Integrating a CHC-200F Capacitive sensor as a THC

- sin-do-re

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 1

02 Nov 2024 22:36 - 02 Nov 2024 22:39 #313680

by sin-do-re

Integrating a CHC-200F Capacitive sensor as a THC was created by sin-do-re

Hey everyone.

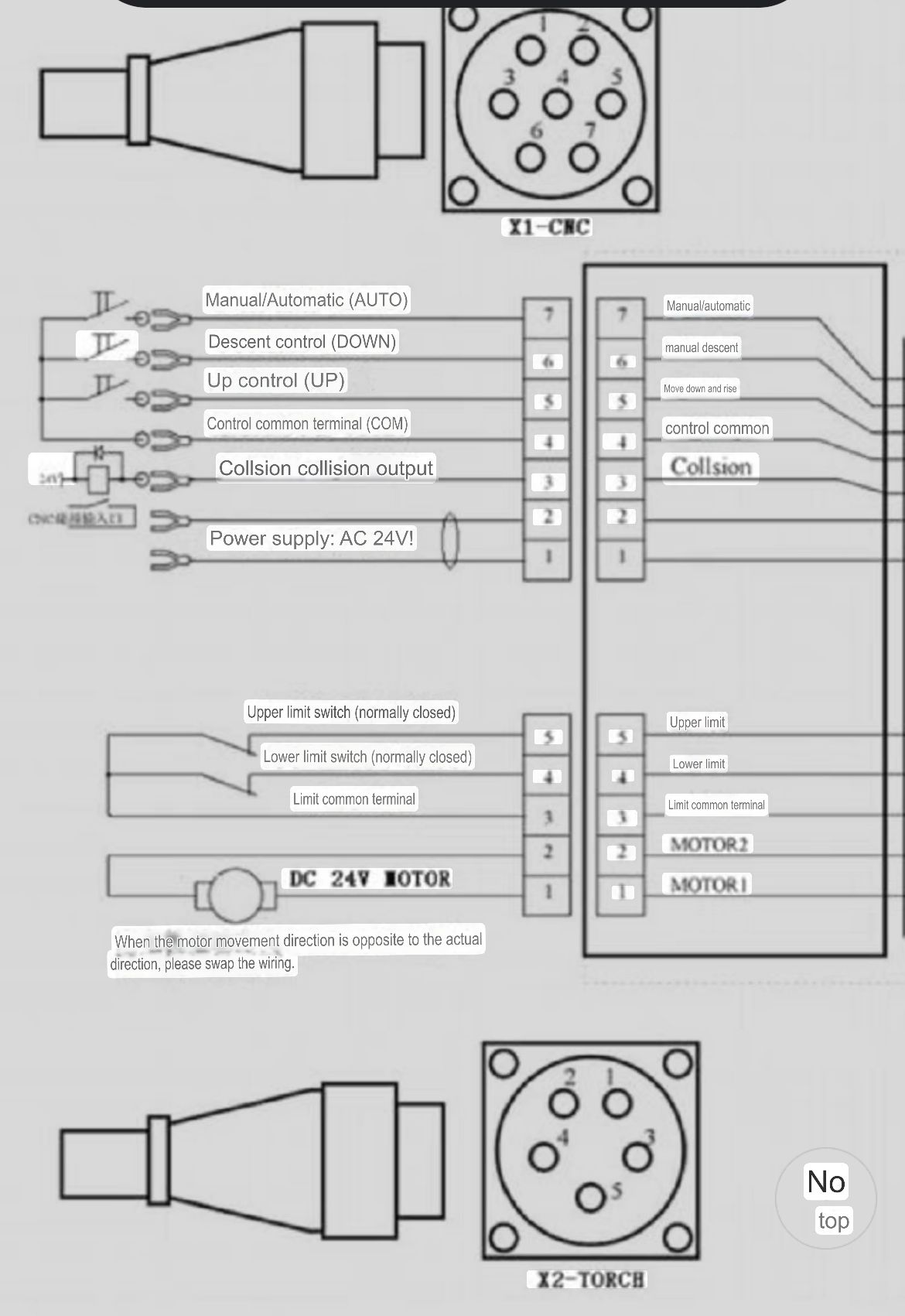

I'm documenting my journey to control a CHC-200F (Capacitive Height Controller) as a Torch Height Controller.

