New member from Germany - CNC retrofit of a Leinen FM1

- Hartwig

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

10 Aug 2025 12:23 #333151

by Hartwig

New member from Germany - CNC retrofit of a Leinen FM1 was created by Hartwig

Dear members,

I would like to say hello and introduce myself. I'm a 66 years old Chemist and since 2 years retired from the industry. I am living in the northwest of Germany, near to the Dutch border and the city of Münster. One of my hobbies are old watchmaker machine tools.

I am grown up in an analog environment. I can not program any computer language (but I have a son, who is capable).

I understand pretty well electrics & electro-mechanical matters. I understand electronic circuits up to a level of using components with a maximum of four soldering feet (eg. bridge rectifiers).

All other components, like IC or even EPROM are a "mystery" to me.

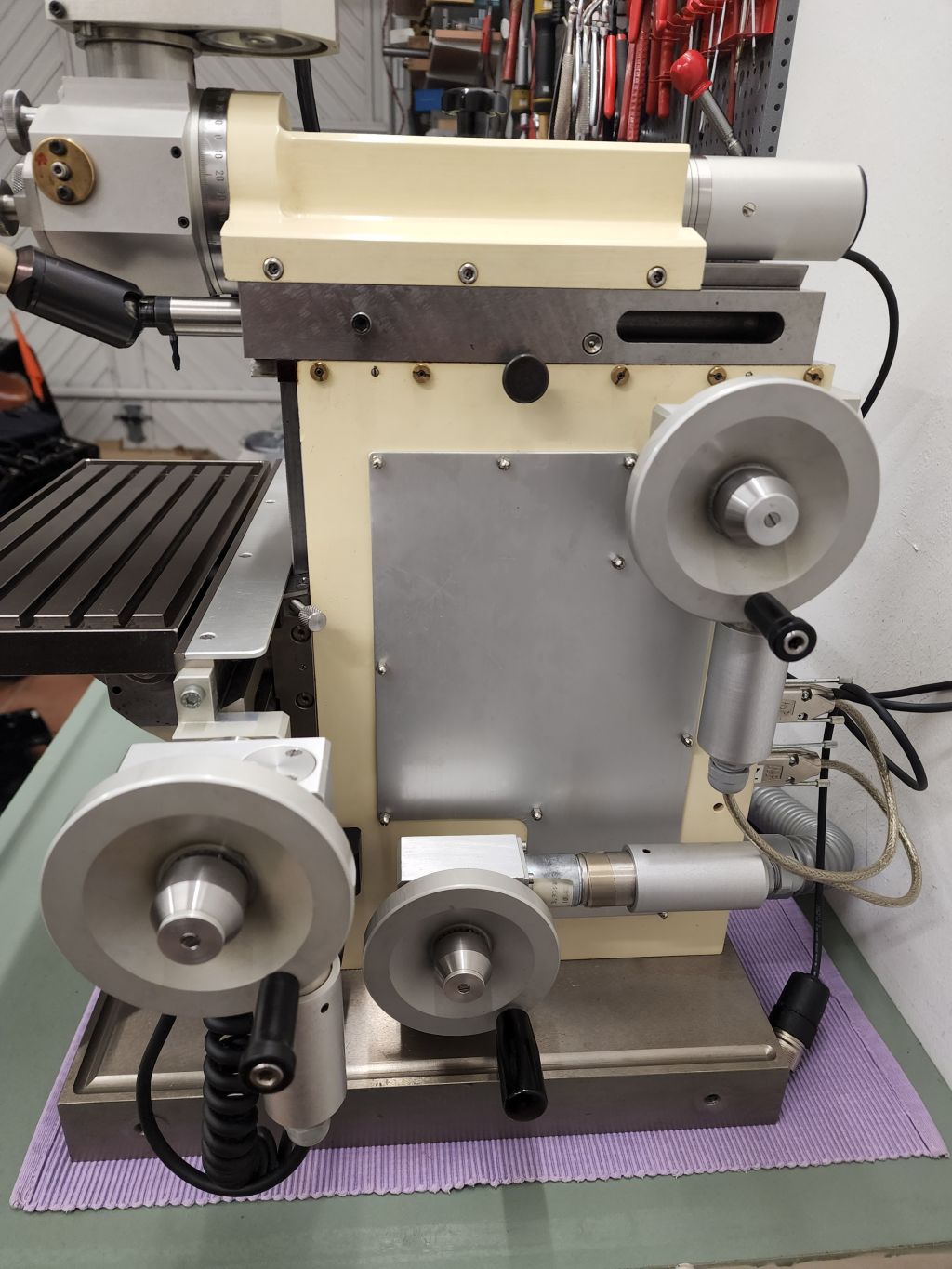

I own a small coordinate milling- and drilling-machine. A Leinen FM1, which is equipped with controls from the mid 80s of the last century.

It uses Heidenhain glass scales on the x-, y- and z-axis and ESCAP 12 V DC Tacho-Servomotors for the movements of these axes.

The indication of position and the positioning to a set coordinate is done by a Heidenhain TNC113 unit, connected with an analog control panel. Furthermore there is a dividing unit with a rotary axis, served by a Heidenhain rotary encoder.

