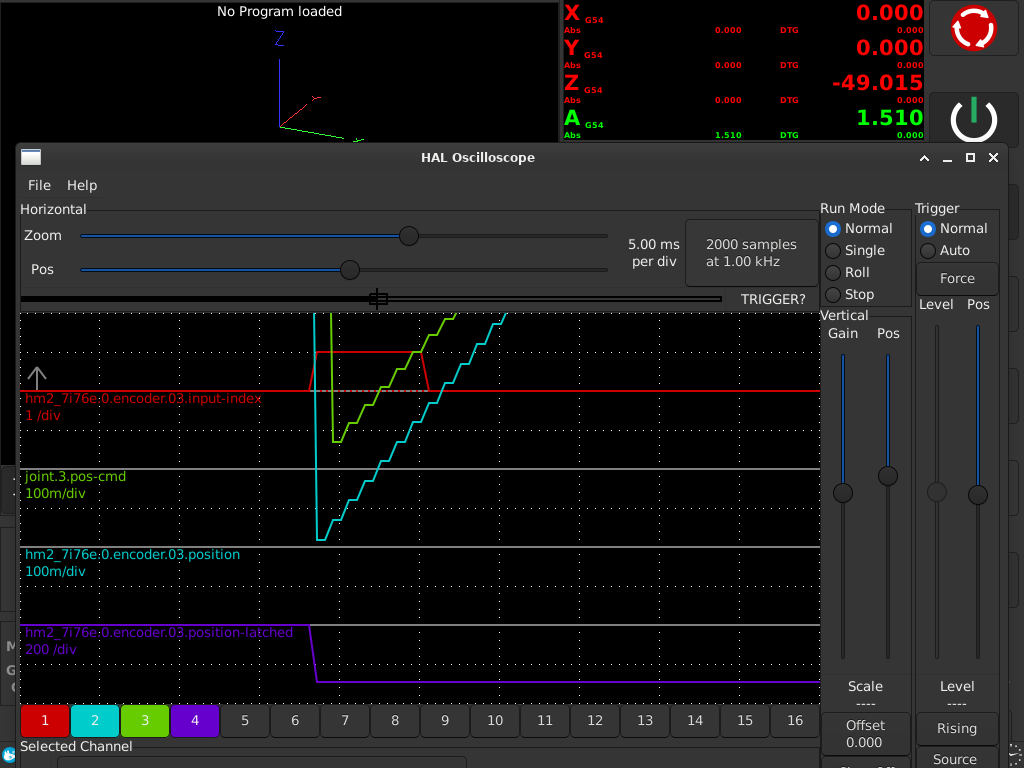

So, i tried with changing the pid values in the ini but the offset is unaffected. The offset value increases proportionally with the homing latch velocity. What I did notice is that the encoder position does not seem to reset to zero:

ini-section:

Hal-section

Thanks for the help.

ini-section:

Warning: Spoiler!

[JOINT_3]

TYPE = ANGULAR

MAX_VELOCITY = 250.0

MAX_ACCELERATION = 1000.0

STEPGEN_MAXVEL = 300

STEPGEN_MAXACCEL = 1400

P = 50

I = 10

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0.01

MAX_OUTPUT = 0

FERROR = 999

MIN_FERROR = 99

ENCODER_SCALE = 100

# these are in nanoseconds

DIRSETUP = 2500

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 1000

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 50

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

TYPE = ANGULAR

MAX_VELOCITY = 250.0

MAX_ACCELERATION = 1000.0

STEPGEN_MAXVEL = 300

STEPGEN_MAXACCEL = 1400

P = 50

I = 10

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0.01

MAX_OUTPUT = 0

FERROR = 999

MIN_FERROR = 99

ENCODER_SCALE = 100

# these are in nanoseconds

DIRSETUP = 2500

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEP_SCALE = 1000

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 50

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

Hal-section

Warning: Spoiler!