CHC-200F is superior to CHC-200E as the "F" has faster processing and also provides a probe output signal.

These systems are made for use with a DC motor in the torch : which LCNC doesnt.

They communicate to the motor with a PWM signal, which overrides the controller's PWM to provide a height correction.

The PWM signal provided is 10V with 9 to 18 KHZ frequency. Which can be read by either the Mesa Encoder input with the proper voltage scaling.

Unlike the arc voltage, which the THCAD converts into an encoder signal, the PWM signal will have a polarity so it will have scaled and offsetted..

It will also have a different "meaning" as the encoder in the THCAD, so it will have to be 'read' in a different way.

Has anyone used mesa systems to read PWM?

Is it more suitable to read it with a THCAD?

PS: Im guessing I could also use the polarity of PWM signal to generate two inputs: Move Torch Up & Move Torch Down, and use QTPLASMAC in Mode 2 (Up/down signals). But this wouldn't provide such a fast thc response as the "arc voltage" does.

This post will be advanced as more progress is made.

I'm documenting my journey to control a CHC-200F (Capacitive Height Controller) as a Torch Height Controller.

CHC-200F is superior to CHC-200E as the "F" has faster processing and also provides a probe output signal.

These systems are made for use with a DC motor in the torch : which LCNC doesnt.

They communicate to the motor with a PWM signal, which overrides the controller's PWM to provide a height correction.

The PWM signal provided is 10V with 9 to 18 KHZ frequency. Which can be read by either the Mesa Encoder input with the proper voltage scaling.

Unlike the arc voltage, which the THCAD converts into an encoder signal, the PWM signal will have a polarity so it will have scaled and offsetted..

It will also have a different "meaning" as the encoder in the THCAD, so it will have to be 'read' in a different way.

Has anyone used mesa systems to read PWM?

Is it more suitable to read it with a THCAD?

PS: Im guessing I could also use the polarity of PWM signal to generate two inputs: Move Torch Up & Move Torch Down, and use QTPLASMAC in Mode 2 (Up/down signals). But this wouldn't provide such a fast thc response as the "arc voltage" does.

This post will be advanced as more progress is made.

Attachments:

Last edit: 02 Nov 2024 22:39 by sin-do-re.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21053

- Thank you received: 7181

03 Nov 2024 01:37 #313687

by tommylight

Replied by tommylight on topic Integrating a CHC-200F Capacitive sensor as a THC

Pretty sure it might be possible to make LinuxCNC do something useful with variable frequency PWM, but i can not recall reading about it here on the forum, but there are some that used capacitive sensors with LinuxCNC and QtPlasmaC for laser height control, a bit fuzzy, but i think they used an ESP32 to translate stuff back and forth.

Some things to be sure:

-is it actually variable frequency PWM or quadrature signal? Quadrature has 50% duty cycle, PWM has variable duty cycle and frequency does not change, usually.

-Can it be controlled in manual mode with the up/down PWM? If yes, that would make things easier as LinuxCNC can output many types of signals like that.

-

Personally, so far i have removed every capacitive sensor i bumped into, there are reasons they are not used in plasma anymore.

Some things to be sure:

-is it actually variable frequency PWM or quadrature signal? Quadrature has 50% duty cycle, PWM has variable duty cycle and frequency does not change, usually.

-Can it be controlled in manual mode with the up/down PWM? If yes, that would make things easier as LinuxCNC can output many types of signals like that.

-

Personally, so far i have removed every capacitive sensor i bumped into, there are reasons they are not used in plasma anymore.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21053

- Thank you received: 7181

03 Nov 2024 01:48 #313689

by tommylight

Replied by tommylight on topic Integrating a CHC-200F Capacitive sensor as a THC

More info on capactive sensors used with LinuxCNC:

forum.linuxcnc.org/plasma-laser/51568-in...e-sensor-to-linuxcnc

forum.linuxcnc.org/plasmac/38701-plasmac...-auto-focuas?start=0

forum.linuxcnc.org/plasma-laser/51568-in...e-sensor-to-linuxcnc

forum.linuxcnc.org/plasmac/38701-plasmac...-auto-focuas?start=0

Please Log in or Create an account to join the conversation.

Time to create page: 0.073 seconds