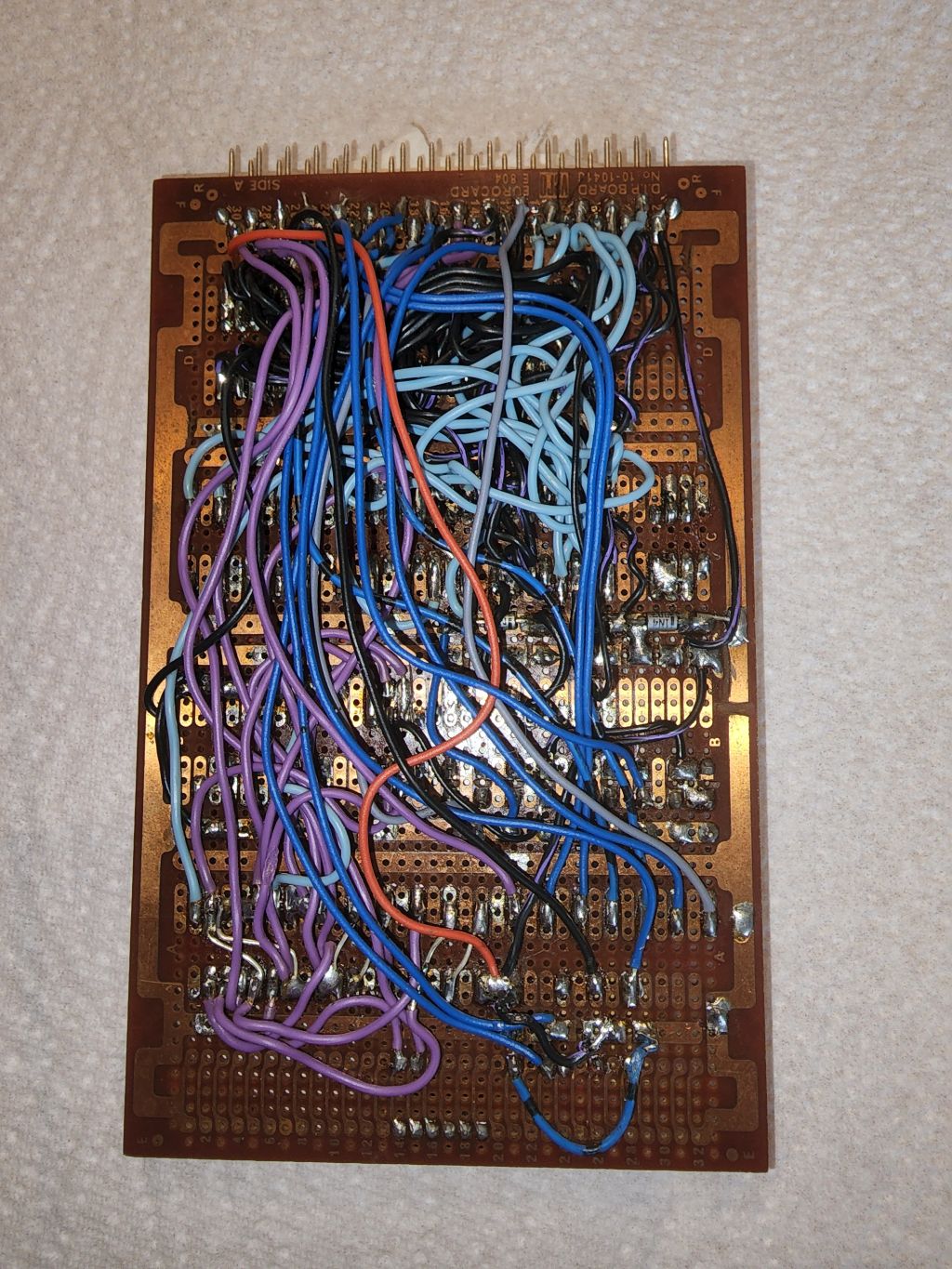

The unit is fully functional. But I`m fearing electric defects in the control panel, without having in hand any documentation of the board layouts, the circuits and the connections. If, after 40 years, a capacitor or a diode would become defective, I would be lost. If needed, the Heidenhain TNC113 can be still repaired by specialists, but a repair is very expensive.

My idea is now, to buy 4 Heidenhain EXE610 on the second hand market and connect them to a newly built LINUX CNC.unit. Could somebody be so kind and advise me, which boards I would need to buy for:

- the INPUTs from the four Heidenhain EXEs

- the INPUTs from the five DC motor tachos (4 from the axes and 1 from the spindle)

- the OUTPUTs to the DC Motors amplifiers/controllers(I have already a second set of amplifiers for the spindle motor of 66 V and the axes drive motors of 12 V).

- some other INPUTs (digital and analog) like limit switches on the axes, emergency switch-off etc., potentiometers

- some other OUTPUTs for indicator lamps/LED

What is the target of this excercise:

- preserve the existing controls in original condition

- plug-in of the existing connectors/interfaces (between the machine and the control panel) to a new CNC unit

- the new CNC unit does not need to be highly sophisticated. I would be happy with a program, which activates the 4 axes in sequential mode. I would guess, that high precision, when running several axis simultaniously, would be impossible to realise with DC Tacho-Servos.

Any feedback is highly appreciated.