#******************************************************************************************************

# --- PID SETUP ---

setp pid.a.Pgain [JOINT_3]P

setp pid.a.Igain [JOINT_3]I

setp pid.a.Dgain [JOINT_3]D

setp pid.a.bias [JOINT_3]BIAS

setp pid.a.FF0 [JOINT_3]FF0

setp pid.a.FF1 [JOINT_3]FF1

setp pid.a.FF2 [JOINT_3]FF2

setp pid.a.deadband [JOINT_3]DEADBAND

setp pid.a.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.a.error-previous-target TRUE

setp pid.a.maxerror .01

# --- STEPGEN SETUP ---

setp hm2_7i76e.0.stepgen.04.dirsetup [JOINT_3]DIRSETUP

setp hm2_7i76e.0.stepgen.04.dirhold [JOINT_3]DIRHOLD

setp hm2_7i76e.0.stepgen.04.steplen [JOINT_3]STEPLEN

setp hm2_7i76e.0.stepgen.04.stepspace [JOINT_3]STEPSPACE

setp hm2_7i76e.0.stepgen.04.position-scale [JOINT_3]STEP_SCALE

setp hm2_7i76e.0.stepgen.04.step_type 0

setp hm2_7i76e.0.stepgen.04.control-type 1

setp hm2_7i76e.0.stepgen.04.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.04.maxvel [JOINT_3]STEPGEN_MAXVEL

# --- ENCODER SETUP ---

setp hm2_7i76e.0.encoder.03.counter-mode 0

setp hm2_7i76e.0.encoder.03.filter 1

setp hm2_7i76e.0.encoder.03.index-invert 0

setp hm2_7i76e.0.encoder.03.index-mask 0

setp hm2_7i76e.0.encoder.03.index-mask-invert 0

setp hm2_7i76e.0.encoder.03.scale [JOINT_3]ENCODER_SCALE

# --- CLOSED LOOP STEPPER SIGNALS ---

net a-index-enable <=> pid.a.index-enable <=> joint.3.index-enable <=> hm2_7i76e.0.encoder.03.index-enable

net a-enable <= joint.3.amp-enable-out => pid.a.enable => hm2_7i76e.0.stepgen.04.enable

net a-pos-cmd <= joint.3.motor-pos-cmd => pid.a.command

net a-output <= pid.a.output => hm2_7i76e.0.stepgen.04.velocity-cmd

net a-pos-fb <= hm2_7i76e.0.encoder.03.position => pid.a.feedback => joint.3.motor-pos-fb

net a-vel-fb <= hm2_7i76e.0.encoder.03.velocity => pid.a.feedback-deriv

# --- PID SETUP ---

setp pid.a.Pgain [JOINT_3]P

setp pid.a.Igain [JOINT_3]I

setp pid.a.Dgain [JOINT_3]D

setp pid.a.bias [JOINT_3]BIAS

setp pid.a.FF0 [JOINT_3]FF0

setp pid.a.FF1 [JOINT_3]FF1

setp pid.a.FF2 [JOINT_3]FF2

setp pid.a.deadband [JOINT_3]DEADBAND

setp pid.a.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.a.error-previous-target TRUE

setp pid.a.maxerror .01

# --- STEPGEN SETUP ---

setp hm2_7i76e.0.stepgen.04.dirsetup [JOINT_3]DIRSETUP

setp hm2_7i76e.0.stepgen.04.dirhold [JOINT_3]DIRHOLD

setp hm2_7i76e.0.stepgen.04.steplen [JOINT_3]STEPLEN

setp hm2_7i76e.0.stepgen.04.stepspace [JOINT_3]STEPSPACE

setp hm2_7i76e.0.stepgen.04.position-scale [JOINT_3]STEP_SCALE

setp hm2_7i76e.0.stepgen.04.step_type 0

setp hm2_7i76e.0.stepgen.04.control-type 1

setp hm2_7i76e.0.stepgen.04.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.04.maxvel [JOINT_3]STEPGEN_MAXVEL