Thanks a lot and best regards

Hartwig

I would like to say hello and introduce myself. I'm a 66 years old Chemist and since 2 years retired from the industry. I am living in the northwest of Germany, near to the Dutch border and the city of Münster. One of my hobbies are old watchmaker machine tools.

I am grown up in an analog environment. I can not program any computer language (but I have a son, who is capable).

I understand pretty well electrics & electro-mechanical matters. I understand electronic circuits up to a level of using components with a maximum of four soldering feet (eg. bridge rectifiers).

All other components, like IC or even EPROM are a "mystery" to me.

I own a small coordinate milling- and drilling-machine. A Leinen FM1, which is equipped with controls from the mid 80s of the last century.

It uses Heidenhain glass scales on the x-, y- and z-axis and ESCAP 12 V DC Tacho-Servomotors for the movements of these axes.

The indication of position and the positioning to a set coordinate is done by a Heidenhain TNC113 unit, connected with an analog control panel. Furthermore there is a dividing unit with a rotary axis, served by a Heidenhain rotary encoder.

The unit is fully functional. But I`m fearing electric defects in the control panel, without having in hand any documentation of the board layouts, the circuits and the connections. If, after 40 years, a capacitor or a diode would become defective, I would be lost. If needed, the Heidenhain TNC113 can be still repaired by specialists, but a repair is very expensive.

My idea is now, to buy 4 Heidenhain EXE610 on the second hand market and connect them to a newly built LINUX CNC.unit. Could somebody be so kind and advise me, which boards I would need to buy for:

- the INPUTs from the four Heidenhain EXEs

- the INPUTs from the five DC motor tachos (4 from the axes and 1 from the spindle)

- the OUTPUTs to the DC Motors amplifiers/controllers(I have already a second set of amplifiers for the spindle motor of 66 V and the axes drive motors of 12 V).

- some other INPUTs (digital and analog) like limit switches on the axes, emergency switch-off etc., potentiometers

- some other OUTPUTs for indicator lamps/LED

What is the target of this excercise:

- preserve the existing controls in original condition

- plug-in of the existing connectors/interfaces (between the machine and the control panel) to a new CNC unit

- the new CNC unit does not need to be highly sophisticated. I would be happy with a program, which activates the 4 axes in sequential mode. I would guess, that high precision, when running several axis simultaniously, would be impossible to realise with DC Tacho-Servos.

Any feedback is highly appreciated.

Thanks a lot and best regards

Hartwig

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

10 Aug 2025 15:53 #333170

by andypugh

Replied by andypugh on topic New member from Germany - CNC retrofit of a Leinen FM1

You _probably_ don't need to take the tachos to LinuxCNC.

Typically the tachos connect only to the servo drives to feed back velocity, and the analogue voltage input from the controller sends a velocity command based on position feedback from the glass scales.

The Leinien FM1 looks like a lovely little thing.

An all-in-one solution from Mesa would be: store.mesanet.com/index.php?route=produc...id=397&search=analog

But there might be cheaper options (for example 6i24 + 7i33TA) but the 7i97T ethernet option will work with just about any supported computer, including the Raspberry Pi.

Other options exist. EtherCAT, Pico PPMC for example.

One of the LinuxCNC developers lives in Münster, I think.

Typically the tachos connect only to the servo drives to feed back velocity, and the analogue voltage input from the controller sends a velocity command based on position feedback from the glass scales.

The Leinien FM1 looks like a lovely little thing.

An all-in-one solution from Mesa would be: store.mesanet.com/index.php?route=produc...id=397&search=analog

But there might be cheaper options (for example 6i24 + 7i33TA) but the 7i97T ethernet option will work with just about any supported computer, including the Raspberry Pi.

Other options exist. EtherCAT, Pico PPMC for example.

One of the LinuxCNC developers lives in Münster, I think.

The following user(s) said Thank You: Hartwig

Please Log in or Create an account to join the conversation.

- Hartwig

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

10 Aug 2025 16:49 #333175

by Hartwig

Replied by Hartwig on topic New member from Germany - CNC retrofit of a Leinen FM1

Hi Andy,

thanks a lot for your response. I will try it and buy the recommended MESA Board.

Yes, you are right, the tacho signal can be connected directly to the DC motor amplifier. I have only one amplifier for the 3 axes. So I can run them only in sequence.

I hope, I will find out how to interpret the inputs (TTL ?) from the Heidenhain EXEs.

Is there any chance to get connected to the LinuxCNC developer in Münster?

Best regards

Hartwig

thanks a lot for your response. I will try it and buy the recommended MESA Board.

Yes, you are right, the tacho signal can be connected directly to the DC motor amplifier. I have only one amplifier for the 3 axes. So I can run them only in sequence.

I hope, I will find out how to interpret the inputs (TTL ?) from the Heidenhain EXEs.

Is there any chance to get connected to the LinuxCNC developer in Münster?

Best regards

Hartwig

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

10 Aug 2025 16:53 #333176

by andypugh

Replied by andypugh on topic New member from Germany - CNC retrofit of a Leinen FM1

Is this one of those systems that can only move one axis at a time?Yes, you are right, the tacho signal can be connected directly to the DC motor amplifier. I have only one amplifier for the 3 axes. So I can run them only in sequence.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1570

- Thank you received: 576

11 Aug 2025 07:02 #333199

by RotarySMP

Replied by RotarySMP on topic New member from Germany - CNC retrofit of a Leinen FM1

I have two ebay bought used EXE's on my mill. 602D/5-F and 602/1-F. I never did figure out Heidenhains model numbering, so I ended up with one providing 1µm resolution, and the other only 5µm.