# --- ENCODER SETUP ---

setp hm2_7i76e.0.encoder.03.counter-mode 0

setp hm2_7i76e.0.encoder.03.filter 1

setp hm2_7i76e.0.encoder.03.index-invert 0

setp hm2_7i76e.0.encoder.03.index-mask 0

setp hm2_7i76e.0.encoder.03.index-mask-invert 0

setp hm2_7i76e.0.encoder.03.scale [JOINT_3]ENCODER_SCALE

# --- CLOSED LOOP STEPPER SIGNALS ---

net a-index-enable <=> pid.a.index-enable <=> joint.3.index-enable <=> hm2_7i76e.0.encoder.03.index-enable

net a-enable <= joint.3.amp-enable-out => pid.a.enable => hm2_7i76e.0.stepgen.04.enable

net a-pos-cmd <= joint.3.motor-pos-cmd => pid.a.command

net a-output <= pid.a.output => hm2_7i76e.0.stepgen.04.velocity-cmd

net a-pos-fb <= hm2_7i76e.0.encoder.03.position => pid.a.feedback => joint.3.motor-pos-fb

net a-vel-fb <= hm2_7i76e.0.encoder.03.velocity => pid.a.feedback-deriv

Thanks for the help.

Attachments:

Last edit: 22 May 2023 09:07 by Aciera.

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

22 May 2023 09:20 - 22 May 2023 09:40 #271914

by Aciera

Replied by Aciera on topic Rotary axis homin on index not working

Just to be clear, this offset does stay. If I do a G53 G0 A0 it does not go to zero. If I set the work offset to the current position the value does also not go to zero. All positional values for the rotary axis are offset by this amount. In the above example if I do G0 A100 it (the DRO) goes to 101.510.

I can see slight changes in the DRO value when I apply torque to the motor shaft, so it is indeed the encoder value.

[edit]

Another observation: Even with conservative following error setting like

FERROR = 10

MIN_FERROR = 1

I get a following error during homing as soon as the index signal is detected. Not sure if that may have something to do with this.

I can see slight changes in the DRO value when I apply torque to the motor shaft, so it is indeed the encoder value.

[edit]

Another observation: Even with conservative following error setting like

FERROR = 10

MIN_FERROR = 1

I get a following error during homing as soon as the index signal is detected. Not sure if that may have something to do with this.

Last edit: 22 May 2023 09:40 by Aciera.

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

22 May 2023 11:54 #271925

by Aciera

Replied by Aciera on topic [SOLVED] Rotary axis homin on index not working

Turns out that the PID settings in the ini were the key to the solution.

Following error must be minimized properly using the pid settings in linuxcnc for homing to work correctly.

Seems obvious now. Thanks for all the support!

Following error must be minimized properly using the pid settings in linuxcnc for homing to work correctly.

Seems obvious now. Thanks for all the support!

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

22 May 2023 18:03 - 22 May 2023 18:57 #271954

by Aciera

Replied by Aciera on topic [SOLVED] Rotary axis homin on index not working

A little update on this matter.

Just as a recap: The optimal P value in the ini would be 1 since we already have a pid in the servo controller that should bring the motor position to the commanded position set by the stepgen.

However, it seems that with a P value of 1 in the joint PID the overshoot of the stepgen count in the index homing process never gets corrected and just stays in the DRO. That is why the offset gets propotionally larger with higher homing latch speed. Hence a sufficiently larges P value is required to eliminate the offset. ie the larger the P value the faster the stepgen and the motor are brought back to the index position (ie encoder zero).

[edit]

Problem is that, after homing is complete this P value leads to overshoots in the position commands.

Just tried setting the p value to 1 after homing and that did not bring the solution to my following error. Not sure as to what to do here but I've got a f-error of 15 when the motor is jogging or en route to a commanded position. Controller - Servo are auto-tuned for a rigid machine. Manual tuning seems a daunting task ...

Just as a recap: The optimal P value in the ini would be 1 since we already have a pid in the servo controller that should bring the motor position to the commanded position set by the stepgen.

However, it seems that with a P value of 1 in the joint PID the overshoot of the stepgen count in the index homing process never gets corrected and just stays in the DRO. That is why the offset gets propotionally larger with higher homing latch speed. Hence a sufficiently larges P value is required to eliminate the offset. ie the larger the P value the faster the stepgen and the motor are brought back to the index position (ie encoder zero).

[edit]

Just tried setting the p value to 1 after homing and that did not bring the solution to my following error. Not sure as to what to do here but I've got a f-error of 15 when the motor is jogging or en route to a commanded position. Controller - Servo are auto-tuned for a rigid machine. Manual tuning seems a daunting task ...

Last edit: 22 May 2023 18:57 by Aciera.

Please Log in or Create an account to join the conversation.

Time to create page: 0.087 seconds