How I wired them up is here:

www.forum.linuxcnc.org/12-milling/33035-...0e?start=1340#152364

Those Leinen FM 1 are lovely machines. Please add pictures to your thread. Lots and lots of pictures

Cheers,

Mark

How I wired them up is here:

www.forum.linuxcnc.org/12-milling/33035-...0e?start=1340#152364

Those Leinen FM 1 are lovely machines. Please add pictures to your thread. Lots and lots of pictures

Cheers,

Mark

Please Log in or Create an account to join the conversation.

- Hartwig

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

11 Aug 2025 11:50 #333210

by Hartwig

Replied by Hartwig on topic New member from Germany - CNC retrofit of a Leinen FM1

Attachments:

Please Log in or Create an account to join the conversation.

- Hartwig

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

11 Aug 2025 12:03 #333213

by Hartwig

Replied by Hartwig on topic New member from Germany - CNC retrofit of a Leinen FM1

Attachments:

The following user(s) said Thank You: COFHAL

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

12 Aug 2025 11:17 #333271

by andypugh

Replied by andypugh on topic New member from Germany - CNC retrofit of a Leinen FM1

Is it this one?

www.instagram.com/furniturenmarkt/p/CKTauBwrZ-F

Which claims that it might be the only one?

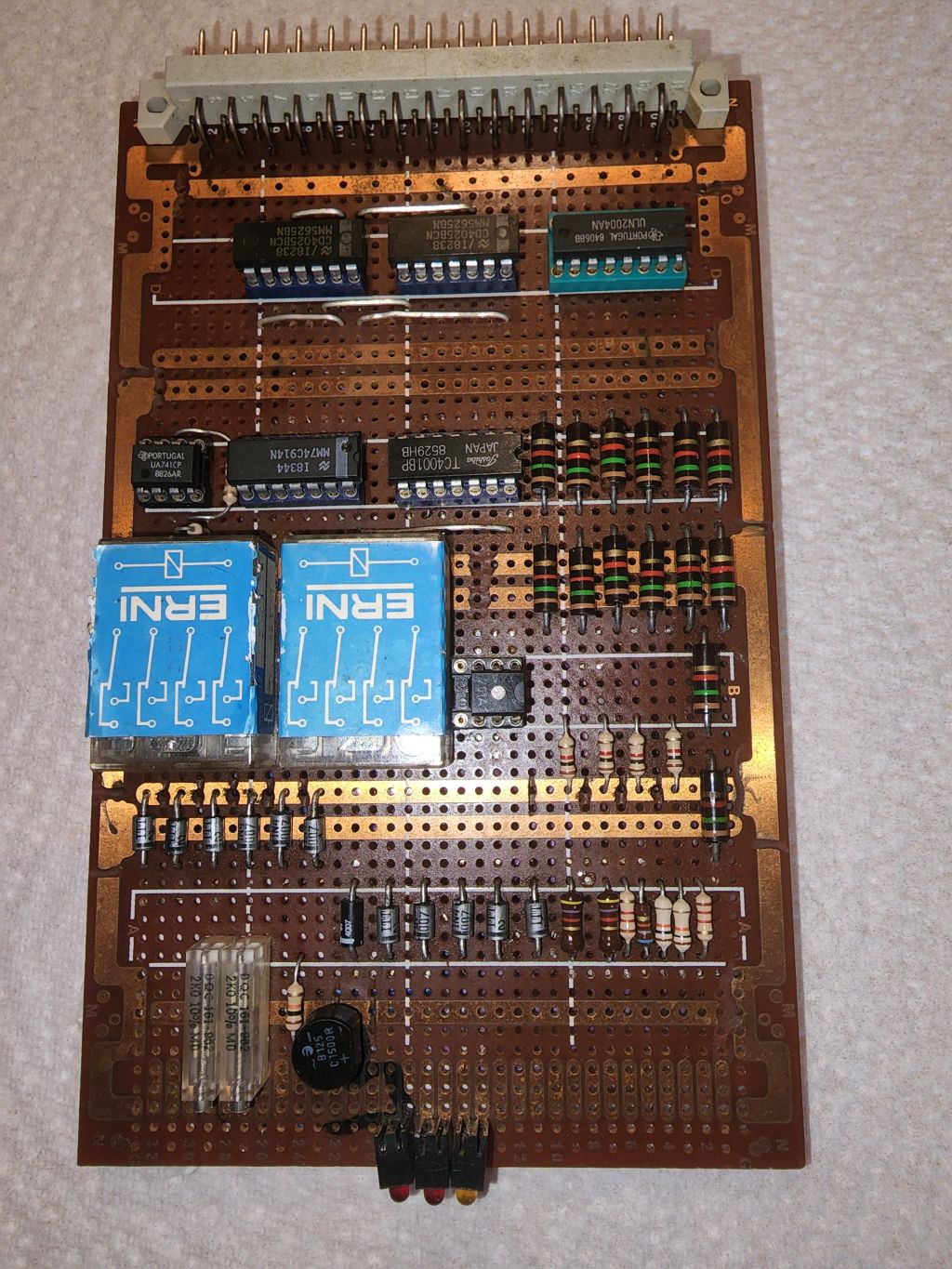

The circuit board is odd, in that it seems to have only one connection.

Do you have any pictures of the inside of the control cabinet? I would not be surprised to find that you already own some EXE units, in that cabinet.

www.instagram.com/furniturenmarkt/p/CKTauBwrZ-F

Which claims that it might be the only one?

The circuit board is odd, in that it seems to have only one connection.

Do you have any pictures of the inside of the control cabinet? I would not be surprised to find that you already own some EXE units, in that cabinet.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4661

- Thank you received: 2078

12 Aug 2025 12:42 #333273

by Aciera

Replied by Aciera on topic New member from Germany - CNC retrofit of a Leinen FM1

Service Manual for the TNC113:

product.heidenhain.de/JPBC/image/FILEBAS...C/599239-00-a-02.pdf

As far as I'm aware the glassscales directly plug into the TNC113. I rather doubt that you are going to find any EXE units in there.

product.heidenhain.de/JPBC/image/FILEBAS...C/599239-00-a-02.pdf

As far as I'm aware the glassscales directly plug into the TNC113. I rather doubt that you are going to find any EXE units in there.

Please Log in or Create an account to join the conversation.

- Hartwig

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 2

12 Aug 2025 20:23 #333294

by Hartwig

Replied by Hartwig on topic New member from Germany - CNC retrofit of a Leinen FM1

Hi Andy,

yes it is that machine, It is not the only machine, it is the only prototype of the NC version..

My information is, that over serveral years less than a total of 20 units of all versions were built and sold.

There were 3 versions available

- a manual version (can be seen on on lathes.co.uk)

- a NC version like mine with combined servo-drives and handwheels

- a CNC version with a Siemens control,unit an without handwheels (there ios one on Ebay in Germany - can be fpund under "Prätecma")

Best regards

Hartwig

yes it is that machine, It is not the only machine, it is the only prototype of the NC version..

My information is, that over serveral years less than a total of 20 units of all versions were built and sold.

There were 3 versions available

- a manual version (can be seen on on lathes.co.uk)

- a NC version like mine with combined servo-drives and handwheels

- a CNC version with a Siemens control,unit an without handwheels (there ios one on Ebay in Germany - can be fpund under "Prätecma")

Best regards

Hartwig

Please Log in or Create an account to join the conversation.

Time to create page: 0.200 seconds